Nanotechnology enhances food safety by providing rapid, highly sensitive ways to detect contaminants like bacteria, pesticides, and toxins. Using nanosensors and nanomaterials, you can identify harmful substances early, often in real-time, and with high accuracy. These advanced devices are portable and easy to use, allowing quick decisions to prevent contaminated products from reaching consumers. Keep exploring to discover how nanotech is transforming food safety and protecting public health.

Key Takeaways

- Nanomaterials enhance sensitivity and speed of food contaminant detection through increased surface area.

- Nanosensors enable real-time, early detection of pathogens, toxins, and residues in various food matrices.

- Technologies like fiber optics and biochips allow portable, on-site testing for rapid food safety assessment.

- Quantum enhancement improves detection accuracy by amplifying signals for trace contaminants.

- Integrating nanotech sensors supports quick intervention, reducing false results and preventing contaminated products reaching consumers.

The Role of Nanomaterials in Detecting Food Contaminants

Nanomaterials have revolutionized food safety detection by enabling highly sensitive and rapid identification of contaminants. Their small size increases surface area, boosting detection sensitivity and speed. However, concerns about nanomaterial toxicity raise questions about their safety for food contact and environmental release. Regulatory standards are essential to guarantee these materials are used responsibly, minimizing health risks. Researchers and manufacturers must evaluate nanomaterial toxicity thoroughly and develop safe applications that meet strict guidelines. This balance helps maximize the benefits of nanotechnology while protecting consumer health. Understanding regulations and proper safety assessments are crucial in this context. By adhering to regulatory standards, you can confidently implement nanomaterials in food safety protocols, knowing they are both effective and safe. This responsible approach ensures nanomaterials contribute positively to contaminant detection without compromising safety.

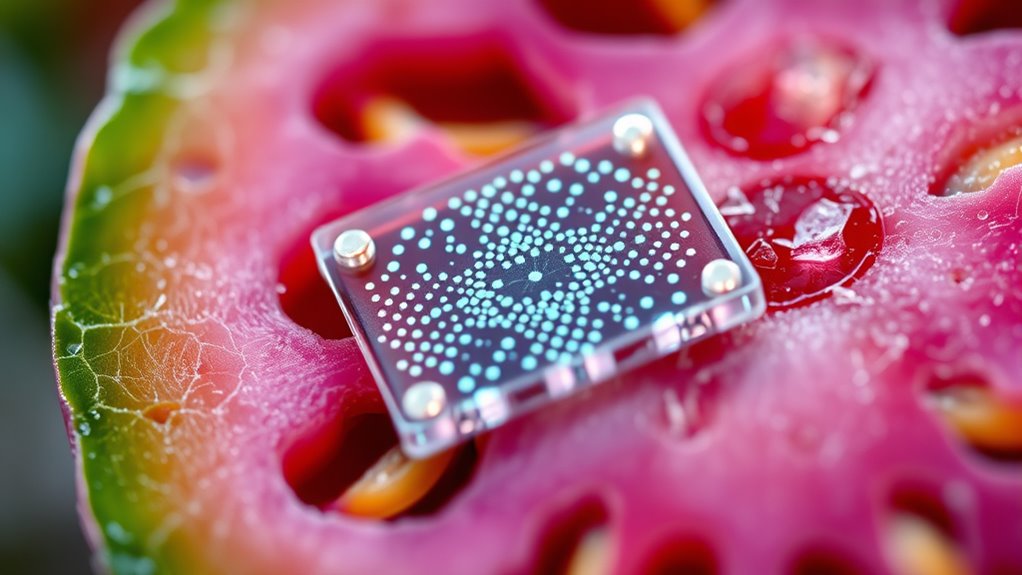

Types of Nanosensors Used in Food Safety Monitoring

Building on the advances in nanomaterials for detecting food contaminants, various nanosensors have been developed to monitor food safety more effectively. These sensors include fiber optics, biochips, and other nano-enabled devices that detect contaminants quickly and accurately. Fiber optics nanosensors use light transmission to identify specific toxins, offering real-time monitoring. Biochips, on the other hand, utilize nanostructured surfaces to capture and analyze pathogens or chemical residues efficiently. These nanosensors are highly sensitive, enabling early detection of contamination before it reaches consumers. Their compact size makes them suitable for on-site testing, reducing the need for complex lab equipment. Additionally, water parks in various locations demonstrate how innovative technologies can enhance safety and enjoyment in leisure environments. Incorporating these nanosensors into food safety protocols can considerably improve contamination detection and prevent outbreaks.

Advantages of Nanotechnology-Enabled Food Testing Methods

Nanotechnology-enabled food testing methods offer you faster results, allowing quick identification of contaminants. They also provide higher sensitivity and specificity, making it easier to detect even tiny traces of harmful substances. These advantages help improve food safety and protect consumers more effectively. Additionally, nanotechnology can be integrated with advanced sensor technology to further enhance detection capabilities.

Rapid Detection Capabilities

Rapid detection is one of the most significant advantages of nanotechnology in food testing, allowing you to identify contaminants quickly and accurately. With nanotech-enhanced sensors, you benefit from increased detection speed and rapid response times, which are vital for ensuring food safety. These advanced methods enable you to detect even trace amounts of harmful substances in real time, reducing delays in decision-making. The technology’s quick turnaround helps prevent contaminated products from reaching consumers, minimizing health risks.

- Faster identification of contaminants

- Immediate response to potential threats

- Reduced testing turnaround time

Enhanced Sensitivity and Specificity

Enhanced sensitivity and specificity are key advantages of nanotechnology in food testing, allowing you to detect contaminants at much lower concentrations than traditional methods. Quantum enhancement plays a vital role by amplifying detection signals, making even trace amounts of harmful substances identifiable. Nanomaterials’ unique properties improve biomolecular recognition, ensuring your sensors selectively target specific contaminants with high accuracy. This precision reduces false positives and negatives, increasing confidence in results. By leveraging quantum effects and nanoscale interactions, nanotechnology dramatically improves your ability to identify contaminants swiftly and reliably. These advancements mean you can implement early interventions, preventing foodborne illnesses and ensuring safety. Overall, enhanced sensitivity and specificity elevate food testing standards, making nanotechnology an invaluable tool for safeguarding public health.

Challenges and Limitations of Nanotech-Based Sensors

Despite the promising potential of nanotech-based sensors in food safety, several challenges and limitations hinder their widespread adoption. Scalability issues make it difficult to produce these sensors in large quantities without losing precision or increasing costs. Regulatory hurdles also pose significant barriers; many nanomaterials are not yet fully assessed for safety or approved for use in food applications. Additionally, concerns about potential toxicity and environmental impact limit their acceptance. You may also face difficulties in standardizing manufacturing processes across different regions, complicating global deployment. To overcome these challenges, ongoing research must focus on developing scalable production methods, clear regulatory frameworks, and exhaustive safety evaluations. Understanding skin type and sun exposure is crucial for safe outdoor tanning practices, which can be paralleled to implementing comprehensive safety assessments for nanotech sensors. Only then can nanotech-based sensors reach their full potential in safeguarding our food supply.

Future Perspectives in Nanotechnology for Food Safety

As nanotechnology continues to advance, its potential to transform food safety practices becomes increasingly promising. You’ll see innovative sensors and detection methods improving contamination monitoring, making food safer and more reliable. However, ethical considerations must guide this progress, ensuring consumer privacy and environmental safety are prioritized. Regulatory challenges also arise, as authorities work to establish standards for nanomaterials in food, balancing innovation with safety. You’ll need to stay informed about evolving policies and contribute to discussions on responsible development. Future perspectives highlight a collaborative effort between scientists, regulators, and industry stakeholders to create sustainable, safe, and effective nanotechnology applications. Embracing these advancements responsibly will be key to accessing nanotechnology’s full potential in safeguarding our food supply. Regulatory compliance will be crucial to navigating the intersection of innovation and safety in this rapidly evolving field.

Real-World Applications and Case Studies

You can now see how nanotechnology is making a real impact through portable detection devices and contaminant-specific sensors. These tools allow you to quickly identify food safety issues in the field, improving response times. For example, a recent case study highlights how nanotech improved milk safety by detecting contaminants more accurately and efficiently. Additionally, advancements in sensor technology enable real-time monitoring of potential hazards, further enhancing food safety protocols.

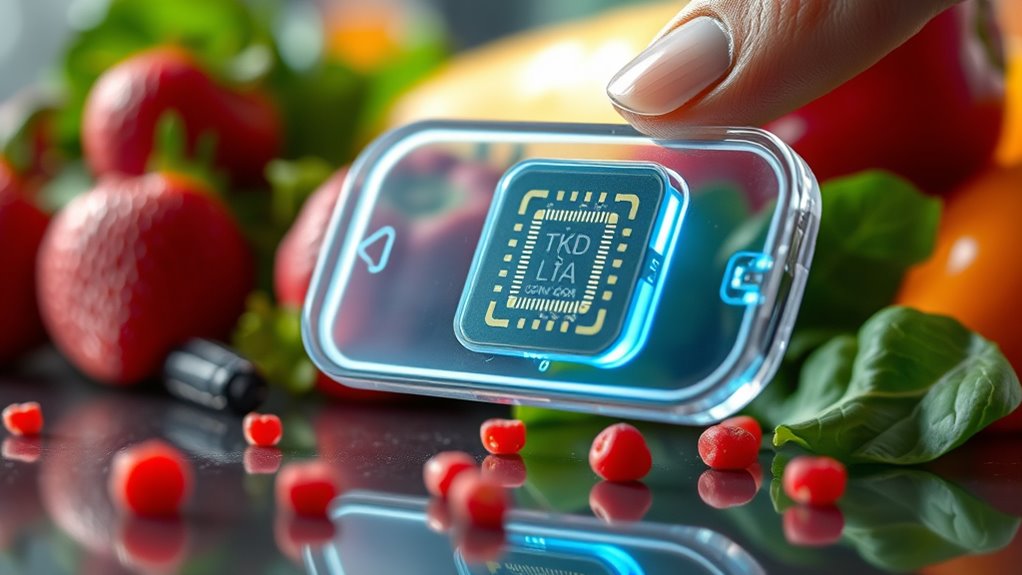

Portable Detection Devices

Portable detection devices have revolutionized food safety by enabling rapid, on-site analysis of contaminants, allergens, and pathogens. These compact tools are designed for ease of use and quick results, making food inspections more efficient. Thanks to advancements in device miniaturization, they are small enough to carry anywhere, from farms to processing plants. The power source is often rechargeable, ensuring reliable operation during field tests. These devices can identify multiple threats simultaneously, reducing the need for laboratory analysis. Their portability helps prevent contaminated products from reaching consumers, saving time and resources.

- Real-time results for immediate decision-making

- Lightweight, battery-powered designs

- User-friendly interfaces for non-experts

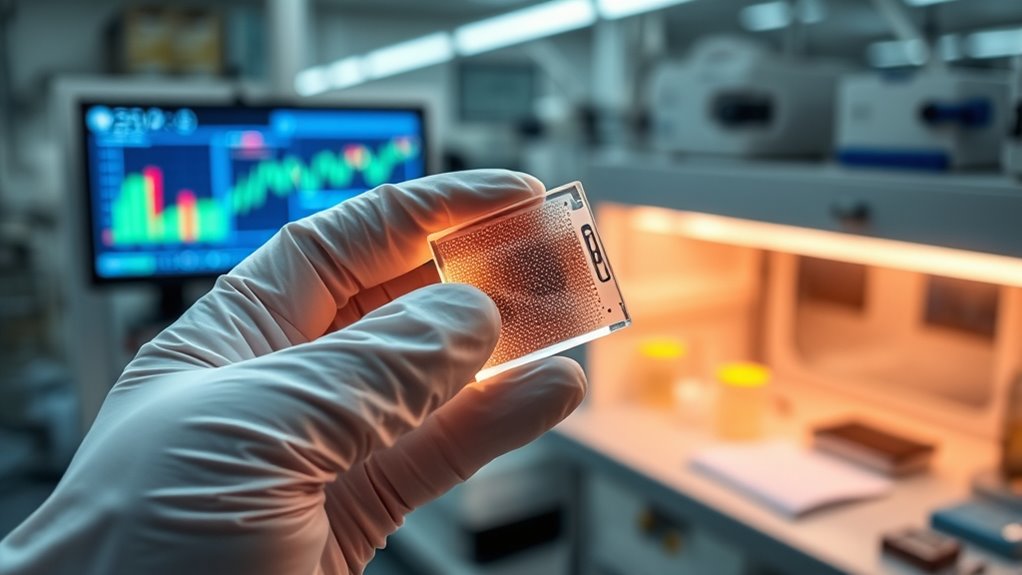

Contaminant-Specific Sensors

Contaminant-specific sensors have become essential tools in real-world food safety applications, allowing for precise detection of particular toxins, pesticides, or microbial contaminants. Through biosensor integration, these sensors can target specific substances with high sensitivity and rapid response times. Contaminant targeting ensures that the sensors are tailored to identify particular risks in diverse food matrices, such as detecting pesticide residues on fruits or microbial toxins in processed foods. This specificity reduces false positives and enhances safety protocols. In practical scenarios, these sensors enable on-site testing, minimizing delays and improving decision-making. Their ability to accurately identify contaminants in complex samples demonstrates their critical role in maintaining food quality and safety, supporting regulatory compliance, and protecting public health.

Case Study: Milk Safety

In recent years, advancements in nanotechnology have revolutionized milk safety by enabling rapid, on-site detection of contaminants. These innovations help guarantee milk meets safety standards during dairy farming practices and after pasteurization. Nanosensors can identify bacteria, antibiotics, and spoilage markers in real-time, reducing reliance on traditional lab tests. This technology allows you to monitor milk quality immediately at collection points, improving safety and reducing contamination risks. With portable nanosensors, you can quickly verify if milk has been properly pasteurized or if harmful substances are present. This approach promotes better dairy farming practices and enhances consumer confidence.

- Detecting pathogens before milk reaches consumers

- Ensuring compliance with pasteurization standards

- Reducing foodborne illness risks in dairy production

Frequently Asked Questions

How Do Nanosensors Differentiate Between Similar Food Contaminants?

You can see that nanosensors differentiate between similar food contaminants through selective detection, which relies on specific recognition elements like antibodies or aptamers that target unique contaminant features. They also use signal amplification to enhance detection sensitivity, making it easier to distinguish tiny differences between contaminants. This combination allows nanosensors to accurately identify and differentiate contaminants even when they’re closely related, ensuring safer food products for consumers.

What Are the Environmental Impacts of Nanomaterial Disposal From Sensors?

You should consider that nanomaterial disposal raises environmental persistence and ecotoxicity concerns. When you discard nanosensors, their tiny particles can linger in ecosystems, potentially harming wildlife and contaminating soil and water. These materials may accumulate over time, making cleanup difficult. To minimize impact, you must develop proper disposal methods and eco-friendly nanomaterials, ensuring you reduce risks associated with environmental persistence and ecotoxicity concerns.

Are Nanotechnology-Based Tests Cost-Effective for Small-Scale Food Producers?

Think of nanotechnology-based tests as a pocket-sized detective that’s easy to carry around. For small-scale food producers, these tests can be cost-effective when you consider their quick results and accuracy. However, a cost analysis shows scalability challenges, like high initial investments or limited availability. While they’re promising, you might need to weigh whether the benefits outweigh the costs based on your production size and resources.

How Is Consumer Safety Ensured With Nanomaterials in Food Testing?

You can be assured of consumer safety with nanomaterials in food testing because researchers focus on nanomaterial stability, ensuring they don’t degrade or release harmful substances. Regulatory agencies set strict guidelines, and transparent communication helps improve consumer perception. Continuous monitoring and rigorous testing confirm that nanotechnology-based sensors are safe, effective, and reliable, giving you confidence that these innovations protect your health while maintaining trust in food safety practices.

What Regulatory Frameworks Govern Nanotechnology Use in Food Safety?

You need to follow international standards and legal compliance when using nanotechnology in food safety. Regulatory frameworks, like those from the FDA, EFSA, and Codex Alimentarius, set guidelines to guarantee safe application of nanomaterials. Staying updated with these regulations helps you meet legal requirements, prevents violations, and assures consumer safety. Always verify that your nanotech practices align with both local and global standards to maintain trust and compliance in food testing processes.

Conclusion

You now hold the key to a safer food future, where nanotechnology acts as a vigilant guardian, tirelessly scanning for invisible threats. Like a finely tuned orchestra, nanosensors harmonize precision and speed, transforming food safety into a symphony of innovation. While challenges remain, the horizon gleams with promise, inviting you to embrace these tiny sentinels that safeguard your plate, turning the complex dance of contaminants into a well-choreographed ballet of hope and health.