Nanomachines in automotive and aerospace applications are revolutionizing safety, efficiency, and durability. They enable real-time monitoring of structural integrity, detecting cracks and corrosion early, and even repairing damage at a microscopic level. These innovations improve material resilience, extend vehicle lifespan, and reduce maintenance costs. Nanotechnology also enhances fuel efficiency and supports the development of autonomous, connected vehicles. To discover how these tiny tech advancements are shaping your future mobility, keep exploring further.

Key Takeaways

- Nanomachines enable real-time structural monitoring and early detection of cracks or corrosion in vehicle frames and aerospace components.

- They facilitate minimally invasive repairs by targeting specific problem areas and restoring materials at a molecular level.

- Nanotech-enhanced materials improve durability, wear resistance, and performance of automotive and aerospace structures under extreme conditions.

- Integration of nanomachines optimizes engine efficiency and emission control, supporting environmentally friendly and fuel-efficient vehicles.

- They enhance sensor systems and structural integrity for autonomous, connected vehicles, improving safety and navigation accuracy.

Enhancing Vehicle Safety and Structural Integrity

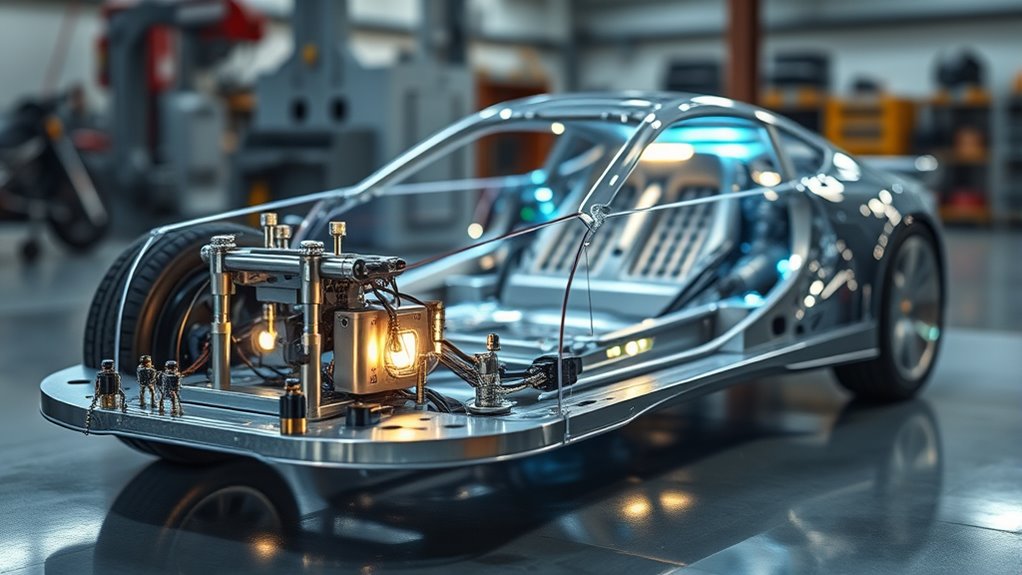

Nanomachines are revolutionizing vehicle safety and structural integrity by enabling real-time monitoring and rapid response to potential damages. When embedded within a vehicle’s frame, they detect stress, cracks, or corrosion long before visible signs appear. This early detection allows you to address issues proactively, reducing the risk of catastrophic failures. Nanomachines can trigger automatic repairs or alert systems to notify you immediately, ensuring your safety. They continuously analyze structural health, adapting to changing conditions and providing detailed data for maintenance planning. This proactive approach enhances durability and extends the lifespan of your vehicle. By integrating nanomachines, manufacturers create safer, more reliable vehicles that respond swiftly to damage, ultimately protecting you and improving overall vehicle performance. Structural health monitoring is a crucial aspect of advanced automotive safety systems that nanomachines significantly improve.

Revolutionizing Maintenance and Repair Techniques

Thanks to nanomachines, maintenance and repair processes are becoming faster and more precise than ever before. You can now detect microscopic cracks or corrosion at an early stage, preventing costly failures. Nanomachines target specific problem areas, enabling you to perform repairs without disassembling entire components. They can inject or remove materials at a molecular level, restoring parts to ideal condition. This technology reduces downtime considerably, saving you time and money. Instead of traditional invasive procedures, nanomachines offer minimally invasive solutions that maintain vehicle integrity. You gain greater control over the repair process, ensuring high-quality results. As a result, maintenance becomes more efficient, reliable, and less disruptive, transforming how you approach vehicle servicing in both automotive and aerospace sectors. Facilitate collaboration among global teams can accelerate the development and deployment of such advanced repair techniques.

Improving Material Durability and Wear Resistance

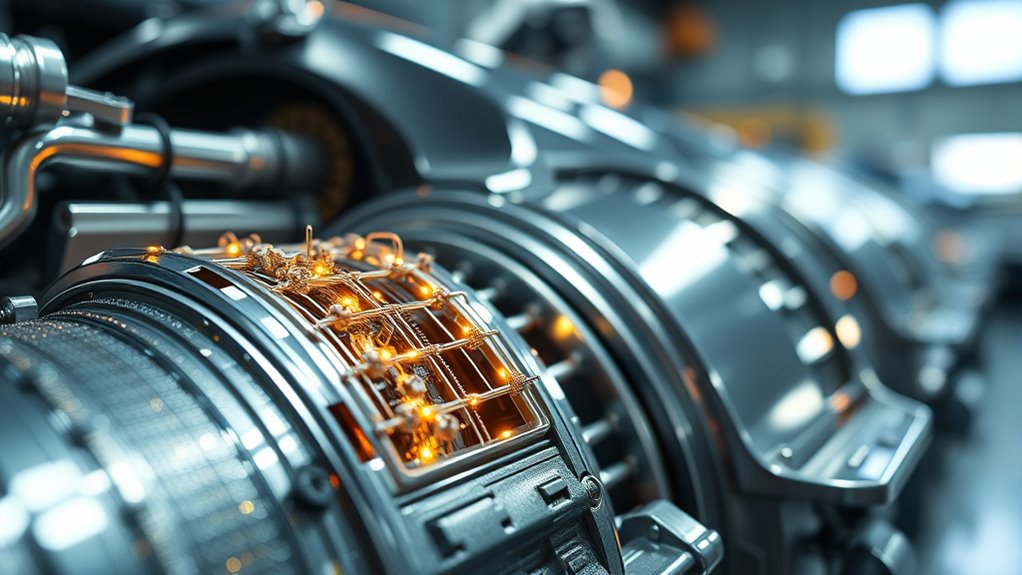

By integrating nanomachines into materials, you can substantially enhance their durability and wear resistance. These tiny machines can detect early signs of damage, such as microcracks or corrosion, and respond by initiating repair processes at the molecular level. They can also reinforce the material’s structure, making it more resistant to friction and mechanical stress. For example, nanomachines embedded in engine components or aerospace surfaces can continuously monitor and adapt to changing conditions, reducing degradation over time. This proactive approach extends the lifespan of parts, lowers maintenance costs, and improves safety. With nanomachines working within materials, you gain a smarter, more resilient system that maintains ideal performance even under extreme conditions. Cost‑of‑ownership considerations are essential when evaluating the long-term benefits of integrating nanomachines into engineering materials.

Advancing Fuel Efficiency and Emission Reduction

Advancements in nanotechnology enable automotive and aerospace systems to optimize fuel consumption and reduce harmful emissions considerably. Nanomachines enhance engine performance by improving fuel combustion efficiency, ensuring more energy is extracted with less fuel. They also enable precise control of catalytic converters, increasing their ability to break down pollutants before they escape into the environment. In addition, nanomaterials used in lightweight composites decrease overall vehicle weight, leading to better fuel economy. These innovations help lower carbon dioxide and other harmful emissions, contributing to cleaner air and compliance with stricter regulations. By integrating nanotech solutions, manufacturers can develop engines and systems that operate more efficiently, ultimately reducing the environmental impact of transportation without sacrificing performance or safety. Incorporating advanced materials can further improve durability and overall system longevity, ensuring sustained environmental benefits over time.

Enabling Next-Generation Autonomous and Connected Vehicles

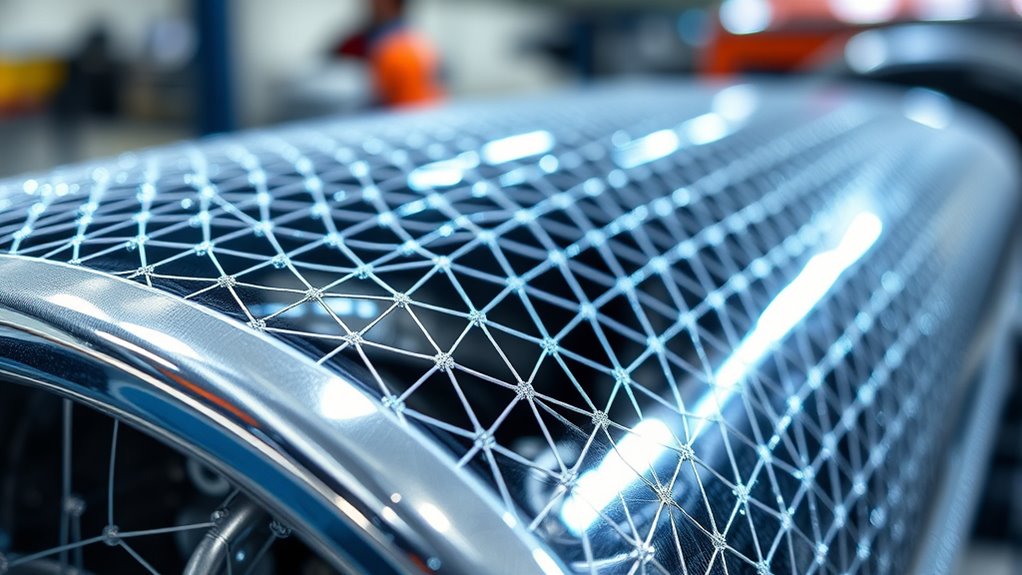

Nanotechnology plays a crucial role in enabling next-generation autonomous and connected vehicles by providing advanced sensors, lightweight materials, and real-time data processing capabilities. These nanomaterials enhance sensor sensitivity, allowing your vehicle to detect obstacles, road conditions, and other vehicles more accurately and faster. Lightweight nanocomposites reduce overall vehicle weight, boosting efficiency and performance without compromising strength. Nanotech-enabled electronics process vast data streams instantly, ensuring quick decision-making and safer navigation. You benefit from improved safety, smoother driving experiences, and better connectivity with infrastructure and other vehicles. As nanomachines continue to advance, they will further integrate AI and IoT systems, making your autonomous vehicle more reliable, efficient, and responsive to real-world demands. This technology paves the way for safer, smarter mobility solutions. Resources and Tools can support the development and deployment of these nanotechnologies in transportation systems.

Frequently Asked Questions

How Are Nanomachines Powered Within Automotive and Aerospace Systems?

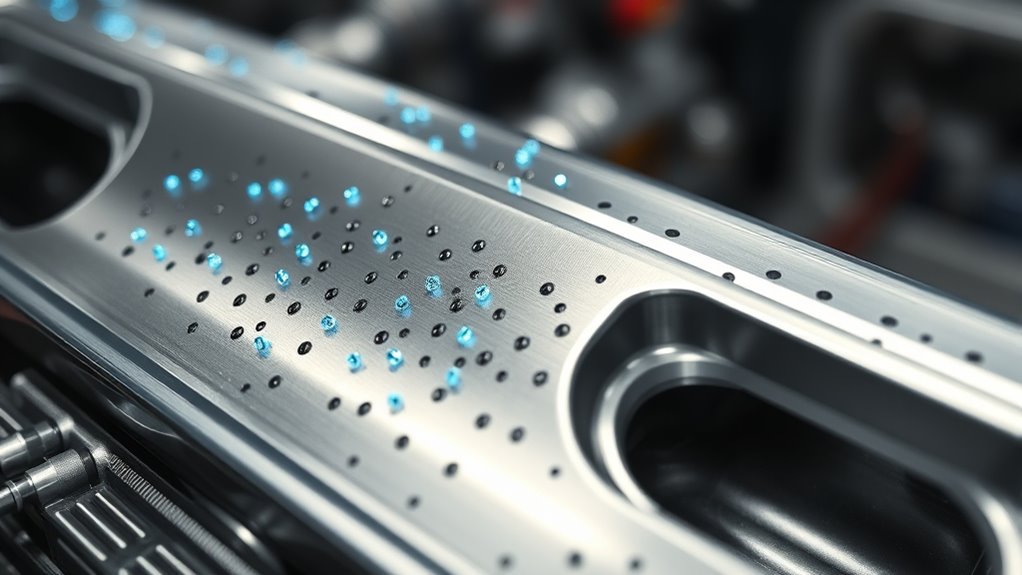

You power nanomachines in automotive and aerospace systems with tiny energy sources like nanogenerators or microscopic batteries. These devices harvest energy from environmental sources such as vibrations, heat, or light, ensuring continuous operation. You might also use energy transfer from nearby systems or electrical signals to activate and sustain nanomachine functions, allowing precise control and efficient performance in demanding environments.

What Are the Environmental Impacts of Deploying Nanomachines in Vehicles?

Imagine you’re stepping into a future where nanomachines are common in vehicles. Their deployment could reduce emissions and fuel consumption, benefiting the environment. However, you should also consider potential risks like nanoparticle pollution or unforeseen ecological impacts. While they promise cleaner transportation, careful regulation and ongoing research are vital to prevent unintended harm. Staying informed ensures you’re part of the solution, not the problem, as technology advances.

How Do Nanomachines Communicate Within Complex Vehicle Networks?

You enable nanomachines to communicate within complex vehicle networks by utilizing tiny, energy-efficient wireless signals or molecular messaging systems. These nanomachines send and receive data through synchronized signal exchanges, often relying on nanometric antennas or chemical signals. You guarantee secure and reliable communication by implementing error correction protocols and encryption, allowing them to coordinate tasks like diagnostics, maintenance, or system optimization seamlessly within the vehicle’s intricate network.

Are Nanomachines Cost-Effective for Large-Scale Automotive and Aerospace Manufacturing?

Yes, nanomachines are cost-effective for large-scale manufacturing because their precision reduces material waste and improves efficiency. You’ll find that their ability to perform complex tasks at a microscopic level speeds up production lines and enhances product quality. While initial investments can be high, the long-term savings on resources and labor make them a worthwhile addition, especially as technology advances and costs decrease over time.

What Safety Regulations Govern the Use of Nanomachines in Transportation?

Think of safety regulations as a shield guarding innovation. You must follow strict guidelines from authorities like the FDA, OSHA, and transportation agencies, which set standards for nanomachine safety, environmental impact, and risk management. These regulations symbolize a safeguard ensuring responsible use. By adhering to them, you protect public health, prevent accidents, and promote trust in emerging nanotech applications within transportation industries.

Conclusion

Imagine a future where nanomachines transform your vehicle and aircraft into marvels of safety, durability, and efficiency. They’re the silent heroes behind smoother rides, longer-lasting materials, and cleaner skies. As you embrace these innovations, remember: every nanomachine is a tiny spark of human ingenuity lighting the way to a safer, smarter world. Together, you’re on the brink of a revolution—where technology and hope collide to elevate your journey beyond imagination.