Designing nanomachines presents key challenges like maintaining structural stability against tiny defects and environmental factors. You must achieve precise control over atomic movements and responses, which requires advanced manipulation techniques. Additionally, optimizing energy efficiency involves reducing friction and implementing smart, adaptable systems. Balancing these factors is complex but vital for reliable and effective nanomachines. If you want to understand how researchers tackle these hurdles, explore further to uncover detailed solutions.

Key Takeaways

- Ensuring nanoscale structural integrity amidst surface forces, defects, and environmental factors.

- Achieving precise fabrication and predictable material behavior at the atomic level.

- Developing accurate control mechanisms for reliable, repeatable nanomachine movements.

- Balancing flexibility and sturdiness to prevent unintended reactions during operation.

- Enhancing energy efficiency by minimizing friction and optimizing smart control systems.

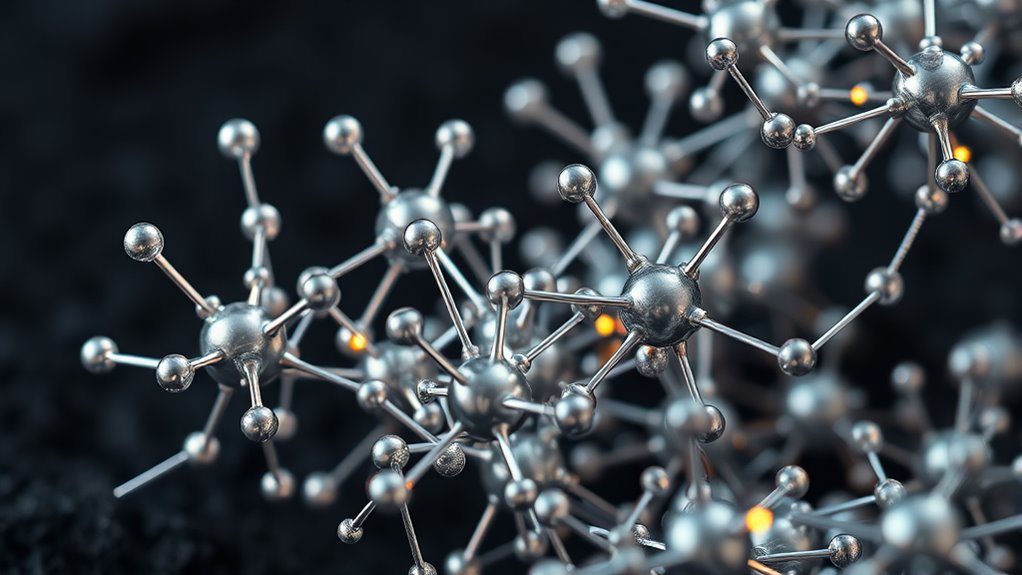

Ensuring Structural Integrity at the Nanoscale

Ensuring structural integrity at the nanoscale presents unique challenges because materials behave differently when scaled down to such tiny dimensions. At this scale, forces like van der Waals interactions and surface tension dominate, making materials more prone to deformation or failure. Tiny defects or inconsistencies can markedly weaken the structure, so precise fabrication is critical. You need to carefully select materials that maintain strength and stability at small sizes. Additionally, environmental factors such as temperature fluctuations and chemical exposure can cause unexpected changes or damage. As you design nanomachines, you must account for these factors to prevent collapse or malfunction. Achieving a balance between flexibility and sturdiness ensures the nanomachine can perform reliably without compromising its delicate structure. Moreover, understanding material behavior at the nanoscale is essential for predicting and enhancing stability under various conditions.

Achieving Precise Manipulation and Functionality

Achieving precise manipulation and functionality in nanomachines requires meticulous control over movements and interactions at the atomic level. You need to guarantee that each component responds accurately to external stimuli or internal signals. This involves developing advanced control mechanisms, such as nanoscale actuators and sensors, that can operate reliably in complex environments. Precise control enables nanomachines to perform specific tasks like targeted drug delivery, molecular assembly, or environmental sensing. To achieve this, you must fine-tune interactions between molecules, avoid unintended reactions, and maintain stability during operation. The challenge lies in balancing responsiveness with stability, ensuring that movements are both accurate and repeatable. Ultimately, mastering this level of control is vital for the practical deployment of functional nanomachines in real-world applications.

Enhancing Energy Efficiency and Performance

How can nanomachines maximize energy efficiency while maintaining high performance? You can achieve this by optimizing their design to reduce energy waste, such as minimizing friction and resistance at the nanoscale. Incorporating smart control systems allows you to adapt operations based on real-time conditions, conserving energy during low-demand periods. Using energy-efficient materials and renewable energy sources enhances overall performance without draining resources. Additionally, fine-tuning the size and operation speed ensures you use energy just enough to accomplish tasks effectively. Balancing these aspects helps you create nanomachines that operate sustainably, with minimal energy input, while still delivering the high precision and output required for complex tasks. This approach ultimately boosts both efficiency and performance in nanomachine design. Mindfulness techniques can also be employed to promote a more focused and efficient workflow during design and operation processes.

Frequently Asked Questions

How Do Environmental Factors Affect Nanomachine Stability?

Environmental factors profoundly impact your nanomachine’s stability. Changes in temperature can cause expansion or contraction, affecting precision. pH levels and chemical exposure may weaken materials or cause corrosion. Mechanical stresses from vibrations or pressure can disrupt operations. Additionally, electromagnetic interference can interfere with control systems. To maintain stability, you need to carefully consider these factors during design, select resilient materials, and implement protective measures against environmental fluctuations.

What Are the Latest Materials Used for Nanomachine Durability?

You should consider using advanced materials like graphene, which offers exceptional strength and flexibility, or carbon nanotubes that provide high durability and conductivity. Recent developments include biocompatible polymers and hybrid nanomaterials that enhance stability in biological environments. These materials help nanomachines withstand various stresses and extend their operational lifespan. Incorporating such cutting-edge substances enables you to design more durable, reliable nanomachines capable of functioning effectively under diverse conditions.

How Can Nanomachine Control Systems Adapt to Real-Time Changes?

Did you know that 85% of successful nanomachine control systems incorporate real-time feedback mechanisms? You can adapt nanomachine control systems to real-time changes by integrating sensors that continuously monitor environmental conditions. These sensors send data to onboard processors, which adjust the nanomachine’s actions instantly. This dynamic feedback loop ensures precise operation amid fluctuating variables, enabling your nanomachines to respond swiftly and maintain ideal performance even in unpredictable environments.

What Are the Safety Concerns in Deploying Nanomachines in Vivo?

You should be aware that deploying nanomachines in vivo raises safety concerns like unintended interactions with healthy tissues, immune system responses, and potential toxicity. These tiny devices might cause inflammation or disrupt normal cell functions if not properly controlled. To guarantee safety, rigorous testing, precise targeting, and fail-safe mechanisms are essential. Continuous monitoring and adapting nanomachine behavior help minimize risks and protect patient health during in vivo applications.

How Is Scalability Addressed in Nanomachine Manufacturing?

You address scalability in nanomachine manufacturing by developing modular designs that can be easily replicated and assembled at larger scales. Utilizing advanced techniques like self-assembly and automated synthesis helps increase production efficiency. You also optimize processes to reduce costs and guarantee quality control. By focusing on scalable fabrication methods, you ensure that nanomachines can be produced reliably in larger quantities for practical applications.

Conclusion

Think of designing nanomachines like building a tiny, delicate bridge—you need strength, precision, and energy. Just as a bridge must withstand forces without collapsing, your nanomachine must stay stable and function perfectly. When you tackle challenges in stability, control, and efficiency, you’re creating tools that could revolutionize medicine or electronics. Remember, every tiny improvement is like tightening a bolt—bringing your nanoscale marvels closer to reality and making the impossible possible.