Nanomachines help drive circular economy models by enabling precise and efficient recovery of valuable materials from waste, especially electronic devices. They target specific chemical bonds to break down complex materials and separate metals like gold and rare earth elements. This process reduces reliance on virgin resources, minimizes environmental impact, and promotes resource reuse. By integrating nanotech into recycling, you can support sustainable practices that keep valuable materials in circulation—exploring more reveals how these tiny machines transform resource management.

Key Takeaways

- Nanomachines enable precise identification, separation, and recovery of valuable materials from waste streams, supporting resource reuse.

- They facilitate targeted dismantling of electronic devices, promoting closed-loop recycling and minimizing waste.

- Nanotech enhances material design for easier recovery, increasing the efficiency of circular resource management.

- Their ability to operate at the atomic level reduces energy use and chemical dependency in recycling processes.

- Nanomachines transform waste into valuable resources, fostering sustainable, regenerative economic models.

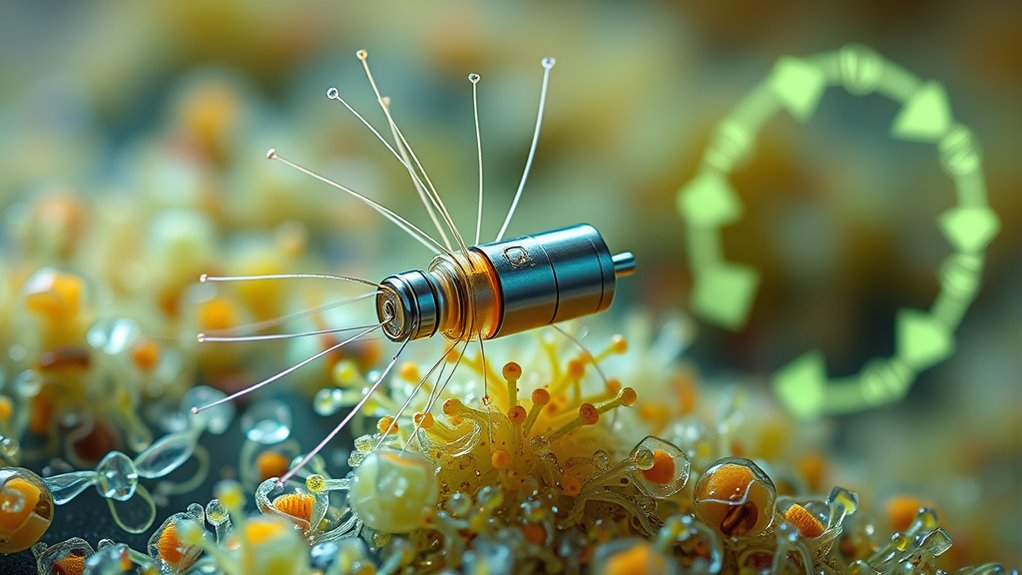

Nanomachines are transforming how we approach the circular economy by enabling precise, efficient, and sustainable processes at the microscopic level. With advancements in nanotech recycling, you can now envision breaking down complex materials into their basic components more effectively than ever before. These tiny machines can identify, separate, and recover valuable materials from waste streams, reducing dependency on virgin resources and minimizing environmental impact. For example, nanomachines can target specific chemical bonds in microfabricated materials, allowing for selective dismantling and recycling that preserves the integrity of recyclable components. This level of precision helps prevent material degradation, making reuse more viable and economically attractive.

Nanomachines enable precise, sustainable recycling by targeting specific materials at the microscopic level, reducing waste and conserving resources.

By leveraging nanotech recycling, you’re not just improving waste management; you’re actively enhancing resource efficiency. Microfabricated materials, which are engineered at the nanoscale, become particularly relevant here. Because these materials are designed with specific properties and functionalities, nanomachines can interact with them at an atomic level, facilitating cleaner, faster, and more complete recycling processes. This capability means that complex electronic waste, for instance, can be processed more thoroughly, recovering critical metals like gold, copper, and rare earth elements with minimal loss. The ability to precisely target microfabricated materials also reduces the need for harsh chemicals or energy-intensive procedures, aligning with sustainability goals. Additionally, advances in nanotechnology are enabling the development of more sophisticated nanomachines tailored for specific recycling tasks.

Furthermore, nanomachines enable the development of closed-loop systems where waste is continuously transformed into usable resources. Imagine a scenario where electronic devices are disassembled using nanomachines that selectively extract valuable components, which are then reused to manufacture new products. This cycle diminishes waste accumulation and fosters a regenerative approach that is core to the circular economy. Because nanomachines operate at such a small scale, they’re capable of working within tight spaces and delicate structures, making them suitable for a broad range of materials and applications.

As you incorporate nanotech recycling into your sustainability strategies, you’re also promoting innovation in material design. Engineers can now develop microfabricated materials optimized for easier disassembly or recovery, which further enhances circularity. This synergy between material science and nanotechnology accelerates the transition from linear take-make-dispose models to truly circular systems. Ultimately, nanomachines empower you to reimagine resource management, turning waste into a valuable resource and driving the circular economy forward with precision, efficiency, and sustainability.

Frequently Asked Questions

How Do Nanomachines Specifically Reduce Waste During Manufacturing?

Nanomachines reduce waste during manufacturing by enhancing material precision and process optimization. You can rely on them to create highly accurate components, minimizing excess material use. Their precise control allows you to optimize each step, reducing by-products and scrap. As a result, you achieve a cleaner, more efficient process that cuts waste, conserves resources, and supports sustainable production, all while maintaining high-quality standards.

What Are the Safety Concerns Associated With Nanomachines in Circular Systems?

You should be aware that nanomachine toxicity raises health risks if these tiny devices are released into the environment or come into contact with humans. Regulatory challenges also complicate safety measures, as existing laws may not fully address nanomachine deployment. To guarantee safety, continuous research and updated regulations are essential. Proper handling, disposal, and monitoring are key to minimizing potential hazards within circular systems.

How Cost-Effective Are Nanomachines Compared to Traditional Recycling Methods?

Nanomachines are generally more cost-effective than traditional recycling methods over time because they enable precise, efficient material recovery, reducing waste and energy use. Their advanced cost comparison shows lower operational expenses and faster processing times, boosting economic viability. Although initial investments might be higher, the long-term savings and sustainability benefits make nanomachines a smarter choice for circular systems, helping you achieve both environmental and financial goals effectively.

Can Nanomachines Be Used to Repair Damaged Products Directly?

Yes, nanomachines can be used for nano repair and product restoration. You can deploy them to fix damaged products directly, as they target specific flaws at the molecular level. This precision allows for effective repair without replacing entire items, extending product lifespans and reducing waste. By integrating nanomachines into maintenance processes, you actively support a circular economy, making repairs more sustainable and efficient.

What Are the Environmental Impacts of Deploying Nanomachines at Scale?

Deploying nanomachines at scale could lower your environmental footprint by enabling efficient recycling and waste reduction. However, you should consider ecosystem risks, such as unintended nanoparticle release and bioaccumulation, which may harm wildlife and habitats. Responsible management, thorough testing, and regulation are essential to minimize these impacts. By doing so, you protect the environment while harnessing nanomachines’ potential to support sustainable, circular economy models.

Conclusion

You now see how nanomachines act as the silent architects of a circular economy, weaving intricate webs of sustainability and innovation. Like tiny alchemists, they transform waste into treasure, turning the cycle of resource use into an endless dance. As these microscopic marvels reveal new possibilities, they breathe life into our planet’s future—an intricate symphony where technology and nature harmonize, ensuring the Earth’s song endures for generations to come.