Nanotechnology plays a key role in making hydrogen production cleaner and more efficient. By using nanomaterials as catalysts, you benefit from larger surface areas and more active sites, which boost reaction rates while reducing energy use. Incorporating quantum dots improves solar energy absorption, increasing hydrogen output. This combination creates faster, cheaper, and greener hydrogen solutions. Keep exploring to discover how these innovative technologies can transform your approach to sustainable energy solutions.

Key Takeaways

- Nanomaterials catalysts enhance hydrogen production efficiency by increasing active surface area and reaction rates.

- Quantum dots improve solar light absorption and energy transfer, boosting solar-driven hydrogen generation.

- Combining nanomaterials with quantum dots creates synergistic systems for more effective, sustainable water splitting.

- Nanotechnology reduces energy consumption and prolongs catalyst lifespan, making clean hydrogen production more cost-effective.

- Nanomaterials contribute to environmentally friendly hydrogen production, supporting the transition to renewable energy sources.

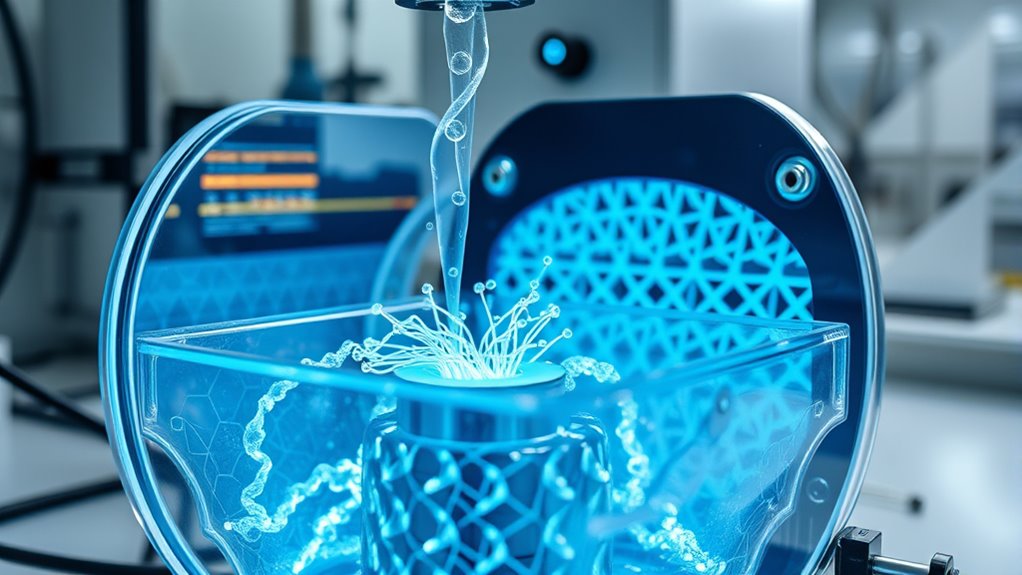

Nanotechnology is revolutionizing how we produce clean hydrogen, offering more efficient and sustainable methods. One of the most promising developments involves the use of nanomaterials catalysts, which dramatically enhance the efficiency of hydrogen generation processes. Unlike traditional catalysts, nanomaterials catalysts operate at a much smaller scale, providing a larger surface area relative to their volume. This increased surface area allows more active sites for reactions to occur, boosting reaction rates and reducing energy consumption. As a result, hydrogen production becomes faster, cheaper, and more environmentally friendly. These nanostructured catalysts are also more durable, resisting degradation over multiple cycles, which extends their operational lifespan and further improves cost-effectiveness.

Nanomaterials catalysts boost hydrogen production efficiency, durability, and environmental sustainability through increased surface area and active sites.

Quantum dots are another game-changing nanotechnology that’s making a considerable impact on hydrogen production. These tiny semiconductor particles, just a few nanometers in size, possess unique optical and electronic properties. Their efficiency in solar-driven processes, such as photocatalytic water splitting, is particularly noteworthy. Quantum dots can absorb a broader spectrum of sunlight and transfer energy more effectively than bulk materials, increasing the overall quantum efficiency of the system. When integrated into photocatalytic setups, they considerably improve the conversion rate of solar energy into hydrogen. This means you get more hydrogen output from the same amount of sunlight, making solar-powered hydrogen production more viable and scalable.

By combining nanomaterials catalysts with quantum dots, researchers are creating highly efficient systems that capitalize on the strengths of each nanotechnology. For example, nanomaterials catalysts can provide the robust, active surface needed for water splitting, while quantum dots optimize the light absorption and energy transfer processes. This synergy results in a more effective, sustainable method for producing hydrogen without relying on fossil fuels. As you look toward a cleaner energy future, these innovations in nanotechnology could drastically reduce the costs and environmental impacts associated with hydrogen production.

In essence, the use of nanomaterials catalysts and quantum dots is transforming hydrogen production into a cleaner, more efficient process. These advanced materials harness the power of the nanoscale to maximize reaction efficiency and energy utilization. This progress not only accelerates the transition to renewable energy sources but also offers a pathway to reduce greenhouse gas emissions considerably. As you consider future energy solutions, understanding the role of nanotechnology in hydrogen production highlights how science is paving the way for a more sustainable and resilient energy landscape.

Frequently Asked Questions

How Does Nanotechnology Improve Hydrogen Storage Efficiency?

Nanotechnology improves hydrogen storage efficiency by enhancing nanomaterial stability and increasing storage capacity. You can rely on nanomaterials that prevent hydrogen leakage and degradation, ensuring safer and more durable storage solutions. By manipulating materials at the nanoscale, you increase surface area, which boosts hydrogen adsorption and release. This leads to higher storage capacity and efficiency, making hydrogen a more practical clean energy source for your applications.

What Are the Environmental Impacts of Nanomaterials Used in Hydrogen Production?

You should know that nanomaterials in hydrogen production can cause environmental toxicity if not managed properly. They may lead to nanoparticle pollution, which harms ecosystems and human health. When these particles are released into air, water, or soil, they can accumulate and cause long-term damage. Consequently, it’s essential to develop safe handling, disposal practices, and regulations to minimize environmental impacts and protect the environment from potential nanomaterial toxicity.

Are Nanotech-Based Hydrogen Production Methods Scalable Commercially?

You can see that nanotech-based hydrogen production methods face scalability challenges, which affect their commercial viability. While promising in lab settings, scaling up involves complex manufacturing, high costs, and ensuring safety. Overcoming these hurdles requires technological advancements and investment. If these challenges are addressed, nanotechnology could become a practical, large-scale solution for clean hydrogen production, helping to meet growing energy demands sustainably.

What Safety Concerns Are Associated With Nanomaterials in Hydrogen Systems?

Think of nanomaterials like tiny guardians—if they become unstable or toxic, they could cause more harm than good. The main safety concerns are nanoparticle toxicity and nanomaterial stability, which could lead to unintended environmental or health impacts. You need rigorous testing and proper handling protocols to prevent accidental exposure, much like handling fragile glassware—care and caution guarantee safety and system integrity.

How Cost-Effective Is Nanotechnology Compared to Traditional Hydrogen Production?

Nanotechnology can be more cost-effective than traditional hydrogen production methods because it enhances efficiency and reduces energy consumption, improving the cost comparison. You’ll find that advancements in nanomaterials lead to better catalysts and storage solutions, boosting economic viability. Although initial investments might be higher, the long-term savings in energy and materials make nanotech-based hydrogen production a promising, cost-efficient alternative for sustainable energy needs.

Conclusion

By harnessing nanotechnology, you’re opening tiny, mighty doors to a cleaner future. Like a delicate brushstroke shaping a masterpiece, these innovations paint a brighter horizon where hydrogen fuels change without scars. Embrace this nanoscopic revolution, for within these minuscule domains lies the power to turn the tide—transforming our world into a lush garden of sustainable energy. Your journey into nanotech’s depths is the key to unlocking a cleaner, greener tomorrow.