Nanomachines in chemical factories enable you to perform on-demand synthesis at the molecular level, offering precise control over chemical reactions. They work by transforming processes at the atomic scale, reducing waste and energy use while creating complex materials efficiently. While challenges like scalability exist, ongoing innovations promise smarter, autonomous systems that prioritize sustainability. To discover how these cutting-edge technologies could revolutionize industry, explore further details below.

Key Takeaways

- Nanomachines enable precise, on-demand chemical synthesis at the molecular level, improving efficiency and reducing waste.

- Advanced fabrication techniques allow scalable construction of nanomachines for industrial chemical applications.

- Integration of nanomachines enhances product quality, consistency, and enables complex material creation.

- Innovations like AI and quantum technologies improve nanomachine adaptability and reaction control.

- They support environmentally sustainable manufacturing by minimizing resource use, waste, and pollutants.

The Fundamentals of Nanomachines in Chemical Manufacturing

Nanomachines are tiny devices that operate at the molecular level, revolutionizing how chemical manufacturing is approached. They work by harnessing molecular mechanisms to perform specific tasks, such as assembling or transforming molecules with precision. Understanding these mechanisms is vital for designing effective nanomachines. Fabrication techniques play an essential role in constructing these devices, enabling you to manipulate materials at an atomic scale. Techniques like chemical vapor deposition, electron beam lithography, and self-assembly allow you to create complex structures with high accuracy. These methods guarantee that nanomachines are reliable and functional for targeted chemical processes. By mastering the molecular mechanisms and fabrication techniques, you can develop sophisticated nanomachines that pave the way for more efficient and innovative chemical manufacturing at the nano scale. Additionally, recent advancements in precision engineering have significantly improved the reliability and scalability of nanomachines for industrial applications.

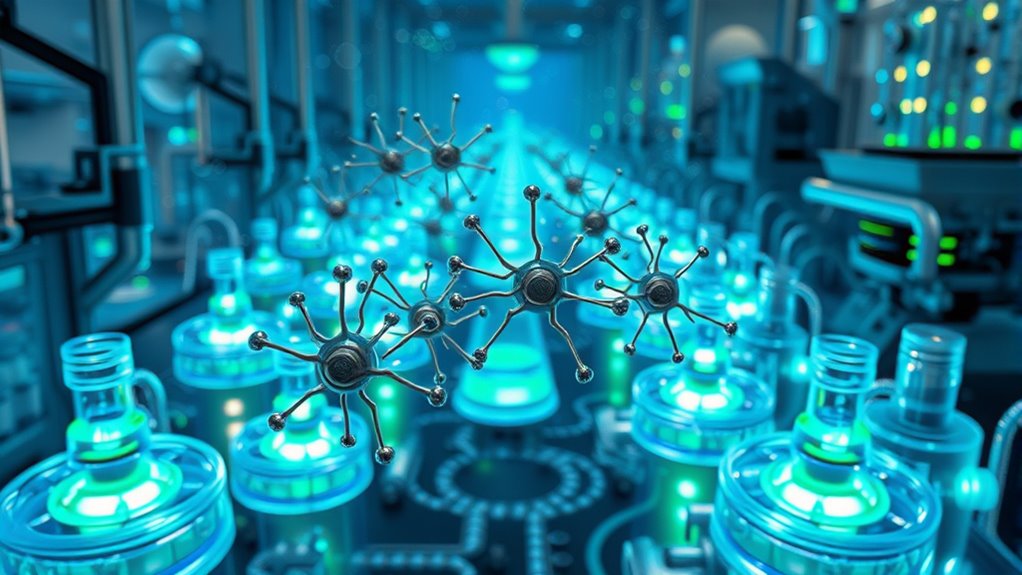

How Nanomachines Enable Precise On‑Demand Synthesis

Thanks to their ability to operate at the molecular level, nanomachines enable you to synthesize chemical compounds precisely when and where you need them. They achieve this through exceptional molecular control, guiding reactions with high accuracy. This control ensures reaction specificity, so unwanted byproducts are minimized, and target compounds are produced efficiently. You can program nanomachines to activate only under specific conditions, allowing on-demand synthesis tailored to your needs. This precision reduces waste, enhances safety, and accelerates production timelines. The table below highlights key aspects of how nanomachines facilitate this process: molecular control.

Benefits of Nano‑Scale Production in Industry

The ability of nanomachines to enable precise, on-demand chemical synthesis directly impacts industrial production processes. With nanoscale control, you can achieve highly efficient molecular assembly, reducing waste and energy consumption. This precision allows for the creation of complex materials and compounds that were previously difficult or impossible to produce at scale. By controlling reactions at the molecular level, you can enhance product quality and consistency. Nano‑scale production also accelerates development cycles, enabling rapid prototyping and customization. Additionally, it minimizes the need for large, resource-intensive manufacturing facilities, lowering costs and environmental footprints. Overall, this technology offers a transformative approach, making industry more agile, sustainable, and capable of meeting specialized demands through precise, scalable molecular assembly. Understanding nanomanufacturing can help illuminate how these innovations are shaping future industry capabilities.

Challenges and Limitations of Using Nanomachines

Despite their promising potential, deploying nanomachines in industrial settings presents significant challenges. Scalability issues make it difficult to produce nanomachines in large quantities reliably, hindering mass adoption. Fabrication challenges also persist, as creating precise, functional nanodevices at scale remains complex and costly. You must consider these limitations when planning implementation. The table below highlights key hurdles:

| Challenge | Impact | Possible Solutions |

|---|---|---|

| Scalability issues | Limited production and deployment | Advanced manufacturing techniques |

| Fabrication challenges | Inconsistent nanomachine quality | Improved precision fabrication methods |

| Cost | High development expenses | Economies of scale and innovation |

| Integration | Difficult system integration | Modular design approaches |

Overcoming these issues is vital for practical, widespread use. Understanding the complexities of nanomachine fabrication is essential for advancing their industrial applications.

Future Perspectives: Innovations and Potential Developments

Advancements in nanotechnology are rapidly opening new possibilities for nanomachines in chemical factories. Quantum integration will enable these machines to process and analyze data at unprecedented speeds, leading to more precise control over synthesis processes. This integration could also enhance energy efficiency and reduce errors during reactions. Meanwhile, AI optimization will play a pivotal role in designing smarter nanomachines that adapt in real-time, improving performance and scalability. You can expect future developments to focus on seamless coordination between nanomachines, enabling complex, multi-step reactions with minimal human intervention. These innovations will drive faster production, higher purity, and more versatile on-demand synthesis. As these technologies evolve, you’ll see a shift toward autonomous, highly efficient systems that revolutionize chemical manufacturing at the nano scale. Additionally, the development of Breakthrough Technologies in 2024 will further accelerate these advancements, integrating cutting-edge innovations into nanomachine applications.

Impact on Sustainability and Environmental Considerations

Nanomachines can markedly reduce waste and lower energy use in chemical production, making processes more sustainable. By minimizing chemical footprints, they help lessen environmental impact and resource depletion. As you explore these innovations, you’ll see how they contribute to a cleaner, more efficient industry. Incorporating advanced composition techniques can further optimize their performance and integration into existing systems.

Reduced Waste Generation

By integrating nanomachines into chemical manufacturing processes, factories can substantially cut down on waste production. Their high nanomachine efficiency allows for precise control over reactions, minimizing by-products and reducing the chemical footprint. This targeted synthesis means fewer excess reagents are used, and unwanted waste is considerably lowered. As a result, waste management becomes simpler, and environmental impact diminishes. The ability of nanomachines to operate with accuracy at the nano scale ensures that reactions proceed with minimal waste, promoting cleaner production methods. This reduction in waste not only benefits the environment but also enhances process sustainability and cost-effectiveness, making nanomachine-enabled manufacturing a promising avenue for greener, more efficient chemical production.

Lower Energy Consumption

Implementing nanomachines in chemical factories considerably reduces energy consumption, leading to more sustainable operations. By enhancing molecular assembly precision, these nanomachines minimize energy waste during synthesis. Their targeted approach ensures reactions occur only where needed, boosting energy efficiency. Consider these impacts:

- Reduced Power Usage: Nanomachines optimize reaction pathways, cutting down unnecessary energy input.

- Faster Processing: Precise molecular assembly accelerates production, lowering overall energy demands.

- Lower Cooling Needs: Less heat is generated, decreasing energy required for cooling systems.

This synergy of advanced molecular assembly and improved energy efficiency makes nanomachines an essential tool for environmentally conscious manufacturing, helping reduce the carbon footprint and conserve resources.

Minimized Chemical Footprints

As nanomachines enable more precise control over chemical reactions, they considerably reduce the need for excess reagents and hazardous substances. This efficiency stems from optimized nanomachine design, which allows for targeted molecular assembly, minimizing waste and byproducts. By controlling reactions at the nanoscale, you lower the environmental impact of chemical processes, reducing emissions and contaminated effluents. The ability to synthesize chemicals on-demand means fewer stockpiles and less risk of spills or leaks. Overall, these advancements support sustainability by decreasing resource consumption and pollutant generation. You can achieve cleaner production methods that align with environmental standards, making nanomachines pivotal in reducing chemical footprints and fostering greener industrial practices.

Frequently Asked Questions

How Do Nanomachines Communicate Within a Manufacturing System?

You’ll find nanomachines communicate through molecular signaling, where they send and receive chemical messages to coordinate actions. They follow specific communication protocols that guarantee messages are accurately interpreted, enabling efficient collaboration. This system allows nanomachines to synchronize their tasks, adapt to changing conditions, and maintain precise control over synthesis processes. By using molecular signaling and communication protocols, you create a highly responsive, autonomous nano-scale manufacturing environment.

What Safety Protocols Are Necessary for Nanomachine Operation?

Think of nanomachine safety like guarding a delicate garden. You must implement containment strategies to prevent accidental release, just as a gardener shields fragile plants. You also need to address biological hazards by using protective gear and sterilization protocols. Regular monitoring, fail-safe shutdowns, and strict access controls become your tools to guarantee safe operation. Stay vigilant, and treat these tiny machines as if they hold the power to reshape your world.

Can Nanomachines Repair Themselves During Synthesis Processes?

Yes, nanomachines can repair themselves during synthesis processes. They incorporate self-repair mechanisms and error correction protocols that detect and fix malfunctions or damages in real time. This guarantees continuous operation and high precision. By actively monitoring their functions, they maintain efficiency, prevent errors from accumulating, and adapt to changing conditions, making the synthesis process more reliable and safe.

How Are Nanomachines Powered at the Nano Scale?

You power nanomachines at the nano scale through molecular energy and quantum charging. Molecular energy supplies the necessary power by harnessing chemical reactions or ambient vibrations, while quantum charging involves transferring energy at the atomic or subatomic level using quantum states. These methods enable nanomachines to operate efficiently, perform precise tasks, and sustain themselves during synthesis processes without bulky batteries or external power sources.

What Are the Potential Risks of Nanomachine Malfunction?

You face risks from nanomachine failures, which can cause unintended reactions if the machines malfunction or lose control. These failures could lead to harmful chemical releases, contamination, or damage to surrounding environments. If nanomachines don’t operate correctly, they might produce unpredictable results, potentially endangering health and safety. Vigilant monitoring and robust safety protocols are essential to guarantee these risks and ensure safe, precise operation at the nano scale.

Conclusion

By embracing nanomachines in chemical factories, you can achieve precise, on-demand synthesis, reducing waste and energy use. Some might worry about safety risks, but visualize a tiny, controlled factory working seamlessly at the nano level—making complex compounds efficiently. This innovation not only streamlines production but also promotes sustainability. As you see, nanomachines could revolutionize industry, transforming how you produce chemicals while protecting the environment.