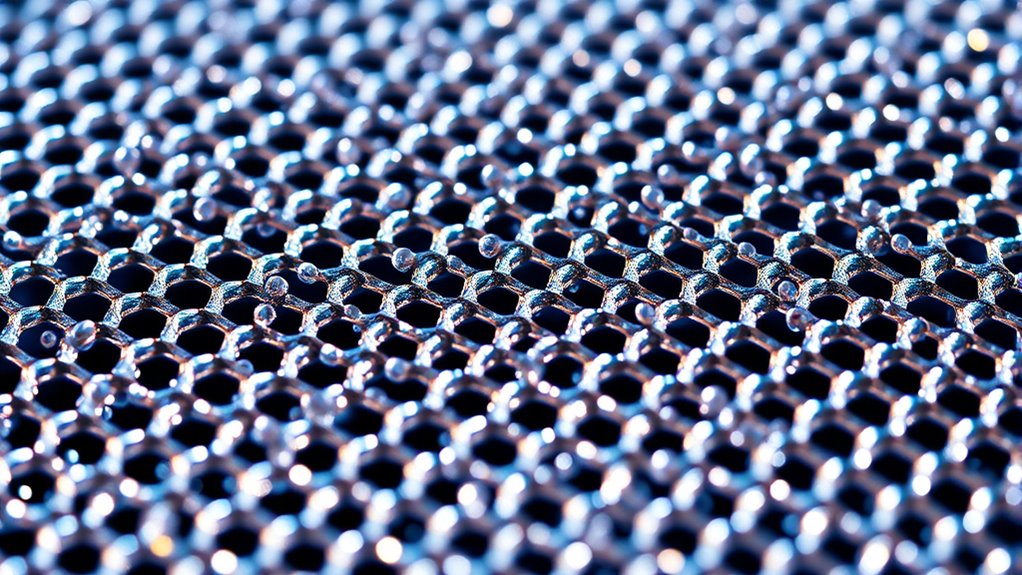

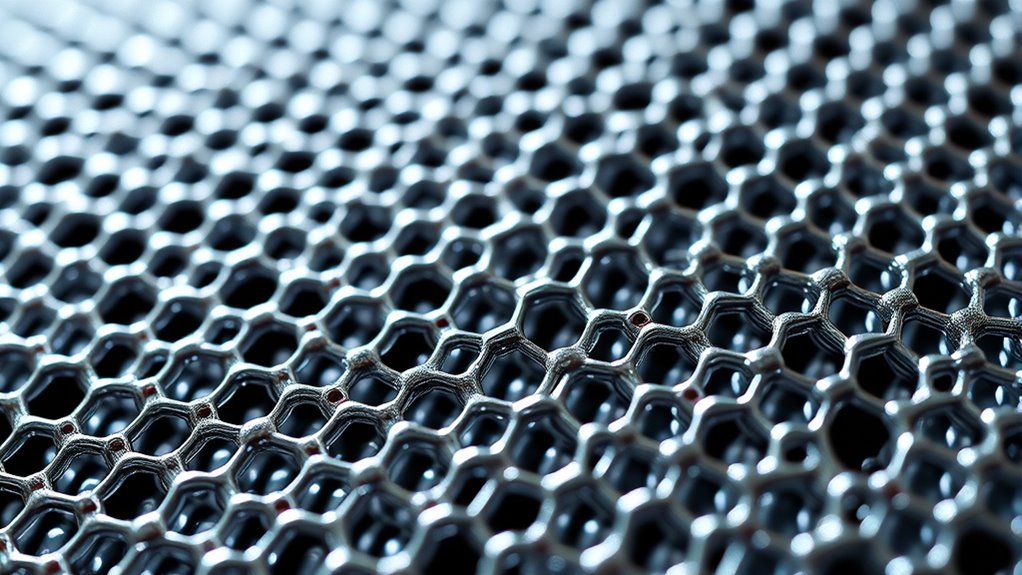

Nanoporous materials are key in boosting catalysis and gas storage capabilities. Their high surface area and customizable pore sizes allow you to enhance reaction efficiency, selectivity, and molecular sieving. These structures also enable safer, more efficient gas storage and even improve sensing and drug delivery. By tailoring their composition, you can optimize performance for specific applications. To see how these innovations can benefit you, discover more about their latest developments and possibilities.

Key Takeaways

- Nanoporous materials enhance catalysis by providing increased surface area and facilitating active site interactions.

- Pore size tuning in nanoporous structures improves selectivity and diffusion for specific reactants.

- These materials enable high-capacity gas storage, improving safety and efficiency for hydrogen and methane applications.

- Different nanoporous compositions like zeolites and MOFs offer tailored properties for specific catalytic and storage needs.

- Challenges such as scalable synthesis and environmental impact must be addressed for sustainable industrial applications.

Enhancing Catalytic Efficiency With Nanoporous Structures

Nanoporous structures markedly boost catalytic efficiency by providing an extensive surface area for reactions. You can enhance this further through surface functionalization, which introduces specific active sites to improve selectivity and activity. Proper surface modifications guarantee that reactants interact efficiently with the catalyst, increasing overall performance. Mechanical stability is also critical; it keeps the nanoporous material intact under reaction conditions, preventing collapse or degradation that could reduce surface area. By focusing on both surface functionalization and mechanical stability, you ensure that your nanoporous catalyst maintains high activity over time. This combination leads to more effective catalytic processes, with better durability and improved reaction rates. Ultimately, optimizing these factors allows you to harness the full potential of nanoporous materials in various catalytic applications. Additionally, attention to environmental factors can help sustain catalytic performance and extend catalyst lifespan.

Tailoring Pore Sizes for Specific Chemical Reactions

Optimizing catalytic performance involves more than just surface modifications; controlling pore sizes plays an indispensable role in ensuring that reactants access active sites efficiently. By fine-tuning pore size optimization, you can enhance reaction rates and selectivity. This process allows you to achieve selective molecular sieving, where only molecules of certain sizes enter the pores.

- Improves catalyst specificity

- Facilitates targeted reactions

- Minimizes unwanted byproducts

- Enhances reactant diffusion

- Boosts overall efficiency

Adjusting pore sizes helps match the dimensions of reactant molecules, ensuring ideal access and interaction. This precise control is essential for reactions involving complex mixtures, where selectivity and efficiency directly impact performance. Tailoring pore sizes, thus, becomes a critical step in designing effective nanoporous catalysts for specific chemical reactions.

Advancements in Gas Storage Technologies Using Nanoporous Materials

Recent advances in gas storage technologies have harnessed the unique properties of nanoporous materials to achieve higher storage capacities and improved safety. These materials enable efficient storage of gases like hydrogen and methane, essential for energy and environmental applications. They also enhance electrochemical sensors, providing better detection of leaks or contaminants. In drug delivery, nanoporous structures control release rates, illustrating their versatility. To visualize, consider this table:

| Nanoporous Material | Functionality | Storage Capacity | Safety Features |

|---|---|---|---|

| Metal-Organic Frameworks | Gas adsorption, sensors | High | Structural stability |

| Zeolites | Molecular sieving | Moderate | Heat resistance |

Such innovations transform gas storage, making it safer and more efficient, while also supporting advancements like sensor accuracy and drug delivery systems. Nanoporous materials play a crucial role in advancing these technologies by providing tailored pore sizes for specific gases and applications.

Comparative Benefits of Different Nanoporous Compositions

Different nanoporous compositions offer distinct advantages that make them suitable for various applications. By focusing on framework optimization and material synthesis, you can tailor pore size, surface chemistry, and stability to meet specific needs. For example, zeolites excel in selective catalysis, while metal-organic frameworks (MOFs) provide high surface area for gas storage. Key benefits include:

Tailoring nanoporous frameworks enhances performance in catalysis, gas storage, and targeted applications.

- Enhanced selectivity through tailored pore structures

- Improved stability for demanding environments

- Greater control over material synthesis processes

- Customizable frameworks for targeted applications

- Increased efficiency in gas adsorption and catalysis

Understanding how each material’s framework optimization impacts its advantages helps you optimize design and application strategies effectively. Additionally, discoloration and mold are signs of spoilage that can compromise the safety and performance of nanoporous materials used in various environments.

Future Perspectives and Challenges in Nanoporous Material Applications

Advancements in nanoporous materials have enabled numerous applications, but realizing their full potential depends on overcoming current limitations and addressing future challenges. Scalability challenges hinder mass production, making it difficult to meet industrial demands. Environmental impacts also raise concerns, as synthesis methods can generate waste or use hazardous chemicals. To picture these hurdles, imagine the following:

| Challenge | Impact | Solution Focus |

|---|---|---|

| Scalability challenges | Limited large-scale application | Developing cost-effective methods |

| Environmental impacts | Pollution and resource depletion | Greener synthesis techniques |

| Durability | Long-term performance issues | Enhancing stability |

| Selectivity | Limited control over properties | Precision engineering |

| Integration | Difficult incorporation into devices | Designing compatible systems |

Additionally, the synthesis methods used for creating nanoporous materials greatly influence their environmental footprint and performance. Addressing these issues will propel nanoporous materials toward sustainable, widespread use.

Frequently Asked Questions

How Do Nanoporous Materials Influence Environmental Sustainability?

Nanoporous materials positively influence environmental sustainability by reducing the environmental impact of industrial processes. They enable more efficient catalysis and gas storage, leading to less energy consumption and lower emissions. By improving pollutant removal and enabling cleaner fuel technologies, you can see sustainability benefits through decreased waste and resource use. These materials help you contribute to a greener future by supporting eco-friendly practices and reducing your overall environmental footprint.

What Are the Cost Implications of Using Nanoporous Catalysts?

You’ll find that using nanoporous catalysts can be more cost-effective long-term because their high efficiency reduces the amount needed for reactions. However, the initial manufacturing costs and complex production processes may be higher, impacting economic feasibility. While these catalysts save money through improved performance, you should weigh these upfront costs against their potential for energy savings and enhanced catalytic activity over time.

Are There Any Health or Safety Concerns With Nanoporous Materials?

While nanoporous materials offer great benefits, you should be aware of potential health hazards and toxicity concerns. Handling these materials carefully minimizes risks, as their tiny pores can sometimes lead to inhalation of fine particles or skin contact. Proper safety measures, such as protective gear and good ventilation, are essential. Staying informed and cautious helps prevent health issues, ensuring safe use while enjoying their advantages.

Can Nanoporous Materials Be Recycled or Reused Effectively?

Yes, you can recycle and reuse nanoporous materials effectively. You should explore recycling techniques like thermal treatment or chemical regeneration to restore their pore structure. Reuse strategies involve cleaning or reconditioning the materials to maintain their functionality. Properly applying these methods guarantees you extend the lifespan of nanoporous materials, making them more sustainable and cost-effective for ongoing applications in catalysis and gas storage.

How Do Manufacturing Methods Affect Nanoporous Material Properties?

Manufacturing methods directly influence your nanoporous material’s properties by determining synthesis techniques and controlling pore size. When you choose specific synthesis techniques, you can tailor pore size and surface area to suit your needs, affecting catalytic activity or gas storage capacity. For example, precise control over synthesis guarantees uniform pore sizes, enhancing performance. Consequently, selecting appropriate manufacturing methods is vital for optimizing your nanoporous materials‘ functionality and efficiency.

Conclusion

By harnessing nanoporous materials, you open the extraordinary potential to revolutionize catalysis and gas storage like never before. These structures dramatically amplify efficiency, tailor reactions with pinpoint precision, and redefine what’s possible in energy and environmental solutions. Embrace the future of nanotechnology, where the tiniest pores hold the power to transform industries and shape a sustainable world—an awe-inspiring leap toward innovations that will leave the universe in awe of your ingenuity.