Nanomaterials are transforming 3D and 4D printing by enabling advanced techniques like nanocomposites that improve flow, adhesion, and durability. Stimuli-responsive nanomaterials allow printed structures to change shape or properties in response to temperature, light, or magnetic fields. Precision layering is enhanced through nano-enabled methods like atomic layer deposition and nanoscale patterning. As you explore further, you’ll discover how these innovations lead to smarter, more functional, and adaptable structures that push the boundaries of manufacturing.

Key Takeaways

- Nanomaterials like carbon nanotubes and graphene enhance printability, strength, and precision in 3D and 4D printing processes.

- Stimuli-responsive nanomaterials enable shape-shifting and functional changes triggered by temperature, light, pH, or magnetic fields.

- Atomic layer deposition and nanoscale patterning improve layer control, surface functionality, and structural complexity.

- Self-assembly of nanoparticles facilitates the creation of adaptable, smart structures with spontaneous organization.

- Integration of multifunctional nanoparticles enhances electrical, magnetic, and bioactive properties of printed nanostructures.

Top picks for "nanomaterial print emerg"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

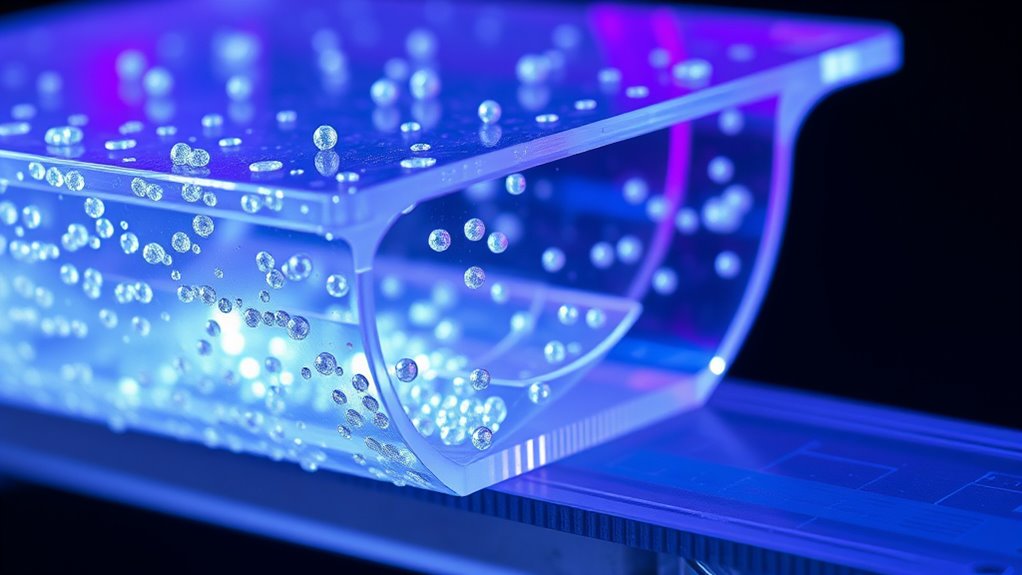

Advanced Nanocomposite Materials for Enhanced Printability

Advanced nanocomposite materials play a crucial role in improving the printability of 3D and 4D printing processes. By incorporating nanomaterials like carbon nanotubes, graphene, or metal nanoparticles into base polymers, you enhance their flow behavior, adhesion, and layer cohesion. These nanomaterials improve the mechanical strength and thermal stability of printed structures, allowing for more complex designs and finer resolutions. You’ll notice better control over extrusion and curing processes, reducing defects and print failures. The increased surface interactions provided by nanomaterials also promote better bonding between layers, ensuring durability. Additionally, understanding BMW Tuning techniques can inspire innovative approaches to material optimization for additive manufacturing. As a result, your ability to produce high-precision, functional components improves markedly. These advanced nanocomposites enable you to push the boundaries of additive manufacturing, creating intricate and reliable structures for various applications.

Stimuli-Responsive Nanomaterials in 4D Fabrication

Stimuli-responsive nanomaterials are transforming 4D fabrication by enabling printed structures to change their shape, properties, or functions in response to external stimuli such as heat, light, pH, or magnetic fields. These nanomaterials can be engineered to react predictably, allowing you to create dynamic, adaptive structures. For example, incorporating thermoresponsive nanoparticles helps structures that morph with temperature shifts, while photo-responsive nanomaterials enable shape changes triggered by light exposure. pH-sensitive nanomaterials allow for environmentally triggered transformations, and magnetic nanoparticles enable remote control through magnetic fields. This versatility opens new possibilities for biomedical devices, soft robotics, and self-assembling systems. By harnessing these materials, you can design smart, functional structures that adapt seamlessly to their environment, pushing the boundaries of 4D printing applications.

Nano-Enabled Techniques for Precision Layering and Assembly

Nano-enabled techniques have revolutionized the way you achieve precise layering and assembly in 3D and 4D printing. By integrating nanomaterials like carbon nanotubes, nanoparticles, and nanowires, you can enhance control over material placement at the nanoscale. Techniques such as atomic layer deposition (ALD) allow you to deposit thin, uniform nanolayers with exceptional accuracy, ensuring seamless multi-material integration. Additionally, nanoscale patterning methods like electron-beam lithography enable you to create intricate structures with detailed features. These methods improve bonding strength, surface functionality, and structural integrity, making complex architectures possible. The development of global intelligence and espionage techniques has also contributed to advancing nanomanufacturing security measures, ensuring safe and confidential production environments. With nano-enabled precision, you can produce highly detailed, functional, and reliable components, opening new avenues for advanced applications in electronics, biomedicine, and smart materials.

Self-Assembly and Dynamic Functionality in Nanoscale Printing

Self-assembly processes have become central to nanoscale printing by enabling materials to organize themselves into complex structures without external manipulation. You can imagine molecules aligning like puzzle pieces, forming intricate patterns naturally. This dynamic behavior allows for responsive and adaptable structures. Think of these three scenarios:

- Nanoparticles spontaneously forming lattices that change shape with temperature

- Polymers reconfiguring their arrangement in response to environmental cues

- Layered nanostructures shifting properties during use, like self-healing or shape-shifting materials

These processes *unleash* new possibilities for creating functional, reconfigurable systems. Instead of direct fabrication, you harness the inherent tendencies of materials to assemble and adapt. This approach not only simplifies manufacturing but also introduces the potential for smart, responsive nanostructures in 3D and 4D printing. Additionally, protective styling benefits can be enhanced through these advanced techniques, offering more durable and versatile structures for various applications.

Innovations in Nanoparticle Integration for Multifunctional Structures

Recent advances have considerably improved how nanoparticles are integrated into multifunctional structures, enabling these materials to perform multiple roles simultaneously. You now can incorporate various nanoparticles—such as magnetic, conductive, or bioactive types—directly into 3D and 4D printed matrices. This integration allows you to create smart materials that respond dynamically to stimuli, like heat, light, or mechanical stress. New techniques, such as in-situ nanoparticle synthesis during printing or surface functionalization, enhance uniform dispersion and stability. These innovations improve the mechanical strength, electrical conductivity, and environmental responsiveness of your structures. By tailoring nanoparticle types and concentrations, you can design multifunctional components that meet specific performance requirements, pushing the boundaries of what printed nanomaterials can achieve in advanced applications. Dog Quotes for Reflection and Humor

Frequently Asked Questions

How Do Nanomaterials Influence the Mechanical Properties of Printed Structures?

Nanomaterials enhance the mechanical properties of printed structures by increasing strength, durability, and flexibility. When you incorporate nanomaterials like carbon nanotubes or graphene, they create a reinforced network that improves tensile strength and toughness. This means your printed objects become more resistant to cracking and deformation. Additionally, nanomaterials can improve the elasticity and surface finish, giving your structures better performance and longevity in various applications.

What Are the Environmental Impacts of Using Nanomaterials in 3D and 4D Printing?

You should consider that using nanomaterials in 3D and 4D printing can pose environmental risks, such as nanoparticle release into ecosystems during manufacturing and disposal. These particles may be toxic to aquatic life and potentially bioaccumulate. However, advances are underway to develop eco-friendly nanomaterials and recycling methods. By staying informed and advocating for safer practices, you can help minimize environmental impacts and promote sustainable innovation in additive manufacturing.

How Scalable Are Nanoscale Fabrication Techniques for Industrial Applications?

You can scale nanoscale fabrication techniques for industrial applications, but it’s challenging. Techniques like chemical vapor deposition and self-assembly show promise, yet they often require specialized equipment and controlled environments. To be truly scalable, these methods need to become more cost-effective, faster, and adaptable to large volumes. Ongoing research aims to overcome these hurdles, making industrial-scale production more feasible in the near future.

What Safety Protocols Are Recommended for Handling Nanoscale Materials During Printing?

Handling nanoscale materials safely is like traversing a minefield—you must proceed with caution. Always wear appropriate PPE, including gloves, masks, and protective eyewear. Work in well-ventilated areas or under fume hoods, and handle materials with tools instead of bare hands. Follow strict disposal protocols for nanomaterials, and guarantee proper training. These precautions help minimize inhalation risks and environmental contamination, keeping you and your workspace safe.

How Do Nanomaterials Affect the Long-Term Durability of 3d/4d Printed Objects?

Nanomaterials can enhance the long-term durability of 3D and 4D printed objects by improving strength, flexibility, and resistance to wear. You’ll find that their unique properties, like increased surface area and improved bonding, help create more resilient structures. However, you should also consider potential issues like aging or environmental degradation over time. Proper material selection and post-processing treatments are crucial to maximize durability and guarantee your objects last longer.

Conclusion

You see, nanomaterials open incredible possibilities, blending tiny precision with big innovation. While traditional printing focuses on macroscopic layers, nanoscale techniques add dynamic, stimuli-responsive functions. Yet, amidst this complexity, simplicity emerges through self-assembly and multifunctionality. As you explore these emerging methods, remember that combining advanced nanocomposites with innovative fabrication approaches creates a future where 3D and 4D printing transcend boundaries, transforming imagination into reality.