Scientists move atoms one by one using advanced tools like scanning tunneling microscopes (STM) for precise lateral placement, atomic force microscopes (AFM) for force-driven manipulation, and optical tweezers to control neutral atoms in 3D. They rely on ultra-high vacuum and cryogenic temperatures to stabilize atoms and enhance precision. Automation and AI help speed up and improve accuracy in assembly. Keep exploring to discover more about the innovative techniques pushing nanotechnology forward.

Key Takeaways

- Scientists use STM for precise lateral atom placement by controlling tunneling current at cryogenic temperatures.

- Force-driven AFM employs mechanical forces to translate, rotate, or trigger reactions at the atomic scale.

- Optical tweezers trap and move neutral atoms in three dimensions with nanometer accuracy using focused laser beams.

- Automation and AI, such as deep reinforcement learning, enable autonomous, accurate, and scalable atom manipulation.

- Supporting techniques like nanolithography and deposition facilitate scaling atomic assembly for practical nanodevices.

Direct-Lateral Atom Placement With STM

Direct-lateral atom placement with scanning tunneling microscopy (STM) enables precise manipulation of individual atoms on conductive surfaces. You use a sharp, conductive tip brought within angstroms of the surface, controlling the tunneling current to sense and reposition adatoms. In lateral manipulation mode, you drag or push atoms across the surface, assembling structures atom by atom with remarkable accuracy. This process typically occurs at cryogenic temperatures (~5 K) to stabilize the atoms and minimize thermal noise. Maintaining ultra-high vacuum conditions** is essential to prevent contamination and ensure precision during manipulation. With this technique, you can create quantum corrals, atom-scale circuits, and other nanoscale architectures. While slow and requiring ultra-high vacuum conditions, STM’s ability to precisely control single atoms opens up possibilities for fundamental quantum research and the development of atomically precise devices. A thorough understanding of scanning tunneling microscopy is essential for advancing nanoscale engineering and quantum technologies. Additionally, ongoing innovations in nanotechnology tools continue to expand the capabilities of atomic manipulation techniques. Furthermore, advances in automation and control systems are enhancing the efficiency and precision of atomic assembly processes. Recent developments** in feedback mechanisms also contribute to increased accuracy and stability during atom manipulation.

Force-Driven Manipulation Using AFM

Force-driven manipulation using AFM leverages the cantilever’s controlled mechanical forces to position or modify nanoscale structures on a surface. You use the AFM’s sharp tip to apply targeted forces, enabling translation, rotation, or chemical reactions at the atomic level. This technique works on both insulating and liquid environments, broadening its versatility. You can manipulate nanowires, nanotubes, and molecules to build or reconfigure nanoscale circuits and structures. Mechanochemical approaches allow you to break or form chemical bonds by precisely applying force, effectively triggering reactions. While AFM offers flexible control over nanostructures, it requires operator skill, has slower throughput compared to lithography, and can face reproducibility challenges. Nevertheless, it remains a powerful tool for direct mechanical manipulation at the atomic and molecular scale.

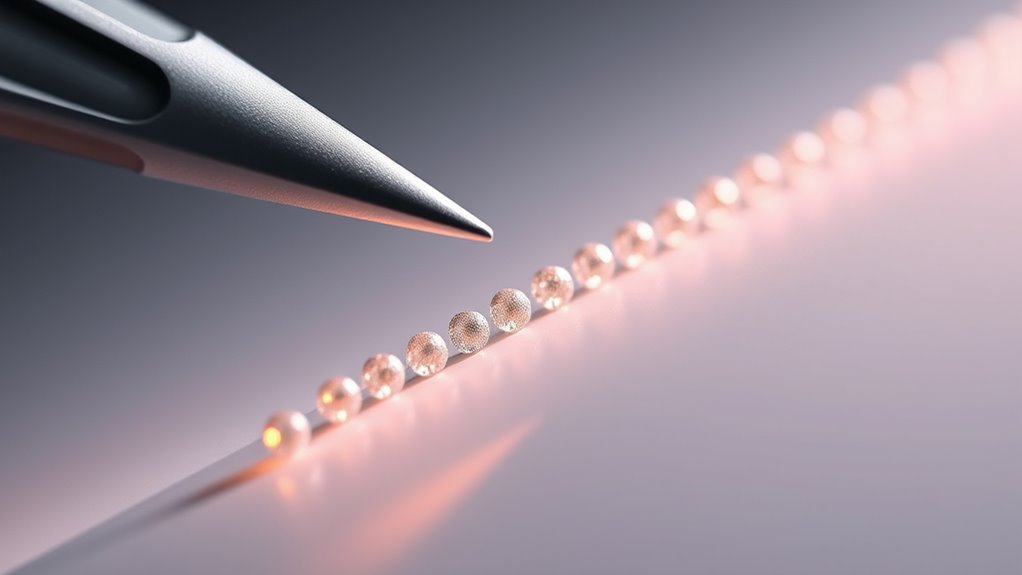

Precision Control of Neutral Atoms With Optical Tweezers

Have you ever wondered how scientists manipulate individual neutral atoms with such remarkable precision? Optical tweezers use highly focused laser beams to trap and move atoms in three dimensions, achieving nanometer to sub-micron accuracy. By adjusting laser intensity and focus, you can hold atoms still or transport them across a surface. This technique allows you to arrange atoms into precise arrays for quantum simulation and information processing. Since neutral atoms aren’t conductive, optical tweezers offer a non-contact, versatile method that works in ultra-high vacuum and at ultracold temperatures. You can also prepare atoms in specific internal states simultaneously, enabling complex quantum architectures. Despite technical challenges like optical stability and scaling, this approach provides unmatched control for building atom-by-atom quantum devices.

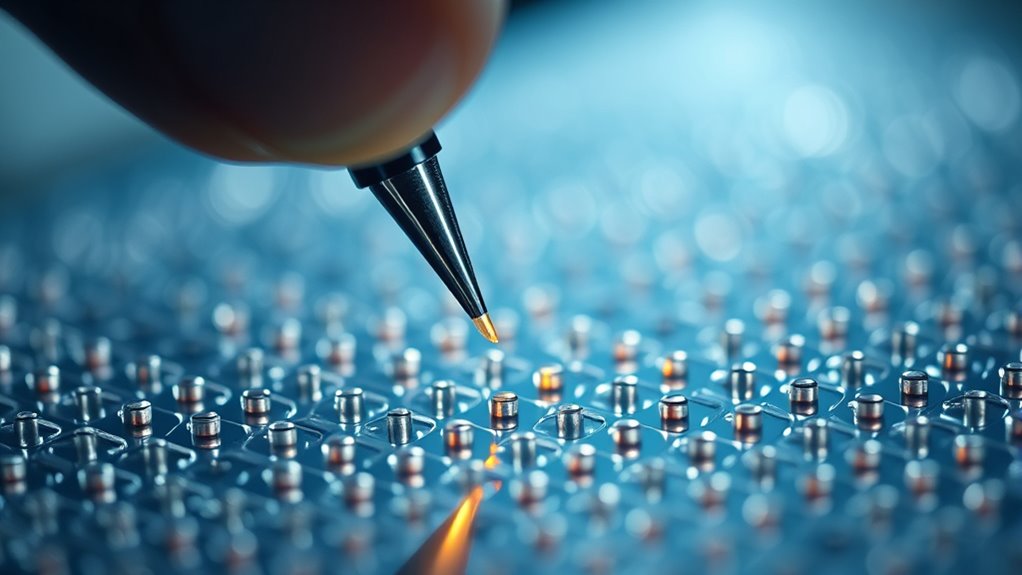

Leveraging AI and Automation for Atom Assembly

Advancements in artificial intelligence and automation are transforming atom assembly by enabling precise, scalable, and efficient manipulation processes. You can now leverage deep reinforcement learning (DRL) agents trained to manipulate adatoms on metal surfaces, achieving autonomous atomic assembly with high accuracy. These AI systems adapt to tip changes and optimize manipulation paths, reducing the need for manual intervention. Integration with path-planning algorithms allows for end-to-end workflows that automate complex atom arrangements. Automated AFM and STM operations predict manipulation stages, run tasks in parallel, and minimize operator involvement. While challenges remain—such as material generalization, real-time sensing, and verification at scale—these innovations markedly accelerate atom-by-atom manufacturing and open new possibilities for constructing nanoscale devices with unprecedented precision. Advanced sensing techniques further enhance real-time feedback, enabling more reliable and scalable atomic manipulation. Incorporating natural landscape inspiration from backyard landscaping principles could lead to more harmonious integration of atomic structures within their environments.

Supporting Techniques and Pathways for Scaling Up

Supporting techniques such as nanolithography, deposition, and spectroscopy are essential for preparing and verifying atomically precise structures at scale. They bridge the gap between single-atom manipulation and larger, functional devices. Electron-beam lithography offers high-throughput patterning, enabling you to create electrical contacts and complex architectures. Controlled deposition methods allow you to place adatoms or molecules precisely where you need them, paving the way for scalable assembly. Spectroscopy techniques, like synchrotron or scanning probe methods, verify your structures’ electronic, magnetic, and chemical properties, ensuring quality and functionality. By integrating these methods, you can accelerate your progress toward mass manufacturing. Atomic-scale precision is increasingly achievable with advancements in supporting techniques, opening new possibilities for scalable nanomanufacturing.

- *Transform your laboratory into a scalable production hub.*

- *Turn atomic precision into everyday products.*

- *Revolutionize manufacturing with atomic-level control.*

Frequently Asked Questions

What Are the Main Challenges in Scaling Atom-By-Atom Manufacturing?

You face several challenges in scaling atom-by-atom manufacturing. First, balancing throughput with precision is tough, as increasing speed often reduces accuracy. You also struggle with complex 3D placement, error correction, and maintaining control over tips and surfaces during large assemblies. Additionally, high costs, sophisticated infrastructure needs, and integrating these precise techniques into practical, scalable processes make it difficult to move from lab demonstrations to industrial production.

How Do Different Techniques Compare in Assembly Speed and Precision?

You’ll find STM achieves atomic precision but at a slow pace—adding just a few atoms per hour. AFM offers better speed for larger structures but sacrifices some accuracy, especially in non-conductive environments. Optical tweezers can manipulate neutral atoms in three dimensions with nanometer precision, yet their assembly rate remains limited. Overall, faster methods trade off precision, while ultra-precise techniques like STM are painstakingly slow, making scale-up a significant challenge.

Can These Methods Be Integrated for Large-Scale Industrial Production?

Yes, you can integrate these methods for large-scale industrial production, but it’s challenging. You’ll need to combine automation, AI, and parallelization to increase throughput and maintain precision. Hybrid approaches, like combining top-down lithography with bottom-up atom manipulation, help. Developing scalable robotic systems and error correction techniques will be essential. While promising, you must address high costs, infrastructure complexity, and ensuring reproducibility to make this practical for industry.

What Are the Environmental Limitations for Atom Manipulation Techniques?

You face environmental limitations like ultra-high vacuum, cryogenic temperatures, and controlled atmospheres for atom manipulation techniques. These conditions prevent contamination and stabilize delicate adatoms or atoms during manipulation. Achieving and maintaining such environments require sophisticated, expensive equipment and strict protocols. Variations in temperature, pressure, or environmental stability can disrupt atom placement, making large-scale industrial application challenging without further technological advances to simplify or adapt these conditions for broader use.

How Is Error Correction Managed During Complex Atomic Assemblies?

You manage error correction during complex atomic assemblies by using real-time feedback from advanced imaging and sensing tools like STM or AFM. Automated systems, often powered by AI and reinforcement learning, monitor the process continuously, adjusting manipulation parameters on the fly. This approach helps rectify deviations, ensure precise placement, and minimize cumulative errors, enabling reliable assembly of intricate atomic structures despite environmental and technical challenges.

Conclusion

Just as a painter carefully places each brushstroke to create a masterpiece, you can manipulate atoms with precision tools like STM, AFM, and optical tweezers. By integrating AI, you’re building a future where atom-by-atom assembly becomes routine—like orchestrating a symphony in miniature. With these techniques, you hold the palette of nanotech mastery, turning science fiction into reality, one atom at a time, shaping worlds unseen but profoundly impactful.