To manufacture nanomachines, you mainly rely on lithography, self-assembly, and DNA origami. Lithography uses light or electrons to shape materials at the nanoscale, while self-assembly harnesses natural forces for molecule arrangement. DNA origami folds DNA into precise structures. Each method has strengths and limitations, and combining them advances nanotech. Exploring these techniques reveals how science designs complex, tiny devices—if you keep exploring, you’ll discover how these methods shape the future.

Key Takeaways

- Lithography, self-assembly, and DNA origami are complementary nanofabrication methods used to create precise and functional nanomachines.

- Lithography offers high-resolution patterning via light or electron beams, enabling nanoscale device fabrication.

- Self-assembly utilizes natural molecular forces to form complex nanostructures efficiently and cost-effectively.

- DNA origami enables programmable, highly precise 2D and 3D nanostructure construction through DNA strand folding.

- Hybrid approaches combine these techniques to overcome individual limitations, enhancing scalability, complexity, and material compatibility.

The Fundamentals of Lithography in Nanoscale Fabrication

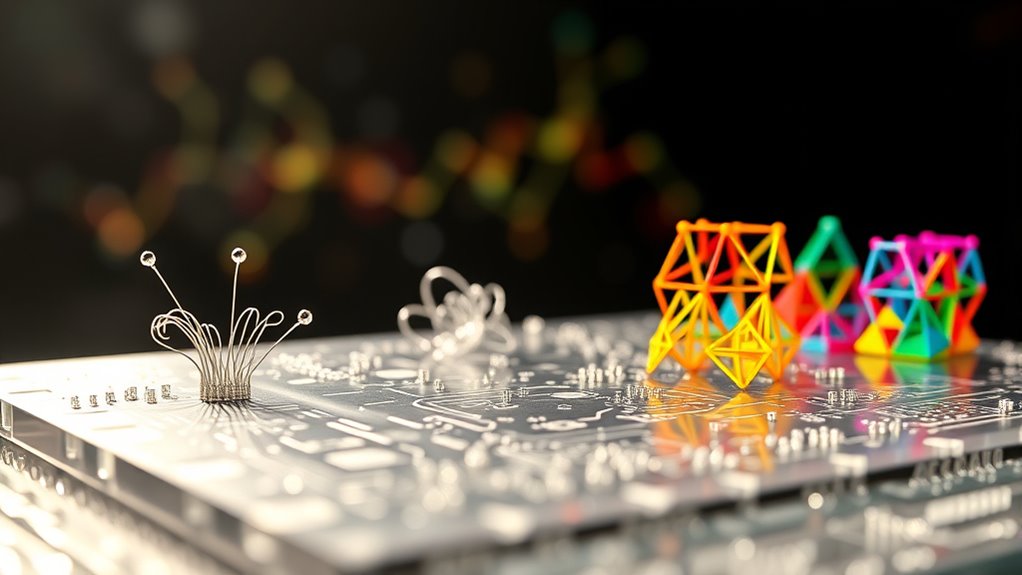

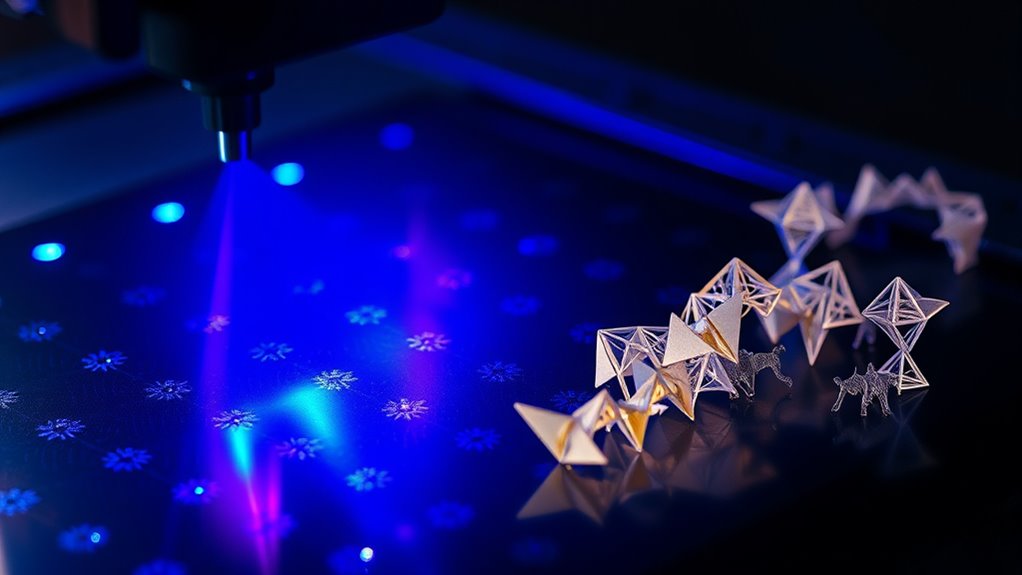

Have you ever wondered how tiny patterns are precisely created on the nanoscale? Lithography is the key process that makes this possible. It involves transferring a pattern onto a surface using light, electrons, or ions to create intricate designs. First, a photosensitive material called a resist is coated onto the substrate. When exposed to a focused beam—like ultraviolet light or an electron beam—the resist undergoes chemical changes. Developing the resist then reveals the pattern, which can be etched or filled with other materials to form nanoscale structures. Lithography’s accuracy depends on factors like wavelength and exposure methods. This technique enables the high-resolution fabrication of nanodevices, essential for advancing electronics, sensors, and other nanotechnologies. Its ability to produce detailed nanoscale features drives innovations across multiple industries. Additionally, ongoing advancements in patterning techniques are expanding the limits of resolution and speed in nanoscale manufacturing.

Techniques and Applications of Self-Assembly in Nanomanufacturing

Building on the precision of lithography, self-assembly offers a powerful alternative for fabricating nanoscale structures. You leverage natural forces—such as electrostatic, hydrophobic, or van der Waals interactions—to guide molecules and nanoparticles into desired arrangements without direct manipulation. These techniques include block copolymer assembly, colloidal crystallization, and protein folding, which create complex, functional nanostructures efficiently. Self-assembly is especially valuable for producing repetitive patterns and large-area coatings quickly and cost-effectively. Its applications span electronics, sensors, drug delivery systems, and catalysis. By harnessing self-organization principles, you can develop intricate nanostructures that would be difficult or impossible to produce with traditional top-down methods, enabling scalable manufacturing of advanced nanodevices. Additionally, understanding climate control principles can help optimize manufacturing environments for sensitive nanostructures.

Exploring DNA Origami and Its Role in Building Nanostructures

DNA origami has emerged as a versatile and precise method for constructing nanoscale structures by folding a long, single-stranded DNA molecule into specific shapes with the help of short staple strands. You can design complex two- and three-dimensional shapes by selecting sequences that guide the DNA to fold into desired configurations. This technique allows you to create nanostructures with high accuracy and functional versatility, making it ideal for applications like drug delivery, biosensing, and nanoelectronics. The process relies on predictable base pairing, enabling you to program structures at the molecular level. DNA origami’s ability to produce intricate, customizable nanostructures has revolutionized nanotechnology, providing a foundation for building sophisticated nanoscale devices and systems with unprecedented control and precision. Asset division strategies offer valuable insights into managing complex arrangements, which can be applied to the precise assembly of nanostructures.

Comparing Lithography, Self-Assembly, and DNA Origami: Advantages and Limitations

To effectively manufacture nanostructures, it’s important to understand the key differences among lithography, self-assembly, and DNA origami. Lithography offers high precision and control, making it ideal for creating complex, repetitive patterns. However, it’s limited by high costs, equipment complexity, and scalability issues. Self-assembly is cost-effective and suitable for large-scale production, but you must accept less precise control over the final structure, and it can be difficult to direct specific arrangements. DNA origami combines programmability with nanoscale precision, allowing you to design intricate shapes, but it’s often slower, more complex, and sensitive to environmental conditions. Each method has unique strengths and weaknesses, so your choice depends on your project’s requirements for precision, scalability, and complexity.

Recent Advances in Nanoscale Manufacturing Technologies

Recent advances in nanoscale manufacturing technologies have markedly expanded the possibilities for constructing complex nanostructures with greater efficiency and precision. Techniques like electron-beam lithography now allow you to create features at sub-10 nanometer scales, improving resolution considerably. Advances in directed self-assembly enable you to guide molecules into desired arrangements more reliably, reducing defects. DNA origami has evolved with improved folding protocols, offering higher yield and structural complexity. Additionally, new hybrid methods combine lithography with self-assembly, maximizing benefits of both approaches. These innovations speed up production times and enhance control over nanostructure geometry. As a result, you can now fabricate increasingly intricate nanomachines, pushing the boundaries of what’s possible at the nanoscale and opening new avenues for applications across medicine, electronics, and materials science. Enhanced precision in nanopatterning also enables the development of more sophisticated nanodevices with customized functionalities.

Challenges and Future Directions in Nanomachine Construction

You’ll face significant hurdles in achieving both precision and scalability when constructing nanomachines, which are essential for reliable performance. Material compatibility also poses challenges, as not all substances behave predictably at the nanoscale. Overcoming these issues will be vital for advancing nanomachine technology and enabling its full potential. Additionally, integrating emerging digital asset management technologies such as blockchain and smart contracts could facilitate secure and transparent tracking of nanomachine components and processes in future developments.

Precision and Scalability

Achieving precise control and scalability in nanomachine construction remains a significant challenge, as current techniques often struggle to reproduce complex structures reliably at such tiny scales. Lithography offers high resolution but faces limits in pattern complexity and throughput. Self-assembly methods excel in scalability but lack exact positioning. DNA origami provides precise nanoscale structures but is difficult to produce at large volumes. To illustrate, consider this overview:

| Technique | Strengths | Limitations |

|---|---|---|

| Lithography | High resolution, precise patterns | Low throughput, complex designs |

| Self-assembly | Scalable, cost-effective | Limited control over exact placement |

| DNA Origami | Nanoscale precision | Challenging to scale up |

Additionally, ongoing research aims to innovate new methods that combine these techniques’ advantages to overcome existing limitations.

Material Compatibility Challenges

Material compatibility poses a critical hurdle in nanomachine construction, as integrating diverse materials at such tiny scales often leads to unforeseen reactions, degradation, or structural failures. Different materials may respond unpredictably when combined, causing issues like corrosion, delamination, or compromised functionality. Choosing compatible materials requires understanding their chemical, thermal, and mechanical properties to prevent adverse interactions. For example, metals and polymers may react differently under nanofabrication conditions, risking instability. Additionally, some materials may not bond effectively at the nanoscale, limiting design options. As you develop nanomachines, you must carefully select and test materials to ensure they work harmoniously. Overcoming these compatibility challenges is essential to building reliable, durable nanodevices capable of performing complex tasks. Incorporating material compatibility considerations early in the design process can significantly improve the success rate of nanomachine fabrication.

Case Studies Demonstrating Nanomachine Fabrication Methods

Examining real-world examples reveals how various fabrication methods are applied to create functional nanomachines. For instance, researchers use electron-beam lithography to produce nanoscale devices with high precision, enabling intricate circuitry. Self-assembly techniques are demonstrated in the creation of nanowires and molecular motors, where molecules naturally organize into desired structures. DNA origami has been used to build programmable nanostructures, like drug delivery vehicles. You can also see how atomic layer deposition forms uniform coatings on nanomachines, enhancing stability. Ultimately, hybrid approaches combine lithography and self-assembly to optimize functionality and scalability. These case studies highlight the versatility of fabrication methods, showing how they can be tailored to specific nanomachine applications across different fields. Mindfulness practices can also play a role in the development and operation of nanomachines by promoting focus and reducing errors during assembly processes.

The Impact of Nanoscale Manufacturing on Industry and Research

Nanoscale manufacturing is transforming how products are developed, making them more efficient and innovative. You’ll see new scientific discoveries accelerated as researchers can manipulate materials at an atomic level. This shift is reshaping both industry and research, opening up exciting possibilities. The integration of advanced algorithms into manufacturing processes further enhances precision and efficiency at the nanoscale.

Revolutionizing Product Development

As manufacturing techniques shrink to the nanoscale, industries and research institutions are experiencing a profound shift in how products are designed and produced. You can now develop highly precise components that were previously impossible at larger scales. This allows for faster prototyping, reducing time to market. Customization becomes more feasible, enabling tailored solutions for specific needs. Nanoscale manufacturing also improves product performance, durability, and efficiency. You’ll see innovations in electronics, medicine, and materials that rely on atomic-level control.

- Faster product development cycles

- Increased customization options

- Enhanced device performance

- Reduced material waste

- New opportunities in emerging markets

Advancing Scientific Discovery

The advent of nanoscale manufacturing has revolutionized scientific research by enabling unprecedented precision in experimentation and data collection. With these tools, you can observe and manipulate molecules, cells, and materials at an atomic level, accelerating discovery. This leap allows for faster development of new materials, medicines, and diagnostic techniques. As a result, research becomes more accurate and efficient, often revealing insights previously impossible to detect. To illustrate, consider this table:

| Nanoscale Tool | Scientific Benefit | Industry Impact |

|---|---|---|

| DNA Origami | Precise molecular arrangements | Targeted drug delivery |

| Self-Assembly | Autonomous structure formation | Material innovation |

| Lithography | High-resolution patterning | Microelectronics |

This synergy propels both research and industry toward groundbreaking advancements.

Frequently Asked Questions

How Do Scalability Issues Affect Nanomachine Manufacturing Methods?

Scalability issues limit how efficiently you can produce nanomachines, often making large-scale manufacturing costly and complex. As you try to increase output, you might face challenges like maintaining precision, controlling defects, and ensuring consistency across batches. These hurdles slow down progress, raise expenses, and prevent you from deploying nanomachines broadly. Overcoming scalability obstacles is vital if you want to shift from lab prototypes to practical, real-world applications.

What Are the Environmental Impacts of Nanoscale Fabrication Processes?

You might overlook the environmental impacts of nanoscale fabrication processes, but they matter. These methods can produce hazardous waste, consume significant energy, and release toxic chemicals, affecting ecosystems and human health. You’re responsible for minimizing these impacts by choosing eco-friendly techniques, properly managing waste, and advocating for sustainable practices. By doing so, you help guarantee that nanotechnology benefits society without harming the environment or future generations.

How Do Cost Considerations Influence the Choice of Fabrication Techniques?

Cost considerations heavily influence your choice of fabrication techniques. You’ll weigh factors like equipment expenses, material costs, and process complexity against your project’s budget. Lithography offers precision but can be costly, while self-assembly and DNA origami may be more affordable for large-scale production. Balancing quality, speed, and costs helps you select the most practical method, ensuring your nanomachines are effective without overspending.

What Safety Protocols Are Necessary During Nanomachine Assembly?

You should wear proper protective gear, including gloves, lab coats, and eye protection, to prevent exposure to harmful materials. Work in a well-ventilated area or under a fume hood to avoid inhaling fumes or particles. Follow strict cleanliness protocols, sanitize equipment regularly, and handle chemicals with care. Guarantee proper training and supervision, and be prepared with emergency procedures for spills, accidents, or exposure to hazardous substances.

How Will Nanomachines Integrate With Existing Technological Systems?

You’ll need to guarantee nanomachines seamlessly connect with current systems by developing compatible interfaces and communication protocols. Focus on standardizing power supplies and data transfer methods to facilitate integration. You’ll also want to test interoperability thoroughly, addressing potential issues like signal interference or misalignment. By designing adaptable, scalable solutions, you make it easier for nanomachines to augment existing technology, ultimately creating more efficient and versatile systems.

Conclusion

As you explore nanomachine manufacturing, you’ll find that each method offers unique pathways to innovation, gently guiding us toward remarkable possibilities. While challenges remain, embracing these techniques with patience and curiosity can lead to subtle yet profound breakthroughs. By harmonizing lithography, self-assembly, and DNA origami, you’ll help shape a future where tiny creations quietly revolutionize industries, reminding us that sometimes, the smallest steps can softly pave the way for extraordinary progress.