Nanomachines are transforming manufacturing by cutting costs, boosting efficiency, and enabling the production of higher-quality products with less waste. They allow for precise, atomic-level assembly, reducing errors and material loss, which lowers prices and increases affordability. This shift encourages innovation, creates new markets, and promotes sustainable practices, reshaping global supply chains. If you stay with us, you’ll discover how this technological leap is driving economic growth and changing industries worldwide.

Key Takeaways

- Nanomachines significantly reduce manufacturing costs through increased precision and minimized waste.

- They enable the production of advanced, energy-efficient products, fostering innovation and new markets.

- Widespread adoption shifts supply chains, promoting on-demand, customized manufacturing and economic flexibility.

- Investment in nanotech infrastructure positions countries as leaders in high-tech industries.

- Enhanced sustainability and efficiency contribute to long-term economic growth and environmental benefits.

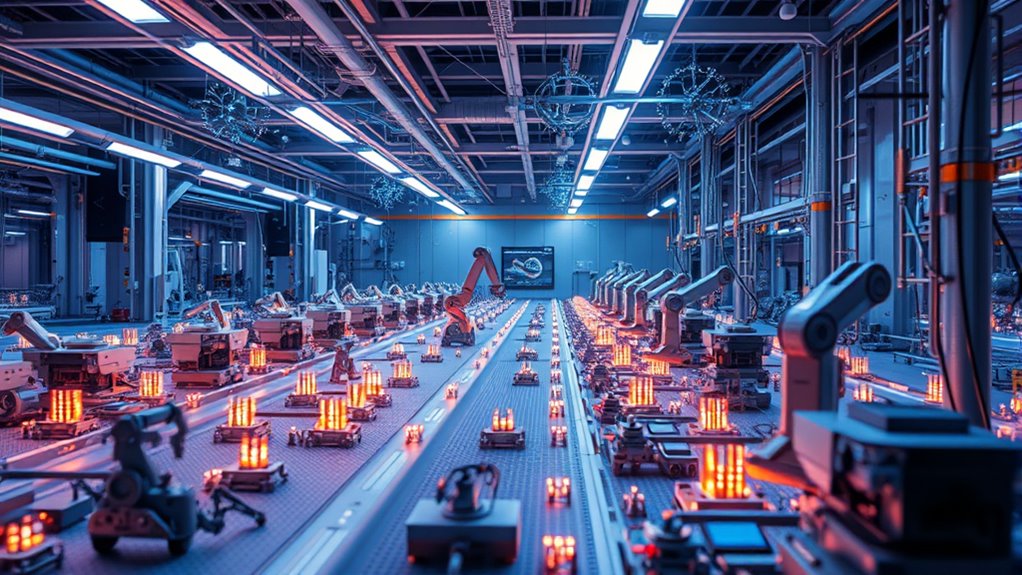

Have you ever wondered how the future of manufacturing might look with tiny machines working at the atomic level? With advancements in nanotechnology, this isn’t just a science fiction idea anymore. Nanomachines could revolutionize how products are built, especially through techniques like molecular assembly and precision engineering. Instead of relying on traditional manufacturing methods, you’ll see a shift toward highly efficient, cost-effective processes that operate at an unprecedented scale. By manipulating individual atoms and molecules, nanomachines can assemble complex structures with incredible accuracy, reducing waste and enhancing product quality. This leap in manufacturing precision means fewer errors and less material loss, directly impacting costs and profitability.

Nanomachines at the atomic level promise revolutionary, precise, and efficient manufacturing transforming industries and economies worldwide

As you consider the economic impact, it’s clear that nanomachines will drastically cut production expenses. Molecular assembly allows for the creation of components with atomic-level precision, which minimizes the need for extensive quality control and rework. This efficiency can translate into lower prices for consumers and higher margins for companies. Furthermore, because nanomachines can operate continuously and with minimal human intervention, labor costs decrease substantially. While initial investments in nanotechnology research and equipment might be high, the long-term savings and productivity boosts are considerable. Industries that adopt these technologies early will gain a competitive edge, potentially dominating markets with superior, more affordable products.

You’ll also find that nanomachines open new avenues for innovation, leading to entirely new product categories and markets. For example, in electronics, molecular assembly can produce smaller, faster, and more energy-efficient components. In medicine, nanomachines could enable on-demand drug manufacturing or targeted therapies, creating entirely new healthcare markets. This expansion of possibilities injects vitality into the economy, fostering new startups and boosting existing industries. Additionally, the integration of nanomachines into manufacturing processes can reduce environmental impact by minimizing waste and energy consumption. As a result, companies that incorporate nanotechnology not only improve their bottom line but also align with growing sustainability demands, appealing to eco-conscious consumers and regulators alike.

Finally, think about the ripple effects across the global economy. As nanomachines lower costs and enable rapid innovation, entire supply chains will transform. Countries investing in nanotechnology infrastructure can become leaders in high-tech manufacturing, attracting investment and creating jobs. The adoption of molecular assembly and precision engineering at scale could reshape economic landscapes, making manufacturing more resilient and adaptable to future challenges. You’ll see a shift from mass production to highly customized, on-demand manufacturing, which could redefine global trade dynamics. Additionally, as nanotechnology advances, new markets and industries will emerge, fueling further economic growth. Overall, nanomachines hold the potential to generate significant economic growth, reshaping industries and markets in ways that benefit consumers, businesses, and entire economies.

Frequently Asked Questions

How Do Nanomachines Affect Global Supply Chain Dynamics?

Nanomachines revolutionize your supply chain by enabling rapid, precise production and assembly, boosting supply chain resilience. They facilitate logistical innovation, reducing delays and costs while ensuring high-quality outputs. By automating complex tasks at a microscale, you can respond swiftly to market changes and disruptions. This technological leap enhances efficiency, shortens delivery times, and makes your supply chain more adaptable, ultimately strengthening your competitive edge in a global marketplace.

What Are the Environmental Risks Associated With Nanomachine Manufacturing?

You might not realize it, but nanomachine manufacturing poses serious environmental risks. It could lead to environmental pollution if waste isn’t properly managed, and resource depletion becomes a concern as raw materials are heavily consumed. These hidden dangers threaten ecosystems and human health. Staying vigilant and adopting strict regulations can help mitigate these risks, but the potential for unforeseen consequences keeps us on edge, questioning what might happen next.

How Do Nanomachines Influence Workforce Skills Requirements?

Nanomachines shift workforce skills requirements by increasing the need for automation skills, as they enable more advanced manufacturing processes. You’ll find that jobs involving manual tasks may face displacement, but new roles emerge for those skilled in programming and maintaining these tiny devices. To stay relevant, you should focus on developing expertise in nanotechnology, automation, and robotics, which are vital for adapting to this technological shift and minimizing job displacement.

What Are the Intellectual Property Challenges in Nanomachine Technology?

Imagine developing a nanomachine that revolutionizes medicine. You face intellectual property challenges like patent infringement if competitors copy your design, and protecting trade secrets becomes essential to maintain your competitive edge. You must carefully navigate patent laws to secure your innovations, while safeguarding sensitive information from theft. These challenges require vigilant legal strategies, ensuring your breakthroughs remain protected from unauthorized use and infringement, ultimately supporting your success in this cutting-edge field.

How Will Nanomachines Impact Small and Medium-Sized Enterprises?

You’ll find nanomachines can offer small and medium-sized enterprises new opportunities, but scaling challenges and cost implications remain hurdles. As you attempt to integrate nanotech, expect initial investments to be high, and scaling up may be complex. However, once adopted, nanomachines could improve efficiency, reduce waste, and foster innovation. Staying informed about technological advances and potential costs helps you make strategic decisions to leverage nanomachines effectively.

Conclusion

Imagine nanomachines as tiny artisans transforming factories into precision workshops. Just last year, a company cut production costs by 30%, thanks to these microscopic workers. As you see, they’re not just tools—they’re the future’s building blocks, reshaping industries piece by piece. Embrace this revolution, because like those tiny artisans, nanomachines hold the power to craft a more efficient, innovative, and prosperous tomorrow. The future is in your hands—literally.