Based on current factors like high throughput capacity, broad sample compatibility, advanced automation features, and seamless system integration, the top automated sample prep system for lab efficiency in 2025 is one that balances speed, flexibility, and user-friendliness. It should support diverse sample types, handle increasing workloads, and come with reliable support and maintenance. If you want to find out which system best fits your specific needs, there’s more you should explore to make an informed choice.

Key Takeaways

- Prioritize systems with high scalability and throughput capacity to meet increasing sample volumes efficiently.

- Ensure broad sample compatibility, supporting diverse sample types, volumes, viscosities, and container formats.

- Choose automated systems with advanced features like robotic handling, barcode scanning, and real-time monitoring for accuracy and traceability.

- Opt for user-friendly interfaces, reliable performance, and comprehensive support to minimize downtime and operational disruptions.

- Integrate systems seamlessly with existing lab infrastructure and LIMS for streamlined workflows and data management.

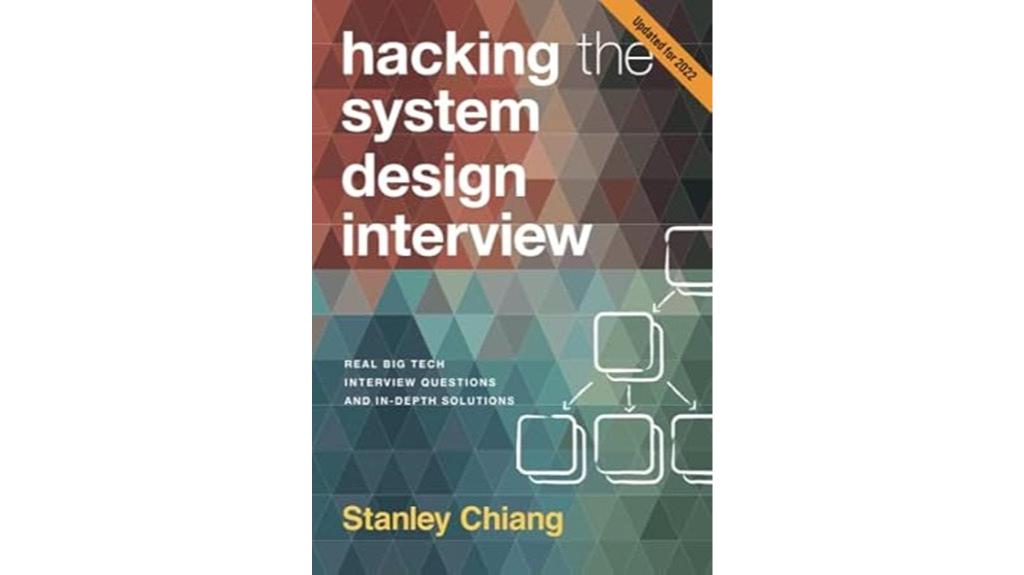

Hacking the System Design Interview Book

If you’re preparing for big tech system design interviews and want a structured, practical guide, “Hacking the System Design Interview” is an excellent choice. I found this book invaluable because it breaks down complex concepts into clear, step-by-step methods based on real interview questions. It covers essential topics like web servers, load balancers, caches, and distributed storage, with practical examples that show how to approach high-level and detailed design. The structured 7-step process helps me stay organized during problem-solving. Overall, it’s a concise resource that builds confidence, especially when combined with real-world practice and targeted review.

Best For: software engineers preparing for big tech system design interviews who want a structured, practical, and concise review guide.

Pros:

- Clear, step-by-step approach based on real interview questions

- Covers essential system components and core concepts effectively

- Short, well-organized, making it easy to review and reinforce knowledge

Cons:

- Contains some superficial explanations and minor technical inaccuracies

- Lacks deep coverage of complex topics like sharding, replication, and scalability challenges

- Outdated in parts, with limited discussion on advanced or evolving system design trends

Factors to Consider When Choosing Automated Sample Prep Systems

When selecting an automated sample prep system, I focus on key factors like throughput capacity and sample compatibility to meet my lab’s needs. I also consider the automation features, ease of maintenance, and how well the system integrates with existing equipment. These points help guarantee I choose a solution that’s efficient, reliable, and scalable for my workflow.

Throughput Capacity Needs

Selecting an automated sample prep system requires careful consideration of throughput capacity to meet your laboratory’s current and future demands. I recommend evaluating the volume of samples processed per hour or day to ensure the system can handle peak loads without bottlenecks. It’s also essential to determine the system’s maximum processing capacity and compare it against peak sample periods, so you’re prepared for surges. Scalability matters—choose a system that can expand to accommodate increasing sample volumes with minimal disruption. Additionally, evaluate whether the system maintains consistent processing times across different throughput levels, ensuring reliable turnaround times. Lastly, consider hardware constraints like processing speed, conveyor efficiency, and reagent delivery, as these can limit overall throughput and affect lab efficiency down the line.

Sample Compatibility Range

Choosing an automated sample prep system hinges on its ability to handle a broad spectrum of sample compatibility requirements. I look for systems that support various sample volumes, from microliters to milliliters, to match different assay needs. Compatibility with diverse sample types—blood, tissue, environmental samples—is essential for versatility. The system must also manage different viscosities and consistencies without sacrificing accuracy or throughput. Additionally, processing multiple container formats like tubes, plates, and vials ensures seamless integration with existing workflows. The sample compatibility range directly influences a system’s flexibility, scalability, and applicability across multiple laboratory tasks. Ensuring broad compatibility helps future-proof my lab and maximizes the return on investment by accommodating an array of sample types and formats effortlessly.

Automation Level Features

Automation level features play a pivotal role in determining the efficiency and reliability of an automated sample prep system. Higher automation levels include robotic liquid handling, automated plate loading, and real-time monitoring, which reduce manual intervention and errors. Advanced features often incorporate barcode scanning and data integration to guarantee sample traceability and minimize mistakes. Fully automated systems can handle larger sample volumes with minimal operator input, boosting throughput and consistency. The degree of customization and programmability varies, from simple pre-set protocols to AI-driven workflows that adapt to changing conditions. Additionally, integrated cleaning and maintenance functions help maintain system reliability and reduce downtime. When choosing a system, consider these automation features to optimize workflow, accuracy, and overall lab productivity.

Maintenance and Support

Ensuring reliable performance from automated sample prep systems depends heavily on proper maintenance and support. Regular maintenance, like calibrating instruments, replacing consumables, and updating software, is crucial to keep systems accurate and prevent unexpected downtime. Support agreements that provide quick access to technical experts and troubleshooting help minimize workflow disruptions. Proper documentation of maintenance activities not only tracks system performance but also aids in identifying recurring issues and ensuring compliance during audits. Additionally, choosing systems with remote diagnostics and proactive monitoring can catch potential problems early, saving time and reducing costs. Ultimately, robust support options ensure your system remains reliable, efficient, and ready to meet your lab’s demanding needs without interruption.

Integration Compatibility

Seamless integration is critical when selecting automated sample prep systems, as it directly impacts workflow efficiency and data accuracy. I look for systems compatible with existing instruments and workflows to avoid disruptions. Compatibility with laboratory information management systems (LIMS) is essential for smooth data tracking and sample management. Supporting standard communication protocols like USB, Ethernet, or RS232 ensures easy interfacing with other devices. Additionally, integration capabilities such as software APIs or SDKs allow customization and automation of processing steps, saving time and reducing errors. Flexibility across various sample types and container formats is also important, as it minimizes the need for extra equipment or adjustments. Prioritizing these compatibility factors helps ensure the system works seamlessly within my lab environment, enhancing overall productivity.

Cost and Budget

Choosing the right automated sample prep system requires careful consideration of your budget, as costs can vary widely based on features and capacity. Initial investments can range from a few thousand dollars to hundreds of thousands, depending on complexity and throughput. It is crucial to evaluate the total cost of ownership, including maintenance, consumables, and potential downtime, not just the purchase price. Budget constraints often influence choices related to automation level and compatibility with existing lab infrastructure. A cost-effective system balances automation capabilities with scalability, allowing for future sample volume increases without immediate additional investments. To make an informed decision, assess your sample throughput needs, desired automation level, and long-term operational costs, ensuring the system aligns with your financial resources and lab goals.

Ease of Use

When selecting an automated sample prep system, ease of use is a critical factor that can substantially impact your laboratory’s efficiency. An intuitive interface minimizes the need for extensive training, allowing staff to operate the system confidently from day one. Simplified workflows with minimal manual steps reduce setup time and operational complexity, keeping processes smooth and consistent. Clear, step-by-step prompts and user guidance ensure samples are processed correctly, even without specialized expertise. Automated systems that are easy to calibrate and maintain boost user confidence and reduce downtime. Additionally, features like troubleshooting support and real-time status updates help operators manage samples efficiently, decreasing errors and delays. Overall, a user-friendly system helps maximize productivity while minimizing frustration and operational overhead.

Reliability and Accuracy

Reliability and accuracy are fundamental considerations when selecting an automated sample prep system, as they directly impact the quality of downstream analyses. I look for systems that deliver high precision and repeatability, typically achieving accuracy levels of 99% or higher. Redundancy features, like backup components and fail-safe mechanisms, are crucial to prevent errors and ensure consistent performance. Regular calibration and validation protocols help verify that the system maintains its accuracy over time. I also prioritize systems with real-time monitoring and error detection capabilities, which quickly identify deviations and prevent compromised samples. Lastly, the robustness of both hardware and software influences overall dependability, reducing downtime and minimizing risks of contamination or sample loss. These factors are essential for dependable, high-quality lab results.

Frequently Asked Questions

How Do Automated Prep Systems Impact Overall Lab Safety?

Automated prep systems considerably improve lab safety by reducing human exposure to hazardous chemicals and biological agents. They handle samples precisely, minimizing spills and accidents, and often include safety features like enclosed chambers and sensor alerts. I’ve seen firsthand how automation decreases errors and risky manual steps, creating a safer environment. Overall, these systems not only boost efficiency but also protect lab staff, making the workspace safer for everyone.

Can These Systems Be Integrated With Existing Laboratory Software?

Ever wondered if these systems can seamlessly fit into your current setup? Yes, most automated sample prep systems are designed for compatibility with existing laboratory software. They often feature open interfaces and API options, making integration straightforward. I’ve seen labs successfully connect these systems without major overhauls, saving time and reducing errors. Isn’t it better to upgrade your efficiency without disrupting your current workflow?

What Are the Common Troubleshooting Issues With Automated Sample Prep?

I often encounter troubleshooting issues like sample contamination, uneven reagent dispensing, and clogging in automated sample prep systems. To fix these, I double-check the system’s calibration, clean the components regularly, and make sure the reagents are fresh and properly loaded. Sometimes, software glitches cause errors, so I update the firmware and run diagnostic tests. Staying proactive helps keep the system running smoothly and minimizes downtime.

How Do Maintenance Costs Compare Across Different System Brands?

Maintenance costs vary considerably between brands, and I’ve found that some systems require more frequent repairs, which can add up over time. For example, premium brands often have higher initial costs but tend to have lower ongoing maintenance expenses, while budget options might save upfront but lead to higher repair bills later. I recommend comparing warranties and support services to get a clearer picture of long-term costs before making a decision.

Are There Specific Certifications Required for Automated Lab Equipment?

Think of certifications as the secret handshake in the lab world. Yes, specific certifications like ISO, CE marking, and CLIA are often required for automated lab equipment to guarantee safety, accuracy, and compliance. I always recommend verifying these before making a purchase. It’s like checking the credentials of a professional—necessary to guarantee the system meets industry standards and keeps your lab running smoothly and safely.

Conclusion

Choosing the right automated sample prep system can subtly elevate your lab’s efficiency without any fuss. By considering throughput, compatibility, and ease of use, you’ll gently steer your workflow toward smoother operations. Investing a little time now guarantees future labs run seamlessly, almost like a well-orchestrated symphony. With the right system in place, you’ll find yourself appreciating the quiet confidence it brings, making every sample prep feel like a small victory.