If you’re exploring the 14 best plasma cutters with CNC control for precision in 2025, I’ve got you covered. I’ve reviewed versatile models like combo machines, CNC plasma tables, and portable units, all tailored for detailed, accurate cuts on various metals. From multi-process welders to advanced CNC tables with torch height control, these options suit different needs and budgets. Stick around, and you’ll find all the critical details to help you make the perfect choice for your shop or project.

Key Takeaways

- The top plasma cutters feature CNC compatibility with advanced THC, shape libraries, and precise movement for professional-grade cuts.

- Many models support dual voltage (110V/220V), ensuring versatile setup options across different work environments.

- High-power units can cut through thicker materials up to 15mm, suitable for industrial and heavy-duty applications.

- Compact and hobbyist-friendly machines offer accurate, precise cuts with minimal setup, ideal for small workshops.

- Durability, support, and consumable costs vary; choosing reputable brands ensures long-term performance and reliability.

Multi-Process 5-in-1 Welding Machine with Digital Display

https://m.media-amazon.com/images/I/71irtak0YKL._AC_SX679_.jpg

If you’re looking for a versatile welding machine that can handle multiple tasks with ease, the Multi-Process 5-in-1 Welding Machine with Digital Display is an excellent choice. It supports dual voltage (110V/220V) and offers precise control over TIG, MMA, and CUT processes through clear digital displays. Compatible with cellulose electrodes like 6011/7018, it also features hand welding, gas protection welding, high-frequency cutting, and argon arc welding. Built for both professionals and DIY enthusiasts, it includes all necessary accessories, ensuring straightforward setup. Its durable design, safety features, and user-friendly operation make it a reliable, all-in-one solution for a wide range of welding tasks.

Best For: DIY enthusiasts, professional welders, and workshop operators seeking a versatile, all-in-one welding machine suitable for a wide range of welding tasks.

Pros:

- Supports dual voltage (110V/220V) with digital displays for precise process control.

- Includes comprehensive accessories for easy setup and operation.

- Durable construction with safety features like thermal protection and certified wiring.

Cons:

- May be bulkier and heavier due to multi-process capabilities.

- Complex features could require some training for optimal use.

- Higher initial cost compared to single-function welding machines.

Plasma Cutter and Welder Combo Machine (Dual Voltage 110/220V)

The Plasma Cutter and Welder Combo Machine with dual voltage support is an excellent choice for hobbyists and DIY enthusiasts who need versatile, portable equipment. Weighing just 23.2 pounds, it supports both plasma cutting and MMA welding, making it ideal for a range of metals like steel, copper, and aluminum. Its advanced IGBT inverter technology guarantees powerful cuts and welds, with capacity up to 14mm at 220V. Its non-HF system and pilot arc enable precise cutting through rust or paint without interference. Compact and easy to transport, it’s perfect for small workshops, though it requires a suitable high-flow compressor and has a dim digital display.

Best For: DIY enthusiasts and hobbyists seeking a portable, versatile plasma cutter and welder combo suitable for various metals and beginner-friendly operations.

Pros:

- Combines plasma cutting and MMA welding in one compact, lightweight unit for versatile use.

- Advanced IGBT inverter technology ensures reliable, powerful performance for both cutting and welding.

- Supports dual voltage (110/220V), making it adaptable to different power sources and portable for small workshops.

Cons:

- Digital display is dim and may be difficult to read under bright lighting conditions.

- Requires a high-flow external compressor; small pancake compressors are insufficient for longer cuts.

- Limited warranty registration options and some users noted minimal manufacturer support or detailed registration info.

Plasma Cutter with Blow Back Pilot Arc and Dual Voltage

For hobbyists and small workshop operators seeking reliable precision, plasma cutters with Blow Back Pilot Arc and dual voltage support are an ideal choice. I recommend the BTC650XP model, which works seamlessly on 110V or 220V power. It delivers clean cuts up to 1/2” on iron, steel, aluminum, and copper, with a maximum thickness of 5/8” at 35A or 1.18” at 50A. Its inverter IGBT technology guarantees efficiency, stability, and easy CNC integration. With features like quick setup, real-time display, and adjustable cooling, this cutter balances performance with user convenience—perfect for DIY projects or light professional use.

Best For: hobbyists and small workshop operators seeking reliable, precise plasma cutting with easy CNC integration and versatile voltage support.

Pros:

- Supports dual voltage (110V/220V) for flexible power options

- Equipped with Blow Back Pilot Arc for stable, clean cuts on rusty or dirty materials

- Features inverter IGBT technology ensuring efficiency, stability, and quick setup

Cons:

- Some users report air leaks and issues with torch handle durability

- Limited customer support and warranty options may affect troubleshooting and repairs

- Consumables are cheaper but may require more frequent replacement over time

LOTOS Plasma Cutter LTP6300DCNC

The LOTOS Plasma Cutter LTP6300DCNC stands out for its powerful 63AMP capacity combined with CNC-ready features, making it an excellent choice for serious hobbyists and small shop operators seeking precise, automated metal cuts. It handles materials like stainless steel, aluminum, copper, and mild steel, with a clean 3/4-inch cut and 1-inch severance. Equipped with pre-installed Torch Height Control (THC) and ARC OK signals, it supports consistent, automated operation. Its dual voltage capability (110-125V and 215-245V) offers flexibility, while its stable pilot arc makes cutting rusty or painted metal easier. Overall, a reliable and versatile cutter for demanding projects.

Best For: hobbyists and small shop operators seeking precise, automated plasma cutting capabilities on thick metal projects.

Pros:

- CNC-ready with pre-installed Torch Height Control (THC) and ARC OK signals for automation

- Handles a variety of metals including stainless steel, aluminum, copper, and mild steel with a clean cut up to 3/4 inch

- Dual voltage operation (110-125V and 215-245V) provides flexibility for different setups

Cons:

- Requires a high-capacity air compressor with proper drying for optimal performance

- Consumables like electrodes and nozzles wear quickly with heavy use, leading to additional costs

- Does not include drag-cutting hardware, so compatible consumables and adjustments are necessary for drag-cutting applications

Eastwood Versa-Cut 4X4 CNC Plasma Table with 40A Plasma Cutter

If you’re seeking a versatile CNC plasma table that balances professional features with an accessible price, the Eastwood Versa-Cut 4X4 stands out. It offers a large 49” x 43” cut area and includes a 40A plasma cutter torch, making it suitable for thicknesses up to 3/8”. The system features robust stepper motors for smooth, accurate cuts with a ±0.2mm precision. Its independent LCD controller supports custom CAD files via USB and preloaded shapes, simplifying operation for both hobbyists and small businesses. With dual voltage support, easy setup, and positive customer feedback on durability, the Versa-Cut 4X4 is a solid, professional-grade choice.

Best For: hobbyists and small-scale metal fabricators seeking a professional-grade CNC plasma table with easy setup and reliable performance.

Pros:

- Large 49” x 43” cut area suitable for various projects

- Precise ±0.2mm movement accuracy with robust stepper motors

- Includes a 40A plasma cutter torch with support for materials up to 3/8” thick

Cons:

- Customer service responsiveness has received some criticism

- Consumable costs, especially for upgraded torches, can be high

- Assembly and setup may be challenging for complete beginners without prior experience

Eastwood Versa-Cut 2X2 CNC Plasma Table

Designed for hobbyists and small workshops, the Eastwood Versa-Cut 2X2 CNC Plasma Table delivers professional-grade accuracy in a compact, accessible package. It pairs with the Eastwood Versa-Cut 40 Plasma Cutter (sold separately) and offers a 24 x 24-inch cutting area perfect for custom brackets, signs, and shapes. The table features robust lead screw-driven stepper motors that achieve ±0.2mm movement accuracy and ±0.5mm cut precision. Its intuitive LCD touchscreen control allows easy operation without a PC, while the waterbed system minimizes heat warping and fumes. Weighing 149 pounds, it’s designed for safe, high-quality fabrication right in your workshop.

Best For: hobbyists and small workshops seeking professional-quality CNC plasma cutting with an easy-to-use interface and compact design.

Pros:

- Compact size suitable for home garages and small workshops

- Precise ±0.2mm movement accuracy and ±0.5mm cut precision

- Independent control system with intuitive LCD touchscreen, no PC needed

Cons:

- Limited maximum plate thickness of 0.25 inches

- Requires separate purchase of Eastwood Versa-Cut 40 Plasma Cutter

- Weighs 149 pounds, which may require assistance for setup and mobility

Plasma Cutter with Pilot Arc, LED, Air Sensor, 50A, Dual Voltage

For those seeking a versatile plasma cutter that combines ease of use with reliable performance, the Plasma Cutter with Pilot Arc, LED, Air Sensor, 50A, Dual Voltage stands out. It offers dual voltage operation (110V/220V), making it suitable for various settings, from workshops to DIY projects. With a 50A capacity, it delivers clean cuts up to 5/8” on 110V and 1” on 220V. Features like blow-back pilot arc technology, real-time air pressure monitoring, and an intuitive LED display make it user-friendly. Its lightweight design and CNC compatibility ensure precise, efficient cuts while maintaining affordability for hobbyists and light professionals.

Best For: DIY enthusiasts, hobbyists, and light professional users seeking a versatile, easy-to-operate plasma cutter for various metals and projects.

Pros:

- Dual voltage operation (110V/220V) for flexible use in different settings

- Blow-back pilot arc technology reduces interference and enhances stability

- Lightweight design and CNC compatibility for precise, efficient cuts

Cons:

- Some users report build quality issues such as broken torch handles and internal air leaks

- Customer support may be inadequate or slow to respond

- Durability may be limited for heavy, continuous industrial use

SILATU Plasma Cutter (85 Amps, Dual Voltage)

The SILATU Plasma Cutter (85 Amps, Dual Voltage) stands out as an excellent choice for professionals and serious hobbyists who need reliable, high-power cutting with CNC compatibility. It operates on dual voltage (110V/220V), making it versatile for different setups, and delivers up to 85A for thick materials. Weighing just over 23 pounds, it features a durable iron frame and supports cutting up to 15mm on 110V or 35mm on 220V. Its integrated digital display, CNC connection ports, and non-HF technology guarantee stable, precise cuts. With a robust air system, safety features, and included accessories, it’s a powerful, user-friendly option for demanding projects.

Best For: DIY enthusiasts, hobbyists, and small professional workshops seeking a versatile, high-power plasma cutter with CNC compatibility and reliable performance.

Pros:

- Dual voltage operation (110V/220V) offers versatile setup options.

- Supports cutting thick materials up to 35mm with precise CNC integration.

- Lightweight design and durable construction make it easy to handle and long-lasting.

Cons:

- Requires an external air compressor and proper safety setup for optimal use.

- Slightly complex initial setup for beginners unfamiliar with CNC systems.

- Delivery delays and potential defect issues reported by some users.

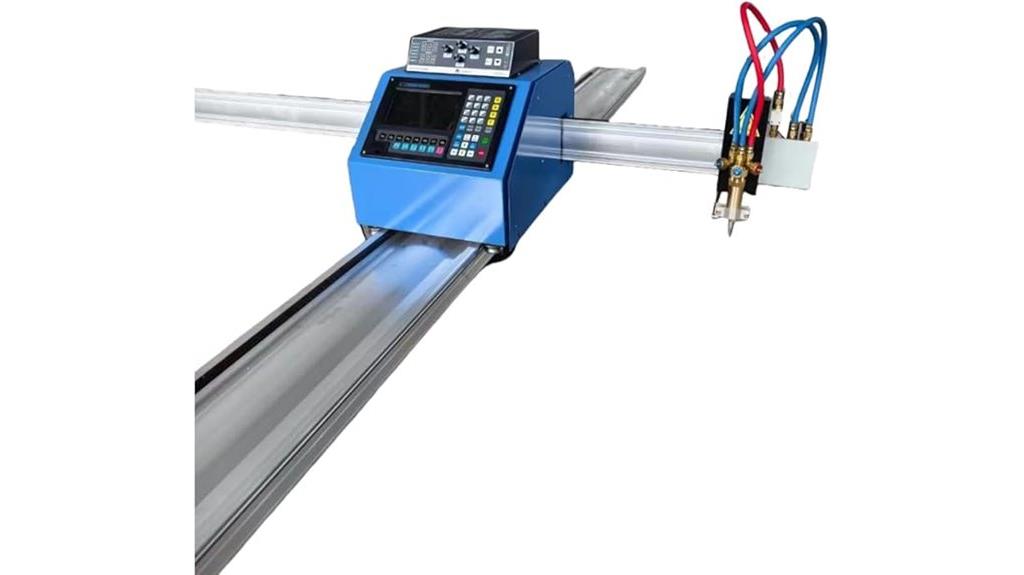

Portable CNC Machine with THC for Oxyfuel and Plasma Cutting

If you’re looking for a portable CNC machine that combines versatility with precise control, the NL-1525 model stands out, especially with its automatic torch height control (THC) for oxyfuel and plasma cutting. It features a sizable 1500x2500mm working area, guide rails up to 3 meters, and a sturdy steel and aluminum build. The machine supports flame and plasma gases, with flame cutting thickness up to 7.87 inches and plasma up to 150mm. Its software supports easy file import and nesting, and the 0.01mm step precision guarantees detailed cuts. Despite a learning curve, users praise its performance, durability, and value for small workshops and hobbyists.

Best For: hobbyists, small workshops, and DIY enthusiasts seeking a portable, precise CNC machine for oxyfuel and plasma cutting projects.

Pros:

- Large working area of 1500x2500mm with robust guide rails for versatile cutting.

- Accurate 0.01mm step precision and integrated THC for high-quality, detailed cuts.

- Durable construction with steel and aluminum alloy components, supporting various gases and thicknesses.

Cons:

- Initial setup and learning curve can be time-consuming for new users.

- Minor assembly imperfections like bent parts and misaligned holes.

- Longer shipping times from China may delay project start.

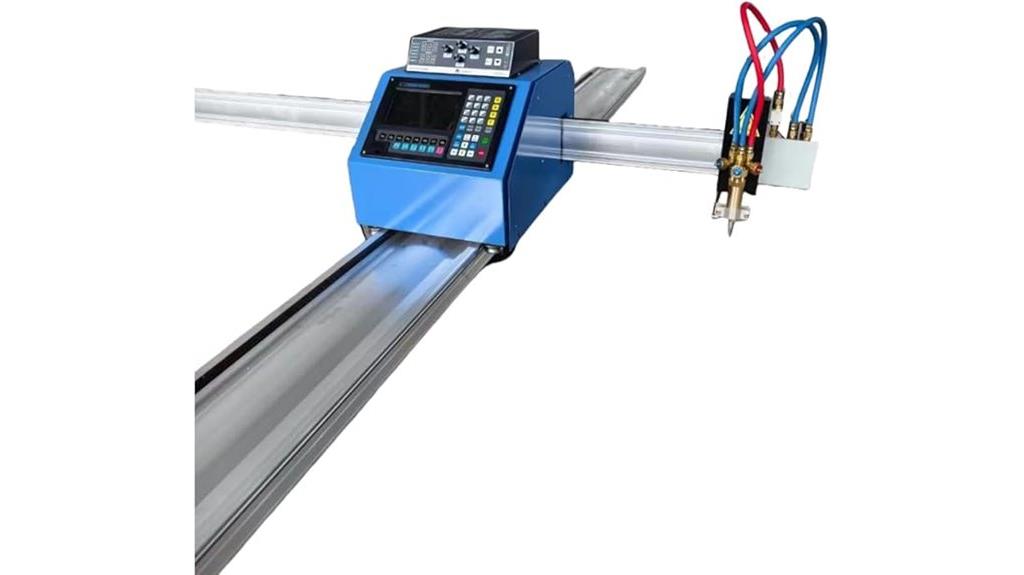

Portable CNC Machine with THC for Oxyfuel and Plasma Cutting

A standout feature of the portable CNC machine with THC for oxyfuel and plasma cutting is its versatility across different fuel sources and cutting methods. I find this model, the NL-1525, impressive because it handles LPG, propane, acetylene, coal gas, and plasma with ease. Its large working area—1500x2500mm—and precise 0.01mm/step movement make detailed cuts simple. The automatic torch height control (THC) ensures consistent plasma and flame height, boosting accuracy. Despite minor assembly imperfections, its sturdy build and reliable software support make it ideal for both hobbyists and small workshops seeking flexible, high-quality cutting solutions.

Best For: hobbyists, small workshops, and DIY enthusiasts seeking a versatile, portable CNC cutting machine capable of handling oxyfuel and plasma processes with high precision and ease of use.

Pros:

- Supports multiple fuel gases (LPG, propane, acetylene, coal gas) and plasma, offering excellent flexibility for various materials and projects.

- Large working area (1500x2500mm) with high movement precision (0.01mm/step) ensures detailed and accurate cuts.

- Automatic torch height control (THC) and user-friendly software simplify operation, making it accessible even for beginners.

Cons:

- Minor assembly imperfections such as bent parts and misaligned holes may require adjustment during setup.

- Software learning curve can be steep initially, necessitating some time to master design import and G-code generation.

- Shipping from China may result in longer delivery times and potential import duties, which could impact project timelines.

Newlin Tech Dual Purpose Plasma Cutter CUT-120

Designed for versatility, the Newlin Tech CUT-120 Plasma Cutter seamlessly switches between manual and CNC modes, making it ideal for professionals who need precise, adaptable cutting solutions. It offers a rated output of 120A, adjustable from 30-120A, and can cut carbon steel up to 25mm manually or 13mm with CNC, with a maximum thickness of 42mm. Powered by stable 3-phase voltage (220/380V), it uses compressed air at 0.4-0.6MPa and features air cooling for reliable operation. The package includes a 26-foot torch, nozzles, electrodes, and essential cables. Its robust design guarantees precision and efficiency in diverse working environments.

Best For: professionals and workshops needing versatile, precise plasma cutting for both manual and CNC applications across various metalworking projects.

Pros:

- Adjustable output current (30-120A) allows for flexible cutting thickness and precision.

- Dual-purpose design supports both handheld manual and CNC automated cutting, enhancing versatility.

- Uses compressed air at optimal pressure (0.4-0.6MPa) with air cooling for reliable, consistent operation.

Cons:

- Requires stable 3-phase power supply and specific environmental conditions for optimal performance.

- Handling and setup may be complex for users unfamiliar with plasma cutters or CNC systems.

- Limited to use below 1000m altitude, restricting operation in higher elevations.

3-in-1 Plasma Cutter/LIFT TIG/Stick Welder Combo (50A Plasma Cutter, 200A Stick & LIFT TIG Welder, Dual Voltage)

For professionals seeking versatility in a single machine, the in-1 Plasma Cutter/LIFT TIG/Stick Welder Combo stands out with its 3-in-1 design, combining plasma cutting, lift TIG, and stick welding. With a 50A plasma cutter and 200A capacity for TIG and stick modes, it handles a wide range of tasks from clean cuts to heavy-duty welds. Its advanced IGBT inverter technology guarantees efficiency and a 60% duty cycle. The dual-voltage operation makes it adaptable to various power sources. The large digital display simplifies monitoring, while features like adjustable post-flow and multiple modes enhance usability and precision across diverse applications.

Best For: professionals and serious hobbyists seeking a versatile, all-in-one welding and cutting machine for diverse tasks across various materials and project sizes.

Pros:

- Combines plasma cutter, lift TIG, and stick welder in a single, space-saving device.

- Features advanced IGBT inverter technology with a 60% duty cycle for efficient, reliable operation.

- Dual-voltage capability allows compatibility with different power sources, enhancing flexibility.

Cons:

- May be complex for beginners due to multiple functions and modes.

- Heavier and bulkier compared to single-function units, impacting portability.

- Requires understanding of various settings and maintenance for optimal performance.

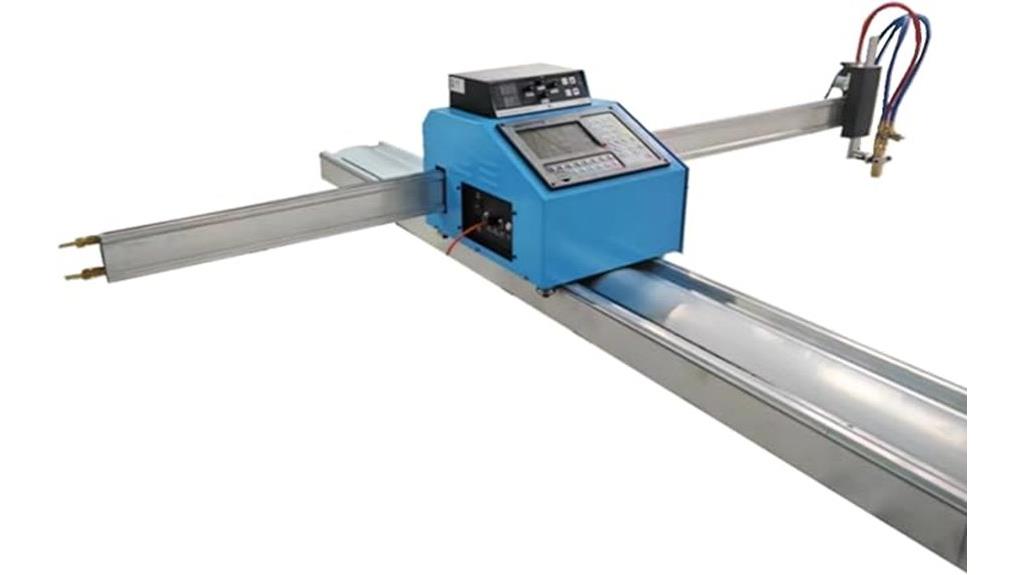

Portable CNC Cutting Machine with Oxyfuel and Plasma Support

If you’re looking for a versatile cutting machine that combines portability with advanced CNC control, the Portable CNC Cutting Machine with Oxyfuel and Plasma Support stands out. It features a wide Y-axis aluminum guide rail, offering an effective cutting width of 70 inches with extendable length. Equipped with a THC-automatic plasma torch height controller and StarCAM software, it handles DXF, TXT, and G-code files effortlessly. With a work area of 1800x3500mm, it can cut flame thicknesses from 5 to 150mm and plasma thicknesses depending on power supply. Weighing 242 pounds, it’s designed for precision, durability, and industrial applications.

Best For: industrial manufacturers and fabrication professionals seeking a portable, precise CNC cutting machine capable of handling both oxyfuel and plasma cutting tasks with extended cutting widths.

Pros:

- Supports multiple cutting methods including oxyfuel gas flame and plasma, increasing versatility.

- Wide Y-axis aluminum guide rail with extendable length for large-scale projects.

- Equipped with automatic torch height control and StarCAM software for high-precision cutting and file compatibility.

Cons:

- Plasma equipment and torches are not included, requiring additional purchases.

- Relatively heavy at 242 pounds, which may affect portability despite being designed as portable.

- Limited to certain gas types and power specifications, which may restrict use in some environments.

Eastwood Versa-Cut 2X2 CNC Plasma Table with 40A Cutter

The Eastwood Versa-Cut 2X2 CNC Plasma Table with 40A Cutter stands out as an excellent choice for hobbyists and small workshops seeking professional-quality precision. It combines accuracy, efficiency, and user-friendly features, making metal fabrication accessible. Its dual voltage setup, integrated torch height adjustment, and durable build enable seamless cutting of various metals. The intuitive LCD interface simplifies operation, while the preloaded shapes and USB compatibility support custom designs. With robust stepper motors ensuring precise cuts and a 24-inch adjustable travel on X and Y axes, this system delivers detailed craftsmanship suitable for both artistic projects and functional fabrication. Plus, Eastwood’s reliable support adds peace of mind.

Best For: hobbyists, small workshop owners, and DIY metal fabricators seeking professional-grade precision and ease of use in a compact CNC plasma cutting system.

Pros:

- User-friendly LCD interface with preloaded shapes and USB file compatibility for easy operation

- Robust stepper motors and adjustable 24-inch travel on X and Y axes ensure precise, detailed cuts

- Dual voltage setup and integrated torch height adjustment offer versatility and seamless metal cutting

Cons:

- Limited to a 2×2 foot work area, which may not suit larger projects

- Requires some familiarity with CNC operation for optimal use, possibly challenging for complete beginners

- The 1-year limited warranty may necessitate additional coverage for long-term peace of mind

Factors to Consider When Choosing Plasma Cutters With CNC Control

When choosing a plasma cutter with CNC control, I focus on key factors like power compatibility, cutting thickness, and ease of software use. I also consider build quality and the air supply requirements to make certain of reliable performance. These points help me find a machine that fits my specific needs and offers long-term durability.

Power and Voltage Compatibility

Choosing a plasma cutter with CNC control requires careful attention to power and voltage compatibility to guarantee smooth operation. First, verify the machine’s voltage matches your power supply—whether it’s 110V, 220V, or dual voltage—to avoid electrical issues. Check the maximum rated amperage and cutting thickness at your intended voltage; higher voltages typically support thicker materials. Confirm that the CNC system supports your power source’s voltage and current for seamless integration. Also, consider if your setup needs external features like air compressors or cooling systems compatible with your voltage. Be aware that some CNC plasma cutters need stable three-phase power, while others work on single-phase, so match your electrical infrastructure accordingly. Proper compatibility prevents operational hiccups and ensures efficient, safe cutting.

Cutting Thickness Range

Understanding the cutting thickness range of a plasma cutter helps guarantee it can handle your project needs effectively. This range indicates the maximum and *ideal* material thickness the cutter can produce clean, precise cuts on. Different models have ratings like 1/2 inch or 3/4 inch, which influence their suitability for various tasks. Achieving consistent cuts at the upper limits depends on factors such as voltage input, torch technology, and material type. Thicker materials generally require higher amperage or specialized equipment to maintain quality and minimize slag or deformation. Knowing the cutter’s rated capacity ensures you select a machine aligned with your typical project requirements, saving time and improving results. Accurate understanding of cutting thickness helps prevent underperformance and ensures your equipment is up to the task.

Software and Control Ease

Selecting a plasma cutter with CNC control becomes much easier when the software interface is user-friendly and intuitive. Clear menus, simple navigation, and a straightforward layout help me program and operate the machine efficiently. Compatibility with common CAD/CAM files like DXF and G-code ensures I can integrate it seamlessly into my existing workflow without hassle. Automated torch height control (THC) systems are a game changer, automatically adjusting focus and maintaining ideal distance, reducing my workload and errors. Digital control panels with real-time monitoring of parameters like air pressure, voltage, and current boost precision and make troubleshooting quicker. An easy setup process and understandable software mean I can deploy the cutter faster and achieve consistent, high-quality cuts with less frustration.

Build Quality and Durability

Build quality and durability are crucial considerations when evaluating plasma cutters with CNC control, as they directly impact long-term performance and reliability. I look for models with sturdy steel or aluminum frames that can handle frequent use and tough environments. Durable components like reinforced torch heads, heavy-duty stepper motors, and corrosion-resistant wiring are essential for consistent operation over time. Precise assembly, with minimal misalignments or bent parts, ensures cutting accuracy remains sharp years down the line. Good durability also depends on features like effective heat dissipation, robust cooling systems, and protective covers that shield against dust, debris, and electrical surges. Ultimately, I seek equipment built to meet industry safety standards and backed by certifications, guaranteeing quality and peace of mind.

Air Supply Requirements

Choosing the right plasma cutter with CNC control hinges heavily on guaranteeing a proper air supply. I’ve learned that a clean, dry, and oil-free compressed air source is essential for the best performance. Typically, this means maintaining around 70 PSI with a flow rate of at least 250 liters per minute. Inadequate or contaminated air can cause unstable arcs, poor cuts, and faster consumable wear, which drives up operational costs. To prevent these issues, I recommend using an external air filter and regulator to keep pressure consistent and remove moisture, oil, and particulates. Some models even have built-in sensors to monitor air pressure, alerting you to supply problems before they affect your cut quality. Using a proper compressor ensures steady airflow, improving efficiency and prolonging tool life.

Frequently Asked Questions

How Does CNC Control Improve Plasma Cutter Accuracy?

CNC control improves plasma cutter accuracy by precisely guiding the torch along programmed paths, reducing human error. I find that it guarantees consistent cuts, even on complex shapes, because the system maintains exact speed and motion. Additionally, CNC software adjusts for material thickness and potential deviations, resulting in cleaner, more precise edges. Overall, CNC control makes my work more efficient and ensures I get professional-quality results every time.

What Safety Features Are Essential in CNC Plasma Cutters?

Safety features are vital in CNC plasma cutters to prevent accidents and guarantee reliable operation. I look for emergency stop buttons that shut down the machine instantly, protective enclosures to shield operators from sparks and hot debris, and proper grounding to avoid electrical hazards. Additionally, automatic shut-off systems and safety interlocks help prevent operation if safety conditions aren’t met. These features keep me safe while working with high-powered equipment.

Can Portable CNC Plasma Cutters Handle Thick Metal Sheets?

Absolutely, portable CNC plasma cutters can handle thick metal sheets, but their capacity depends on the model. Imagine slicing through a steel sheet like butter—some units can cut through 1-inch or thicker materials with precision, while others are better suited for thinner metals. I’ve seen portable units excel in field jobs, offering mobility without sacrificing power, making them ideal for on-site projects involving heavy-duty metalwork.

How Do Maintenance Requirements Vary Among CNC Plasma Cutters?

Maintenance needs vary among CNC plasma cutters, depending on their size, usage, and build quality. I find that regular cleaning of the torch and consumables is essential to prevent malfunctions. Lubricating moving parts and inspecting electrical connections also help maintain performance. Higher-end models often require less frequent upkeep, but I always follow the manufacturer’s guidelines to guarantee consistent, precise cuts and prolong the cutter’s lifespan.

What Software Compatibility Options Exist for CNC Plasma Cutting Machines?

Think of software compatibility for CNC plasma cutters as a passport to seamless operation. I find most machines work with industry-standard programs like Mach3, LinuxCNC, and Fusion 360, which makes integration smooth. Some newer models even support direct import of CAD files, easing the design-to-cut process. It’s crucial to verify if the cutter’s software aligns with your existing design programs to avoid compatibility issues and guarantee precision every time.

Conclusion

If you’re serious about precision and versatility, these plasma cutters with CNC control are game-changers. They make complex cuts easier and more accurate, saving you time and effort. Whether you’re a hobbyist or a professional, isn’t it worth investing in the right equipment to elevate your projects? With options spanning from combo machines to CNC tables, there’s something for everyone. So, why settle for less when precision is just a button away?