Nano-coatings for corrosion resistance form ultra-thin, eco-friendly layers that act as a strong barrier against moisture, oxygen, and corrosive elements. They often have self-healing properties, automatically fixing small cracks to extend the surface’s lifespan. These coatings are quick to apply, require less material, and produce minimal waste, making them environmentally friendly. If you want to discover how these advanced solutions can protect your surfaces sustainably, there’s more to explore ahead.

Key Takeaways

- Ultra-thin nanometer layers form a durable barrier against moisture, oxygen, and corrosive agents.

- Self-healing properties enable nano-coatings to repair cracks automatically, maintaining long-term protection.

- Eco-friendly formulations reduce VOCs and hazardous chemicals, making application safer and more sustainable.

- Quick, efficient application with minimal materials leads to less waste and lower maintenance costs.

- Combining advanced technology with sustainability supports resilient, environmentally responsible corrosion prevention.

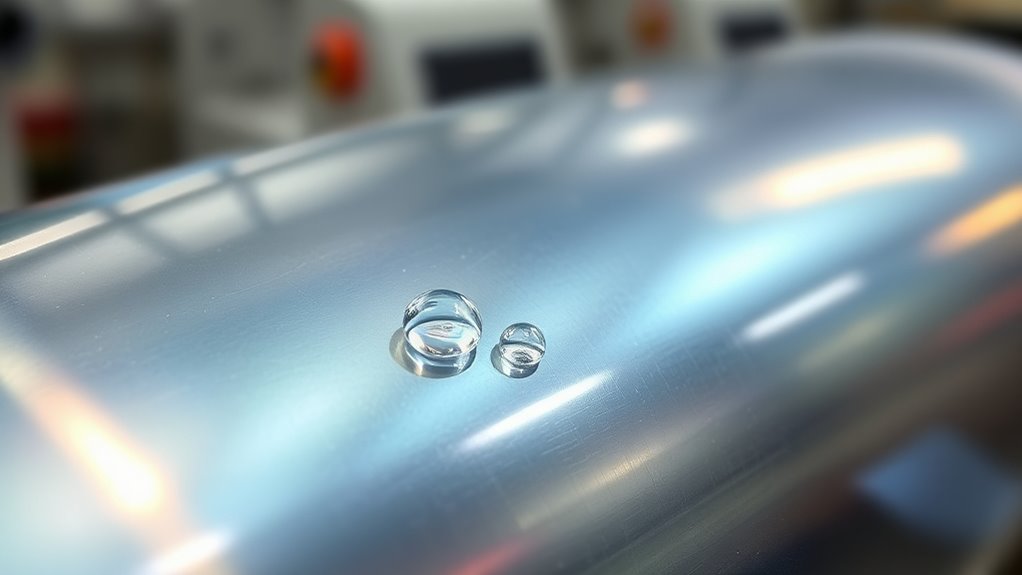

Have you ever wondered how to protect metal surfaces from rust and corrosion more effectively? Nano-coatings are revolutionizing the way industries approach this challenge. These ultra-thin layers, often just a few nanometers thick, provide a robust barrier that prevents moisture, oxygen, and other corrosive agents from reaching the metal. One of the standout features of advanced nano-coatings is their self-healing properties. When tiny cracks or scratches occur, the coating can automatically repair itself, maintaining its protective integrity without requiring manual reapplication. This self-healing ability means your metal surfaces stay protected longer, reducing maintenance costs and downtime. Plus, it markedly enhances the lifespan of equipment, infrastructure, or vehicles exposed to harsh environments. The environmental benefits of nano-coatings are also significant, as many formulations are designed to be eco-friendly, containing fewer volatile organic compounds (VOCs) and hazardous chemicals. Unlike traditional paints and corrosion inhibitors, many nano-coatings are designed to be environmentally friendly. They often contain fewer volatile organic compounds (VOCs) and hazardous chemicals, making them safer for workers and reducing pollution during manufacturing and application. This eco-conscious approach aligns with global efforts to minimize industrial footprints and promote sustainability. Additionally, because nano-coatings are so efficient at preventing corrosion, there’s less need for frequent reapplications or replacements, which ultimately reduces waste and conserves resources. Their durability means fewer replacements over time, making them a greener choice overall.

Nano-coatings offer self-healing protection, extending metal lifespan and reducing maintenance needs.

The application process of nano-coatings also contributes to their environmental benefits. They require less material and can be applied quickly with minimal solvents or cleaning agents. This efficiency translates into lower emissions and waste during the coating process. Furthermore, the long-lasting nature of these coatings means fewer interventions are necessary, saving energy and reducing environmental disturbances associated with maintenance activities.

In essence, nano-coatings combine technological innovation with environmental responsibility. Their self-healing properties ensure continuous protection, even in challenging conditions, while their reduced environmental impact supports sustainable practices. If you’re looking to extend the life of your metal assets while minimizing ecological harm, adopting nano-coatings could be a game-changer. They offer a smarter, more sustainable solution that keeps corrosion at bay and helps protect our planet. As research advances, expect even more eco-friendly formulations that maximize performance without compromising environmental safety. So, whether for industrial, automotive, or infrastructure purposes, nano-coatings are paving the way toward a cleaner, more resilient future for metal protection.

Frequently Asked Questions

How Long Do Nano-Coatings Typically Last in Harsh Environments?

Nano-coatings in harsh environments typically last between 2 to 10 years, depending on their durability lifespan and environmental stability. You’ll find that high-quality coatings with strong resistance to extreme conditions can provide longer-lasting protection. Regular maintenance and proper application also extend their effectiveness. Keep in mind, factors like temperature, humidity, and chemical exposure influence how well the coating performs over time, so choose coatings suited to your specific environment.

Are Nano-Coatings Environmentally Friendly and Biodegradable?

Like a gentle breeze, nano-coatings are often eco-friendly and biodegradable, making them a smart choice for sustainable practices. They’re designed to minimize environmental impact, with many formulations crafted from non-toxic, renewable materials. While not all nano-coatings are biodegradable, advancements now focus on eco-friendliness to reduce pollution. You can choose environmentally conscious options that balance protection with sustainability, helping you stay green without sacrificing performance.

Can Nano-Coatings Be Applied to Existing Corrosion-Damaged Surfaces?

Yes, you can apply nano-coatings to existing corrosion-damaged surfaces. To guarantee proper coating adhesion, you need to start with thorough surface preparation, removing loose rust, dirt, and old coatings. Proper cleaning and possibly light abrasion help create a smooth, clean surface, allowing the nano-coating to bond effectively. This process helps protect the underlying material from further corrosion and extends the lifespan of the surface.

What Is the Cost Comparison Between Nano-Coatings and Traditional Coatings?

You’ll find that nano-coatings often have a higher initial cost compared to traditional coatings, but their durability and protective qualities can lead to long-term savings. When doing a cost analysis, consider factors like application expenses, maintenance, and lifespan. If your budget considerations prioritize longevity and reduced upkeep, nano-coatings might be more cost-effective over time, despite the upfront investment.

Do Nano-Coatings Affect the Electrical Conductivity of Materials?

Imagine a shield that both guards and empowers your material, like a secret passage that changes the landscape. Nano-coatings can slightly alter electrical properties, sometimes increasing conductivity or acting as insulators, depending on their composition. They also enhance coating adhesion, creating a seamless barrier. You’ll find that these tiny layers influence electrical behavior subtly, but they mostly serve to protect and improve your material’s performance, keeping it resilient and efficient.

Conclusion

So, next time your metal surfaces seem destined to rust, just slap on some nano-coatings. Who knew that tiny particles could outsmart corrosion so effortlessly? It’s almost amusing—your everyday metal struggles meet their match in microscopic innovation. Instead of endless maintenance, you get a sleek, resilient shield that laughs in the face of rust. Irony at its finest: the tiniest coatings, the biggest difference. Now, isn’t that a little nano miracle worth trying?