Chemical reactions power nanomachines by converting chemical energy into mechanical movement, offering high force output and steady operation, ideal for demanding tasks. Light-driven propulsion uses lasers or LEDs to activate nanomachines with precise, remote control, but often produces less force and depends on environmental conditions. Each approach has pros and cons, and hybrid systems are emerging to combine their strengths. To explore how these methods compare and the latest innovations, keep exploring further.

Key Takeaways

- Chemical reactions provide steady, high-force propulsion suitable for demanding tasks, while light-driven systems excel in precise, controllable movement.

- Light-driven nanomachines offer rapid activation and remote control but may have lower energy efficiency compared to chemical methods.

- Chemical propulsion often has higher molecular efficiency and longer operational sustainability than light-based mechanisms.

- Light-driven systems require specific wavelengths and intensities, enabling precise navigation but potentially risking thermal damage.

- Combining both approaches creates hybrid nanomachines, leveraging chemical force and optical control for enhanced versatility.

Fundamentals of Nanomachine Propulsion

Understanding how nanomachines move is essential to grasping their potential applications. At this scale, molecular motors serve as the core components, converting energy into directed motion. These tiny engines harness chemical or light energy, enabling nanomachines to perform tasks like cargo transport or assembly. Interestingly, quantum effects can influence their movement, especially as their size approaches atomic levels, causing behaviors that classical physics can’t explain. You’ll find that the dynamics of molecular motors involve complex interactions between energy states and molecular structures, allowing precise control over movement. This understanding helps in designing more efficient nanomachines capable of functioning reliably in biological or synthetic environments. Additionally, the role of color accuracy in the energy conversion processes can significantly impact the efficiency and reliability of nanomachine operations. By mastering these fundamentals, you’re better equipped to explore the vast possibilities of nanomachine applications.

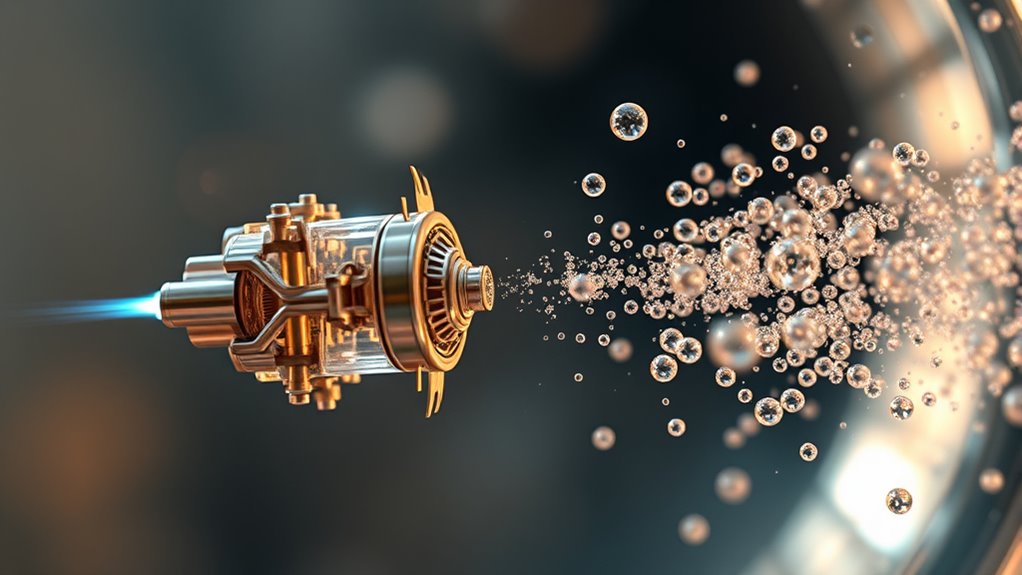

Mechanisms Behind Chemical-Driven Movement

Chemical energy serves as the primary force driving nanomachine movement, with molecular motors converting these chemical reactions into mechanical work. This process relies on specific molecular interactions that facilitate force generation. Catalytic mechanisms accelerate reactions, enabling rapid, targeted movement. The efficiency depends on how well the motors harness chemical energy through structural changes and binding events. The following table illustrates key aspects:

| Molecular Interaction | Catalytic Mechanisms | Resulting Movement |

|---|---|---|

| Binding of ATP/ADP | Enzymatic hydrolysis | Conformational shifts drive motion |

| Substrate recognition | Catalysis of chemical change | Propulsion via mechanical displacement |

| Force transmission | Energy release control | Directional nanomachine movement |

| Structural flexibility | Catalytic site activation | Controlled, sustained propulsion |

Additionally, the conversion of chemical energy into mechanical work involves complex molecular interactions that are finely tuned to optimize energy transfer and movement efficiency.

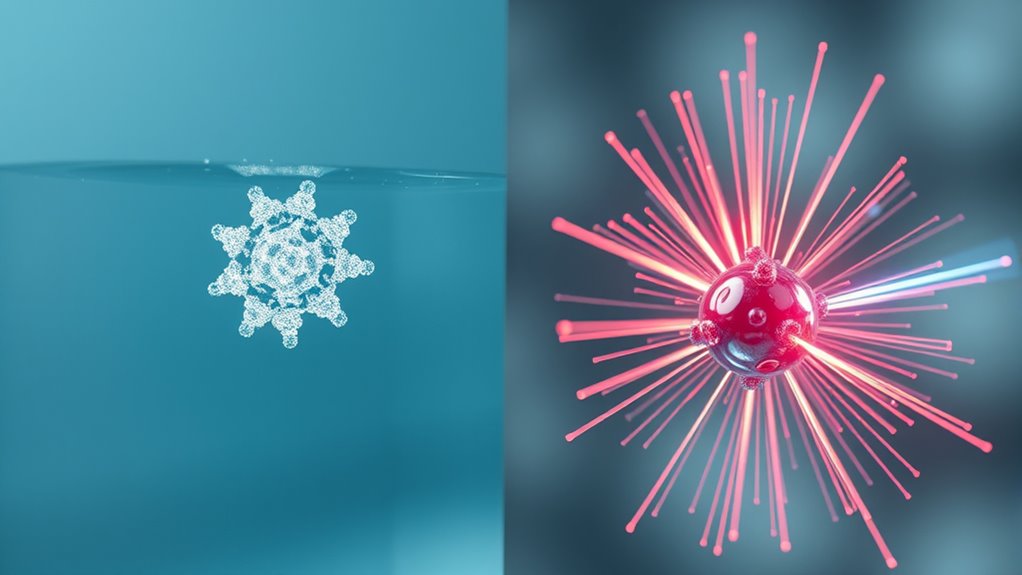

Light-Activated Propulsion Techniques

Light-activated propulsion requires specific light sources that can be precisely controlled to activate nanomachines. You’ll need to contemplate strategies for directing movement, such as using focused beams or patterned illumination. Understanding these requirements is key to manipulating nanomachine motion effectively. Additionally, leveraging local ingredients and seasonal menus can enhance the precision and effectiveness of light-driven propulsion by tailoring the environment to optimize energy absorption and response.

Light Source Requirements

To effectively propel nanomachines using light, the source must deliver precise wavelengths and intensities that can activate specific internal mechanisms without damaging surrounding tissues. You need to match the light’s wavelength requirements to the nanomachine’s photoresponsive components, guaranteeing efficient energy absorption. The light intensity must be carefully controlled; too high can cause thermal damage, while too low may result in inadequate propulsion. Additionally, selecting the appropriate light source—such as lasers or LEDs—depends on achieving the necessary wavelength accuracy and stability. Consistent output ensures reliable activation of propulsion mechanisms. Overall, optimizing the light source involves balancing wavelength requirements and light intensity to achieve effective, safe, and targeted movement of nanomachines in biological environments.

Movement Control Strategies

Movement control strategies for light-activated nanomachines rely on precisely timed and spatially targeted illumination to initiate and steer propulsion. You can manipulate their movement by adjusting light intensity, wavelength, and exposure patterns. This approach offers high spatial and temporal precision but faces challenges with biocompatibility concerns and manufacturing complexities. To better understand, consider the following table:

| Control Method | Advantages | Challenges |

|---|---|---|

| Photothermal Activation | Precise control, rapid response | Potential biocompatibility issues |

| Photochemical Activation | Fine spatial control | Manufacturing complexities |

| Light Patterning | Programmable navigation | Limited tissue penetration |

| Multi-wavelength Control | Multi-modal steering | Complex setup |

These strategies enable sophisticated navigation, yet demand careful consideration of safety and manufacturing feasibility.

Efficiency and Power Output Comparison

When comparing nanomachine propulsion methods, you should consider how efficiently they convert energy into motion. Force generation capacity determines how much work they can perform, while power sustainability impacts their ability to operate over time. Analyzing these factors helps you identify which systems deliver the best balance of performance and endurance.

Energy Conversion Rates

How do nanomachines compare in their ability to convert energy into motion? Chemical nanomachines often have higher molecular efficiency due to direct energy transfer, but their energy density can be limited. Light-driven nanomachines excel in energy density, harnessing abundant photons, yet may suffer from lower efficiency due to losses. The table below highlights these differences:

| Aspect | Chemical Reactions | Light-Driven Movement | Implication |

|---|---|---|---|

| Molecular Efficiency | High | Moderate | Affects energy utilization |

| Energy Density | Moderate to Low | High | Influences total energy available |

| Power Output | Steady, controlled | Variable, dependent on light | Determines propulsion effectiveness |

Force Generation Capacity

Nanomachines’ ability to generate force depends heavily on their energy conversion efficiency and power output. Chemical propulsion often offers higher force generation due to efficient energy use, but biocompatibility concerns can limit its application in medical settings. Light-driven nanomachines, while providing precise control and lower toxicity, typically produce less force and have lower power output. Manufacturing scalability also influences force capacity; complex designs may hinder mass production, affecting overall force consistency. When comparing these propulsion methods, consider that chemical systems tend to deliver greater force but raise biocompatibility issues, whereas light-driven systems excel in safety and control but may compromise on force output. Balancing these factors is vital for optimizing nanomachine performance across diverse applications.

Power Sustainability

Have you ever wondered which propulsion method offers the best balance between efficiency and sustained power output? Chemical reactions often excel in energy storage, providing a steady, long-lasting power source for nanomachines. Light-driven movement, on the other hand, typically delivers rapid bursts of energy but may struggle with continuous operation due to material durability issues. When comparing these methods, consider how well the materials can withstand prolonged use; durability impacts overall power sustainability. Chemical propulsion systems tend to maintain consistent output because they rely on stable reactions, while light-driven systems require resilient materials to prevent degradation from intense illumination. Ultimately, the choice depends on balancing energy storage capacity with material robustness to achieve ideal efficiency and sustained performance.

Control and Precision in Navigation

Achieving precise control and orientation in nanomachines is essential for their effective operation within complex environments. You rely on advanced orientation algorithms to steer accurately, ensuring your movements respond to dynamic surroundings. Effective obstacle avoidance is critical to prevent collisions and maintain mission integrity. These systems enable you to adapt in real-time, navigating tight spaces and unpredictable terrains. To illustrate, consider the following:

| Navigation Strategy | Key Feature | Application |

|---|---|---|

| Algorithm-based | Real-time data processing | Precise pathfinding |

| Light-guided | External control | Targeted movement |

| Chemical cues | Environment sensing | Reacting to chemical signals |

| Hybrid systems | Combined methods | Complex navigation tasks |

Additionally, nanomachine tuning plays a vital role in optimizing response times and movement accuracy, especially when operating under specific environmental conditions.

Environmental Compatibility and Safety

How do nanomachines guarantee they operate safely and compatibly within diverse environments? They’re designed with eco-friendly materials that minimize environmental impact. Using biodegradable components ensures that, once their task is complete, they break down naturally without leaving harmful residues. This approach reduces pollution and prevents accumulation of toxic substances in ecosystems. You can trust that these nanomachines are developed with safety in mind, avoiding materials that could harm living organisms or disrupt delicate biological processes. By prioritizing biodegradable components and eco-friendly materials, you help ensure their deployment remains sustainable and safe. Additionally, employing forSale 100 components can further enhance their environmental compatibility. These considerations are essential for integrating nanomachines into real-world settings where environmental integrity and safety are paramount.

Practical Applications and Use Cases

Nanomachines are increasingly being integrated into a variety of practical applications, demonstrating their potential to revolutionize multiple fields. In medical imaging, nanomachines can navigate your body to deliver targeted contrast agents, enhancing imaging precision and early diagnosis. Their ability to move accurately allows for minimally invasive procedures and real-time monitoring. In environmental cleanup, nanomachines can seek out and neutralize pollutants at the source, offering a highly efficient solution for contamination. Light-driven nanomachines are especially useful here, as you can activate them remotely for controlled cleanup efforts. Chemical reaction-powered nanomachines, on the other hand, can perform sustained tasks in harsh environments. These innovations open new possibilities for healthcare and environmental management, making processes faster, safer, and more targeted. Additionally, understanding material durability is essential for designing nanomachines capable of operating effectively over extended periods in demanding conditions.

Challenges and Limitations of Each Approach

While nanomachines offer promising capabilities, each approach faces significant challenges that can hinder their practical deployment. Chemical reaction-based propulsion struggles with scalability challenges, as controlling reactions at the nanoscale remains complex. Material limitations also restrict durability and efficiency. Light-driven movement faces issues like limited light penetration and energy transfer inefficiencies. Both methods encounter issues with integrating suitable materials that withstand operational stresses. To illustrate:

| Approach | Challenges |

|---|---|

| Chemical Reactions | Scalability challenges, material stability concerns |

| Light-Driven Movement | Limited light penetration, material durability |

| Material Limitations | Durability, biocompatibility |

| Scalability Challenges | Manufacturing at nanoscale, consistent performance |

Additionally, managing energy transfer remains a critical hurdle to improve the efficiency of light-driven nanomachines.

Future Directions in Nanomachine Propulsion

Future advancements in nanomachine propulsion may focus on hybrid systems that combine multiple mechanisms for greater efficiency. You’ll also see bio-inspired methods that mimic nature’s solutions to navigate complex environments. Additionally, developing environmental responsiveness will allow nanomachines to adapt dynamically to their surroundings, enhancing their functionality. Exploring nutritional advantages, such as energy-efficient processes derived from natural sources, could further revolutionize nanomachine design.

Hybrid Propulsion Systems

Could hybrid propulsion systems revolutionize nanomachine efficiency? By combining chemical reactions with light-driven movement, you can mimic biological systems more closely through biological mimicry. These systems harness energy from multiple sources, optimizing energy harvesting in diverse environments. Hybrid approaches allow nanomachines to switch seamlessly between propulsion methods, improving adaptability and performance. This versatility enhances their ability to operate in complex biological or artificial settings, where reliance on a single energy source might be limiting. Integrating different propulsion mechanisms also reduces energy waste and extends operational lifespan. As you develop these systems, you’ll release new potential for precision tasks, targeted delivery, and environmental sensing, pushing nanomachine capabilities toward more autonomous and efficient designs capable of responding to dynamic conditions.

Bio-Inspired Mechanisms

Building on hybrid propulsion approaches, bio-inspired mechanisms aim to emulate nature’s efficient and adaptable movement strategies. By applying biomimetic design, you can develop nanomachines that mimic biological systems, such as flagella or muscle fibers, to enhance performance. These mechanisms often incorporate energy harvesting techniques, allowing nanomachines to draw power from their environment, much like organisms do. This approach reduces reliance on external energy sources and increases autonomy. You can optimize movement efficiency by studying natural propulsion methods and integrating them into nanomachine design. Bio-inspired mechanisms hold promise for creating versatile, self-sustaining nanomachines capable of complex tasks, advancing the field toward more sophisticated, adaptive, and sustainable nanorobotics.

Environmental Responsiveness

As nanomachines become more integrated into complex environments, their ability to respond dynamically to changing conditions will be essential for effective operation. To achieve this, you’ll need to address biocompatibility issues, ensuring that nanomachines don’t provoke adverse reactions in biological systems. Environmental responsiveness involves designing nanomachines that can detect and adapt to stimuli such as pH, temperature, or chemical signals. Additionally, efficient energy storage becomes critical, so your nanomachines can operate autonomously without constant external input. Developing responsive systems that harness environmental cues allows for precise control and improved functionality. By focusing on biocompatibility and energy management, you’ll enhance nanomachine performance in real-world settings, paving the way for applications in medicine, environmental sensing, and beyond.

Integrating Chemical and Light-Based Methods

Integrating chemical and light-based propulsion methods offers a promising approach to enhance nanomachine performance. By combining these techniques, you can leverage quantum coherence to optimize energy transfer, making movement more efficient. Light-driven mechanisms allow precise control via optical signals, while chemical reactions provide sustained propulsion. Magnetic actuation can also be incorporated to guide nanomachines using external magnetic fields, offering directional control. This hybrid approach enables you to exploit the strengths of each method, overcoming limitations like limited penetration depth for light or short-lived chemical reactions. When integrated thoughtfully, these methods create versatile, responsive nanomachines capable of steering through complex environments with improved speed, accuracy, and energy efficiency. This synergy opens new pathways for applications in targeted drug delivery and environmental sensing. Additionally, understanding the fundamental principles of energy transfer in these systems can further enhance their efficiency and functionality.

Frequently Asked Questions

How Do Nanomachines Communicate With Each Other During Movement?

You observe that nanomachines communicate through molecular signaling, sending chemical signals or messages to coordinate their actions. This allows for cooperative coordination, where each nanomachine responds to signals from others, ensuring synchronized movement. By detecting these signals, they work together efficiently, avoiding collisions and achieving complex tasks. This communication method mimics natural biological systems, enabling nanomachines to operate seamlessly during their movement and interactions.

What Are the Cost Implications of Developing Chemical Versus Light-Driven Nanomachines?

Your mind might explode trying to grasp the staggering cost comparison between chemical and light-driven nanomachines. Developing chemical nanomachines generally incurs higher manufacturing expenses due to complex catalysts and reactions, while light-driven ones benefit from simpler manufacturing processes but require costly, precise light sources. So, if you’re balancing innovation and budget, expect chemical systems to be pricier, but potentially more versatile, whereas light-driven options might save you money on production but demand expensive tech for activation.

Can These Propulsion Methods Be Combined for Enhanced Performance?

You can definitely combine these propulsion methods to create hybrid systems that leverage propulsion synergy. By integrating chemical and light-driven movement, you enhance control and efficiency, allowing nanomachines to adapt to various environments. This hybrid approach can provide more reliable and versatile performance, especially in complex settings where a single method might fall short. Embracing propulsion synergy through hybrid systems offers a promising way to optimize nanomachine functionality.

How Do Environmental Factors Affect Nanomachine Propulsion Efficiency?

Think of nanomachines as tiny boats steering a river. Environmental impact can cause currents or obstacles, affecting their speed and direction. Temperature sensitivity plays a vital role—high temperatures might accelerate chemical reactions, boosting efficiency, but excessive heat can damage the nanomachine, while cold conditions slow movement. You need to contemplate these factors to optimize propulsion, ensuring your nanomachines operate smoothly amid fluctuating environmental conditions.

What Are the Long-Term Stability and Durability Concerns?

You should consider that long-term stability and durability are impacted by material degradation and energy depletion. Over time, nanomachines may weaken due to material fatigue or corrosion, reducing their effectiveness. Additionally, energy sources like chemical fuels or light may run out, limiting operation lifespan. To guarantee longevity, you need to select robust materials and efficient energy management strategies that minimize degradation and conserve energy for sustained performance.

Conclusion

No matter which propulsion method you choose, advancements are opening exciting possibilities for nanomachines. While chemical reactions offer powerful, sustained movement, light-driven techniques provide precise control. Don’t worry about complexity—you can harness both for versatile applications. As technology progresses, combining these methods could overcome current limitations, enabling smarter, more efficient nanomachines. Embrace these innovations, and you’ll be at the forefront of transforming how tiny machines operate across medicine, industry, and beyond.