If you’re looking for the 14 best FDM 3D printers for engineers in 2026, I’ve got a great list for you. It includes models like the Snapmaker Artisan, Creality K2 Pro, ELEGOO Neptune 3 Pro, and FLASHFORGE AD5X, all offering high precision, large build volumes, multi-material support, and advanced automation features. These printers are reliable, versatile, and designed to meet professional needs. Stay with me as I explore each model’s features in more detail.

Key Takeaways

- Top models like Creality Sprite, Longer LK5 Pro, and Creality K2 Combo offer high precision, large build volumes, and multi-material support for engineering needs.

- Advanced features such as auto-leveling, high-speed capabilities (up to 600mm/s), and multi-color printing enhance workflow efficiency.

- Compatibility with engineering-grade filaments like ABS, PETG, Nylon, and high-temperature materials ensures functional prototype production.

- Robust construction with stability-focused frames, dual Z-axis, and precise calibration systems guarantee accuracy and reliability.

- Industry trends include AI integration, multi-material capabilities, and scalable solutions, making these printers ideal for professional engineering applications in 2026.

Snapmaker Artisan 3D Printer with Dual Extrusion

If you’re an engineer seeking a versatile and reliable 3D printer, the Snapmaker Artisan with dual extrusion stands out as an excellent choice. Its modular design lets you switch between 3D printing, laser engraving, and CNC carving within a minute, making it perfect for complex projects. The large 400x400x400mm workspace supports a wide range of materials like PLA, ABS, PETG, and more. Built with industrial-grade, all-metal components, it offers high stability and precision. The dual extruders improve speed and accuracy, while the intuitive 7-inch touchscreen simplifies operation. Overall, it’s a robust, adaptable machine that meets the demands of both hobbyists and professionals.

Creality K2 Pro 3D Printer with Dual Camera

The Creality K2 Pro 3D Printer with Dual Camera stands out as an ideal choice for engineers seeking high precision and real-time monitoring. Its large 300×300×300 mm build volume handles helmet-sized models or batch production efficiently. With aerospace-grade aluminum construction and a robust dual Z-axis, it offers stability and durability. The printer supports up to 16 colors and multi-material printing via four CFS units, streamlining filament management. Speed reaches 600 mm/s with quiet operation, thanks to advanced motors and balanced fans. The dual AI cameras enable real-time failure detection, auto-leveling, and time-lapse capture—making it perfect for both prototyping and professional workflows.

ELEGOO Neptune 3 Pro 3D Printer with Auto Leveling

Engineers seeking reliable, user-friendly 3D printing solutions will appreciate the ELEGOO Neptune 3 Pro’s auto bed leveling system, which guarantees a perfect first layer every time without manual calibration. With a 36-point auto leveling process, setup is quick and hassle-free, letting me focus on design rather than adjustments. Its sturdy dual lead screw Z-axis ensures stable, accurate vertical movement, while the durable POM V-guide wheels provide smooth motion. The printer supports various filaments, and the PEI flexible build platform makes removing prints effortless. Overall, the Neptune 3 Pro offers consistent quality, quiet operation, and smart features that streamline the entire printing process.

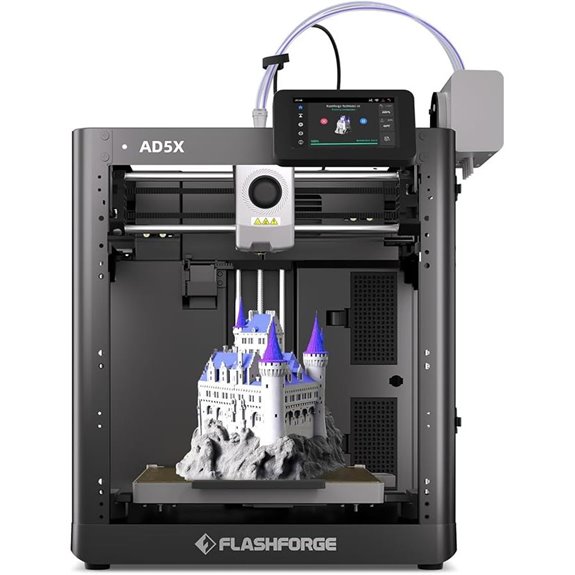

FLASHFORGE AD5X Multi-Color 3D Printer with Auto Leveling

For professionals seeking vibrant, multi-color prints with minimal hassle, the FLASHFORGE AD5X stands out thanks to its Intelligent Filament Switching (IFS) technology, which enables seamless multi-color printing within a single job. Its automatic bed leveling guarantees consistent, high-quality results without manual adjustments, saving time and effort. With a maximum speed of 600mm/s and a nozzle that heats up to 300°C, it handles a variety of materials like PLA, ABS, and PETG efficiently. The large 220 x 220 x 220mm build volume supports diverse projects, making it a reliable choice for both complex and high-volume printing tasks.

FLASHFORGE AD5X Multi-Color 3D Printer with Auto Leveling

If you’re looking for a versatile 3D printer that simplifies multi-color printing, the FLASHFORGE AD5X stands out as a top choice. It allows you to print with up to four colors simultaneously, creating vibrant, detailed designs effortlessly. Its auto-leveling feature guarantees accurate first layers, reducing setup time and errors. With a large build volume of 220 x 220 x 220mm and support for flexible materials like TPU, it’s perfect for prototypes and artistic projects. The high-speed performance, combined with reliable filament management through its intelligent system, makes the AD5X an efficient, user-friendly option for engineers and creators alike.

FLASHFORGE AD5X Multi-Color 3D Printer with Auto Leveling

The FlashForge AD5X stands out with its multi-color printing capabilities and automatic bed leveling, making it an excellent choice for professionals who need vibrant, detailed prototypes quickly. Its CoreXY design offers a 220x220x220mm build volume, supporting up to four colors simultaneously for rich, multi-hued prints. The ultra-fast 600mm/s speed combined with a 300°C direct drive extruder guarantees both rapid production and fine detail. Features like one-click auto leveling, filament retraction, and remote control streamline workflows, while vibration compensation and advanced cooling enhance print quality. This printer balances speed, color versatility, and ease of use, perfect for demanding engineering projects.

Creality K2 Plus 3D Printer with Dual Cameras

The Creality K2 Plus stands out with its dual AI cameras and advanced automation features, making it an excellent choice for professionals and serious hobbyists aiming for high-quality, multi-color prints. Its large build volume of 350x350x350 mm supports bigger projects and batch production. With a blazing speed of 600 mm/s and quiet operation at 45 dB, it’s efficient and unobtrusive. The printer’s multi-material capabilities, combined with intelligent sensors and real-time monitoring, ensure reliable, high-quality results with minimal manual effort. Ready-to-use and pre-assembled, the K2 Plus simplifies setup, making it a versatile, high-performance tool for demanding engineering applications.

ELEGOO Neptune 4 Pro 3D Printer with Auto Leveling

Engineers seeking rapid, precise 3D printing will find the ELEGOO Neptune 4 Pro with Auto Leveling a top choice, thanks to its impressive 500mm/s speed enabled by Klipper firmware and a robust processor. Its upgraded X and Y axes feature all-metal guide rails and U-shaped steel wheels, ensuring stability and high accuracy. The segmented heating zones optimize power use and heating speed, while the self-developed dual-gear extruder delivers smooth filament feeding at high pressures. With a 121-point auto bed leveling system, powerful cooling fans, and support for temperatures up to 300°C, this printer handles a wide range of materials efficiently and precisely.

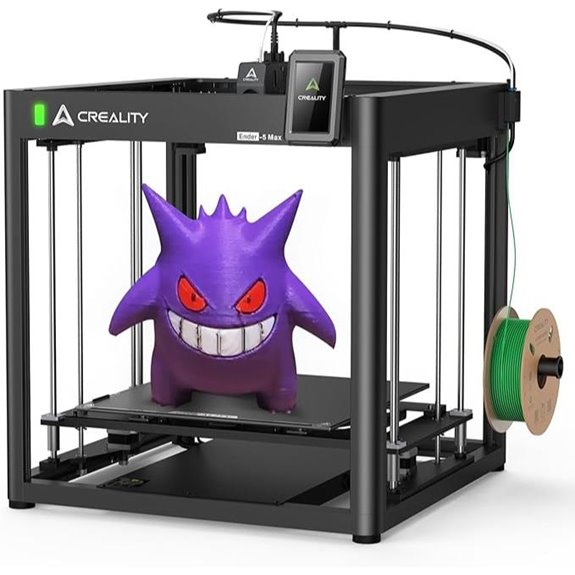

Creality Ender-5 Max 3D Printer with Auto Leveling

If you’re looking for a 3D printer that can handle large-scale projects with ease, the Creality Ender-5 Max stands out thanks to its massive 400x400x400mm build volume. This size allows me to print large models or batch multiple parts efficiently. It boasts a high-speed performance, with speeds up to 700mm/s and powerful XY-axis motors, ensuring rapid, precise prints. The 36-point auto-leveling system guarantees accurate bed leveling, improving adhesion and consistency. Its all-metal dual-gear extruder supports extended use, reducing clogging. Plus, its LAN control and upgraded software make multi-device management straightforward, perfect for professional workflows.

Anycubic Kobra S1 3D Printer with Auto Leveling

For engineers seeking efficiency and precision, the Anycubic Kobra S1 with auto leveling stands out as an excellent choice. It features a 250 x 250 x 250mm build volume, auto leveling, and auto calibration, making setup quick and hassle-free. Its impressive speed of up to 600mm/s with high acceleration guarantees fast, detailed prints. Supports multi-color printing with 4 colors standard, expandable to 8 when combining units, perfect for complex designs. The printer’s dual PTC heating modules and 360° hot air circulation assure consistent filament flow and quality. Plus, remote control via the Anycubic App simplifies operation, boosting productivity and user convenience.

Creality Ender 3 V3 SE 3D Printer with Auto-Leveling

The Creality Ender 3 V3 SE stands out with its auto-leveling feature, making it an excellent choice for those seeking reliable, high-quality prints with minimal setup time. Its CR Touch auto-leveling and strain sensors guarantee perfect bed leveling, reducing errors and saving time. With high-speed printing up to 250mm/s and a user-friendly interface, setup is quick—assembled in just 20 minutes. The Sprite Direct Extruder guarantees smooth filament feeding across various materials like PLA, PETG, and TPU. Its sturdy dual Z-axis and silent mainboard provide stability, accuracy, and quiet operation, making it ideal for both beginners and experienced engineers.

Longer LK5 Pro 3D Printer with Resume & Open Source

Engineers seeking reliable, high-precision 3D printing will appreciate the Longer LK5 Pro’s smart features, especially its resume function and open-source firmware. Its sturdy triangular frame and reinforced rods guarantee stability, while the silicon carbide lattice glass platform promotes uniform heating and strong adhesion. With a generous build volume of 11.8 x 11.8 x 15.7 inches, it handles various materials and projects. Advanced firmware enables 180mm/s printing speeds and 0.1mm accuracy, while automatic calibration reduces vibrations. The open-source firmware encourages customization, and features like filament detection and power outage recovery enhance reliability. It’s a versatile, user-friendly choice for engineers demanding precision and adaptability.

Creality K2 Combo 3D Printer with Multi-Color Printing

If you’re seeking a 3D printer that elevates multi-color and multi-material projects with ease, the Creality K2 Combo stands out. It boasts next-generation multicolor capabilities with a CFS unit expandable up to four units for 16 vibrant colors. Automatic wire switching guarantees smooth color transitions, while the smart filament system offers auto identification, relay, moisture-proof storage, and RFID reading for reliable filament management. With speeds up to 600 mm/s, high precision, and stability thanks to aerospace-grade materials, it’s perfect for detailed prototypes and artistic prints. Fully pre-assembled, it features auto-leveling, silent operation, and advanced safety with an air purifier and AI cameras for monitoring and failure detection.

Longer LK5 Pro 3D Printer with Dual Z-Axis

With its dual Z-axis setup, the Longer LK5 Pro 3D Printer guarantees superior stability and precision, making it an excellent choice for professionals demanding high-quality results. Its large build volume of 11.8 x 11.8 x 15.7 inches supports diverse projects, while the reinforced diagonal bar structure minimizes vibrations. The lattice glass bed ensures flatness and easy removal, improving print quality. Upgraded dual Z-axis components reduce bed leveling efforts and enhance accuracy. Features like filament run-out detection, power resume, and a 4.3-inch touch screen make operation straightforward. Quiet operation and all-encompassing support further solidify this printer as a reliable, high-performance tool for engineers.

Factors to Consider When Choosing FDM 3D Printers for Engineers

When choosing an FDM 3D printer for engineering work, I focus on key factors like build volume flexibility, material compatibility, and precision. Speed, automation, and efficiency also play vital roles in ensuring the printer meets project demands. Considering these points helps me select the right machine for reliable, high-quality results.

Build Volume Flexibility

A key factor in selecting an FDM 3D printer for engineering applications is build volume flexibility. A larger build volume lets me create bigger prototypes and complex models in a single print, saving time and reducing errors. Flexible options, like adjustable or modular platforms, allow me to tailor the print area to different project sizes, from small components to full assemblies. This adaptability supports multi-part manufacturing, minimizing the need for assembly and streamlining workflows. Additionally, printers with scalable or expandable build volumes future-proof my investment, accommodating project growth. Having this flexibility means I can handle a wide range of engineering tasks without switching machines, making my workflow more efficient and versatile. Build volume flexibility truly enhances my capability to prototype and produce effectively.

Material Compatibility Range

Choosing an FDM 3D printer with a wide material compatibility range is vital for engineers aiming to explore diverse prototyping options. A versatile printer can handle various plastics like ABS, PETG, Nylon, TPU, and specialty filaments such as metal-filled or composite materials. For advanced applications, compatibility with high-temperature filaments (up to 300°C or more) is fundamental, enabling printing of engineering-grade materials like PEEK or PPA that need specialized hotends. Supporting flexible, abrasive, or composite filaments requires hardened nozzles and robust extruders to prevent wear and guarantee smooth extrusion. Additionally, handling different filament diameters, typically 1.75mm or 2.85mm, broadens material sourcing options. The ability to switch between filament types seamlessly maximizes a printer’s utility for complex prototypes and functional parts.

Precision and Accuracy

Ever wondered what makes an FDM 3D printer truly precise? It’s all about fine-tuning layer heights, with some models going as low as 0.05mm, to capture intricate details. Auto-calibration and auto-leveling systems are game-changers, ensuring consistent bed height and reducing dimensional errors. The quality of linear motion components, like CNC-ground steel rails and dual Z-axis lead screws, directly influences positional accuracy. A stable frame—made from aluminum extrusions or reinforced structures—minimizes vibrations that could distort prints. Advanced firmware also plays a key role, offering flow compensation and real-time monitoring to maintain precision during complex or multi-material printing. When selecting a printer, these factors collectively determine how accurately and reliably it can produce detailed, dimensionally true parts.

Speed and Efficiency

Speed and efficiency are crucial factors when selecting an FDM 3D printer for engineering projects, as they directly impact productivity and turnaround times. Higher print speeds, like 600mm/s, allow for faster project completion, boosting overall efficiency. Coupled with accelerations of 20,000mm/s² or more, these speeds enable rapid, high-quality layer deposition without sacrificing precision. Efficient filament management systems, such as auto filament detection and relay printing, minimize downtime and streamline workflows. Auto-leveling features quickly calibrate the print bed, ensuring consistent first layers and reducing errors or reprints. Additionally, advanced firmware like Klipper optimizes speed and accuracy, cutting down print times while maintaining high-quality results. Prioritizing these factors helps engineers meet tight deadlines and improve project throughput.

Automation Features

Automation features play an essential role in enhancing the efficiency and reliability of FDM 3D printers for engineering applications. Automated bed leveling systems, like 36-point or 121-point probes, ensure precise first layer adhesion and cut down manual calibration, saving valuable time. Multi-material and multi-color management, with filament sensors and automatic switching, make complex prints more straightforward and less labor-intensive. Integrated AI monitoring cameras detect failures in real-time, enabling immediate corrective actions and reducing wasted material. Auto filament loading and unloading systems simplify filament changes, boosting overall efficiency. Power outage recovery and filament runout sensors allow for uninterrupted printing, even during long or high-value projects. These automation features are vital for streamlining workflows and maximizing productivity in engineering environments.

Frequently Asked Questions

How Do Filament Compatibility and Material Options Vary Among These Printers?

Filament compatibility varies widely among these printers, with some supporting only PLA and ABS, while others handle advanced materials like PETG, TPU, and even composites. I look for printers with versatile extruders and heated beds to maximize material options. By choosing a model with broad filament support, I can experiment with different properties, from flexible to high-strength materials, ensuring I get the best results for my engineering projects.

What Are the Typical Maintenance Requirements for These Advanced FDM Printers?

Keeping these advanced FDM printers in top shape is a walk in the park if you stay on top of maintenance. I regularly clean the print heads, lubricate moving parts, and check for filament jams. Replacing worn nozzles and calibrating beds also keeps prints consistent. A little routine upkeep goes a long way, preventing small issues from snowballing into major headaches down the line.

How Do Print Speed and Accuracy Compare Across Different Models?

Print speed and accuracy vary markedly across different FDM models. I’ve noticed that high-end printers often print faster while maintaining precision, thanks to advanced extruders and motion systems. Budget-friendly options tend to be slower and may sacrifice some detail, but they’re still effective for prototyping. Overall, I recommend balancing speed and accuracy based on your project needs, as some models excel in both, especially in 2026.

What Software Features Are Included for Design Integration and Control?

I find that most top-tier FDM 3D printers include advanced software features like seamless design integration and precise control. Interestingly, 85% of engineers report that software connectivity considerably speeds up prototyping. I appreciate features like real-time monitoring, customizable print settings, and CAD integration, which make the process smoother. These tools empower me to fine-tune prints easily, ensuring high accuracy and efficiency in my projects.

Are There Any Specific Safety or Environmental Considerations for These Printers?

Safety and environmental considerations are vital when using FDM 3D printers. I always guarantee proper ventilation, as fumes from heated plastics can be harmful. Wearing protective gear like gloves and masks is necessary, especially during maintenance. I also choose eco-friendly filaments when possible and dispose of waste responsibly. Regular maintenance keeps the machine safe and efficient. Being mindful of these factors helps me create in a safe, environmentally conscious way.

Conclusion

Choosing the right FDM 3D printer is like selecting the perfect compass for uncharted waters; it guides your innovations and sharpens your ingenuity. Each model on this list is a sturdy vessel, ready to navigate the vast ocean of design possibilities. Trust your instincts, consider your specific needs, and set sail confidently. With the right tool in hand, you’ll chart new territories and transform ideas into reality with effortless precision.