Nanocoatings are advanced protective layers made from nanomaterials like nanoparticles and nanocomposites, designed to prevent corrosion and reduce wear. They form dense, uniform barriers that block water, salts, and acids, effectively shielding surfaces. These coatings also minimize friction and absorb impacts, extending the lifespan of materials. With innovations like self-healing and smart features, nanocoatings offer long-lasting protection. Continue exploring to discover how these cutting-edge solutions can enhance your surfaces’ durability.

Key Takeaways

- Nanocoatings form dense, uniform barrier layers that prevent water, oxygen, salts, and acids from penetrating surfaces, resisting corrosion.

- They enhance surface hardness and reduce friction, providing effective wear and abrasion resistance.

- Incorporation of self-healing microcapsules allows nanocoatings to repair cracks automatically, extending lifespan.

- Proper application techniques, surface preparation, and environmental control are crucial for optimal protective performance.

- Emerging innovations include eco-friendly, multifunctional nanocoatings with smart sensors for real-time corrosion and wear monitoring.

Understanding the Composition and Types of Nanocoatings

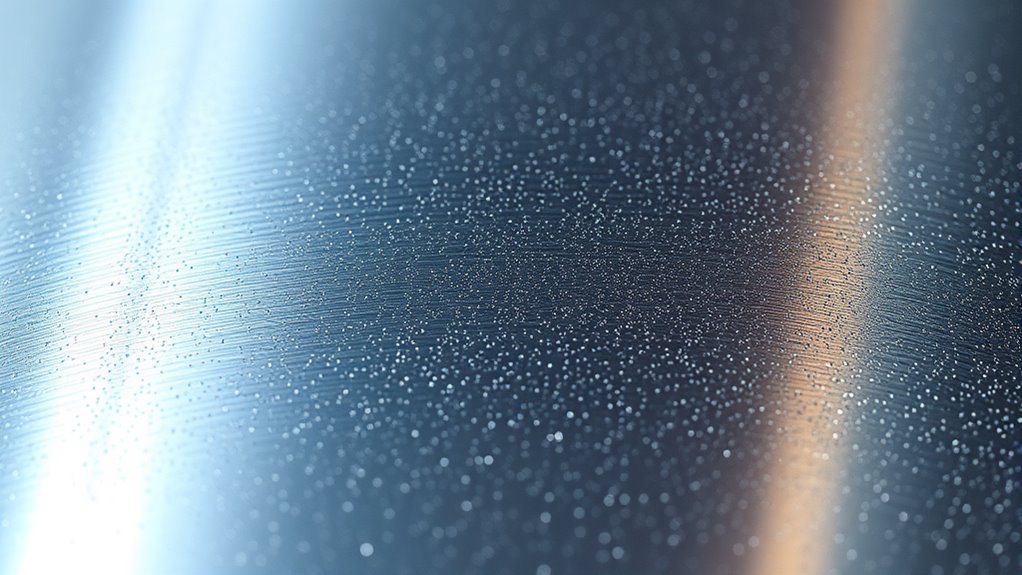

Nanocoatings are thin, functional layers applied to surfaces to enhance their properties, and understanding their composition is key to appreciating their capabilities. These coatings typically consist of nanomaterials such as nanoparticles, nanocomposites, or nanotubes, which provide unique features due to their extremely small size. You’ll find that nanocoatings can be made from various materials, including metals, ceramics, polymers, or hybrid compounds. Each type offers specific benefits like increased hardness, chemical resistance, or hydrophobicity. The manufacturing processes often involve techniques like spray coating, dip coating, or chemical vapor deposition, allowing precise control over thickness and uniformity. Additionally, knowledge of expiration of vape juice and related storage considerations can inform the development of nanocoatings that enhance chemical resistance and longevity. By understanding the composition and types, you can better select the right nanocoating to meet your specific needs and improve surface performance.

How Nanocoatings Provide Superior Corrosion Resistance

Nanocoatings create a strong barrier that blocks corrosive elements from reaching the underlying surface. They also improve surface stability, reducing the chances of damage over time. Plus, their self-healing capabilities help repair minor scratches, maintaining protection longer. Additionally, nanocoatings are inspired by biological systems, which enhances their ability to adapt and self-repair under various conditions.

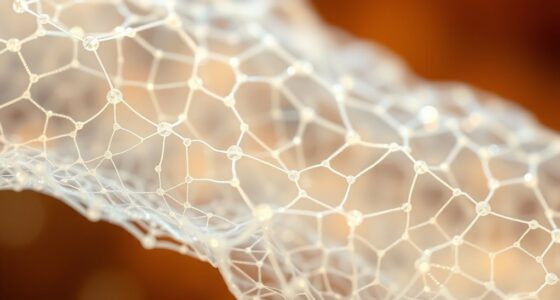

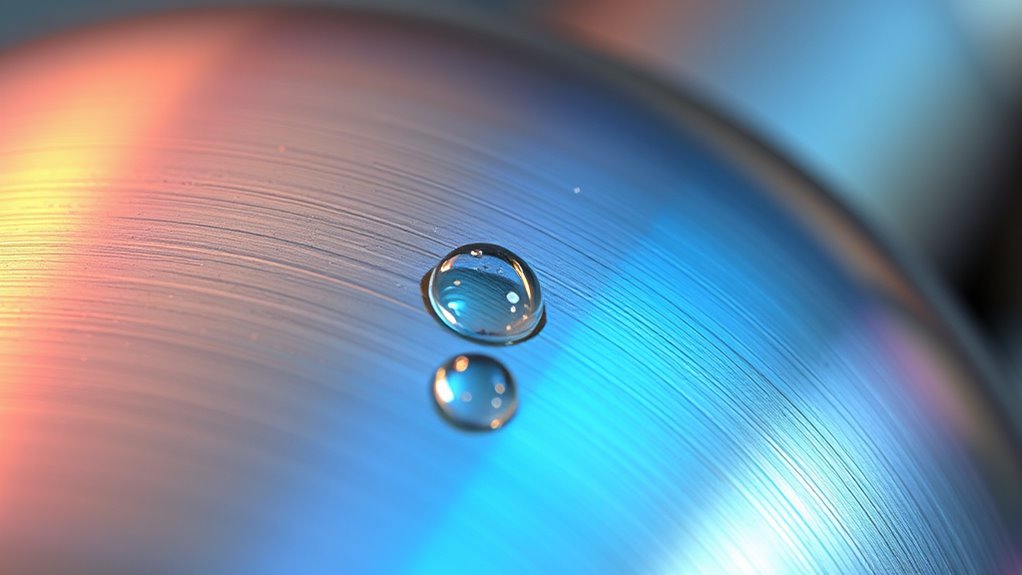

Barrier Against Corrosive Elements

Because of their incredibly small size, nanocoatings create a dense, uniform barrier that effectively blocks corrosive elements like water, oxygen, and salts from reaching the underlying material. This thin yet robust layer prevents these elements from penetrating, reducing the risk of rust and degradation. The nanostructure’s compactness ensures minimal porosity, making it difficult for corrosive agents to find pathways. To illustrate, consider this table:

| Element | How Nanocoatings Block It | Effectiveness | Result |

|---|---|---|---|

| Water | Forms a waterproof barrier | Highly effective | No moisture contact |

| Oxygen | Tight molecular packaging | Very effective | No oxidation |

| Salts | Dense coating prevents infiltration | Effective | Reduced corrosion risk |

| Acidic compounds | Neutralized or blocked | Good protection | Corrosion minimized |

| Dirt & debris | Repelled by surface properties | Maintains barrier integrity | Less corrosion chance |

Additionally, nanocoatings can be engineered to enhance durability and withstand harsh environmental conditions, ensuring long-lasting protection.

Enhanced Surface Stability

Enhanced surface stability is a key factor in how nanocoatings deliver superior corrosion resistance. When applied, nanocoatings create a uniform, tightly bonded layer that minimizes surface imperfections and reduces vulnerabilities. Their nanometer-scale structures fill microscopic cracks and pores, preventing corrosive agents from penetrating. This stable, cohesive layer resists degradation over time, even under harsh environments. The durability of nanocoatings ensures they withstand physical wear and chemical exposure better than traditional coatings. By maintaining a consistent protective barrier, they help prevent the initiation of corrosion processes. Your surfaces benefit from prolonged protection, reduced maintenance, and enhanced lifespan. This increased stability underpins the nanocoating’s ability to serve as a reliable shield against corrosion, ensuring your materials stay intact and functional longer. Additionally, the long-term effectiveness of nanocoatings is supported by ongoing research and advancements in nanotechnology, which continually improve their protective properties.

Self-Healing Capabilities

Have you ever wondered how some coatings can repair themselves after minor damage? Nanocoatings with self-healing capabilities make this possible. Embedded microcapsules or nanocapsules contain repairing agents that activate when a crack or scratch occurs. As damage develops, these capsules break open, releasing their contents to fill and seal the defect. This process restores the coating’s integrity, preventing corrosion from reaching the underlying material. Additionally, some nanocoatings utilize responsive materials that react to environmental triggers, like moisture or pH changes, to initiate healing. This proactive approach not only extends the lifespan of the coating but also reduces maintenance costs. Knowledge of self-healing nanocoatings enables the development of advanced protective layers that can autonomously respond to damage, further enhancing durability. With self-healing nanocoatings, your surfaces gain a remarkable ability to recover from minor damages, ensuring superior corrosion resistance over time.

The Role of Nanocoatings in Wear and Abrasion Protection

Nanocoatings play a crucial role in protecting surfaces from wear and abrasion by forming a durable, thin barrier at the microscopic level. This coating reduces friction and minimizes surface damage caused by repeated contact or scraping. Its hard, resilient layer absorbs impacts and prevents material removal, extending the lifespan of equipment and components. Because nanocoatings are extremely thin, they do not alter the shape or dimensions of the surface, guaranteeing precise performance. Their self-limiting thickness ensures they remain effective over time without peeling or cracking. Additionally, nanocoatings can be engineered to be hydrophobic or oleophobic, reducing dirt buildup and corrosion that could accelerate wear. Furthermore, the development of nanocoatings is increasingly focused on enhancing wear resistance and durability in demanding environments. Overall, they provide a robust shield that maintains surface integrity and performance in harsh, abrasive environments.

Benefits of Nanocoatings in Various Industries

The protective qualities of nanocoatings extend well beyond wear resistance, offering a range of benefits across various industries. In the automotive sector, they improve durability and reduce maintenance costs by preventing corrosion and damage. In electronics, nanocoatings provide water and dirt resistance, enhancing device longevity. The medical field benefits from biocompatible nanocoatings that prevent bacterial growth and improve implant performance. In aerospace, they protect aircraft surfaces from harsh environmental elements, reducing weight and fuel consumption. The packaging industry uses nanocoatings to create barrier layers that extend shelf life and prevent contamination. Additionally, innovative textile applications leverage nanocoatings to enhance fabric durability and resistance to environmental factors. Overall, nanocoatings enable industries to increase product lifespan, improve safety, and reduce environmental impact, making them a versatile solution for a wide array of applications.

Challenges and Considerations in Applying Nanocoatings

Applying nanocoatings can be tricky because of the precise methods required, which may need specialized equipment or techniques. You also have to contemplate how well the coating will hold up over time and in different environments. Addressing these challenges is vital to guarantee the coatings deliver their intended benefits long-term. Additionally, understanding the vulnerabilities in AI models can help inform safer and more reliable coating application processes.

Application Method Challenges

While nanocoatings offer remarkable benefits, their application presents several challenges that can hinder effective deployment. Achieving uniform coverage at the nanoscale requires precise control over application techniques. Factors like surface preparation, coating thickness, and environmental conditions substantially impact results. Additionally, equipment calibration and operator expertise are vital for consistent quality. You must also consider the potential for agglomeration of nanoparticles, which can compromise coating integrity. The table below highlights common application challenges and their implications:

| Challenge | Impact | Consideration |

|---|---|---|

| Surface contamination | Poor adhesion | Proper cleaning protocols |

| Agglomeration of particles | Irregular coating, defects | Use dispersants or surfactants |

| Inconsistent application | Non-uniform coverage | Advanced spray/roll techniques |

| Surface roughness | Difficulties in achieving uniform coating | Surface smoothing prior to application |

Durability and Long-term Performance

Ensuring nanocoatings maintain their protective and functional properties over time requires careful attention to durability and long-term performance. You need to consider environmental factors like temperature fluctuations, humidity, and chemical exposure, which can degrade the coating. Mechanical stresses such as scratching, abrasion, or impact also threaten longevity. To improve performance, selecting appropriate materials and optimizing application processes are crucial. Regular inspection and maintenance help identify early signs of wear or failure. It’s essential to understand the limitations of nanocoatings under specific conditions and tailor them accordingly. Developing formulations with enhanced bonding and resistance properties can extend service life. Ultimately, balancing initial effectiveness with sustainable durability ensures nanocoatings provide reliable protection throughout their lifespan. Additionally, fostering a creative practice mindset can lead to innovative solutions for enhancing nanocoating formulations and application techniques.

Future Developments and Emerging Trends in Nanocoating Technology

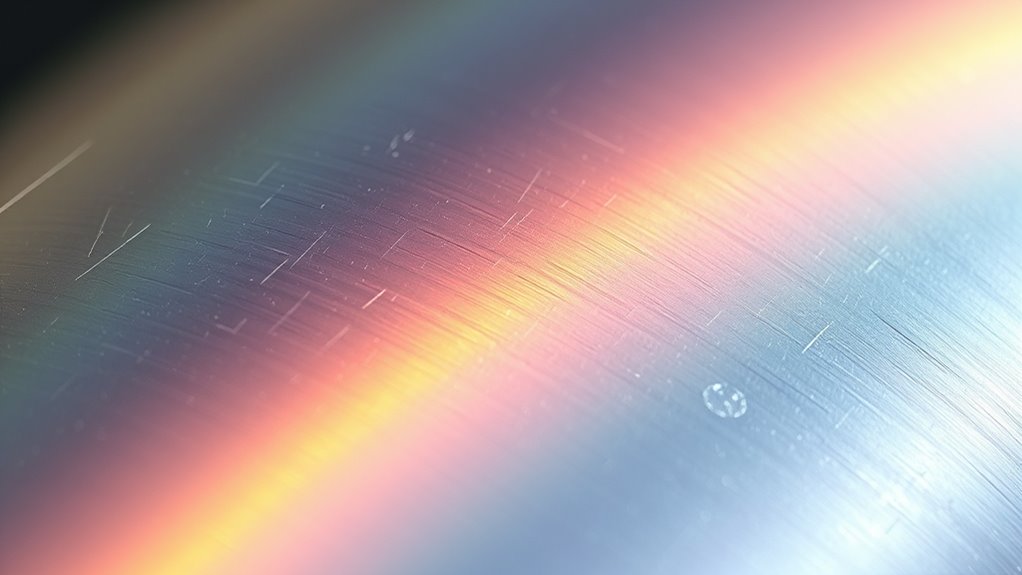

Advancements in nanocoating technology are expected to drive significant innovations across industries, as researchers explore new materials and methods to enhance performance. Emerging trends focus on multifunctionality, sustainability, and smart capabilities. Expect nanocoatings that respond to environmental changes, self-heal, or actively resist microbes. Researchers are also developing eco-friendly formulations with reduced environmental impact. Additionally, integration with IoT devices could enable real-time monitoring of coating integrity. These innovations are likely to revolutionize sectors like aerospace, healthcare, and electronics. To illustrate, consider the following potential future applications:

| Trend | Impact |

|---|---|

| Self-healing coatings | Extend lifespan by repairing damage autonomously |

| Eco-friendly nanomaterials | Reduce environmental footprint |

| Smart sensors | Enable real-time performance monitoring |

| Multifunctional layers | Combine corrosion, wear, and antimicrobial properties |

Frequently Asked Questions

Are Nanocoatings Environmentally Friendly and Eco-Safe?

Nanocoatings can be environmentally friendly and eco-safe, especially when they’re designed with sustainable materials and processes. You should look for coatings that use non-toxic, biodegradable substances and avoid harmful chemicals. When properly formulated, nanocoatings reduce the need for frequent replacements and chemical cleaners, minimizing waste and pollution. By choosing eco-certified options, you guarantee that your protective layers support environmental health without compromising performance.

What Are the Cost Implications of Nanocoating Applications?

Applying nanocoatings is like planting a seed for long-term savings; it can be costly upfront but reduces maintenance expenses over time. You might spend more initially on materials and specialized equipment, but the durability and protection they offer can lower repair and replacement costs later. Overall, while the initial investment is higher, the long-term savings and performance benefits often make nanocoatings a cost-effective choice.

How Long Do Nanocoatings Typically Last Under Harsh Conditions?

Nanocoatings usually last between 2 to 10 years under harsh conditions, depending on the coating type, application method, and environmental exposure. If you’re dealing with extreme temperatures, chemicals, or abrasion, expect a shorter lifespan. Proper maintenance and surface preparation can extend their durability. Regular inspections help identify wear early, so you can reapply or repair coatings before damage compromises protection.

Can Nanocoatings Be Repaired or Restored After Damage?

Yes, nanocoatings can often be repaired or restored after damage. You typically need to clean the affected area thoroughly to remove debris or contaminants. Then, you can apply a fresh layer of the nanocoating, either through reapplication or touch-up techniques, depending on the extent of the damage. Some nanocoatings are designed for easy reapplication, making maintenance straightforward and prolonging their protective benefits.

Are There Health Risks Associated With Nanocoating Application?

You might think it’s a walk in the park, but applying nanocoatings can pose health risks if proper precautions aren’t taken. Fine nanoparticles can become airborne and be inhaled, potentially causing respiratory issues or skin irritation. It’s essential to use protective gear, guarantee good ventilation, and follow safety guidelines. While nanocoatings offer great benefits, cutting corners during application can put your health at risk.

Conclusion

Nanocoatings act like invisible shields, silently guarding your surfaces against corrosion and wear. By embracing these advanced layers, you harness a fortress that withstands the test of time and environment. As technology evolves, these protective veils will become even smarter and more resilient, transforming industries and daily life. With nanocoatings, you’re not just protecting materials—you’re weaving a future where durability is as endless as the stars.