If you’re looking for the 13 best microfluidic flow controllers, I recommend focusing on units with precise flow management, durable materials like PDMS or stainless steel, and versatile interfaces such as RS485 or 4-20mA outputs. Features like real-time LCD display, adjustable flow rates, and compatibility with various fluids are essential for accuracy. I’ll guide you through options that combine reliable performance with easy integration, so stay tuned to discover devices that meet your microfluidic needs effortlessly.

Key Takeaways

- Select flow controllers with adjustable flow rates up to 2 ml/min for accurate microfluidic applications.

- Prioritize devices made from durable, chemically resistant materials like PDMS, glass, or PTFE for longevity.

- Ensure compatibility with system interfaces, including electrical outputs (4-20mA, RS485) for seamless integration.

- Opt for compact, reliable units with precise control features and stability under varying operational conditions.

- Consider customizable options and single-use designs that can be rinsed for repeated, precise fluid management.

Digital LCD Water Control System with Flow Sensor and Solenoid Valve, 24V

If you’re looking for precise and automated flow control, the Digital LCD Water Control System with Flow Sensor and Solenoid Valve, 24V is an excellent choice. This system features a clear 3-inch LCD screen that displays flow rate, total flow, and temperature, making monitoring straightforward. It can set and manage specific flow amounts, automatically shutting off or triggering alarms when limits are reached. Its compact design allows easy installation in various environments, and it operates reliably with a wide voltage range. Perfect for industrial or laboratory settings, it ensures accurate, hands-free control of liquids and gases during complex processes.

Best For: users in industrial, pharmaceutical, chemical, or food processing sectors seeking precise, automated liquid and gas flow management with easy monitoring and control.

Pros:

- Clear 3-inch LCD display for real-time monitoring of flow rate, total flow, and temperature

- Automated flow control with preset thresholds and alarms, ensuring accurate batch processing

- Compact and flexible design allows easy installation in various environments

Cons:

- Requires proper calibration and system understanding for optimal performance

- Minor discrepancies in dosage may occur due to system delays or calibration issues

- Limited flow range (1-30 L/min), which may not suit very high flow applications

Brand accu-Jet S Pipette Controller (Anthracite)

The Brand accu-Jet S Pipette Controller (Anthracite) is an excellent choice for laboratories that require precise and effortless control when aspirating and dispensing small volumes. It offers fine motor speed adjustment with one hand, ensuring exceptional accuracy across a range of pipettes from 0.1 mL to 200 mL. Capable of filling a 25 mL pipette in about three seconds at maximum speed, it balances speed with precision. The lightweight, ergonomic design reduces hand fatigue, making it comfortable during extended use. With up to 8 hours of battery life, fast recharge, and a clear LED indicator, it’s reliable and user-friendly for demanding lab environments.

Best For: laboratories that require precise, effortless control for aspirating and dispensing small to medium volumes with minimal hand fatigue.

Pros:

- Enables fine motor speed adjustment with one hand for high accuracy

- Lightweight and ergonomic design reduces hand fatigue during extended use

- Up to 8 hours of continuous operation with fast recharge and clear battery indicator

Cons:

- May be less suitable for extremely high-volume pipetting tasks outside its range

- Requires regular charging for continuous use over multiple days

- Compatibility limited to pipettes from 0.1 mL to 200 mL; not suitable for larger or specialized pipettes

FM-PS2130 Micro Optical Flow Sensor (3 Pack)

For those seeking compact and reliable flow measurement solutions, the FM-PS2130 Micro Optical Flow Sensor (3 Pack) stands out because of its small size and straightforward installation. Designed for liquid dispensers, this pack includes three units that offer versatile, high-precision measurement within a flow range of 30-150 ml/min. They efficiently measure flow rate, speed, and volume changes, making them ideal for volumetric and velocity assessments. Thanks to advanced algorithms, these sensors adapt dynamically to flow variations, ensuring accuracy without gap compensation. With a long lifespan, high repeatability, and a one-year warranty, they deliver dependable performance for long-term fluid management applications.

Best For: those seeking compact, high-precision flow measurement solutions for liquid dispensers and fluid management systems.

Pros:

- Small size and easy to install, saving space and simplifying setup

- High accuracy and repeatability for reliable flow measurement

- Dynamic algorithms adapt to flow variations, ensuring consistent performance

Cons:

- Nonlinear signal output may require calibration for specific applications

- Limited flow range (30-150 ml/min) may not suit very high or low flow needs

- Requires electronic integration and proper setup to maximize measurement accuracy

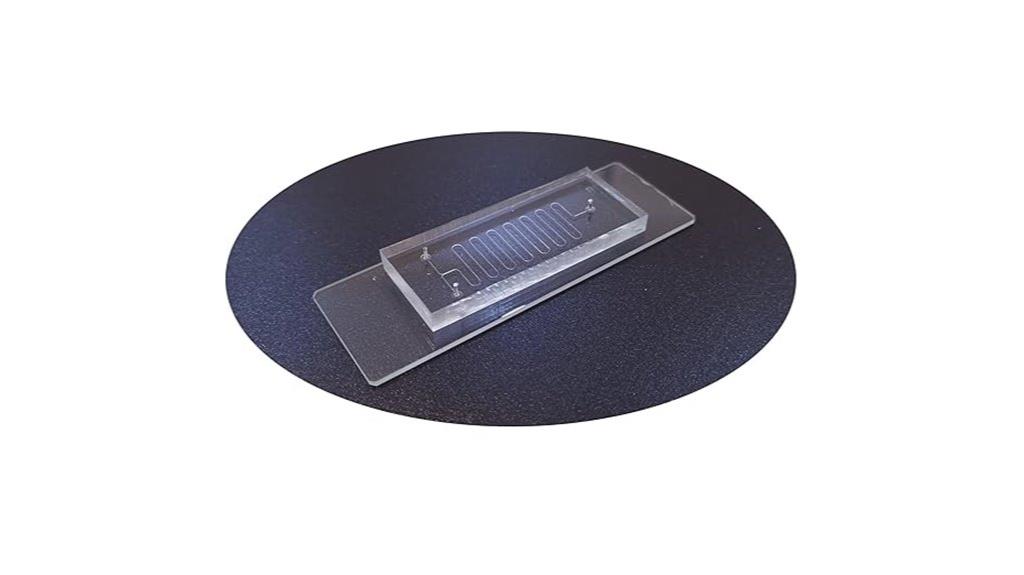

Standard PDMS Microfluidic Chip for Fluid Control Systems

A standard PDMS microfluidic chip with a precise 100 µm channel depth offers reliable fluid control for research and industrial applications. Its design ensures consistent flow and minimizes leaks, thanks to secure plasma-bonded packaging with glass slides. With a maximum injection pressure of 2 bar and a flow rate of 2 ml/min, it maintains chip integrity during experiments. Intended for single-use, it’s easy to rinse with alcohol or water for safe disposal or reuse. Customizable options are available to meet specific needs, making it versatile for fluid management, laminar flow studies, and biochip development. Overall, it provides dependable performance in demanding microfluidic environments.

Best For: researchers and industrial professionals needing reliable, precise microfluidic control for fluid management, laminar flow experiments, or biochip development.

Pros:

- Precise channel depth of 100 µm for consistent flow control

- Secure plasma bonding with glass slides ensures durability and leak prevention

- Suitable for single-use applications with easy rinsing for disposal or reuse

Cons:

- Designed for single-use, limiting long-term or repeated applications

- Priced per chip, which may increase costs for large-scale projects

- Customization options might require additional consultation and lead time

LF6000 Water Microfluidic Flow Meter with LCD Display

If you need precise flow measurement for water or similar liquids, the LF6000 Water Microfluidic Flow Meter with LCD display stands out as an ideal choice. It measures flow rates from 0 to 400 mL/min with an accuracy of ±(2+0.5FS)%, making it suitable for applications demanding high precision. Its 3/4-inch joint pipe bore and NPT connection ensure easy integration into existing setups. Designed for a wide working temperature range (-10°C to +55°C) and powered by 3.6-6V DC, it features RS485 and 4-20mA outputs for versatile data transmission. Compact and reliable, it’s perfect for industrial, food, and semiconductor fluid control needs.

Best For: industrial, food processing, semiconductor, and water measurement professionals seeking high-precision, reliable flow monitoring solutions.

Pros:

- High accuracy with ±(2+0.5FS)% measurement precision.

- Wide flow range (0-400 mL/min) suitable for various applications.

- Versatile output options (RS485 and 4-20mA) for easy integration.

Cons:

- Limited to water and similar liquids; not suitable for highly viscous fluids.

- Physical dimensions may be bulky for very compact setups.

- Requires power supply of 3.6-6V DC, which may necessitate additional power management.

Tylan FM-3901V-4S Flow Controller 50 SCCM

The Tylan FM-3901V-4S Flow Controller 50 SCCM stands out as an excellent choice for laboratories and industrial settings requiring precise regulation of small fluid flows. It’s designed to regulate flow at 50 SCCM, making it ideal for applications needing accurate, steady fluid delivery. Its compact size (23 x 16 x 18 inches) and lightweight (5 pounds) make installation and handling straightforward. Manufactured by Tylan, it offers reliable performance backed by a warranty. Whether for research or production, this flow controller ensures consistent results, giving you confidence in your fluid management. It’s a dependable tool for achieving precise, controlled microfluidic flows.

Best For: laboratories and industrial settings requiring precise regulation of small fluid flows at 50 SCCM.

Pros:

- Accurate and steady flow regulation suitable for microfluidic applications

- Compact and lightweight design for easy installation and handling

- Reliable performance with manufacturer-backed warranty

Cons:

- Dimensions may still be sizable for very limited space setups

- Limited flow range (50 SCCM) may not suit all applications

- Requires proper calibration and maintenance for optimal performance

Microfluidics BioChip Laminar Flow PDMS Chip

Designed for precise fluid control in research and laboratory settings, the Microfluidics BioChip Laminar Flow PDMS Chip features a 100 µm channel depth that supports consistent laminar flow. Made with PDMS bonded to glass slides through advanced plasma bonding, it ensures durability and reliable performance during experiments. This single-use chip is ideal for experiments requiring steady flow rates, supporting up to 2 ml/min at a maximum pressure of 2 bar. To maintain performance, rinse with alcohol or water if reuse is needed. Custom options are available for tailored designs, making this chip a versatile choice for controlled microfluidic applications.

Best For: researchers and laboratory professionals requiring precise, reliable, and customizable microfluidic control for experimental applications.

Pros:

- Ensures consistent laminar flow with a 100 µm channel depth for accurate fluid manipulation.

- Made with durable PDMS bonded to glass, offering reliable performance and longevity during experiments.

- Customization options available to tailor the chip design to specific research needs.

Cons:

- Intended for single-use; reuse requires careful rinsing to prevent contamination.

- Limited maximum pressure of 2 bar, which may not suit high-pressure applications.

- Flow rate is capped at 2 ml/min, potentially limiting use in high-volume experiments.

LM1109 Water Microfluidic Flow Meter (4-20mA Output, 0-50L/Min)

For professionals needing precise microfluidic flow measurement, the LM1109 Water Microfluidic Flow Meter stands out with its high accuracy and versatile output options. It measures flows from 0 to 50 liters per minute, supporting a wide range of industrial applications. Its 4-20mA output provides reliable signals for integration into control systems, while compatibility with gases broadens its utility. Whether monitoring small or large flow rates, this meter delivers consistent performance across industries like semiconductor manufacturing and food processing. Its flexibility and precision make it an essential tool for ensuring accurate fluid management in complex microfluidic setups.

Best For: professionals requiring precise and versatile microfluidic flow measurement across a wide range of industrial applications, including gases and liquids.

Pros:

- High accuracy measurements suitable for microfluidic applications

- Multiple output options (analog and digital) for seamless system integration

- Wide measurement range (0-50L/min) accommodating diverse flow rates

Cons:

- May require calibration for specific gases or liquids to ensure optimal performance

- Potentially higher cost compared to simpler flow meters

- Complex setup may need technical expertise for proper installation and configuration

Tylan FM-3901V-4V Flow Controller 50 SCCM

If you’re seeking precise flow control at a compact size, the Tylan FM-3901V-4V Flow Controller with a 50 SCCM capacity stands out as an excellent choice. Its small package dimensions—just over 9 by 7 inches—make it easy to integrate into tight spaces. Manufactured by Tylan, this model offers reliable performance for microfluidic applications. It includes a warranty for added peace of mind, and customer feedback highlights its accuracy and durability. Whether you’re working on research or industrial projects, this flow controller provides precise fluid management in a user-friendly package. Overall, it’s a dependable solution for controlled microfluidic flow.

Best For: microfluidic researchers and industrial professionals seeking precise, reliable flow control in compact spaces.

Pros:

- Compact size for easy integration into tight environments

- Accurate and durable performance based on customer feedback

- Includes a product warranty for added peace of mind

Cons:

- Limited to a maximum flow rate of 50 SCCM, which may not suit high-flow applications

- No detailed specifications on compatibility with all fluid types

- Price may be higher compared to simpler flow control options

Microfluidics BioChip Laminar Flow Chip

The Microfluidics BioChip Laminar Flow Chip stands out as an ideal choice for laboratory professionals seeking precise fluid control in microfluidic applications. Made of PDMS, it features a 100-micrometer channel depth, perfect for controlled experiments. The chip is securely packaged with glass slides and plasma-bonded for durability. It’s designed for single use, with simple cleaning using alcohol or water to maintain performance. Excellent operation occurs with pure water at room temperature, supporting flow rates up to 2 ml/min and pressures up to 2 bar. Custom solutions are available to meet specific research needs, making this chip versatile and reliable for lab use.

Best For: laboratory researchers requiring precise and reliable microfluidic fluid control for experimental setups and fluid manipulation.

Pros:

- Provides accurate laminar flow control with a channel depth of 100 micrometers.

- Made of durable PDMS with plasma bonding for enhanced longevity and secure packaging.

- Easy to clean and maintain with simple rinsing using alcohol or water, suitable for single-use applications.

Cons:

- Designed primarily for single use; not intended for multiple or long-term applications.

- Price excludes accessories, which may increase total setup costs.

- Requires operation with pure water at room temperature and specific flow rates and pressures, limiting flexibility with other fluids or conditions.

Standard PDMS Microfluidic BioChip for Fluid Control Systems

When precision fluid control is critical in laboratory settings, the Standard PDMS Microfluidic BioChip stands out as an ideal choice. It features a 100 µm channel depth, ensuring accurate laminar flow management for various experiments. Manufactured with standard glass slides and bonded via plasma technology, it provides reliable, leak-proof seals. Its single-use design prevents cross-contamination and maintains performance. To keep the chip in excellent condition, I recommend rinsing with alcohol or water after each use. Operating best with pure water at room temperature and pressures up to 2 bar, this biochip offers consistent, precise fluid control tailored to laboratory needs.

Best For: researchers and laboratory professionals requiring precise, reliable microfluidic fluid control in experimental setups.

Pros:

- Ensures accurate laminar flow with 100 µm channel depth for high-precision applications

- Bonded with plasma technology for leak-proof and durable seals

- Single-use design minimizes cross-contamination and maintains performance

Cons:

- Limited to laboratory use; not suitable for industrial-scale applications

- Requires careful handling to avoid damage during rinsing and operation

- Price may vary depending on customization options and quantity needed

Microfluidics BioChip for Fluid Control System

For researchers seeking precise and reliable fluid control in laboratory applications, the Microfluidics BioChip offers an ideal solution. This PDMS LNP Chip features a 100-micron channel depth, enabling accurate management of fluids across various experiments. Constructed from durable PDMS bonded to glass slides via plasma bonding, it ensures consistent performance. Designed for single-use, it’s recommended to rinse with alcohol or water after each use to maintain functionality. Operating at a maximum injection pressure of 2 bar and flow rate of 2 ml/min, it provides reliable control within safe limits. Customization options are available, allowing tailored designs to meet specific research needs.

Best For: researchers and laboratory professionals requiring precise and reliable fluid control in microfluidic experiments.

Pros:

- Durable construction with PDMS bonded to glass for reliable performance

- Precise fluid management with 100-micron channel depth for accurate experiments

- Customizable designs to meet specific research needs

Cons:

- Intended for single-use, which may increase consumable costs

- Maximum operation limits (2 bar pressure, 2 ml/min flow rate) may restrict certain applications

- Requires careful handling and rinsing post-use to maintain functionality

Microfluidics PDMS BioChip Laminar Flow Chip

If you’re seeking precise fluid control in microfluidic applications, the Microfluidics PDMS BioChip Laminar Flow Chip stands out as an excellent choice. It features a 100 µm channel depth, designed for accurate laminar flow management. Made from flexible, biocompatible PDMS, it’s suitable for single-use, with rinsing recommended for reuse to preserve integrity. Packaged with glass slides bonded via plasma, it offers reliable performance within a 2 ml/min flow rate limit and 2 bar pressure. Proper handling and cleaning ensure ideal function. This chip’s customizable designs make it adaptable for various research and diagnostic needs, making it a versatile tool in microfluidics.

Best For: researchers and professionals requiring precise, biocompatible microfluidic control for single-use or experimental applications.

Pros:

- High precision with a 100 µm channel depth for laminar flow management

- Made from flexible, biocompatible PDMS suitable for sensitive biological samples

- Customizable designs available to meet specific research needs

Cons:

- Suitable primarily for single-use; cleaning for reuse may affect performance

- Pressure and flow rate limits (2 bar and 2 ml/min) may restrict some applications

- Handling and proper sealing are necessary to prevent leaks during operation

Factors to Consider When Choosing Microfluidic Flow Controllers

When selecting a microfluidic flow controller, I consider several key factors to guarantee peak performance. These include the flow rate range, compatibility with different liquids, and the level of control precision needed. Additionally, size, power requirements, and how well the device fits into my setup play vital roles in my decision-making process.

Flow Rate Range

Selecting the right microfluidic flow controller hinges on matching its flow rate range to your application’s specific needs. I consider whether I need to handle small volumes, like cell culture, or larger volumes, such as industrial processes. Flow rate ranges can vary from 0.1 mL/min to over 400 mL/min, so choosing a controller that fits within these limits is essential. A narrow range offers precise control for sensitive experiments, while a broader range suits general fluid management. Ensuring the flow rate range aligns with your system’s maximum and minimum requirements prevents underperformance or damage. Accurate selection helps optimize stability, measurement accuracy, and overall process control, making it a critical factor in achieving reliable, efficient fluid management in any microfluidic setup.

Compatibility With Liquids

Choosing a microfluidic flow controller that’s compatible with your liquids is essential for guaranteeing reliable operation and preventing damage. You need to verify that the controller can handle the specific fluids you plan to use, whether water, gases, or chemical solvents, to avoid corrosion or deterioration. Check the maximum injection pressure and flow rate limits to match your liquids’ viscosity and flow needs. It’s also important to confirm that the materials in the controller, like PDMS or metal alloys, are chemically resistant to your fluids. Additionally, ensure the sensors and measurement algorithms suit the physical properties of your liquids for accurate readings. Ultimately, confirm that the controller supports the output signals required for seamless integration with your liquid handling system.

Control Precision Level

Achieving precise control over flow rates is key to obtaining reliable results in microfluidic applications. To do this, I look for controllers that offer fine flow adjustments, often measured in SCCM or µL/min, guaranteeing accurate modulation of fluids. Advanced digital regulation features are essential, as they can maintain flow accuracy within ±1%, providing consistency across experiments. High-resolution sensors with sensitive detection capabilities help monitor even minimal flow variations, crucial for delicate processes. Stability is also vital; a good controller compensates for pressure fluctuations and changes in medium viscosity. Additionally, proper calibration against known standards and accounting for environmental factors like temperature stability are necessary to attain optimal control precision. These factors collectively ensure dependable, repeatable microfluidic operations.

Size and Footprint

The size and footprint of a microfluidic flow controller are critical factors that influence how well it fits into your workspace. If space is limited, a compact controller can seamlessly integrate into your system without major adjustments, making setup easier and more efficient. Larger controllers, while sometimes offering advanced features, tend to take up more bench or rack space, which can hinder workflow and reduce available room for other equipment. It’s also essential to contemplate the size of connected tubing and accessories to ensure compatibility and prevent unnecessary clutter. Additionally, smaller controllers are more portable and easier to install, especially in mobile or field-based applications. Ultimately, choosing a size that balances your space constraints with your operational needs is key.

Power Supply Needs

Selecting the right power supply for a microfluidic flow controller is vital to guarantee stable and accurate operation. Most controllers need a consistent voltage, typically between 12V and 24V DC, to maintain precise flow regulation. Some units are compatible with wide input ranges, like 100-240V AC adapters, making them suitable for various regional electrical systems. Power consumption varies, with devices drawing between 0.3A and 1A, so choosing an appropriate power source is essential. Reliable power sources prevent flow fluctuations, especially in sensitive applications. Additionally, integrating surge protection, proper grounding, and compatibility with control systems ensures device safety and peak performance. A well-chosen power supply directly impacts the accuracy and stability of your microfluidic system.

Material Durability

Material durability is essential when choosing a microfluidic flow controller because it directly impacts the device’s lifespan and performance in demanding environments. The materials used must withstand repeated use and exposure to chemicals without degrading or losing integrity. For example, PDMS is popular for its flexibility and chemical resistance, but it can degrade with certain solvents or under high pressure. Selecting materials with high tensile strength and chemical inertness improves longevity and system reliability. Proper material choice also helps prevent leaks, cracks, or structural failures that could compromise flow accuracy and safety. It’s critical to think about the compatibility of materials with your working fluids and operating conditions to ensure the device remains durable and effective over time.

Integration Features

When choosing a microfluidic flow controller, it’s crucial to take into account its integration features to guarantee smooth operation within your existing system. Make sure the controller offers multiple output interfaces, like analog signals (4-20mA, RS485) or digital options, for easy integration with your control systems. Compatibility with common electrical standards and communication protocols simplifies data exchange and setup. Opt for controllers with configurable output options to suit various device requirements and allow flexible system design. Check that the input and output connections match your setup, whether NPT fittings or custom connectors. Additionally, consider controllers with integrated communication modules or compatibility with external controllers to enable real-time monitoring and automated process management. These features ensure seamless integration and reliable operation.

Frequently Asked Questions

How Do Microfluidic Flow Controllers Handle Temperature Variations?

Microfluidic flow controllers handle temperature variations through integrated sensors and feedback mechanisms that automatically adjust flow rates. I’ve seen models with built-in temperature compensation features that maintain accuracy despite environmental changes. Some use active heating or cooling elements to stabilize fluid temperature. By continuously monitoring and adjusting, these controllers guarantee precise fluid management, even when external temperatures fluctuate, keeping experiments consistent and reliable.

What Is the Maximum Flow Rate Supported by These Controllers?

Think of these controllers as skilled river guides, steering the flow with precision. They typically support maximum flow rates ranging from a few microliters per minute to several milliliters per minute, depending on the model. I’ve found that high-end controllers can handle up to 100 milliliters per minute, ensuring smooth, accurate fluid movement even at demanding speeds. This flexibility helps me tailor fluid management to my specific microfluidic applications.

Are These Flow Controllers Compatible With Chemical-Resistant Materials?

Yes, many of these flow controllers are compatible with chemical-resistant materials. I always check the specifications to make they’re made from or coated with materials like PTFE or PEEK, which resist corrosion from aggressive chemicals. This compatibility is essential for maintaining accuracy and longevity in my experiments. When selecting a controller, I prioritize those with proven chemical resistance to guarantee reliable, precise fluid management without degradation or leaks.

How Often Should Microfluidic Flow Controllers Be Calibrated?

I recommend calibrating your microfluidic flow controllers every three to six months, depending on usage and the fluids you’re handling. Regular calibration guarantees accuracy and consistent performance. If you notice irregular flow rates or fluctuations, recalibrate sooner. Always follow the manufacturer’s guidelines for calibration procedures, and keep detailed records. Proper maintenance and timely calibration help prevent errors and extend the lifespan of your flow controllers.

Can These Controllers Integrate With Automated Laboratory Systems?

Did you know over 75% of labs now integrate microfluidic flow controllers with automation systems? I can tell you these controllers are highly compatible with automated lab setups, making workflows smoother and more precise. They often feature digital interfaces and communication protocols like I2C or UART, enabling seamless integration. When choosing a controller, I recommend checking compatibility with your existing equipment to guarantee effortless automation and peak fluid management.

Conclusion

Choosing the right microfluidic flow controller is like finding the perfect tool in your toolbox—precision makes all the difference. By considering factors like accuracy, compatibility, and ease of use, you guarantee smooth fluid management. Remember, a chain is only as strong as its weakest link, so investing in reliable controllers pays off. With the right choice, you’ll keep your experiments flowing flawlessly and confidently.