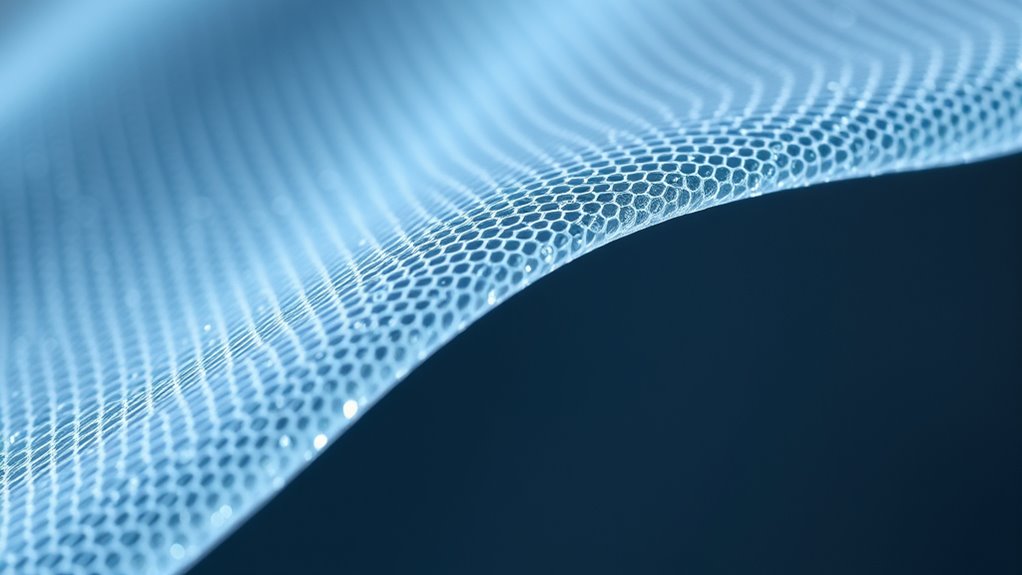

Advanced nano-membranes for filtration use nanoscale engineering and innovative fabrication methods to achieve highly selective, durable, and efficient separation of contaminants. These membranes incorporate materials like graphene and nanomaterials, with precisely engineered pores that can be tailored for specific molecules or particles. They improve filtration performance by controlling pore size, shape, and surface properties. To discover how these cutting-edge membranes can revolutionize your filtration needs, explore further insights below.

Key Takeaways

- Nano-membranes utilize atomic-scale pores for highly selective contaminant removal.

- Advanced fabrication techniques enable precise control over membrane structure and pore characteristics.

- Pore engineering enhances selectivity and permeability, optimizing filtration performance.

- Material innovations like graphene improve membrane durability and chemical resistance.

- Their versatile applications include water purification, healthcare, and industrial processes.

Nano-membranes are revolutionizing filtration technologies by enabling highly efficient separation of contaminants at the molecular level. These ultra-thin membranes are crafted with precision, allowing you to target specific molecules and particles that traditional filters might miss. The secret lies in advanced membrane fabrication techniques, which give you the ability to control the membrane’s structure and functionality. From layer-by-layer assembly to chemical vapor deposition, each method offers unique advantages, guaranteeing you can produce membranes tailored to your specific needs. This meticulous process is vital because the performance of nano-membranes heavily depends on their internal architecture. Additionally, incorporating innovative materials, such as graphene or other nanomaterials, can further enhance membrane performance and durability.

Pore engineering plays a pivotal role in optimizing nano-membranes for diverse applications. By manipulating pore size, shape, and distribution, you can fine-tune the membrane’s selectivity and permeability. For instance, reducing pore size allows you to block smaller contaminants, while maintaining high flow rates. You might also incorporate functional groups into the pore walls, enabling the membrane to selectively attract or repel certain molecules based on charge or chemical affinity. This level of customization guarantees that your filtration system is not only efficient but also highly specific, reducing waste and energy consumption. Pore engineering involves advanced techniques like atomic layer deposition and focused ion beam milling, which give you precise control over nanoscale features, critical for targeting complex mixtures and challenging contaminants. Mastering pore size control is essential for achieving the desired separation performance.

As you develop nano-membranes, you’ll find that the interplay between membrane fabrication and pore engineering is key to achieving top performance. High-quality fabrication methods guarantee the structural integrity and uniformity of the membrane, minimizing defects that could compromise filtration. Meanwhile, pore engineering allows you to refine the membrane’s selectivity, enhancing contaminant rejection without sacrificing flow rate. This synergy enables the creation of membranes capable of tackling emerging challenges in water treatment, healthcare, and industrial processes. The ability to engineer pores at the nanoscale also opens doors for innovative applications, like selective drug delivery and biosensing, where precision is paramount.

Frequently Asked Questions

How Do Nano-Membranes Compare Cost-Wise to Traditional Filtration Methods?

You’ll find that nano-membranes generally have higher manufacturing costs upfront compared to traditional filtration methods. However, their cost comparison over time often favors nano-membranes because they last longer, require less maintenance, and provide more efficient filtration. While initial investment is higher, the durability and performance improvements can lead to cost savings in the long run, making them a competitive choice despite the higher initial expense.

What Are the Environmental Impacts of Nano-Membrane Production and Disposal?

You should be aware that the environmental concerns surrounding nano-membrane production involve the use of hazardous chemicals and energy-intensive processes, which can contribute to pollution. Disposal challenges also arise because nano-membranes may release nanoparticles into the environment, posing risks to ecosystems and human health. It is crucial to develop sustainable manufacturing and disposal methods to mitigate these impacts and guarantee responsible use of this advanced technology.

Can Nano-Membranes Filter Viruses Effectively?

Yes, nano-membranes can filter viruses effectively due to their high membrane selectivity. Their tiny pore sizes allow them to trap viruses while letting water pass through, making them ideal for virus filtration. You can depend on these membranes for enhanced safety, especially in water treatment. Their precision in filtering viruses ensures you get cleaner, safer water, reducing health risks associated with viral contaminants.

What Are the Limitations of Nano-Membranes in High-Pressure Applications?

You might find nano-membranes face challenges in high-pressure applications due to limited pressure resistance, which can lead to membrane deformation or damage. Additionally, higher pressures often accelerate membrane fouling, reducing filtration efficiency and lifespan. These limitations mean you need to carefully consider operating conditions and possibly incorporate cleaning protocols or membrane modifications to improve durability and performance under demanding high-pressure scenarios.

How Scalable Are Nano-Membrane Manufacturing Processes?

You’ll find that nano-membrane manufacturing processes are becoming increasingly scalable due to manufacturing innovations. However, scalability challenges still exist, especially when trying to produce large volumes while maintaining quality and precision. Advances in fabrication techniques, automation, and cost-effective methods are helping overcome these hurdles. With ongoing research and technological improvements, you can expect nano-membrane production to become more efficient and adaptable for widespread industrial applications.

Conclusion

You now see how advanced nano-membranes revolutionize filtration, offering unmatched efficiency. Did you know they can filter particles as small as 1 nanometer? That’s about 100,000 times thinner than a human hair! This incredible precision means cleaner water, safer medicines, and better environmental protection. As technology improves, expect these membranes to become even more essential in solving global challenges. Embrace the future of filtration—it’s clearer, safer, and more sustainable thanks to nano-membranes.