Nanotech has the power to revive declining industries by making products stronger, more efficient, and longer-lasting. It improves manufacturing, boosts energy storage, and enhances healthcare devices. Innovations like nanomaterials and coatings reduce costs, waste, and environmental impact. If you explore further, you’ll discover how these technologies are enabling surprising industry comebacks and shaping a more sustainable future. Stay tuned to see how nanotech’s potential can turn setbacks into success stories.

Key Takeaways

- Nanotech enhances manufacturing durability and efficiency, enabling industries to reduce costs and extend product lifecycles.

- Integration of nanomaterials improves electronics, energy storage, and renewable solutions, revitalizing tech sectors.

- Nanotech-driven environmental remediation and filtration help industries meet sustainability goals and reduce regulatory pressures.

- Advancements in nanomaterials and scalable production methods lower barriers to adopting innovative technologies.

- Public funding and workforce development support nanotech-driven industry innovations and economic recovery.

Revitalizing Manufacturing Through Nanomaterials

Nanomaterials are transforming manufacturing by enabling the creation of stronger, lighter, and more durable components. You can now produce composites with higher strength-to-weight ratios, which means parts last longer and perform better. Carbon nanotubes and graphene are added to materials to improve electrical conductivity and resistance to fatigue, making them ideal replacements for obsolete metal parts in aerospace and automotive industries. Nano-coatings protect surfaces from corrosion and wear, reducing maintenance and failure rates in heavy industries like automotive and aerospace. Additionally, nanoscale catalysts and increased surface areas boost chemical process yields and cut energy use. Moreover, advancements in scalable production methods are helping to address the challenges of cost and manufacturing volume, unlocking broader industrial adoption. The development of cost-effective synthesis techniques is crucial for scaling up production while maintaining quality and affordability. This progress is supported by innovations in manufacturing scalability, which are essential for widespread application. While scaling up production and managing costs remain challenges, the potential for nanomaterials to revitalize manufacturing sectors is significant, with ongoing growth fueling industry transformation. Furthermore, ongoing research into renewable materials is paving the way for even more sustainable manufacturing practices, especially as researchers explore environmentally friendly synthesis techniques to reduce ecological impact.

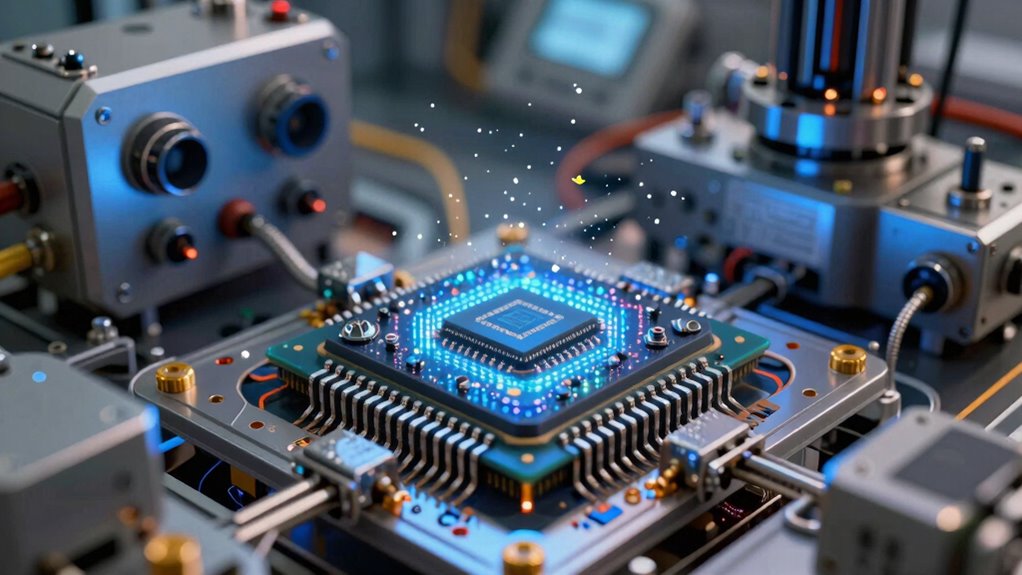

Extending Product Lifecycles in Electronics and Semiconductors

Innovations in nanotechnology are opening new opportunities to extend the lifespan of electronic and semiconductor products. By integrating nanoelectronics like semiconductor nanomembranes and quantum-dot displays, you can create thinner, more efficient devices that retrofit into existing product lines, releasing upgrade markets. Nanoscale interconnects and materials such as graphene and metallic nanoparticles boost device performance and energy efficiency, helping you stay competitive in mature consumer sectors. Nanosensors and MEMS devices also enable predictive maintenance and smart-grid retrofits for legacy equipment, reducing downtime and costs. Additionally, advancements in nanofabrication techniques are making these innovations more scalable and cost-effective for manufacturers. As these manufacturing methods continue to advance, the barriers to adoption are gradually decreasing, allowing more firms to capitalize on nanotech opportunities. The integration of renewable energy solutions like solar-powered components into product designs can further reduce operational costs and environmental impact. However, adopting nanofabrication requires significant investment and skilled labor, limiting immediate uptake for struggling firms. Despite these barriers, the large projected market—up to USD 190 billion by 2035—highlights the potential to revive declining electronics industries through nanotech-driven product lifecycle extension, especially as scalable manufacturing methods continue to evolve.

Powering the Future With Energy Sector Nanotech

Nanotech is transforming energy production by enhancing battery performance and solar efficiency. With nanostructured electrodes and additives, you can expect longer-lasting batteries and more cost-effective solar panels. These advancements are vital for retooling declining fossil-based sectors and powering the future sustainably. Additionally, nanotech’s potential to improve energy storage solutions could address intermittency issues and support a more resilient renewable energy infrastructure. Innovations in nanomaterials are also opening new pathways for cleaner energy technologies and smarter grid management. For example, the development of nanostructured catalysts can significantly increase the efficiency of energy conversion processes.

Battery Innovation Boost

Have you ever wondered how breakthroughs at the nanoscale are transforming energy storage? Nanotech enhances battery performance by improving electrode materials with nanostructured designs, boosting energy density and extending cycle life. Carbon nanotube additives increase conductivity and mechanical resilience, making batteries more durable and efficient. Researchers develop nanoscale coatings that prevent degradation, reducing charging times and enhancing safety. These innovations enable the retrofitting of existing batteries and support the progression to electric vehicles and renewable energy storage. Tokenization is revolutionizing how digital assets are managed securely, which could further accelerate the deployment of advanced energy storage solutions. While scaling production remains a challenge, ongoing investments and technological advances are accelerating commercialization. As a result, nanotech-driven battery improvements could revitalize declining industries by making energy storage more reliable, cost-effective, and adaptable to new applications. Advanced nanomaterials are also being explored to further optimize energy storage solutions. Additionally, the development of scalable manufacturing processes is critical to bringing these innovations from laboratory to market efficiently. Moreover, ongoing research into nanostructured electrode materials aims to further enhance battery capacity and lifespan. Understanding the role of nanostructures in electrochemical processes is vital for designing next-generation batteries.

Solar Efficiency Gains

Solar energy systems are increasingly benefiting from nanomaterials that enhance light absorption and reduce energy losses. You’ll see significant improvements as nanotech boosts solar panel performance, making renewable energy more affordable and efficient. Consider these breakthroughs:

- Enhanced Light Capture: Nanostructured coatings trap more sunlight, increasing energy conversion rates. Incorporating nanomaterial-enabled light absorption techniques can further optimize this process.

- Lower Losses: Nanoscale layers reduce reflection and resistive losses, maximizing output.

- Durability Boost: Nano-coatings protect panels against environmental wear, extending their lifespan by up to 50%. Incorporating water resistance in nano-coatings further ensures that panels withstand harsh weather conditions, maintaining efficiency over time.

Additionally, ongoing research into nanomaterial stability aims to improve long-term performance under diverse environmental stresses. These advancements not only drive down the cost of solar power but also accelerate deployment in traditional markets. By integrating nanomaterials, you can expect more reliable, long-lasting solar solutions that power a cleaner, sustainable future, revitalizing industries and transforming energy landscapes.

Transforming Healthcare and Biotech Industries

Transforming healthcare and biotech industries hinges on leveraging nanoparticle-based technologies to improve diagnostics, therapeutics, and medical devices. You can expect targeted drug delivery systems that increase treatment efficacy while reducing side effects, thanks to nanoparticles that precisely reach affected cells. Nanoscale diagnostics and point-of-care sensors now enable rapid, accurate detection of diseases, expanding markets for startups and contract manufacturers. Medical implants and antimicrobial coatings benefit from nanostructured materials that enhance durability and reduce infections, creating retrofit opportunities for legacy devices. Although regulatory and manufacturing complexities slow progress, industry forecasts indicate sustained growth. Understanding regulatory hurdles will be key to unlocking widespread adoption of these advanced technologies. Additionally, ongoing research into scalable manufacturing processes can help address production challenges and accelerate commercialization. Public funding and innovation efforts will likely accelerate adoption, transforming regional biotech hubs and revitalizing declining sectors. Nanotech’s role in healthcare promises safer, more effective solutions that reshape patient care and industry landscapes alike, especially as nanomanufacturing techniques evolve to meet industry demands.

Advancing Environmental Cleanup and Circular Economies

Building on advances in healthcare nanotech, nanomaterials are now making a significant impact on environmental cleanup and circular economy initiatives. You can harness nanofiltration membranes and nano-adsorbents to drastically improve water purification, turning old plants into high-value remediation hubs. Nanocatalysts and nanoadsorbents enable more efficient recycling, helping industries recover metals and materials with less waste. Air-filtration nanofibers and surface treatments reduce emissions and lower retrofit costs for aging facilities. These innovations make it possible for you to understand cleaning appliances and adopt smarter solutions that enhance sustainability. The development of nanomaterial-based filtration further supports the push toward eco-friendly industrial processes. Additionally, sustainable manufacturing practices benefit from nanotech developments that minimize environmental impact. These progress not only revitalizes industries but also aligns economic growth with ecological responsibility.

Navigating Policy, Workforce, and Market Dynamics

Exploring the complex landscape of policy, workforce, and market dynamics is essential to unlock nanotech’s full potential for industry revival. You need to navigate evolving regulations, safety standards, and environmental assessments that influence how quickly nanotech can be adopted. Developing a skilled workforce is critical—training technicians and engineers in nanomanufacturing ensures quality and efficiency. Market demand forecasts show significant growth, but scaling production and securing funding remain hurdles. Public R&D investments and government procurement can accelerate adoption, creating anchor customers. However, inconsistent policies and lack of harmonized standards pose risks. To succeed, you must align regulatory frameworks, invest in workforce development, and leverage market opportunities, turning these challenges into catalysts for industry comeback.

Frequently Asked Questions

How Quickly Can Nanotech-Driven Innovations Lead to Industry-Wide Economic Recovery?

You can expect nanotech-driven innovations to start boosting industries within 3 to 7 years, depending on the sector and adoption hurdles. As nanomaterials improve durability, efficiency, and product lifecycles, industries like energy, electronics, and healthcare will see gradual but steady recoveries. However, scale-up challenges, costs, and regulation may slow widespread impact, meaning full industry-wide recovery might take a decade or more. Active investments and policy support accelerate this timeline.

What Are the Main Regulatory Hurdles Delaying Nanotech Adoption in Traditional Sectors?

You face regulatory hurdles like unclear safety standards, lengthy approval processes, and environmental concerns that slow nanotech adoption. These challenges require extensive testing for toxicity, waste handling, and lifecycle impacts, which delay commercialization. Without harmonized regulations and clear guidelines, industries hesitate to invest heavily. Overcoming these barriers demands collaboration between regulators, industry players, and researchers to develop consistent standards, ultimately speeding up nanotech integration into traditional sectors.

How Cost-Effective Is Scaling Nanomaterials for Large-Volume Industrial Applications?

Scaling nanomaterials for large-volume industrial applications can be quite cost-effective over time, especially as production methods improve and economies of scale kick in. You’ll see reduced costs per unit as manufacturing ramps up, making nanotech more competitive with traditional materials. While initial investments and scale-up challenges exist, ongoing technological advancements and increasing market demand are expected to lower costs, boosting overall cost-effectiveness in the long run.

What Skills Are Most Critical for Workforce Adaptation to Nanotech-Enabled Industries?

You need to develop highly specialized skills because nanotech transforms industries at a lightning-fast pace. Critical abilities include nanofabrication expertise, materials science knowledge, and precision quality control. You should also master regulatory compliance, environmental safety protocols, and advanced characterization techniques. Strong problem-solving skills and adaptability are essential to keep up with rapid innovations. Embracing continuous learning guarantees you stay ahead in this complex, ever-evolving field, making you indispensable in nanotech-driven industries.

How Do Environmental and Safety Concerns Impact Nanotech Commercialization Timelines?

Environmental and safety concerns slow nanotech commercialization timelines because regulatory agencies require thorough testing and monitoring to guarantee nanoparticle safety and environmental impact. You’ll find that lengthy approval processes, compliance costs, and potential restrictions on nanoparticle use can delay product launches and industry adoption. These concerns necessitate additional research, environmental assessments, and development of safe manufacturing practices, which together extend timelines but ultimately foster responsible and sustainable nanotechnology growth.

Conclusion

Nanotech may seem like a futuristic dream, but it’s already breathing new life into declining industries. While traditional sectors struggle with obsolescence, nanomaterials boost manufacturing, extend product lifespans, and clean our environment. It’s a reminder that innovation isn’t just about new tech—it’s about transforming the old into the new. As industries face decline, nanotech offers a surprising comeback, proving that even in decay, there’s potential for renewal.