Nano-based lubricants for wind turbines and renewable equipment use nanoparticles to boost performance by reducing friction, wear, and heat buildup. They form durable, protective films on metal surfaces, extending equipment life and enhancing efficiency. These advanced lubricants also lower maintenance needs and are eco-friendly, aligning with sustainable practices. If you want to discover how these innovations can improve reliability and environmental impact, there’s much more to explore ahead.

Key Takeaways

- Nano-based lubricants form durable, uniform films that reduce friction and wear in wind turbine components, enhancing performance and longevity.

- Incorporating nanoparticles improves thermal stability and oxidation resistance, allowing operation under harsh environmental and operational conditions.

- These lubricants extend service intervals and decrease maintenance costs by promoting longer-lasting, stable lubricant films.

- Advanced surface modifications and dispersants ensure nanoparticles remain stable and well-dispersed within lubricants, optimizing efficiency.

- Eco-friendly nano lubricants support sustainable wind energy operations by reducing resource use, lowering environmental impact, and improving equipment reliability.

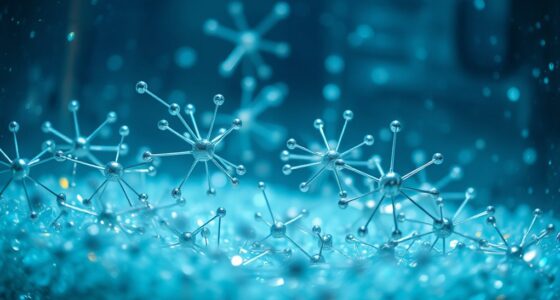

Understanding Nano-Based Lubricants and Their Composition

Nano-based lubricants are advanced fluids that incorporate nanoparticles to improve performance. These lubricants are carefully designed through nanoparticle synthesis, which controls particle size, shape, and surface properties to guarantee compatibility and stability within the lubricant formulation. The process involves selecting appropriate materials and techniques to produce nanoparticles that enhance lubrication without compromising fluid flow. When integrated into the lubricant, these particles create a more uniform and resilient film, reducing friction and wear. The formulation process balances particle concentration, dispersants, and base oils to attain ideal performance. By understanding the fundamentals of nanoparticle synthesis and precise lubricant formulation, you can develop nano-based lubricants tailored to meet the demanding conditions of renewable energy equipment like wind turbines. Proper formulation ensures optimal dispersion and performance of the nanoparticles within the lubricant matrix.

The Role of Nanoparticles in Enhancing Lubrication Efficiency

Nanoparticles play a crucial role in boosting lubrication efficiency by forming a more durable and uniform film between moving surfaces. Their effectiveness depends on nanoparticle stability, which prevents aggregation and maintains consistent performance over time. Surface modification is essential, as it enhances compatibility with base lubricants and improves dispersion, ensuring the nanoparticles evenly distribute and adhere to surfaces. When properly stabilized and surface-modified, nanoparticles can reduce friction and wear more effectively, leading to smoother operation of wind turbine components. Additionally, Kia Tuning techniques can optimize the performance of components that benefit from improved lubrication. This synergy of stability and surface engineering maximizes the lubrication film’s integrity, allowing for better load distribution and minimized contact between surfaces. Ultimately, these factors contribute to more reliable, efficient, and longer-lasting wind turbine operations.

Benefits of Nano Lubricants for Wind Turbine Components

Utilizing nano lubricants in wind turbines offers significant advantages by reducing friction and wear on critical components. Nanoparticle coatings enhance surface durability, decreasing downtime and maintenance costs. As lubricant additives, they improve lubricity and thermal stability, ensuring consistent performance. The benefits include:

Nano lubricants reduce friction, wear, and maintenance costs, boosting wind turbine efficiency and longevity.

- Extended lifespan of turbine components due to reduced mechanical wear

- Enhanced efficiency through lower energy losses caused by friction

- Better protection against corrosion and environmental contaminants

- Improved reliability with stable lubrication under varying operational conditions

Additionally, nanoparticle coatings provide a protective barrier that can withstand harsh environmental factors, further contributing to the longevity of turbine parts. These benefits make nano lubricants a valuable solution for wind turbine maintenance and performance. By incorporating nanoparticle coatings and advanced lubricant additives, you can optimize turbine operation, reduce costs, and increase energy output over the long term.

Challenges and Considerations in Implementing Nano Lubricants

Implementing nano lubricants in wind turbines presents several challenges that need careful consideration. One major concern is the cost implications, as nano additives can increase the initial expenses of lubricant formulation and application. Although they offer long-term benefits, upfront investments may deter some operators. Additionally, regulatory hurdles pose significant barriers, since nano materials are subject to evolving safety and environmental standards. You must navigate complex approval processes, which can delay deployment and increase compliance costs. Ensuring the safe handling, disposal, and environmental impact of nano lubricants is vital. Without clear regulations, adopting these advanced lubricants becomes more complicated. Moreover, the personality traits of stakeholders, such as risk aversion or openness to innovation, can influence the adoption process. Balancing the potential performance advantages with these economic and regulatory challenges is essential for successful implementation.

Comparing Nano Lubricants to Traditional Lubrication Solutions

Compared to traditional lubrication solutions, nano lubricants offer notable improvements in performance and efficiency. They reduce friction more effectively, extend equipment lifespan, and improve energy savings. When considering market adoption, nano lubricants are gaining traction due to these benefits. Conducting a thorough cost analysis shows that, although initial expenses are higher, long-term savings from decreased maintenance and increased efficiency outweigh costs. Key advantages include:

Nano lubricants improve efficiency, extend equipment life, and reduce maintenance costs compared to traditional solutions.

- Enhanced wear protection

- Superior thermal stability

- Reduced friction coefficients

- Longer service intervals

Enhanced natural language processing can improve the development of smarter lubrication systems by enabling better data analysis and predictive maintenance. These factors make nano lubricants appealing for renewable equipment like wind turbines. As the market evolves, their adoption is expected to grow, driven by improved performance metrics and favorable cost-benefit ratios over traditional lubricants.

Case Studies: Successful Applications in Renewable Equipment

You’ll see how nano-based lubricants boost equipment efficiency and reduce maintenance costs in renewable energy systems. These applications demonstrate significant improvements in operational performance and lubricant longevity. Such case studies highlight the tangible benefits of adopting nano technology in renewable equipment. Additionally, incorporating advanced lubrication techniques can further enhance the durability and efficiency of wind turbines and other renewable components.

Enhanced Equipment Efficiency

Recent case studies demonstrate how nano-based lubricants substantially boost the efficiency of renewable energy equipment. By optimizing nanoparticle synthesis, these lubricants reduce friction and wear, enabling turbines and gearboxes to operate more smoothly. One key factor is maintaining ideal lubricant viscosity, which ensures proper flow and minimizes energy losses. Nano-additives improve heat dissipation, preventing overheating and enhancing performance. Additionally, these lubricants decrease maintenance downtime by protecting critical components.

- Lower friction levels lead to less energy consumption.

- Improved heat management extends equipment lifespan.

- Consistent viscosity guarantees stable operation.

- Reduced wear minimizes operational disruptions.

Extended Lubricant Lifespan

As renewable energy equipment operates under demanding conditions, extending lubricant lifespan becomes essential for maintaining ideal performance. Nano‑particles within nano‑based lubricants help achieve this by reducing lubricant degradation caused by heat, pressure, and contaminants. These tiny particles create a protective film on metal surfaces, minimizing wear and slowing down lubricants’ breakdown over time. Successful case studies in wind turbines and renewable machinery show that nano‑lubricants markedly prolong service intervals and reduce maintenance costs. By enhancing thermal stability and preventing oxidation, nano‑particles help maintain optimal lubrication even under harsh conditions. As a result, your equipment benefits from longer-lasting lubricants, improved reliability, and reduced downtime, making nano‑based solutions a smart choice for sustainable, cost-effective operation.

Future Trends and Innovations in Nano Lubrication Technology

The future of nano-based lubricants promises significant advancements driven by ongoing research and technological innovation. You can expect improvements in nanoparticle synthesis and lubricant formulation, making lubricants more efficient and durable. Innovations will focus on enhancing nanoparticle stability, reducing wear, and increasing thermal conductivity. Here are some key trends to watch:

- Advanced nanoparticle synthesis techniques for better control over size and shape.

- Smart lubricants that respond to temperature and pressure changes.

- Eco-friendly formulations that minimize environmental impact.

- Integration of nanomaterials with sensors for real-time condition monitoring.

– Additionally, ongoing research into wear reduction methods aims to extend the lifespan of wind turbine components and renewable equipment, ensuring more reliable operation and decreased maintenance costs.

These innovations will lead to lubricants that are more effective, longer-lasting, and better suited for demanding applications like wind turbines and renewable equipment.

Environmental Impact and Sustainability of Nano-Based Lubricants

Nano-based lubricants can considerably lower your carbon footprint by reducing energy consumption. They are often designed to be biodegradable and safe for the environment, minimizing pollution risks. Additionally, their resource-efficient production helps conserve materials and promote sustainable practices. Using high-quality essential oils in manufacturing processes can further enhance environmental benefits essential oils 101.

Reduced Carbon Footprint

Nano-based lubricants markedly reduce the carbon footprint of machinery by improving fuel efficiency and decreasing energy consumption. This is achieved through advanced nano synthesis techniques that enhance lubricant performance, leading to less friction and wear. By extending lubricant maintenance intervals, you minimize resource use and waste. Additionally, these lubricants enable machinery to operate more smoothly, conserving energy and lowering emissions. Key benefits include:

- Enhanced efficiency reduces fuel consumption.

- Longer-lasting lubricants cut down on replacement frequency.

- Improved heat dissipation decreases energy loss.

- Reduced need for frequent lubricant replenishment minimizes environmental impact.

Together, these factors contribute to a smaller carbon footprint, supporting sustainability goals and promoting environmentally friendly operation of wind turbines and renewable equipment.

Biodegradability and Safety

Although nano-based lubricants offer significant environmental benefits, their biodegradability and safety profiles are fundamental for guaranteeing sustainable use. Conducting thorough biodegradability assessments helps determine how these lubricants break down in the environment, minimizing long-term pollution risks. Safety regulations set standards to prevent potential toxic effects on ecosystems and human health, guiding manufacturers in developing eco-friendly formulations. By adhering to these regulations, you ensure that nano-based lubricants do not compromise environmental integrity. Continuous testing and compliance are essential to demonstrate that these lubricants are safe throughout their lifecycle. Prioritizing biodegradability and safety not only aligns with sustainability goals but also fosters trust among users and regulators, supporting the broader adoption of environmentally responsible renewable energy technologies.

Resource Efficiency Gains

By leveraging nanotechnology, these lubricants considerably improve resource efficiency, reducing the amount of material needed for effective lubrication. Nanoparticle synthesis enables the creation of highly effective additives that enhance lubricant viscosity with minimal quantities. This means you use less lubricant overall, decreasing resource consumption. The benefits include:

- Reduced raw material use, lowering environmental impact

- Improved lubricant longevity, decreasing frequent replacements

- Enhanced thermal stability, minimizing waste

- Lower energy consumption due to decreased friction and wear

These efficiencies contribute to sustainability by lessening material extraction and waste. Better control of lubricant viscosity through nanoparticle synthesis ensures ideal performance while conserving resources. As a result, nano-based lubricants support greener, more sustainable maintenance practices in wind turbines and renewable equipment.

Frequently Asked Questions

How Do Nano Lubricants Perform Under Extreme Wind Turbine Operating Conditions?

You’ll find nano lubricants excel under extreme wind turbine conditions by providing superior performance stability and wear resistance. They adapt to high temperatures and mechanical stresses, reducing friction and preventing component degradation. This means your turbines operate smoothly and reliably even in harsh environments. The nanomaterials ensure consistent lubrication, extending equipment life and minimizing maintenance needs, so you can trust your turbines to perform efficiently, no matter the challenging conditions.

What Are the Safety Considerations for Handling Nano-Based Lubricants?

When handling nano-based lubricants, you should prioritize safety by wearing protective clothing, gloves, and masks to reduce health hazards like skin and respiratory irritation. Be mindful of environmental impacts, ensuring proper disposal to prevent contamination. Always follow manufacturer guidelines and safety data sheets, and work in well-ventilated areas to minimize exposure. Regular training helps you stay informed about potential risks and safe handling practices.

Are Nano Lubricants Cost-Effective Compared to Traditional Options Long-Term?

Nano lubricants can be cost-effective long-term by reducing maintenance costs through enhanced performance and durability. When you conduct a thorough cost analysis, you’ll find that initial investments may be higher, but savings from less frequent replacements and repairs outweigh those costs. Over time, this improved efficiency can lead to significant savings, making nano lubricants a smart choice for your equipment’s longevity and operational stability.

How Do Nano Particles Affect the Recyclability of Lubricants?

You might think nano particles make recycling easier, but they actually pose recyclability challenges. Their tiny size makes nano particle separation difficult, complicating lubricant recovery. Instead of simplifying recycling, these particles can contaminate the process, leading to inefficiencies and waste. It’s ironic—what’s meant to enhance performance ends up complicating the recycling process, forcing you to face unexpected hurdles in waste management and environmental sustainability.

What Regulatory Standards Govern Nano Lubricant Use in Renewable Equipment?

You need to guarantee that nano lubricant use in renewable equipment complies with regulatory standards like REACH in Europe and EPA guidelines in the US. These regulations focus on regulatory compliance and evaluating environmental impact. It’s vital to stay updated on safety data sheets, labeling requirements, and disposal protocols to prevent environmental harm and meet legal obligations. Doing so helps protect ecosystems and guarantees safe, effective operation of renewable systems.

Conclusion

As you embrace nano-based lubricants, think of them as the tiny seeds of innovation, planting resilience and efficiency within your wind turbines. These nanomaterials symbolize a future where sustainability and performance grow hand in hand, transforming renewable energy into a more sustainable journey. By harnessing their power, you’re nurturing a cleaner, greener world—where every small step, like a nanoparticle, can create ripples of lasting impact for generations to come.