I’ve compiled the 12 best tensile testing machines of 2025, combining accuracy, versatility, and durability for precise material analysis. These devices support various tests like tensile, peel, tear, and shear, with force ranges from 10 to 2000N. They feature user-friendly digital displays and adaptable fixtures suitable for small to medium samples. To choose the right one and guarantee long-term reliability, keep reading as I share more details about each model’s features and benefits.

Key Takeaways

- Look for machines supporting multiple testing modes like tensile, shear, tear, and puncture for comprehensive material analysis.

- Prioritize models with force ranges from 10N to 2000N to accommodate small to medium-sized sample testing.

- Select devices with high-precision sensors (±0.001%) and digital data export for accurate, reliable results.

- Ensure equipment features adjustable fixtures, user-friendly interfaces, and compatibility with industry-specific standards.

- Consider durability, ease of calibration, and manufacturer support for long-term performance and investment value.

peel tester tensile tester Peel strength tester

If you’re looking for a reliable machine to measure both peel and tensile strength, the Peel Tester, Tensile Tester, and Peel Strength Tester from YUCHENGTECH is an excellent choice. I’ve used this equipment for various testing projects, and its versatility impresses me. It features an electric drive with adjustable test speed (30-300mm) and a maximum load of 1000N, accommodating different material requirements. The fixtures are designed with one up and one down, ensuring accurate measurements. Its compact size (380mm x 280mm x 1050mm) and 48kg weight make it easy to handle. Overall, it’s a dependable solution for quality control and research needs.

Best For: professionals in quality control and research laboratories seeking a versatile and reliable machine to measure peel and tensile strengths of various materials.

Pros:

- Adjustable test speed (30-300mm) allows customization for different testing needs

- Compact and portable design with a weight of 48kg for easy handling

- Compatible with multiple force gauges for accurate force measurement

Cons:

- Limited maximum load capacity of 1000N may not suit very high-force testing requirements

- Only features fixtures with one up and one down setup, which may not accommodate all sample types

- Discontinued status could mean limited availability of replacement parts or support

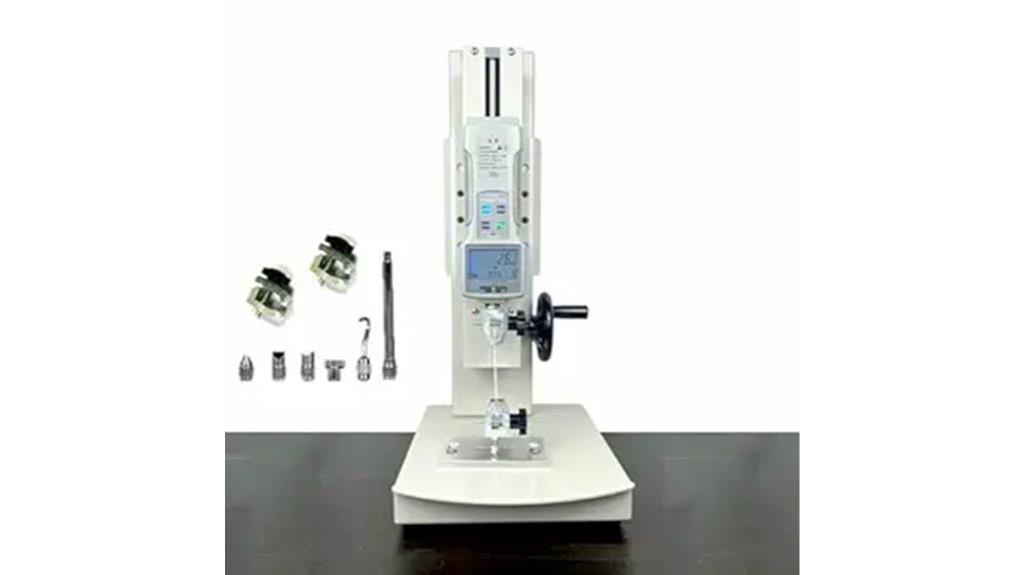

Desktop Tensile Testing Machine with Digital Force Gauge (10-2000N)

The desktop tensile testing machine with a digital force gauge from 10 to 2000N is an ideal choice for laboratories and industries that require precise, versatile force measurements on small to medium-sized samples. Its adjustable force range supports both tensile and compression tests, with a maximum stroke of 270mm and adjustable clamping from 0-8mm. The device features a clear LCD backlight display, stores up to 999 test data sets, and connects to a laptop for real-time analysis. Built with durable ABS plastic and metal, it offers stability, long-term reliability, and ease of use, making it perfect for testing ropes, wires, springs, and small components across multiple sectors.

Best For: laboratories and industries requiring precise force measurement and testing of small to medium-sized samples such as ropes, wires, springs, and small components across sectors like sports, electronics, automotive, and textiles.

Pros:

- Supports both tensile and compression tests with a wide force range of 10-2000N for versatile applications

- Equipped with a LCD backlight display and data storage for up to 999 test results, enabling easy data management and analysis

- Durable construction with ABS plastic and metal ensures stability, reliability, and long-term use

Cons:

- Maximum stroke of 270mm may be insufficient for testing larger or thicker samples

- Manual operation with hand crank may require physical effort for extensive testing sessions

- Limited to small to medium-sized samples, not suitable for very large or heavy-duty testing applications

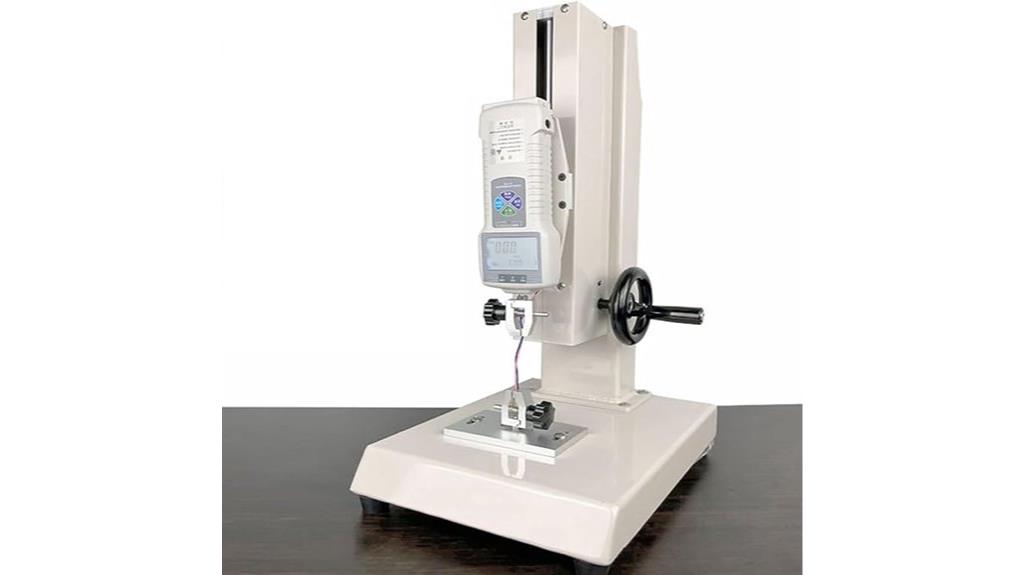

10-1000N Digital Tensile Pressure Tester with Digital Ruler

Designed for researchers and quality control professionals, the 1000N Digital Tensile Pressure Tester with Digital Ruler offers precise force measurement and displacement tracking, making it ideal for testing materials like wires, springs, and rubber bands. Its desktop, hand-crank design supports both tensile and compression tests with a stroke of 270mm and a 200mm digital ruler for accurate displacement readings. The device features a digital LCD display, supports force measurements from 10N to 2000N, and stores up to 999 test data sets. Its durable construction and easy operation make it a versatile tool for scientific research, manufacturing, and quality assurance processes.

Best For: Researchers, quality control professionals, and manufacturers needing precise tensile and compression testing of materials like wires, springs, and rubber bands.

Pros:

- Supports force measurement from 10N to 2000N, suitable for a wide range of testing needs

- Digital LCD display with backlight ensures clear and easy-to-read measurements

- Stores up to 999 test data sets and connects to a laptop for real-time data analysis

Cons:

- Hand-crank operation may require physical effort for repetitive testing

- Fixed stroke length of 270mm might limit testing of longer samples

- Made of ABS plastic and metal, which, while durable, may be less lightweight compared to other materials

Electric Tensile Testing Machine, 10N-2000N Digital Force Gauge

For those needing precise tension and compression measurements across various materials, the Electric Tensile Testing Machine with a digital force gauge offers an ideal solution. It measures forces from 10N to 2000N, with a 450mm stroke for versatile testing. Its rack-mounted design is built from high-quality ABS plastic and metal, ensuring durability. The LCD backlight display provides clear readings, while the device’s multi-function controls make operations straightforward. It supports tensile and compression tests, storing up to 999 data sets for easy analysis. Whether testing textiles, wires, or springs, this machine delivers accurate results with minimal effort, making it a essential tool in many industries.

Best For: professionals and researchers in textiles, sports equipment, electronics, and industrial testing requiring precise tension and compression measurements.

Pros:

- Wide force measurement range from 10N to 2000N for versatile testing needs

- Durable construction with high-quality ABS plastic and metal housing

- Stores up to 999 test data sets for efficient data management and analysis

Cons:

- Limited to specific force ranges; may not suit extremely high-force applications

- Requires connection to a laptop for detailed data analysis, which may need additional accessories

- The device’s size and rack-mounted design might be less portable for field testing

Tensile Testing Machine Electric Single Column Vertical Tester 500N

If you’re seeking a reliable tensile testing machine capable of precise measurements, the Electric Single Column Vertical Tester with a 500N capacity is an ideal choice. It features a high-precision ball screw for smooth, quiet operation and is equipped with worktables to enhance testing versatility. The machine includes a push-pull force meter with 0.5% accuracy, supporting various tests like tensile, bending, peeling, shearing, tearing, and puncture. Its compact dimensions and adjustable speed (10-350mm/min) make it suitable for factories, labs, and quality control. High-quality components ensure consistent, accurate results for thorough material analysis.

Best For: manufacturers, laboratories, and quality inspectors seeking precise and versatile tensile testing solutions for material analysis.

Pros:

- High-precision ball screw ensures smooth and quiet operation.

- Supports multiple testing methods including tensile, bending, peeling, shearing, tearing, and puncture.

- Compact size with adjustable speed allows versatile testing in various environments.

Cons:

- Maximum load capacity of 500N may not suit testing of very high-strength materials.

- Limited to testing with a maximum stroke of 450mm without fixtures.

- Requires a 220V power supply, which may not be compatible in all locations.

Tensile Testing Machine, 10-1000N Digital Tensile Pressure Tester

The Tensile Testing Machine, 10-1000N Digital Tensile Pressure Tester, stands out as an ideal choice for professionals needing precise, manual tension and compression testing across various industries. Its 5 probes and 300-trip hand crank vertical test bench make it versatile for applications in textiles, sports, fishing, furniture, and scientific research. The device supports both tension and compression experiments, with manual controls designed for ease of use. Its durable ABS shell, LCD backlight display, and data storage for up to 999 tests ensure accurate, reliable measurements. Plus, the ability to connect to a laptop enables real-time data analysis, making it a valuable tool for detailed material testing.

Best For: professionals and researchers requiring precise manual tension and compression testing in textiles, sports, fishing, furniture, and scientific research industries.

Pros:

- Accurate measurement with digital display and data storage for up to 999 tests

- Versatile application supporting tension and compression experiments

- Durable ABS plastic and metal shell suitable for rigorous testing environments

Cons:

- Manual operation may require more effort compared to automated systems

- Limited force range of 10-1000N might not suit very high-force testing needs

- Requires connection to a laptop for detailed data analysis, which may not be convenient in all settings

500N Digital Force Gauge with Test Stand and Clamp

The N Digital Force Gauge with Test Stand and Clamp excels in compression testing scenarios due to its push-pull measurement capability and versatile setup. It features a 500N capacity, a force test stand with lever operation, and a 70mm stroke, making it easy to perform precise compression tests. The adjustable mounting plate and bottom height guarantee flexible positioning, while the included accessories, like the HJJ-001 clamp, support various test parts. Its digital display, USB data output, and software facilitate accurate data collection and analysis. Although optimized for compression, it’s a reliable tool for versatile testing needs, with a portable design and battery-powered operation for convenience.

Best For: professionals and researchers performing precise compression testing in laboratory or industrial settings who need versatile, easy-to-use force measurement equipment.

Pros:

- Supports accurate push-pull force measurement with a clear digital display.

- Adjustable mounting features allow flexible positioning for various test setups.

- Comes with comprehensive accessories and software for efficient data collection and analysis.

Cons:

- Primarily designed for compression testing; less suitable for tensile testing without additional models.

- Disassembly of load cell mounting bracket may require technical knowledge as instructions are not provided.

- Battery life is approximately 6 hours, which may require frequent recharging during extended testing sessions.

10-1000N Digital Tensile Pressure Tester with 5 Probes

Designed for precise tension and compression testing, the 1000N Digital Tensile Pressure Tester with 5 Probes is ideal for industries requiring accurate force measurements on small to medium-sized components. It features a digital display with backlight, storing up to 999 test results, and connects to laptops for real-time data analysis. The hand crank operation, combined with adjustable clamps, ensures stable and repeatable testing. Suitable for testing textiles, wires, springs, and more, this tester’s durable ABS and metal construction offers long-term reliability. Its versatility makes it a valuable tool for research, manufacturing, and quality control across various sectors.

Best For: professionals and researchers in industries like textiles, electronics, automotive, and manufacturing who require precise tension and compression force testing of small to medium-sized components.

Pros:

- Accurate digital measurement with a backlit LCD display for easy reading in various lighting conditions

- Stores up to 999 test data sets for comprehensive data management and analysis

- Durable construction with ABS plastic and metal ensures long-term reliability and robust performance

Cons:

- Limited maximum capacity of 1000N may not suit testing of larger or stronger items

- Manual hand crank operation might be less efficient for high-volume testing compared to motorized alternatives

- Clamp size adjustable only up to 8mm, which may restrict testing of larger specimens

EL Electric Single Pole Test Bench 500N

If you’re seeking a reliable tensile testing machine for precise force measurement, the EL Electric Single Pole Test Bench 500N stands out as an excellent choice. It’s versatile, handling tensile, force, bending, peeling, shearing, tearing, and puncture tests. With a maximum load of 500N and a test travel of 450mm, it offers adjustable speeds from 10 to 350mm/min for flexibility. The machine features a high-precision ball screw for smooth, quiet operation and multiple fixtures to suit various tests. Its design emphasizes accuracy and ease of use, making it ideal for factories, research institutions, and quality control, despite some noted concerns about functionality and customer service.

Best For: factories, research institutions, and quality inspection stations needing precise, versatile tensile and mechanical testing.

Pros:

- Wide range of testing capabilities including tensile, bending, peeling, shearing, tearing, and puncture tests

- High-precision ball screw ensures smooth, quiet operation with accurate force measurement

- Adjustable test speed from 10 to 350mm/min provides flexibility for different test requirements

Cons:

- Some reports of functionality issues may affect reliability

- Customer service and refund policies have raised concerns among users

- Limited maximum load capacity of 500N may restrict use for heavier testing applications

Force Gauge Test Stand with 250mm Stroke and 2 Clamps

When selecting a force gauge test stand for tension and compression testing, the model with a 250mm stroke and two clamps stands out for its versatility and precision. I appreciate its manual operation, which offers fine control through the handwheel, ensuring accurate measurements. The two clamps, rated at 500N, accommodate various testing needs, from tensile to destructive tests. Its compatibility with ZMF force gauges and adjustable mounting plates make setup straightforward. With a compact design and lightweight build, this stand is ideal for industries like automotive, electronics, and textiles, delivering reliable results in a range of load testing applications.

Best For: professionals and technicians in industries like automotive, electronics, textiles, and hardware who need precise tension and compression testing with versatile, reliable equipment.

Pros:

- Manual operation with a handwheel provides fine control and accurate measurement.

- Compatible with ZMF force gauges and adjustable mounting plates for easy setup.

- Supports a variety of testing applications including tensile, destructive, and insertion force tests.

Cons:

- Limited to specific force gauge models (ZMF), which may require additional purchases.

- The maximum stroke of 250mm may not be suitable for very large or extreme load tests.

- The stand’s weight and dimensions could be less portable for on-the-go testing needs.

INTBUYING Tensile Testing Machine Universal Power Fixture

The INTBUYING Tensile Testing Machine Universal Power Fixture is an excellent choice for laboratories and testing facilities that require reliable and precise fixtures for high-force tensile tests. Compatible with 100kN electronic universal testing machines, it features a maximum test force of 100kN and an adjustable flat plate jaw from 0-7mm. This fixture is ideal for testing metals and non-metals, including plates and bars, ensuring accurate measurement of tensile strength. Its design provides stable support during tests, and it includes universal testing machine accessories for versatile use. Overall, it offers dependable performance for demanding tensile testing applications.

Best For: laboratories and testing facilities that need reliable, high-force tensile fixtures for precise measurement of materials like metals and non-metals.

Pros:

- Compatible with 100kN electronic universal testing machines for versatile use

- Adjustable flat plate jaw from 0-7mm allows for customization of test samples

- Provides stable and accurate support during tensile testing of various materials

Cons:

- May require additional accessories for specific testing applications

- Limited to testing metal and non-metal plates, bars, and similar samples

- Not suitable for low-force or micro-tensile testing scenarios

Tensile Testing Machine (Test Bench, Tensiometer, Dynamometer)

Tensile Testing Machines are ideal for professionals who need accurate, versatile equipment to measure tensile strength, pressure, and pulling forces. These machines include test benches, tensiometers, and dynamometers designed for precise data collection. They feature large LCD displays for easy readings and high-sensitivity sensors that deliver fast, accurate measurements. The dual-use vertical and horizontal operation modes make testing adaptable to various scenarios. Easy to install on desktops using a 152mm mounting size, they guarantee space efficiency. Whether for material research or quality control, these instruments provide reliable, detailed results essential for advanced material analysis.

Best For: professionals and researchers requiring precise measurement of tensile strength, pressure, and pulling forces across various testing scenarios.

Pros:

- Large LCD display for clear, easy-to-read data

- High-sensitivity sensors ensure fast, accurate measurements

- Dual-use vertical and horizontal operation modes enhance versatility

Cons:

- Installation may require specific space and setup considerations

- Limited to desktop (tabletop) mounting with a 152mm size, which may not suit larger testing environments

- May require training for optimal operation due to multiple modes and features

Factors to Consider When Choosing Tensile Testing Machines

When selecting a tensile testing machine, I focus on factors like force range compatibility to guarantee it handles my sample sizes properly. I also consider testing method flexibility and measurement accuracy to match my specific testing needs. Finally, I look for durable devices with simple interfaces to make operations straightforward and long-lasting.

Force Range Compatibility

Choosing a tensile testing machine with an appropriate force range is essential to guarantee accurate and safe testing. It’s critical to match the machine’s maximum force capacity to your testing requirements to prevent overload or inadequate measurement. Consider whether the force range is adjustable or fixed, making sure it covers the minimum and maximum forces needed for your materials. Accurate force measurement within this range is imperative for reliable results. For delicate materials, a lower force range prevents damage, while heavy-duty materials demand higher capacity. Additionally, verify compatibility with force gauges or load cells that operate within the specified range. Proper alignment ensures precise readings and seamless integration, ultimately leading to consistent, trustworthy material analysis.

Testing Method Flexibility

A flexible tensile testing machine enhances versatility by supporting multiple testing modes and accommodating various specimen types. This is achieved through features like reversible installation or multiple testing modes, allowing seamless switching between tensile and compression tests. The ability to handle different fixture sizes and types broadens application scope, assure compatibility across diverse materials and sample shapes. Adjustable test speeds, typically from 10 to 350mm/min, provide precise control tailored to specific testing protocols. A wide force measurement range, such as 10N to 2000N, enables testing of both small and large specimens. Variable stroke lengths and adjustable clamping mechanisms further enhance adaptability, making the machine suitable for various specimen dimensions. Such flexibility guarantees comprehensive testing capabilities, maximizing the machine’s utility for diverse material analysis needs.

Measurement Accuracy Precision

Measurement accuracy is a key factor to contemplate when selecting a tensile testing machine, as it directly impacts the reliability of test results. High-precision models can achieve errors as low as ±0.001%, guaranteeing consistent and trustworthy data. When evaluating machines, I look for those with minimal test error percentages, which indicates their ability to measure material responses accurately. Precise measurement is essential for detailed material analysis, especially in research and quality control. A machine’s calibration process, sensor quality, and control algorithms all contribute to its accuracy. Investing in a model with superior measurement precision means fewer errors, more reproducible results, and increased confidence in your testing outcomes. Ultimately, selecting a machine with excellent accuracy ensures your material evaluations are both reliable and scientifically valid.

Device Durability Longevity

When selecting a tensile testing machine, considering its durability and longevity is *vital* to guarantee reliable performance over time. I look for machines made from high-quality materials like high-strength alloys and corrosion-resistant components, ensuring they withstand harsh testing environments. Robust mechanical parts such as ball screws, heavy-duty frames, and reinforced fixtures are essential for enduring repeated cycles without failure. Regular maintenance, including lubrication and calibration, extends the machine’s lifespan and keeps performance consistent. A sturdy design with durable force gauges and overload protection minimizes wear and tear, reducing repair needs. Choosing a device built with durable construction not only saves money but also guarantees reliable, precise results over many years, making it a wise investment for long-term material analysis.

User Interface Simplicity

Choosing a tensile testing machine with a simple user interface is essential for efficient and accurate testing. An intuitive design with clear controls minimizes training time and reduces operational errors. Digital displays with backlit readings make it easier to read measurements in various lighting conditions, improving accuracy. Simplified menu navigation and preset testing modes streamline setup, saving valuable time during routine tests. Whether it’s a touchscreen or physical buttons, interfaces that require minimal input lower user confusion and boost testing efficiency. A well-designed interface also facilitates quick data export, allowing for seamless analysis without complex software navigation. Overall, prioritizing user interface simplicity ensures smoother operation, enhances precision, and increases productivity during material testing.

Price and Budget Considerations

The cost of tensile testing machines varies greatly, so it’s essential to find a model that fits your budget while meeting your testing needs. Affordable models can start around a few hundred dollars, supporting forces up to 1000N, but they often lack advanced features like digital data export or multiple testing modes. More expensive systems, costing tens of thousands, can handle forces exceeding 10,000N and offer better accuracy, durability, and long-term reliability. When budgeting, consider additional costs such as accessories, calibration, maintenance, and software, which can substantially increase the total expense. Cheaper machines may save money upfront but might require more frequent repairs or upgrades. Investing in a higher-priced model can provide better performance and reliability, ultimately saving money and ensuring precise, consistent testing results.

Frequently Asked Questions

How Do Different Testing Machines Compare in Measurement Accuracy?

I find that different testing machines vary considerably in measurement accuracy. High-quality models equipped with advanced sensors and precise calibration tend to give more consistent and reliable results. Lower-end machines may have slight variances due to less sensitive components. I always guarantee proper calibration and maintenance to get the most accurate measurements. Comparing machines based on their specifications, calibration options, and user reviews helps me choose the best for precise material analysis.

What Maintenance Is Required for Longevity of Tensile Testing Machines?

To keep my tensile testing machine in top shape, I regularly calibrate it and check for wear and tear. I clean the grips and load cells to prevent dirt buildup, lubricate moving parts as recommended, and verify the software is up to date. I also inspect electrical connections and perform routine safety checks. Consistent maintenance like this extends the machine’s lifespan and guarantees accurate, reliable test results.

How Does Sample Size Affect Testing Results and Machine Selection?

Sample size directly impacts testing accuracy and machine choice. Larger samples might require machines with higher load capacities and sturdier frames, while smaller samples need more precise, sensitive equipment. I always consider sample dimensions and material type before selecting a machine to guarantee reliable results. Properly matching sample size to testing equipment helps prevent inaccurate data, reduces equipment strain, and ensures consistent, repeatable outcomes for my material analysis.

Are There Specific Safety Standards for Operating Tensile Testers?

Safety standards are vital, and yes, there are specific ones for operating tensile testers. I always follow OSHA guidelines and manufacturer instructions to guarantee safe use. While the equipment is precise, neglecting safety can lead to accidents. Proper training, regular maintenance, and wearing protective gear are essential. I believe adherence to these standards not only safeguards me but also guarantees accurate, reliable test results.

Can Portable Tensile Testing Machines Replace Lab-Based Systems?

Portable tensile testing machines can’t fully replace lab-based systems yet. I find they’re perfect for quick, on-site assessments, but they lack the precision, advanced features, and consistent results of lab setups. For critical, detailed analysis, I still rely on traditional lab machines. However, for convenience and rapid checks, portable testers are invaluable. They complement but don’t completely replace the extensive capabilities of stationary systems.

Conclusion

Choosing the right tensile testing machine can feel a bit overwhelming, but I believe that with a little guidance, you’ll find one that seamlessly fits your needs. Remember, the perfect tool isn’t about having the most features, but about what aligns best with your testing requirements. Take your time, weigh your options, and trust that the ideal machine will gently support your material analysis journey, making accuracy feel almost effortless.