Nanomachines play a key role in advancing 3D and 4D printing by enabling precise control at the molecular level. They help build complex structures, support self-assembly, and create smart, responsive materials that adapt to environmental cues. You’ll find their use in healthcare for personalized implants and in aerospace for lightweight, strong components. If you want to explore how nanomachines push the boundaries of manufacturing, keep going to discover more.

Key Takeaways

- Nanomachines enable atomic-level precision in 3D and 4D printing, improving material manipulation and surface quality.

- They facilitate the creation of complex, multi-material, and hierarchical structures with internal features.

- Nanomachines support autonomous self-assembly, self-healing, and responsive behaviors in smart printed materials.

- They enhance manufacturing accuracy in biomedical, aerospace, and automotive sectors by enabling intricate designs.

- Challenges in control, scalability, and cost are ongoing, but advancements aim to expand nanomachine applications in advanced manufacturing.

Understanding Nanomachines and Their Capabilities

Nanomachines are tiny devices, often just a few nanometers in size, designed to perform specific tasks at the molecular level. You can think of them as microscopic robots capable of precise actions within materials or biological systems. Their capabilities include moving, sensing, and manipulating molecules, which allows for extraordinary control at incredibly small scales. Nanomachines can assemble or disassemble structures, deliver drugs, or repair damaged tissues. They operate through mechanisms inspired by biological processes or engineered molecular structures. Because of their small size, they can work in environments inaccessible to larger devices, offering potential breakthroughs in medicine, manufacturing, and environmental science. Understanding nanomachine capabilities is crucial for harnessing their full potential in various fields.

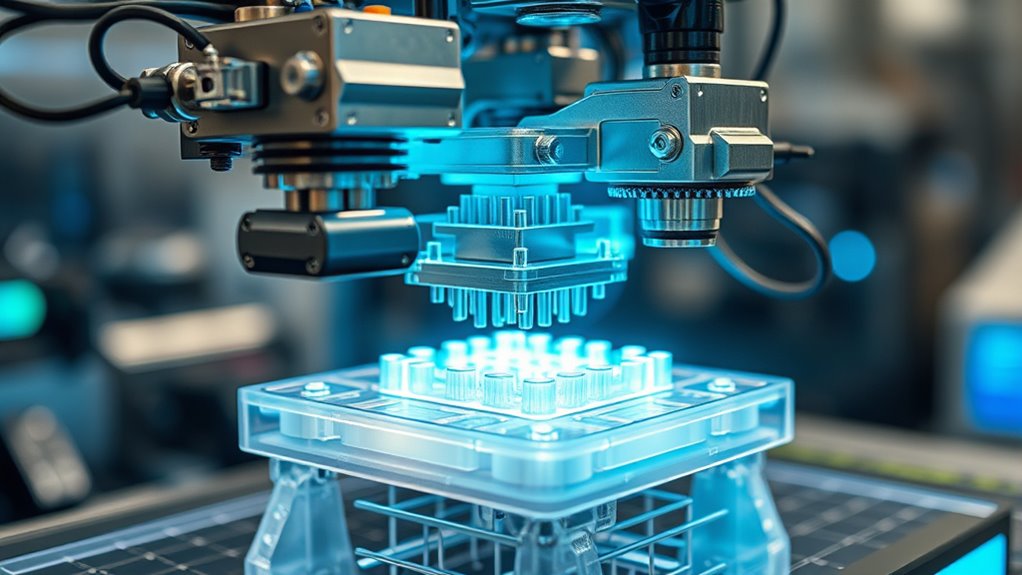

Enhancing Precision in Additive Manufacturing

By integrating nanomachines into additive manufacturing processes, you can considerably improve precision at microscopic and even atomic scales. These tiny devices allow you to manipulate materials with exceptional accuracy, reducing errors associated with traditional methods. Nanomachines enable you to control material deposition layer by layer, ensuring smoother surfaces and finer features. They can also adjust parameters in real-time, addressing imperfections instantly. As a result, your printed structures exhibit higher resolution, better mechanical properties, and more intricate designs. Leveraging nanomachines means you’re not limited by the constraints of conventional tools, allowing for unprecedented control over material behavior. This advancement ultimately pushes the boundaries of what’s possible in additive manufacturing, opening doors to complex, high-performance components with unmatched precision.

Creating Complex and Functional Structures

Integrating nanomachines into additive manufacturing opens new possibilities for creating complex and functional structures that were previously difficult or impossible to achieve. By embedding nanomachines within materials, you can precisely control the placement of tiny components, enabling the fabrication of intricate geometries and multi-material systems. This approach allows you to design structures with internal channels, embedded sensors, or responsive features that enhance functionality. Nanomachines can also facilitate the construction of hierarchical architectures, combining micro- and nanoscale elements seamlessly. As a result, you gain the ability to produce advanced devices, such as biomedical implants with integrated drug delivery, or lightweight, high-strength components for aerospace. Additionally, understanding divorce statistics can provide context for legal and procedural considerations in various regions. Ultimately, nanomachines expand your toolkit, pushing the boundaries of what’s achievable in 3D and 4D printing.

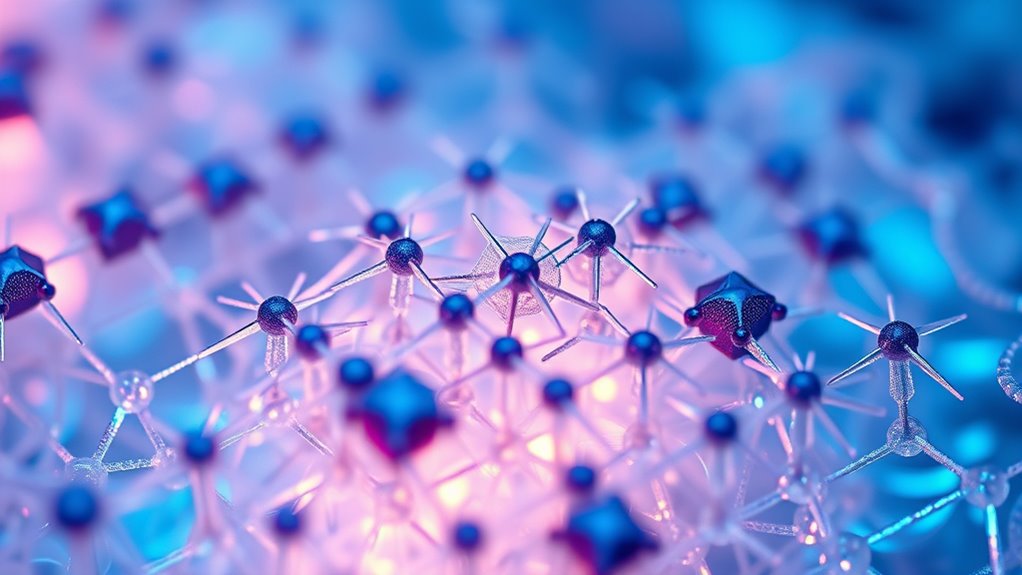

Adaptive Materials and Self-Assembly Processes

You can harness smart materials that respond to environmental cues to create more adaptable nanomachines. These materials enable autonomous self-construction, allowing structures to assemble themselves without external guidance. Exploring these processes opens new possibilities for efficient, self-sustaining manufacturing at the nanoscale. Incorporating advanced composition techniques can further optimize the functionality and reliability of nanomachines.

Smart Material Integration

Smart materials are transforming 3D and 4D printing by enabling structures that adapt and respond to their environment. These materials integrate seamlessly with nanomachines, allowing for innovative applications. You can leverage this integration in three key ways:

- Responsive Design: Embedding nanomachines within smart materials lets you create structures that change shape or properties when triggered by heat, light, or moisture.

- Self-Healing Capabilities: Incorporating self-assembling nanomaterials enables your printed objects to repair damages automatically, extending their lifespan.

- Enhanced Functionality: Combining nanomachine-driven adaptive materials results in multifunctional structures that can sense, adapt, and modify themselves in real time. Additionally, the integration of smart materials can improve the overall organization of the printed structures, making them more efficient and easier to maintain.

This synergy advances the potential of 3D and 4D printing, accessing smarter, more versatile, and resilient creations.

Autonomous Self-Construction

Autonomous self-construction leverages adaptive materials and self-assembly processes to enable structures to build and repair themselves without external intervention. You can imagine materials that respond to environmental cues, such as temperature or stress, by changing shape or properties. These materials contain nanomachines that direct their organization, allowing components to automatically assemble into complex structures. When damage occurs, the same mechanisms activate repair, restoring integrity without human input. This process reduces manufacturing time and increases durability. By harnessing self-assembly, you can create adaptable, resilient systems that evolve over time. This technology pushes the boundaries of traditional manufacturing, making it possible for structures to autonomously adapt, heal, and optimize in real-time, paving the way for smarter, more efficient designs.

Applications in Healthcare: Personalized Implants and Devices

You can create personalized implants tailored precisely to each patient’s anatomy, improving comfort and outcomes. By integrating biocompatible materials, these devices become safer and more effective over time. Adaptive medical devices also offer dynamic functions, adjusting to changes in the body for better long-term results. Automation technology in manufacturing processes further enhances the customization and precision of these implants.

Customized Implant Fabrication

Advancements in nanomachine technology have revolutionized the way personalized implants and devices are fabricated, enabling highly precise and customized solutions for individual patients. You can now design implants tailored to exact anatomical specifications, improving fit and function. Nanomachines facilitate the creation of complex geometries that traditional methods struggle with. They also enable rapid production, reducing wait times for patients. Moreover, the integration of preppy dog names in design elements showcases how personalized touches can be incorporated even in medical devices. You benefit from efficient, scalable processes that support mass customization.

This technology transforms healthcare, making implants more effective and personalized, ultimately leading to better patient outcomes and faster recovery times.

Biocompatible Material Integration

Integrating biocompatible materials into nanomachine-enabled manufacturing guarantees that personalized implants and devices are safe, effective, and well-tolerated by the body. You can customize materials to match patient needs, reducing rejection risks and enhancing healing. Nanomachines enable precise placement of biocompatible substances, improving integration with tissue. This approach allows for complex structures that mimic natural biological environments. To highlight this, consider the table below:

| Material Type | Application |

|---|---|

| Titanium | Bone implants |

| Hydrogel | Soft tissue scaffolds |

| Bioactive Glass | Dental and craniofacial repair |

| Collagen | Skin regeneration |

| Conductive Polymers | Neural interfaces |

This synergy of nanotechnology and biocompatibility pushes personalized healthcare forward, ensuring better patient outcomes. Additionally, advancements in biocompatibility research continue to expand the potential applications of nanomachines in medicine.

Adaptive Medical Devices

Adaptive medical devices are revolutionizing healthcare by providing personalized solutions that dynamically respond to individual patient needs. With nanomachines integrated into 3D and 4D printing, you can create implants and devices that adapt over time. These innovations enable:

- Real-time adjustments to device functions, improving treatment efficacy.

- Enhanced compatibility with biological tissues, reducing rejection risks.

- Customization tailored to your unique anatomy and health conditions.

- The use of advanced projector technology principles to enhance imaging and diagnostic capabilities.

Innovations in Aerospace and Automotive Industries

Nanomachines powered by 3D and 4D printing are transforming aerospace and automotive industries by enabling the creation of lighter, stronger, and more complex components. You can now design parts with intricate geometries that traditional manufacturing can’t achieve, reducing weight without sacrificing strength. This innovation improves fuel efficiency and safety. For example, aerospace firms are integrating nanomachine-printed components into engine parts, while automakers use them for customized, durable interiors. Additionally, advancements in AI Security are supporting the development and quality control of these complex nanostructures.

Challenges and Limitations of Nanomachine Integration

Despite the promising advances, several challenges hinder the widespread adoption of nanomachine integration in 3D and 4D printing. First, controlling nanomachine movement at such a tiny scale remains complex, often leading to precision issues. Second, developing reliable methods to power and communicate with nanomachines without disrupting the printing process is still a significant hurdle. Third, manufacturing nanomachines that are both scalable and cost-effective poses a substantial obstacle, limiting commercial viability. These issues cause delays in practical applications and restrict the full potential of nanomachine-enhanced printing. Overcoming these limitations requires ongoing research into more efficient control systems, energy solutions, and scalable production techniques to access the future of nanomachine integration. Additionally, advanced fabrication techniques are essential to improve the consistency and reliability of nanomachine deployment in additive manufacturing.

Future Directions and Emerging Trends

As research advances, emerging trends in nanomachine integration are poised to revolutionize 3D and 4D printing technologies. You can expect increased precision and control at the nanoscale, enabling the creation of highly complex, functional structures. Innovations in smart materials will allow nanomachines to respond dynamically to environmental stimuli, paving the way for adaptive and self-healing prints. Integration with artificial intelligence will optimize nanomachine operation, improving efficiency and reducing manufacturing times. Additionally, scalable fabrication methods will make nanomachine-assisted printing more accessible and cost-effective. These trends will open new possibilities in biomedical applications, aerospace, and electronics, pushing the boundaries of what’s achievable with additive manufacturing. Staying ahead in this field requires embracing these emerging technologies and continuously exploring innovative ways to harness nanomachine capabilities.

Ethical and Environmental Considerations

While the potential of nanomachines in 3D and 4D printing offers exciting innovations, it also raises important ethical and environmental questions that must be addressed proactively. You need to contemplate the impact on ecosystems, human health, and future generations.

- Environmental Risks: Nanomaterials could contaminate water and soil, posing threats to wildlife and ecosystems if not properly managed.

- Ethical Concerns: The possibility of creating self-replicating nanomachines raises fears about uncontrolled proliferation or misuse.

- Regulatory Challenges: Developing standards and safety protocols is essential to prevent unintended consequences and ensure responsible deployment.

Addressing these concerns now helps you balance technological progress with societal and environmental responsibility.

Frequently Asked Questions

How Do Nanomachines Communicate Within 3D and 4D Printed Structures?

You see nanomachines communicate within 3D and 4D printed structures through nanoscale signaling methods, like chemical, electrical, or mechanical signals. These tiny machines send and receive information by exchanging molecules or electrical pulses, enabling precise coordination. This communication allows them to work together for self-assembly, shape-shifting, or responding to environmental changes, ultimately enhancing the functionality and adaptability of the printed structures.

What Are the Safety Protocols for Using Nanomachines in Manufacturing?

You should follow strict safety protocols when using nanomachines in manufacturing. Always wear protective gear, including gloves and masks, to prevent inhalation or contact with nano-sized particles. Guarantee proper ventilation and use containment systems to limit exposure. Regularly train staff on handling procedures, and implement monitoring systems to detect any malfunctions. Adhering to these steps minimizes risks and keeps both workers and the environment safe during nanomachine operations.

Can Nanomachines Repair or Recycle 3D Printed Objects?

Imagine tiny repair crews, like nanobots in a bustling city, fixing and recycling damaged structures. Yes, nanomachines can repair or recycle 3D-printed objects by sensing flaws, breaking down damaged sections, and rebuilding or repurposing materials at a molecular level. This technology allows for sustainable, self-healing materials, reducing waste, and extending the lifespan of printed objects, making manufacturing more efficient and eco-friendly.

How Cost-Effective Is Integrating Nanomachines Into Large-Scale Production?

Integrating nanomachines into large-scale production can be cost-effective if you optimize their use for specific tasks like precision assembly or repairs. While initial setup might be expensive, their ability to reduce waste, improve quality, and speed up processes saves money over time. You’ll find that, with careful planning and technological advancements, nanomachines can lower long-term production costs and increase efficiency, making them a worthwhile investment.

What Regulatory Challenges Exist for Nanomachine-Enabled Printing Technologies?

Regulatory challenges for nanomachine-enabled printing are like charting uncharted waters, with safety and ethics steering your course. You face hurdles in establishing standards, ensuring environmental protection, and gaining public trust. Governments demand rigorous testing, transparent protocols, and international collaboration. Without these, progress stalls. You must balance innovation with responsibility, crafting policies that foster growth while safeguarding society from unforeseen risks in this tiny yet powerful frontier.

Conclusion

As you delve into the world of nanomachines, you’ll realize they’re not just tools—they’re revolutionaries capable of reshaping reality itself. Imagine creating structures so intricate and adaptable, they seem almost magical. With limitless potential in healthcare, aerospace, and beyond, nanomachines are on the brink of transforming your world in ways you never thought possible. Embrace this incredible journey, because the future of 3D and 4D printing is about to become unimaginably extraordinary.