Nanomaterials boost thermoelectric device efficiency by reducing thermal conductivity through nanostructuring, quantum confinement, and phonon scattering, while maintaining or enhancing electrical performance with doping and surface modifications. Surface passivation prevents degradation, supporting stability and charge transport. Advanced synthesis techniques create high-quality nanostructures, and integrating these materials into devices requires overcoming scalability and environmental challenges. Continuing further reveals how these innovations are shaping the future of high-performance thermoelectric technologies.

Key Takeaways

- Nanostructuring reduces thermal conductivity via phonon scattering, enhancing thermoelectric efficiency without compromising electrical properties.

- Surface passivation and chemistry modifications improve nanomaterial stability, interface quality, and electronic performance in thermoelectric devices.

- Quantum confinement effects in nanomaterials optimize electronic density of states, boosting the Seebeck coefficient and electrical conductivity.

- Advanced synthesis techniques enable precise control over nanostructure size, composition, and interfaces, essential for high-performance thermoelectric materials.

- Scaling up eco-friendly production methods and ensuring material stability are critical for commercializing nanomaterial-based thermoelectric devices.

Advances in Nanostructured Thermoelectric Materials

Recent developments in nanostructured thermoelectric materials have considerably enhanced their efficiency by reducing thermal conductivity while maintaining electrical performance. Achieving nanomaterial stability is essential; it guarantees the durability of these materials during operation. Surface passivation plays a key role by protecting nanostructures from oxidation and environmental degradation, which can impair thermoelectric properties over time. Proper passivation techniques help maintain the integrity of interfaces and prevent defect formation that could scatter charge carriers or phonons undesirably. These strategies collectively improve the longevity and performance of nanomaterials, making them more reliable for thermoelectric applications. Additionally, insights from material tuning in related fields such as automotive performance enhancements can inform strategies to optimize nanostructure stability and efficiency. By focusing on stability and surface passivation, researchers can optimize the nanostructures to maximize efficiency, paving the way for more practical and durable thermoelectric devices.

Quantum Confinement and Its Impact on Thermoelectric Performance

Quantum confinement occurs when the size of nanomaterials approaches the de Broglie wavelength of charge carriers, leading to significant changes in their electronic properties. This effect is prominent in quantum dots, where size quantization alters energy levels, enhancing thermoelectric performance. By reducing dimensions, you can:

Quantum confinement modifies electronic properties in nanomaterials by size quantization and energy level alterations.

- Increase the Seebeck coefficient through sharper density of states.

- Suppress thermal conductivity by scattering phonons at boundaries.

- Tune electronic band structures for optimized charge carrier transport.

These modifications improve the efficiency of thermoelectric devices by balancing electrical conductivity and thermal insulation. Quantum dots exemplify how size quantization can be leveraged at the nanoscale, reveal new pathways for high-performance thermoelectric materials. Understanding quantum confinement helps you design better nanostructures tailored for energy conversion applications.

Strategies for Enhancing Electrical Conductivity in Nanoscale Materials

To boost electrical conductivity in nanoscale materials, you should focus on optimizing doping techniques to increase carrier concentration. Engineering surface states can reduce electron scattering, further improving conductivity. Additionally, ensuring proper nanostructure connectivity helps create continuous pathways for charge transport, maximizing performance. Incorporating high-quality materials can also significantly enhance overall device efficiency.

Doping Techniques Optimization

Optimizing doping techniques is essential for enhancing the electrical conductivity of nanoscale thermoelectric materials. Achieving doping uniformity ensures consistent charge carrier distribution, which boosts performance. You should focus on impurity control to prevent unwanted defects that can reduce conductivity. Consider these key strategies:

- Use precise doping methods like ion implantation or in-situ doping during synthesis to improve uniformity.

- Carefully control impurity concentrations to avoid creating localized states that hinder charge flow.

- Implement advanced characterization techniques to monitor doping profiles and detect inhomogeneities early.

Surface State Engineering

Surface state engineering plays a critical role in boosting the electrical conductivity of nanoscale thermoelectric materials. By applying surface passivation, you can reduce surface trap states that hinder charge transport, thereby improving carrier mobility. Defect control is equally essential; carefully managing surface defects minimizes scattering centers that impede electrical flow. These strategies help maintain high conductivity levels by stabilizing the electronic structure at the surface. Techniques such as chemical treatments or atomic layer deposition can effectively passivate surfaces, preventing unwanted interactions that degrade performance. When you optimize surface conditions, you enhance the overall charge carrier density and mobility, directly contributing to higher electrical conductivity. This focus on surface state engineering ensures your nanoscale materials perform at their best, supporting more efficient thermoelectric energy conversion.

Nanostructure Connectivity

Enhancing the connectivity between nanostructures is essential for increasing electrical conductivity in nanoscale thermoelectric materials. Strong interparticle bonding improves charge transport pathways, reducing resistance. To achieve this, consider these strategies:

- Optimize sintering processes to promote better nanostructure stability and interparticle bonding without causing grain growth.

- Use atomic-scale dopants or binders that facilitate electron flow between particles, maintaining nanostructure integrity.

- Apply surface modification techniques, like coating or functionalization, to enhance nanostructure connectivity and prevent separation or degradation over time.

These approaches strengthen the links between nanostructures, improving electrical pathways while preserving nanostructure stability, ultimately boosting thermoelectric performance.

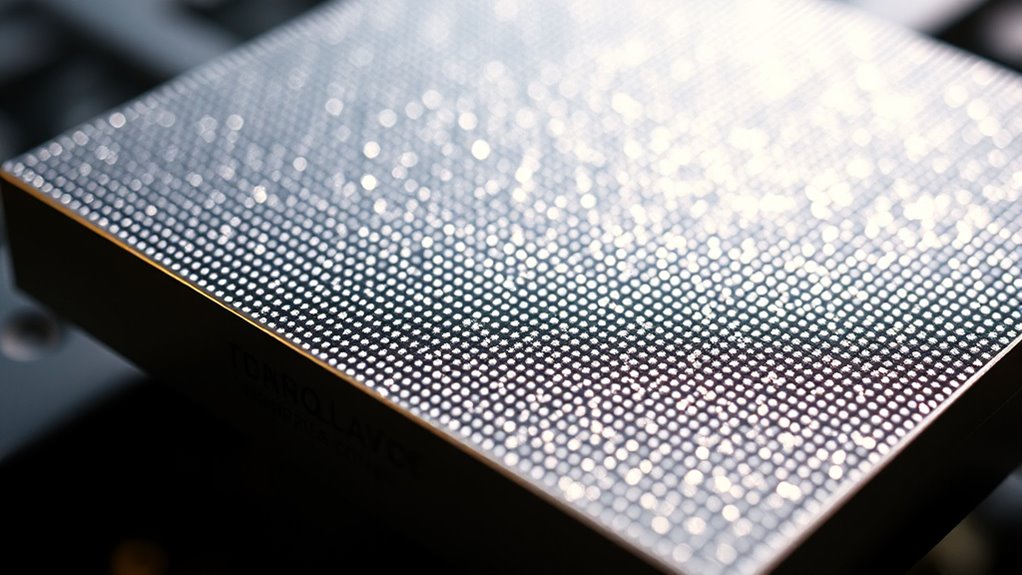

Reducing Thermal Conductivity Through Nanostructuring

Nanostructuring has emerged as a powerful strategy to reduce thermal conductivity in thermoelectric materials. By introducing features at the nanoscale, you enhance phonon scattering, which impedes heat flow. Grain boundaries act as effective phonon scatterers, disrupting the transport of heat-carrying vibrations without profoundly affecting electrical conductivity. When you create smaller grains or incorporate nanoinclusions, you increase the density of grain boundaries, further hindering phonon movement. This targeted disruption lowers the material’s ability to conduct heat, boosting thermoelectric efficiency. Importantly, nanostructuring allows you to tailor the balance between thermal and electrical properties, making it a key approach for high-performance thermoelectric devices. Through controlling grain size and boundary characteristics, you optimize phonon scattering and minimize thermal conductivity effectively. Controlling grain size is essential for fine-tuning phonon scattering mechanisms and optimizing thermoelectric performance.

Synthesis Techniques for High-Quality Thermoelectric Nanomaterials

You need to understand how precise fabrication techniques impact the quality of thermoelectric nanomaterials. Advanced synthesis methods enable you to control size, composition, and structure at the nanoscale. Mastering these techniques is essential for optimizing thermoelectric performance vibrational properties and achieving higher efficiency in device applications.

Precise Nanomaterial Fabrication

Achieving high-quality thermoelectric nanomaterials depends on precise synthesis techniques that control their size, composition, and structure at the nanoscale. To do this effectively, you should consider methods like:

- Employing layer-by-layer assembly to precisely stack materials, ensuring uniform thickness and controlled interfaces.

- Applying surface functionalization to modify surface properties, improve stability, and tailor electronic interactions.

- Combining these techniques allows you to fine-tune nanomaterial properties, optimize charge transport, and minimize defects, which are critical for high thermoelectric performance. Precise control over synthesis parameters ensures the nanomaterials meet the stringent quality standards needed for efficient thermoelectric devices. By focusing on these methods, you can produce nanostructures with the desired size, composition, and surface chemistry necessary for maximizing energy conversion efficiency.

Advanced Synthesis Methods

Advanced synthesis techniques are essential for producing high-quality thermoelectric nanomaterials with precise control over their properties. You can achieve scalable production by optimizing methods like solution-based processes, which allow for large-scale, uniform fabrication. Eco-friendly synthesis methods, such as green chemistry approaches, minimize environmental impact and reduce hazardous waste. Techniques like hydrothermal and sol-gel synthesis enable you to tailor nanostructures with specific size, shape, and composition, enhancing thermoelectric performance. You’ll find that these advanced methods offer better control over defect levels and doping, pivotal for optimizing electrical conductivity and Seebeck coefficient. By adopting eco-conscious and scalable synthesis routes, you can develop efficient, sustainable nanomaterials suitable for commercial thermoelectric applications.

Integration of Nanomaterials Into Practical Thermoelectric Devices

Integrating nanomaterials into practical thermoelectric devices requires overcoming several engineering and manufacturing challenges. Scalability challenges are significant, as producing nanomaterials consistently at large scales can be complex. You must also address cost implications, since high-quality nanomaterials often involve expensive synthesis methods. To successfully integrate these materials, consider these key steps:

- Develop scalable synthesis techniques that maintain nanomaterial quality.

- Optimize manufacturing processes to reduce costs without compromising performance.

- Ensure compatibility between nanomaterials and existing device architectures for efficient integration.

- Address material stability to prevent degradation over time and ensure long-term device reliability.

Future Perspectives and Challenges in Nanomaterial-Based Thermoelectrics

As nanomaterial-based thermoelectrics move closer to widespread application, several key challenges and opportunities lie ahead. Scalability issues pose significant hurdles; producing nanomaterials consistently at large scales remains difficult and costly. You’ll need to develop manufacturing methods that guarantee uniformity and quality without sacrificing performance. Additionally, environmental impact is a growing concern. The synthesis and disposal of nanomaterials may introduce toxicity or pollution risks, which could hinder adoption and regulation. Addressing these challenges requires innovative, sustainable approaches to nanomaterial production and lifecycle management. Despite these obstacles, advancements in synthesis techniques and eco-friendly materials offer promising pathways. By overcoming scalability and environmental hurdles, you can help realize the full potential of nanomaterials to revolutionize thermoelectric technology. Cybersecurity vulnerabilities during the development and deployment phases must also be considered to protect these advanced materials from potential cyber threats.

Frequently Asked Questions

How Do Nanomaterials Influence Thermoelectric Device Stability Over Time?

Nanomaterials enhance thermoelectric device stability over time by improving long-term durability and reducing degradation mechanisms. They create more robust interfaces and better thermal stability, which prevents material breakdown. You’ll notice less performance loss because nanostructuring inhibits grain growth and oxidation. However, you should still monitor for potential issues like nanomaterial agglomeration or interface deterioration, which could impact device longevity if not properly managed.

What Are the Environmental Impacts of Producing Thermoelectric Nanomaterials?

You should consider that producing thermoelectric nanomaterials can increase the environmental footprint due to resource depletion and energy consumption. Manufacturing processes often involve rare or toxic elements, which may lead to environmental contamination if not managed properly. Additionally, mining and processing these materials can harm ecosystems. To minimize impact, focus on sustainable sourcing, recycling, and developing eco-friendly production methods that reduce resource depletion and energy use.

Can Nanostructuring Improve Thermoelectric Efficiency at Low Temperatures?

You can definitely improve thermoelectric efficiency at low temperatures through nanostructuring. Quantum confinement enhances electron energy filtering, boosting the Seebeck coefficient, while phonon scattering reduces thermal conductivity. Although these effects are more prominent at higher temperatures, careful design of nanomaterials can still optimize performance in low-temperature ranges, making thermoelectric devices more efficient and practical for diverse applications.

How Do Interface Effects in Nanomaterials Affect Device Performance?

Interface effects in nanomaterials improve device performance by enhancing energy filtering and increasing interface scattering. You’ll find that energy filtering at interfaces allows low-energy carriers to be blocked, boosting thermoelectric efficiency. Meanwhile, interface scattering reduces thermal conductivity by hindering phonon transport, which helps maintain a temperature gradient. Together, these effects optimize charge carrier flow and thermal management, markedly enhancing the overall performance of thermoelectric devices.

What Are the Cost Implications of Scaling Nanomaterial-Based Thermoelectrics?

Scaling nanomaterial-based thermoelectrics could revolutionize energy recovery, but it’s no small feat. You’ll face significant costs initially, yet as manufacturing scalability improves and cost reduction strategies kick in, expenses will plummet. Large-scale production makes these advanced devices more affordable, transforming the market. While early investments are high, the long-term savings and efficiency gains make the effort worth it, ultimately enabling widespread adoption of cutting-edge thermoelectric solutions.

Conclusion

You see, nanomaterials truly revolutionize thermoelectric devices by boosting efficiency through quantum confinement and nanostructuring. As you explore synthesis methods and integration strategies, it’s clear that ongoing innovations are shaping the future. While challenges remain, like balancing electrical conductivity and thermal insulation, you can trust that continued research will turn these materials into practical solutions. Embracing this progress, you’re part of a breakthrough transforming waste heat into clean energy more effectively.