A glossary of nanomachine terms bridges the gap between tiny structures and larger systems. It covers units like nanometers, which measure at the atomic level, and explains components such as molecular motors, sensors, and gears. You’ll learn about materials like graphene and gold, fabrication techniques from self-assembly to top-down shaping, and applications from medicine to industry. If you keep exploring, you’ll gain a deeper understanding of how these tiny devices influence our world.

Key Takeaways

- Nanomachine terms include units like nanometer (nm), atomic scale, and molecular components, bridging nano to macroscale concepts.

- Key concepts cover bottom-up assembly, top-down fabrication, and materials such as graphene, gold, and biological molecules.

- Components range from molecular motors and gears to nanosensors and valves, illustrating various functional elements.

- Measurement accuracy and fabrication techniques are critical for precise control from atomic to macroscopic levels.

- Applications span medical, industrial, and environmental fields, emphasizing the importance of terminology across scales.

Fundamental Concepts and Units of Measurement

Understanding the fundamental concepts and units of measurement is essential when exploring nanomachines. At this scale, traditional measurements don’t work well, so you need specialized units like the nanometer (nm), which equals one-billionth of a meter. This tiny unit helps you grasp how small nanomachines are. You’ll also encounter concepts like atomic scale, where individual atoms and molecules are the building blocks. Precision matters, so you’ll use tools like atomic force microscopes to measure features at the nanoscale. Understanding these units and concepts helps you visualize how nanomachines operate and interact within biological or synthetic systems. For example, the contrast ratio of a projector can significantly affect image quality, just as precise measurement units influence our understanding of nanoscale structures. Without a solid grasp of these fundamentals, it’s challenging to appreciate their design, function, or potential applications fully.

Types of Nanomachines and Their Functions

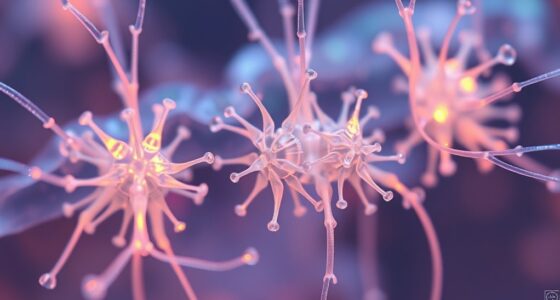

Nanomachines come in various types, each designed for specific functions at the microscopic scale. You might encounter molecular motors that convert chemical energy into mechanical work, powering cellular processes like muscle contraction. There are also nanorobots engineered for targeted drug delivery, steering through the bloodstream to reach specific cells. Some nanomachines function as sensors, detecting environmental changes such as pH or temperature, providing real-time data. Molecular assemblers build complex structures at the nanoscale, enabling precise manufacturing. Additionally, nanoscale pumps and valves control fluid movement within tiny channels, vital in medical and industrial applications. By understanding these types, you grasp how nanomachines perform essential roles in medicine, electronics, and materials science, revolutionizing technology from the smallest to the largest scales. For instance, dog behavior and companionship can be studied using nanotechnology to develop better training and care methods for pets.

Materials and Components Used in Nanotechnology

Materials and components form the foundation of nanotechnology, enabling the construction and function of tiny devices. You’ll primarily use materials like carbon-based structures (fullerenes, graphene), metals (gold, silver), and ceramics for their strength, conductivity, and stability at small scales. These materials often exhibit unique properties not seen at larger sizes, such as increased reactivity or enhanced strength. You’ll also incorporate biological molecules like DNA and proteins for precise, programmable assembly. Nanocomposites combine different materials to optimize functionality. Components include nanoscale gears, switches, and sensors, which perform specific tasks. Selecting the right materials and components guarantees your nanodevice can operate efficiently, withstand environmental conditions, and achieve desired performance at the microscopic level. Optimal angles can also influence the behavior and durability of nanodevices, highlighting the importance of precise design considerations.

Fabrication and Assembly Techniques

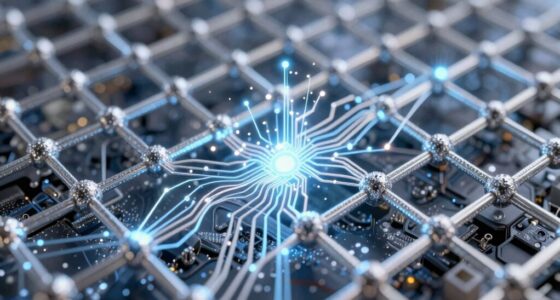

You’ll explore how nanomachines are built using bottom-up or top-down approaches. Bottom-up methods assemble structures from individual molecules, while top-down processes carve away material from larger components. Understanding these techniques helps you grasp the fundamentals of nanofabrication.

Bottom-Up Construction Methods

Bottom-up construction methods build nanomachines by assembling them from individual atoms or molecules, rather than carving or etching from larger structures. You utilize processes like chemical synthesis, self-assembly, and molecular templating to create precise nanoscale components. In chemical synthesis, you design specific molecules that naturally organize into desired structures. Self-assembly involves molecules spontaneously forming ordered arrangements under suitable conditions, driven by intermolecular forces. Molecular templating guides the arrangement of building blocks around a scaffold or template, ensuring accuracy. These methods enable you to produce highly organized, functional nanostructures with atomic precision. Bottom-up techniques are essential for developing complex nanomachines, as they allow you to construct systems that mimic biological functions and enable innovations in medicine, electronics, and materials science. Additionally, these techniques often involve precise control over molecular interactions, which is crucial for achieving desired functionalities at the nanoscale.

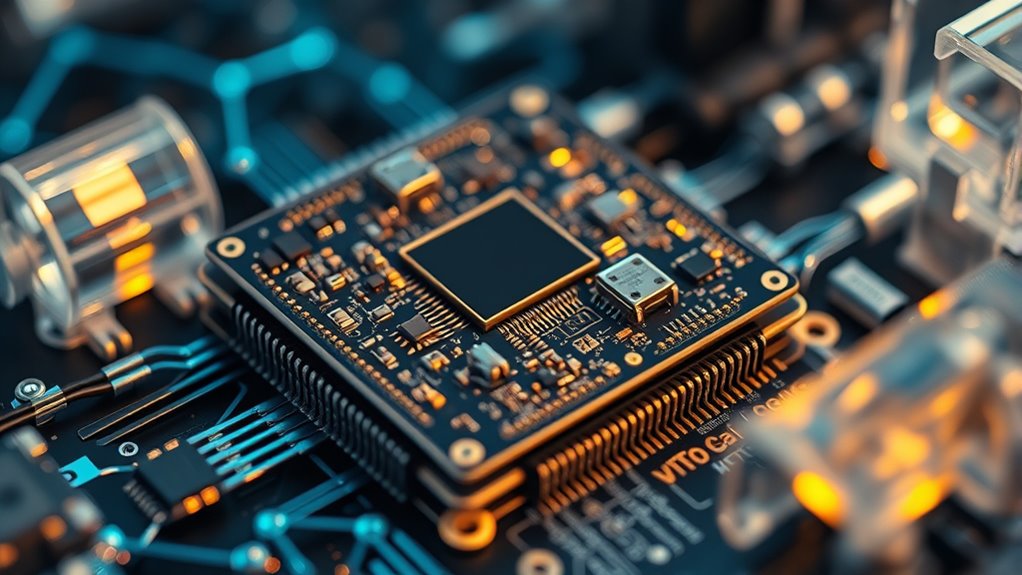

Top-Down Fabrication Processes

Top-down fabrication processes start with a bulk material and shape it into nanoscale structures through precise removal or modification techniques. You use methods like photolithography, etching, or milling to carve out desired features, controlling dimensions at the nanometer scale. These techniques allow for high accuracy and repeatability, making them ideal for creating complex devices such as microchips and sensors. You can also employ techniques like reactive ion etching or focused ion beam milling to refine structures further. While top-down methods are often limited by resolution and can generate waste material, they excel in producing well-defined, reliable components. These processes are widely used in electronics manufacturing, where precision and scalability are vital for translating macroscopic designs into functional nanoscale parts. Additionally, understanding power consumption insights is essential when designing and testing these nanoscale devices to ensure energy efficiency and safety.

Applications Across Industries and Scales

Nanomachines are transforming various industries by enabling precise, scalable solutions at the microscopic level. In medicine, they target specific cells for drug delivery, reducing side effects and increasing treatment effectiveness. In manufacturing, nanomachines create stronger, lighter materials with nanoscale properties, improving product performance. The electronics industry benefits from nanoscale components that enable faster, more efficient devices. Environmental applications include detecting pollutants and breaking down toxins at a molecular level. Agriculture uses nanomachines for targeted nutrient delivery and pest control, minimizing chemical use. Across scales, nanomachines facilitate innovations from microscopic sensors to macro-scale assemblies, streamlining processes and enhancing product capabilities. Their versatility across sectors *access* new potentials, making industries more efficient, sustainable, and responsive to evolving needs. Additionally, advancements in astrological research have begun to influence design and innovation in nanotech applications, highlighting the interdisciplinary growth of this field.

Challenges and Future Directions in Nanomachinery

Despite their promising potential, nanomachines face significant challenges that could impede their widespread adoption and development. One major hurdle is controlling and reliably manufacturing these tiny devices at scale. Achieving precise assembly and avoiding defects remain difficult, limiting their practical use. Additionally, energy supply at the nanoscale poses problems; nanomachines require efficient, sustainable power sources. You also need to address biocompatibility and safety concerns, especially for medical applications, to prevent unintended effects. Future directions focus on advancing fabrication techniques, such as self-assembly and molecular engineering, to overcome these issues. Research aims to improve control mechanisms, integrate artificial intelligence, and develop hybrid systems. For example, Honda Tuning innovations like ECU remapping and suspension upgrades demonstrate how precise control and customization are crucial for performance optimization. Overcoming these challenges will be vital for enabling nanomachines’ full potential across medicine, industry, and environmental sectors.

Frequently Asked Questions

How Do Nanomachines Communicate Within Biological Systems?

You can think of nanomachines communicating in biological systems as sending signals similar to how neurons transmit information. They use chemical signals, like neurotransmitters, or physical interactions such as vibrations and electrical signals to coordinate actions. You might also see them exchanging information through receptor-ligand interactions on cell surfaces. This communication allows nanomachines to work together effectively, enabling precise control of biological processes at the microscopic level.

What Safety Protocols Exist for Nanomachine Deployment?

Safety protocols for nanomachine deployment are like guardrails guiding a delicate dance. You’ll implement strict controls, including extensive testing, containment measures, and real-time monitoring, to prevent unintended interactions. Regulatory frameworks and ethical guidelines also guarantee responsible use. You’ll need to stay updated on new risks and develop fail-safes, so these tiny machines serve you safely without causing harm, much like a well-trained team working seamlessly behind the scenes.

Can Nanomachines Repair Human Tissues Autonomously?

Yes, nanomachines can potentially repair human tissues autonomously. They’re designed to identify damaged cells, deliver necessary nutrients or drugs, and even perform minor repairs at a cellular level. You would likely see them operate with minimal supervision, guided by smart algorithms to guarantee safety and precision. While this technology is promising, ongoing research aims to improve their reliability and control before they become widely available for medical treatments.

How Are Nanomachines Powered at the Nanoscale?

Nanomachines are powered at the nanoscale primarily through chemical energy, such as catalytic reactions, or external sources like magnetic, optical, or ultrasonic fields. You might see them harnessing ATP or other biological molecules, or being activated by external stimuli. These methods enable nanomachines to perform tasks autonomously or under external control, making them versatile tools for medical, environmental, and industrial applications.

What Ethical Issues Surround Nanotechnology Development?

You should consider that ethical issues in nanotechnology include potential health and environmental risks, privacy concerns, and the possibility of misuse or weaponization. As you develop nanotech, you might face challenges related to regulation and consent, especially with sensitive applications like medicine or surveillance. It is crucial to weigh these concerns carefully, ensuring responsible innovation that prioritizes safety, transparency, and societal benefits to prevent harm and promote trust.

Conclusion

Imagine building a car with LEGO bricks—you can create anything from tiny robots to massive machines. Just like those bricks, nanomachines are the building blocks of future technology, transforming industries from medicine to electronics. With ongoing breakthroughs, you’re on the cusp of a world where the tiniest tools can have the biggest impact. Embrace this journey, because mastering nanomachine terms today sets you up to shape tomorrow’s innovations.