Using nanotechnology, industrial sensors become incredibly small, sensitive, and versatile. You can deploy these sensors in tight spaces or harsh environments, thanks to their enhanced durability and resistance. They detect a wider range of parameters, like trace chemicals and mechanical stress, helping prevent failures and optimize resources. Wireless data collection and remote analysis are also possible, making operations smarter and safer. Keep exploring to see how these innovations are transforming industry standards.

Key Takeaways

- Nanotech enables manufacturing ultra-sensitive, reliable sensors capable of detecting minute chemical and physical changes in industrial environments.

- Miniaturized nanosensors can be integrated into machinery and pipelines for real-time monitoring and predictive maintenance.

- Advanced nanofabrication allows sensors to operate reliably in harsh conditions like extreme temperatures and corrosive chemicals.

- Wireless nanosensors facilitate remote data collection, enhancing automation and reducing maintenance costs.

- The integration of nanotechnology broadens sensor capabilities, improving process efficiency, safety, and overall industrial performance.

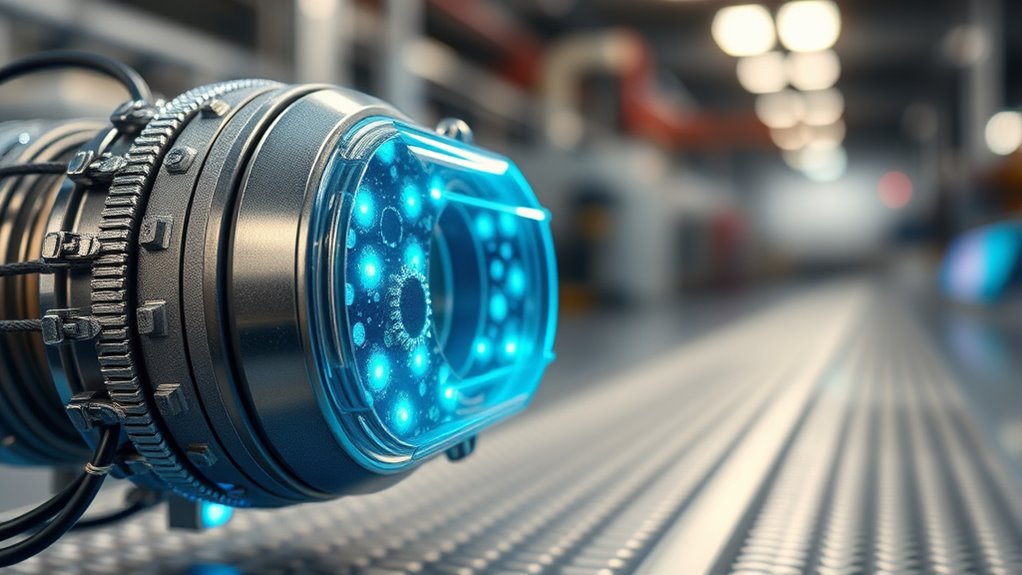

Nanotechnology is transforming industrial sensors by enabling them to detect changes at the molecular level with unprecedented accuracy. This technological leap is largely driven by advancements in nanotech fabrication, which allows engineers to create sensor components at an extremely small scale. With nanotech fabrication, sensors are no longer limited by traditional manufacturing constraints; instead, they can be engineered at the atomic or molecular level, resulting in devices that are more sensitive, faster, and more reliable. This precision manufacturing process guarantees that each sensor component performs at its best, capturing even the slightest variations in environmental conditions or chemical compositions.

Sensor miniaturization plays a pivotal role in this transformation. By shrinking sensors down to the nanoscale, you can incorporate them into a variety of environments where space was previously a limiting factor. Smaller sensors mean less invasive installations, making it easier to deploy them in confined or hard-to-reach locations—such as inside machinery, pipelines, or even within biological systems. This miniaturization also leads to significant improvements in response time because the smaller the sensor, the quicker it can react to changes. As a result, industrial processes become more efficient, with real-time data providing the basis for immediate adjustments and improved control.

Sensor miniaturization enables faster response times and easier deployment in confined or hard-to-reach industrial environments.

The combination of nanotech fabrication and sensor miniaturization opens up new possibilities for industrial monitoring. You can now develop sensors capable of detecting a broader range of chemical and physical parameters, including trace pollutants, temperature fluctuations, or mechanical stress at a granular level. This heightened sensitivity helps prevent equipment failure, optimize resource use, and guarantee safety standards are met more effectively. Additionally, nanotechnology enables the integration of these sensors into wireless networks, allowing you to collect and analyze data remotely, which enhances predictive maintenance and reduces downtime.

Furthermore, the durability of nanotech-fabricated sensors is improved, making them suitable for harsh environments where traditional sensors might fail. Their small size and robust construction mean they can withstand extreme temperatures, corrosive chemicals, and high pressures, broadening their application scope. As you adopt nanotechnology-driven sensors, you’ll notice that their maintenance costs decrease because of their increased lifespan and reliability. Advances in sensor fabrication techniques ensure these devices are not only more precise but also more cost-effective over their operational lifespan. Overall, nanotech fabrication and sensor miniaturization are revolutionizing industrial sensing, providing you with tools that are more precise, adaptable, and resilient, ultimately leading to smarter, safer, and more efficient industrial operations.

Frequently Asked Questions

What Are the Main Challenges in Integrating Nanotechnology With Existing Sensor Systems?

You face scaling challenges when integrating nanotechnology with existing sensor systems, making it tough to produce consistent, large-scale components. Material compatibility also poses issues, as nanomaterials may not seamlessly blend with traditional sensor materials, risking performance and durability. Overcoming these hurdles requires careful design, advanced fabrication techniques, and thorough testing to guarantee the nanotech-enhanced sensors work reliably within current systems.

How Do Nanotech Sensors Compare in Cost to Traditional Industrial Sensors?

While nanotech sensors may seem to carry a higher price tag initially, their cost comparison to traditional sensors often favors long-term savings through enhanced durability and efficiency. An affordability analysis reveals that, despite the upfront investment, nanotechnology can reduce maintenance and energy costs over time. So, you might find that embracing nanotech sensors offers more value, even if their initial expenses are slightly elevated.

What Safety Concerns Are Associated With Nanomaterials in Industrial Environments?

You should be aware that nanomaterials pose safety concerns like toxic exposure if particles become airborne or come into contact with skin. Additionally, their environmental impact raises worries about contamination and long-term ecological effects. To protect yourself and the environment, always follow safety protocols, use proper protective equipment, and guarantee proper disposal of nanomaterials. Staying informed about potential risks helps you minimize hazards in industrial environments.

Can Nanotechnology Improve Sensor Lifespan and Durability?

Think of nanotechnology as a knight’s armor for sensors, boosting their lifespan and durability. You can expect improvements through sensor miniaturization and enhanced nanomaterial stability, making sensors more resistant to wear and environmental factors. This means your sensors will last longer and perform reliably under tough conditions. By leveraging nanotech, you’re fundamentally giving your sensors a superpower, ensuring they stand the test of time and maintain precision.

How Scalable Are Nanotech Sensor Manufacturing Processes?

You’ll find that nanotech sensor manufacturing processes are becoming increasingly scalable, though some scalability hurdles remain. Advances in manufacturing techniques, like roll-to-roll processing and self-assembly, help address these challenges, making mass production more feasible. While scaling up still requires overcoming technical and cost-related hurdles, ongoing innovations suggest that large-scale production of nanotech sensors will soon become more practical and cost-effective for industrial applications.

Conclusion

As you embrace nanotechnology in industrial sensors, you open unparalleled precision and miniaturization. Yet, amidst this cutting-edge progress, remember that simple, traditional sensors still hold value in basic applications. The contrast highlights how innovation and familiarity coexist, shaping the future of industry. By blending nanoscale advancements with established methods, you can achieve smarter, more efficient systems—proving that in technology, sometimes the smallest details make the biggest difference.