Nanotechnology improves carbon capture and storage by creating nanomaterials with high surface areas and tailored surface properties that enhance CO₂ adsorption. These advanced materials enable faster, more efficient, and cost-effective capture processes while supporting innovative storage solutions. Despite challenges like scalability and safety concerns, ongoing developments are promising for real-world applications. Keep exploring to find out how this cutting-edge technology is shaping a cleaner, more sustainable future.

Key Takeaways

- Nanotechnology enhances carbon capture efficiency through highly selective, high surface area nanomaterials tailored for CO₂ adsorption.

- Nanostructured materials enable faster, cost-effective gas adsorption and desorption processes, improving storage and removal.

- Advanced nanomaterials facilitate safer, more compact CO₂ storage solutions with improved stability and recyclability.

- Scaling production and addressing toxicity concerns remain challenges for widespread nanotech-based CCS deployment.

- Pilot projects demonstrate nanotechnology’s potential to deliver efficient, scalable, and environmentally friendly carbon capture solutions.

The Role of Nanomaterials in Enhancing Carbon Capture Efficiency

Nanomaterials play a essential role in improving carbon capture efficiency by offering highly selective and reactive surfaces. Their unique properties enable them to adsorb CO₂ more effectively, making capture processes faster and more cost-efficient. Additionally, understanding the material properties of nanomaterials helps optimize their design for specific applications. However, concerns about nanomaterial toxicity are critical, as some nanomaterials may pose health or environmental risks if not properly managed. These safety issues can lead to regulatory hurdles, slowing down deployment and adoption. Addressing these challenges requires developing safer nanomaterials and establishing clear guidelines for their use. Despite these obstacles, the potential for nanomaterials to revolutionize carbon capture remains significant. By balancing innovation with safety and regulation, you can harness nanomaterials’ capabilities while minimizing risks, ultimately advancing cleaner energy solutions.

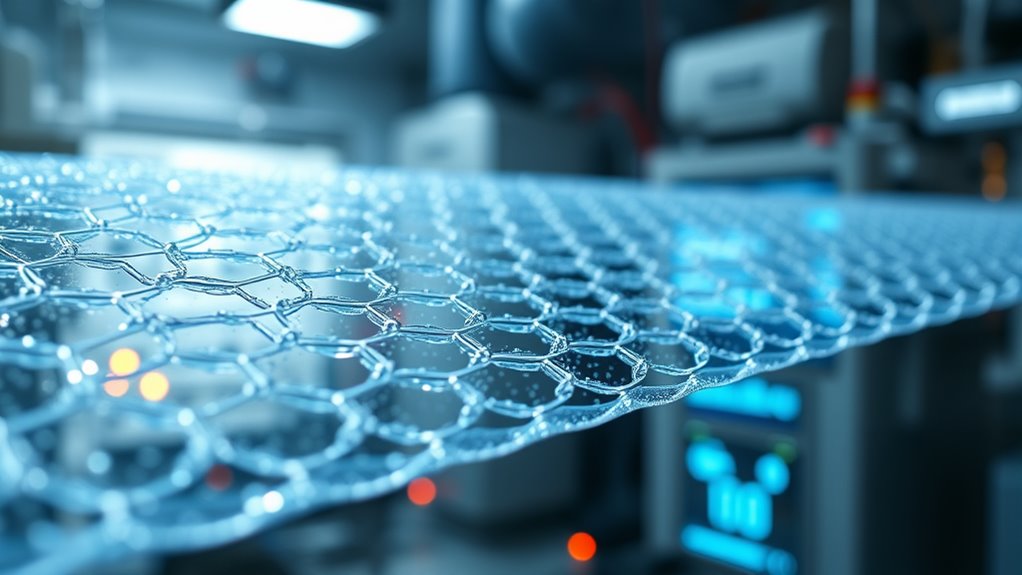

Designing Advanced Nanostructures for Gas Adsorption

Building on the advances in nanomaterials for carbon capture, designing advanced nanostructures offers a promising pathway to further enhance gas adsorption capabilities. You focus on nanostructure synthesis to create tailored architectures with high surface areas and controlled pore sizes, which are vital for efficient gas molecule interactions. By manipulating synthesis parameters, you can optimize the surface chemistry and structural features to improve selectivity and capacity for specific gases like CO₂. These engineered nanostructures facilitate stronger and more specific interactions with gas molecules, increasing adsorption efficiency. Precision in nanostructure design ensures maximized contact between the adsorbent and gases, leading to better performance in carbon capture applications. Additionally, understanding the WWE Raw’s financial impact can inspire innovative strategies for funding sustainable technologies. This strategic approach paves the way for more effective, scalable solutions in reducing atmospheric carbon levels.

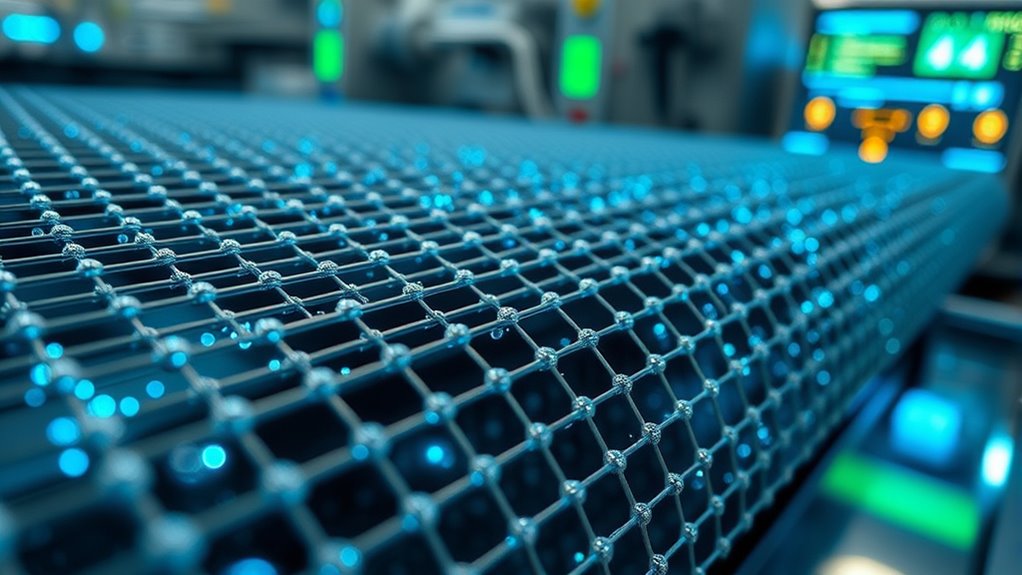

Nanotechnology-Driven Innovations in Storage Technologies

Innovations driven by nanotechnology are revolutionizing storage technologies, enabling more efficient, compact, and safer ways to hold energy and essential gases. You benefit from breakthroughs like nanoparticle synthesis, which produces highly specialized materials for gas containment. Nanoscale catalysts enhance storage efficiency by facilitating faster adsorption and desorption processes. These advancements lead to smaller, more robust storage units that improve safety and reduce space requirements. Additionally, the development of sulfate-free options reduces environmental impact and enhances sustainability. The table below highlights key nanotech innovations:

| Technology | Application | Benefit |

|---|---|---|

| Nanoparticle synthesis | Gas storage materials | Increased capacity, durability |

| Nanoscale catalysts | Accelerated gas adsorption/desorption | Faster response times |

| Nanostructured containers | Compact storage solutions | Space-saving, safer |

These innovations pave the way for smarter, more adaptable storage solutions across industries.

Environmental and Economic Benefits of Nanotech-Based CCS

By leveraging nanotechnology in carbon capture and storage (CCS), industries can substantially reduce their environmental footprint while realizing economic gains. Nanomaterials enable more efficient CO₂ capture, lowering energy consumption and operational costs. This technology also benefits from the use of vetted materials like Snake Plant and Peace Lily, which are known for their air-purifying qualities. This improves environmental impact by decreasing greenhouse gas emissions and reducing pollution. Additionally, nanotech-based CCS offers economic incentives through improved process efficiency and potential subsidies for cleaner technologies.

You can expect benefits such as:

- Reduced energy requirements for capture processes

- Lower operational costs over time

- Enhanced scalability for industrial applications

- Increased regulatory compliance

- Positive public perception and sustainability credentials

These advantages make nanotech-based CCS a compelling choice for industries aiming to balance profitability with environmental responsibility, fostering a sustainable future.

Challenges and Limitations of Applying Nanomaterials in CCS

Despite the promising potential of nanomaterials in CCS, several significant challenges hinder their widespread application. Scalability hurdles are a major obstacle; producing nanomaterials consistently and in large quantities remains complex and costly. You might find that laboratory successes don’t easily translate to industrial-scale processes, limiting practical deployment. Toxicity concerns also pose serious questions about safety; some nanomaterials could harm ecosystems or human health if released during manufacturing or operation. Additionally, long-term stability and durability under harsh conditions are uncertain, risking reduced effectiveness over time. Addressing these issues requires rigorous research, innovative manufacturing techniques, and all-encompassing safety assessments. Until these challenges are overcome, the full integration of nanomaterials into CCS strategies will remain limited and cautious.

Future Perspectives and Emerging Trends in Nanotech Carbon Capture

As nanotechnology continues to advance, promising new approaches are emerging to overcome current limitations in carbon capture and storage. You can expect innovations that enhance nanotech scalability, making deployment more feasible at industrial levels. Emerging trends focus on developing more efficient, cost-effective nanomaterials that adapt to various environments. Regulatory frameworks are also evolving to support safe and responsible integration of nanotech into CCS projects. Future perspectives include:

- Larger-scale production of nanomaterials

- Tailored nanostructures for specific capture targets

- Integration with renewable energy sources

- Improved lifespan and durability of nanomaterials

- Clearer safety and environmental regulations

- Accessible manufacturing processes are being developed to ensure that nanotech solutions are scalable and economically viable for widespread use.

These trends aim to accelerate adoption, improve performance, and ensure sustainable, compliant nanotech solutions for carbon capture.

Case Studies and Real-World Applications of Nanotechnology in CCS

You can see how enhanced capture materials are making a difference in real-world applications, improving efficiency and reducing costs. Pilot projects worldwide showcase successful implementations of nanotechnology in CCS, providing valuable insights. These case studies prove that nanotech-based solutions are increasingly viable for large-scale carbon management increasingly viable solutions.

Enhanced Capture Materials

Nanotechnology has revolutionized the development of enhanced capture materials for carbon capture and storage (CCS), offering more efficient and selective solutions. You can now leverage advances like nanoparticle synthesis and surface functionalization to improve adsorption capacity and durability. Researchers create tailored nanomaterials that target CO₂ molecules specifically, reducing energy costs. These materials often feature high surface area and customizable surface properties. You might see applications such as metal-organic frameworks (MOFs) with functionalized surfaces or nanostructured sorbents designed for maximum efficiency. The integration of nanotechnology enables rapid, scalable solutions adaptable to existing infrastructure. These innovations demonstrate real-world potential for cost-effective, high-performance capture systems that could transform CCS practices.

- Tailored nanomaterials with high selectivity

- Enhanced surface area for better adsorption

- Functionalized surfaces for targeted CO₂ capture

- Improved stability and recyclability

- Scalable synthesis methods for industrial use

Pilot Project Successes

Have recent pilot projects demonstrated the practical benefits of nanotechnology-enhanced carbon capture? Yes, they’ve shown promising results, but scalability challenges remain. For example, a pilot in Europe successfully used nanomaterials to increase CO₂ absorption efficiency. However, expanding this technology requires overcoming production and cost hurdles. Public perception also plays a role, as communities remain cautious about new nanotech applications. Here’s a snapshot of notable pilot projects:

| Project Name | Location | Key Outcome |

|---|---|---|

| NanoCapture Pilot | Europe | Improved CO₂ capture efficiency, initial success |

| GreenTech CCS Trial | North America | Demonstrated scalability potential |

| EcoNano Storage | Asia | Addressed public concerns through transparency |

These projects highlight progress but also underscore the need to address scalability and public perception for broader adoption.

Frequently Asked Questions

How Do Nanomaterials Compare to Traditional Solvents in Carbon Capture?

Nanomaterials generally outperform traditional solvents in carbon capture because of their higher efficiency and larger surface area. You’ll find that nanomaterial efficiency allows for faster and more effective CO₂ adsorption. Compared to solvents, nanomaterials often require less energy to regenerate, making the solvent comparison favorable. Overall, nanomaterials offer a promising, more sustainable alternative by enhancing capture rates and reducing operational costs.

What Are Potential Environmental Risks Associated With Nanomaterial Deployment in CCS?

You should consider that deploying nanomaterials in CCS could pose environmental risks like nanoparticle toxicity if they escape into ecosystems. You might face issues with environmental dispersion, where nanoparticles spread beyond intended areas, potentially harming wildlife and water sources. It is crucial to assess these risks carefully, implement containment strategies, and monitor for unintended release to minimize negative impacts on the environment.

How Scalable Are Nanotech-Based Carbon Storage Solutions?

You’ll find that nanotech-based carbon storage solutions face notable scalability challenges due to manufacturing hurdles. Producing nanomaterials at an industrial scale requires advanced, cost-effective methods, which are still being developed. While promising, these solutions aren’t yet fully scalable for widespread deployment, as current manufacturing processes need refinement to meet large-scale demands efficiently and sustainably. Overcoming these hurdles is essential for realizing the full potential of nanotechnology in carbon storage.

What Regulatory Challenges Exist for Nanotechnology in CCS Applications?

You might think regulations are clear-cut, but nanotech in CCS faces plenty of hurdles. Regulatory frameworks lag behind tech advances, creating uncertainty. Liability concerns add to the mix—what happens if nanomaterials escape or cause damage? Governments struggle to craft policies that keep pace with innovation. So, while you push for cleaner solutions, you’ll find yourself tangled in a web of rules and responsibility questions that slow progress.

How Long Do Nanomaterials Typically Retain Their Effectiveness in CCS Systems?

You can expect nanomaterials in CCS systems to retain their effectiveness for several years, but it depends on factors like material durability and operating conditions. Regular lifecycle assessments help determine how long they remain efficient, accounting for potential degradation. Proper maintenance and monitoring are essential to guarantee they perform at their best over their lifespan, which typically ranges from five to ten years, though some advanced nanomaterials may last longer with proper care.

Conclusion

Nanotechnology is transforming carbon capture and storage, making processes more efficient and cost-effective. By designing advanced nanostructures, you can enhance gas adsorption and storage capabilities while reducing environmental impact. Although challenges remain, ongoing innovations promise a cleaner future. Don’t you want to be part of the solution that fights climate change? Embracing nanotech in CCS could be the breakthrough we need—so why not explore its full potential today?