Nanotechnology is helping make mining more sustainable by offering greener extraction and processing techniques that lower environmental impact. You can benefit from advanced methods like bioleaching and nanomaterials that improve mineral selectivity, reduce chemical use, and increase efficiency. These innovations help protect ecosystems, cut pollution, and conserve resources. By embracing nanotech, the mining industry moves toward a future of responsible, eco-friendly resource management—discover how these technologies can reshape mining’s environmental footprint.

Key Takeaways

- Nanotechnology enables eco-friendly mineral extraction methods like bioleaching, reducing chemical use and environmental impact.

- Nano-enhanced processing achieves higher purity and recovery rates with minimal hazardous chemicals.

- Nanomaterials improve selectivity in mineral separation, decreasing waste and pollution.

- Integrating nanotech promotes sustainable resource management by lowering emissions and conserving natural resources.

- Future nanotechnology applications support responsible mining practices, benefiting ecosystems and local communities.

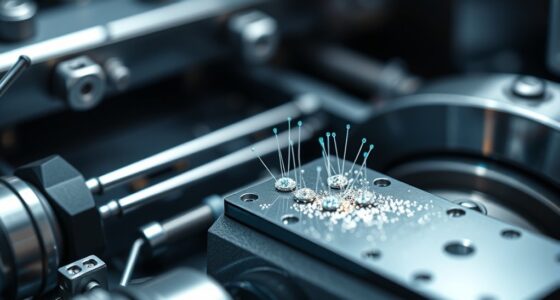

Have you ever wondered how mining can become more sustainable? The answer lies in innovative techniques that minimize environmental impact while maximizing efficiency. One promising approach is eco friendly extraction, which aims to reduce the ecological footprint of traditional mining methods. Instead of relying on harmful chemicals and energy-intensive processes, eco friendly extraction uses greener alternatives, such as bioleaching or solvent-less methods, to recover valuable minerals. These techniques not only decrease pollution but also conserve water and energy, making the entire process more sustainable. When combined with nanotechnology, eco friendly extraction becomes even more effective. Tiny nanomaterials can improve the selectivity of mineral separation, allowing you to target specific elements with greater precision and less waste. This means fewer chemicals are needed, reducing the risk of environmental contamination. Moreover, nanomaterials can enhance the efficiency of extraction processes, speeding up recovery times and lowering operational costs.

Another exciting development is nano enhanced processing, which transforms how minerals are refined after they’re extracted. By incorporating nanotechnology into processing methods, you can achieve higher purity levels with fewer steps and less energy consumption. For example, nanoparticles can act as catalysts or adsorbents, improving the separation of valuable metals from ore. This not only boosts recovery rates but also cuts down on the use of hazardous chemicals often associated with traditional refining techniques. Nano enhanced processing also enables better control over particle size and distribution, which improves the overall quality of the final product. This precision reduces waste and minimizes the environmental footprint of mineral processing plants. Additionally, the use of innovative materials like nanomaterials in mining supports the transition toward more sustainable resource management practices.

Using nanotechnology in these ways aligns with the broader goal of sustainable mining: balancing economic benefits with environmental stewardship. It allows you to extract and process minerals more responsibly, reducing the depletion of natural resources and lowering emissions. As technology advances, the scalability of nano-enabled solutions will only improve, making sustainable mining more accessible and practical across the industry. By embracing eco friendly extraction methods and nano enhanced processing, you’re helping to forge a path toward a more environmentally conscious mining industry. This shift not only benefits ecosystems and local communities but also ensures the longevity of mining operations in an increasingly resource-conscious world. In essence, nanotechnology offers the tools needed to transform mining into a more sustainable and responsible enterprise.

Frequently Asked Questions

How Does Nanotechnology Reduce Environmental Impacts of Mining?

Nanotech environmental solutions help reduce the environmental impacts of mining by making processes more efficient and less wasteful. You can use nanotechnology to develop sustainable resource extraction methods that lower energy consumption and minimize harmful emissions. These innovations enable you to detect, extract, and process minerals more precisely, reducing environmental disturbance. Overall, nanotech environmental advances support cleaner, more sustainable mining practices that protect ecosystems and conserve resources for future generations.

What Are the Potential Health Risks of Nanomaterials in Mining?

You should be aware that nanomaterials in mining pose health risks like toxic exposure, which can affect worker safety. Tiny particles may penetrate skin or lungs, leading to respiratory issues or other health problems. Proper safety measures, such as protective gear and ventilation, are essential to safeguard against these risks. Monitoring exposure levels and conducting safety training help ensure you stay protected from potential health hazards associated with nanomaterials.

Can Nanotechnology Improve Ore Extraction Efficiency Significantly?

Imagine harnessing the tiny power of nanotech applications to revolutionize ore processing. Yes, nanotechnology can markedly boost ore extraction efficiency by enabling more precise targeting of mineral particles, reducing waste, and accelerating recovery rates. With innovations like nanostructured materials and sensors, you’ll find that the scale of improvement is remarkable, transforming the way you extract resources and making mining more sustainable and cost-effective than ever before.

What Are the Economic Costs of Implementing Nanotech in Mining?

Implementing nanotech in mining involves significant upfront costs, including research, development, and specialized equipment. You should conduct a thorough cost analysis to understand these expenses and weigh them against potential benefits. While initial investments are high, nanotechnology can positively impact the market by increasing efficiency and reducing environmental costs. Over time, these improvements may lead to cost savings and a competitive edge, making the investment worthwhile.

How Is Nanotechnology Regulated in the Mining Industry?

You should know that nanotechnology in mining is regulated through industry standards and regulatory frameworks designed to guarantee safety and environmental protection. Authorities monitor the development and application of nanotech, requiring companies to follow strict guidelines for risk assessment, safety protocols, and environmental impact. These regulations evolve as technology advances, aiming to balance innovation with responsible practices, so you can operate confidently within a well-defined legal landscape.

Conclusion

By embracing innovative insights and integrating intelligent nanotechnology, you can dramatically diminish environmental damage while maximizing mineral extraction. Sustainable mining becomes simple when you leverage less waste, lower emissions, and lessen land loss. With a mindful mindset and modern methods, you can champion clean, conscientious mining practices. Let’s lead the way, transforming traditional techniques into trailblazing, eco-friendly solutions that guarantee Earth’s resources endure for generations to come.