Smart packaging with nanotech uses tiny sensors and advanced materials to keep your products fresh and safe. It can detect changes in temperature, humidity, or spoilage, alerting you immediately. These developments allow packaging to be more durable, lightweight, and eco-friendly. By incorporating nanomaterials, packaging becomes an active partner in product management and safety. If you keep exploring, you’ll discover how these innovations are revolutionizing supply chains and consumer experiences.

Key Takeaways

- Nanotech-enhanced packaging improves durability, barrier properties, and sustainability by incorporating nanomaterials like nanoclays and metal oxides.

- Embedded nanoscale sensors detect environmental changes and spoilage indicators, enabling real-time product monitoring.

- Wireless data transmission from nanotech sensors enhances supply chain transparency and allows proactive management.

- Smart packaging with nanotech offers active preservation, extending shelf life and ensuring product safety.

- Advances in nanomaterials and sensor integration are transforming packaging into an intelligent, eco-friendly, and responsive system.

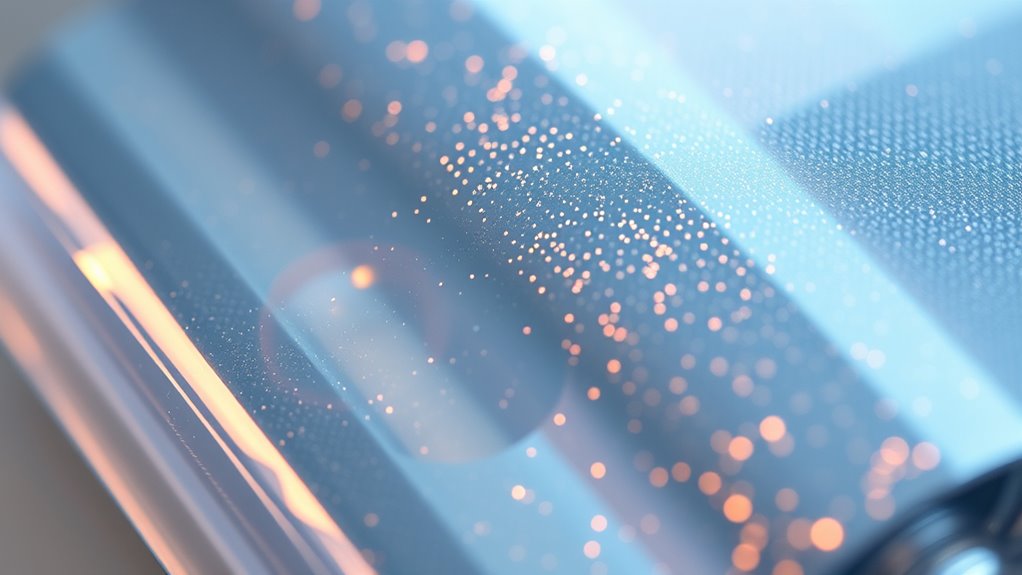

Smart packaging with nanotech is revolutionizing how products are preserved, tracked, and interacted with. At the heart of this transformation are nanomaterials in packaging, which are engineered at the molecular level to offer enhanced strength, barrier properties, and responsiveness. These tiny materials improve the durability of packaging, making it more resistant to damage, moisture, and contamination. For example, incorporating nanoclays or metal oxides into packaging films creates an effective barrier that extends shelf life and maintains freshness. As you examine these innovations, you’ll notice how nanomaterials enable the creation of lightweight yet sturdy packaging solutions, reducing material waste and transportation costs while improving product safety.

Nanomaterials in packaging boost durability, extend shelf life, and create lightweight, eco-friendly solutions.

Sensor integration techniques further elevate smart packaging by enabling real-time monitoring and data collection. These techniques involve embedding nanoscale sensors directly into packaging materials, allowing the packaging to detect changes such as temperature fluctuations, humidity levels, or spoilage indicators. You can think of these sensors as the packaging’s sensory organs, constantly gathering critical information about the product’s condition. The integration process often uses advanced nanotechnology to guarantee that sensors are both highly sensitive and minimally intrusive, preserving the packaging’s integrity and appearance. Techniques like nanoscale printing, layer-by-layer assembly, and the incorporation of conductive nanomaterials allow these sensors to be seamlessly integrated into various packaging formats.

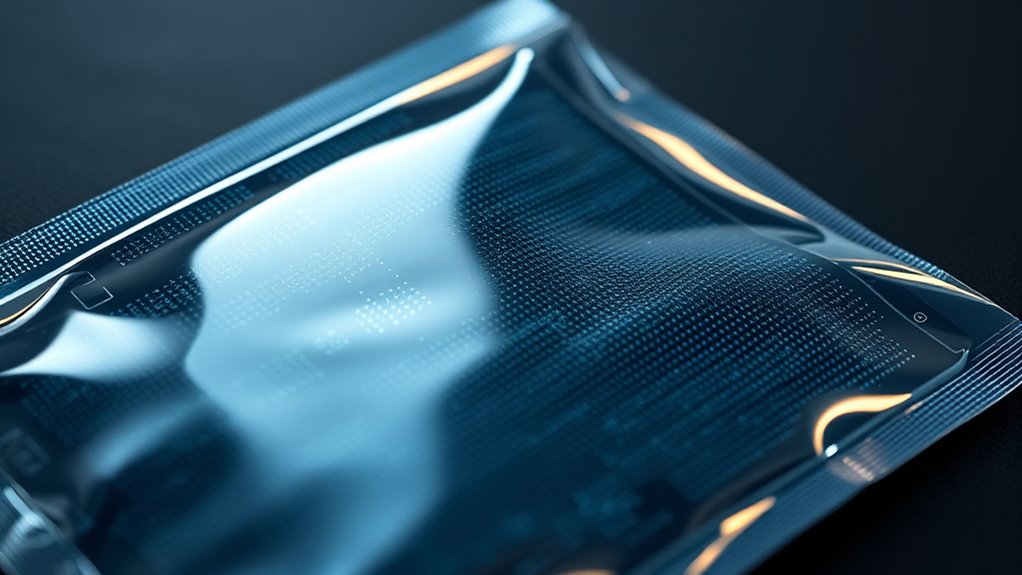

By leveraging sensor integration techniques, you gain immediate access to crucial data, which can be transmitted wirelessly to retailers, manufacturers, or consumers. This connectivity ensures that you’re always informed about the product’s freshness or safety status without opening the package. Imagine receiving a notification when a perishable item nears its expiry date or when environmental conditions threaten its quality. This proactive approach reduces waste, enhances consumer confidence, and streamlines supply chain operations.

The combination of nanomaterials and sensor integration techniques results in packaging that isn’t just a passive container but an active participant in product management. You benefit from smarter, more responsive packaging that keeps products at ideal conditions, reduces spoilage, and provides transparency throughout the supply chain. As nanotech continues to evolve, expect even more sophisticated sensor systems and nanomaterial innovations that will further redefine how products are preserved, monitored, and interacted with, making your packaging smarter and more efficient every step of the way. Additionally, advances in nanomaterials are enabling the development of environmentally friendly packaging options that align with sustainability goals.

Frequently Asked Questions

Are Nanotech-Based Smart Packages Environmentally Sustainable?

Nanotech-based smart packages can be environmentally sustainable, but you need to ensure biodegradability concerns and energy consumption. While nanotech can reduce waste and improve efficiency, producing these materials often requires significant energy, impacting sustainability. Additionally, some nanomaterials may not biodegrade easily, raising environmental concerns. To guarantee sustainability, focus on developing biodegradable nanomaterials and optimizing manufacturing processes to lower energy use.

What Are Potential Health Risks of Nanomaterials in Packaging?

You should be aware that nanomaterials in packaging pose potential health risks due to nanoparticle toxicity. When nanoparticles leach into food or beverages, they can be ingested, raising consumer health concerns. These tiny particles may penetrate biological barriers, potentially causing cellular damage or immune responses. While research continues, it is crucial to monitor and regulate nanotech use in packaging to guarantee consumer safety and minimize health risks.

How Cost-Effective Are Nanotech Smart Packaging Solutions?

You’ll find nanotech smart packaging solutions can be quite cost-effective over time, especially when you consider enhanced shelf life and reduced waste. A thorough cost analysis shows initial implementation challenges, like high setup costs and technical complexity, but these often decrease as technology advances. In the long run, you may save money through improved product safety and customer satisfaction, making nanotech packaging a smart investment despite some upfront hurdles.

Can Nanotech Packaging Be Recycled or Reused Easily?

You can’t teach an old dog new tricks, so nanotech packaging isn’t always easy to recycle or reuse. While some nanotech-enabled packaging uses biodegradable materials, recycling challenges remain due to complex composites and tiny particles that complicate separation. This makes reuse or recycling less straightforward, often requiring specialized processes. To truly embrace sustainability, advancements must focus on developing nanotech packaging that’s both environmentally friendly and easy to recycle or reuse.

What Regulations Govern Nanotech Use in Packaging Industries?

You should know that regulations governing nanotech in packaging are mainly guided by regulatory frameworks and safety standards set by agencies like the FDA and EPA. These bodies evaluate the potential risks and establish guidelines to guarantee safe use. You need to stay updated on evolving policies, as they aim to protect consumers and the environment while encouraging innovation. Compliance with these regulations is essential for safe and legal nanotech packaging application.

Conclusion

Embracing smart packaging with nanotech is truly a game-changer, offering smarter, safer, and more sustainable solutions. As the saying goes, “A stitch in time saves nine,” investing in this technology now can prevent future waste and problems. By staying ahead of the curve, you’re not just protecting products—you’re shaping a better, more efficient world. So, don’t wait; the future of packaging is nanotech, and it’s knocking at your door.