Nanofibers are created mainly through electrospinning, where high voltage draws polymer solutions like PVA, PAN, or PLA into ultra-thin fibers. These fibers are perfect for filtration and textiles because of their high surface area and porosity. They can trap particles, microbes, and pollutants effectively while enhancing fabric strength and durability. If you explore further, you’ll discover how their surface modifications and innovative production methods expand their uses and address current challenges.

Key Takeaways

- Nanofibers are mainly produced via electrospinning, utilizing high-voltage electric fields to create ultra-thin, high-surface-area fibers from various polymers and inorganic precursors.

- Characterization techniques like SEM, TEM, and AFM analyze nanofiber morphology, surface properties, and internal structures, influencing their filtration and textile performance.

- In filtration, nanofibers effectively trap particles, microbes, and pollutants, enhancing air and water purification systems with high porosity and efficiency.

- Surface functionalization through chemical or plasma treatments improves nanofiber adhesion, durability, and tailored properties for specific filtration and textile applications.

- Challenges include scalable manufacturing, cost reduction, and environmental impacts, with future research focusing on sustainable, eco-friendly nanofiber production methods.

Methods of Nanofiber Production

To produce nanofibers effectively, researchers primarily use techniques like electrospinning, which employs a high-voltage electric field to draw fine fibers from a polymer solution. In this process, you prepare a polymer solution and load it into a syringe connected to a high-voltage power supply. When the electric field is applied, the solution forms a jet that elongates into thin fibers as it travels toward a grounded collector. Parameters like voltage, solution viscosity, and flow rate influence fiber diameter and quality. Electrospinning allows you to produce continuous nanofibers with high surface area, making it ideal for filtration and textiles. This method’s versatility also enables you to control fiber morphology, producing mats with specific porosity and density suited to various applications. Additionally, understanding field recording techniques can enhance the customization of nanofiber production environments to optimize fiber quality.

Materials Used in Nanofiber Synthesis

You’ll find that common polymer materials like polyvinyl alcohol and polyacrylonitrile are popular choices for nanofiber synthesis. Inorganic precursors, such as silica or alumina, are also used to create nanofibers with specific properties. Understanding these materials helps you choose the right one for your filtration or textile application. Additionally, selecting materials with robust safety measures can help mitigate potential vulnerabilities in nanofiber production processes.

Common Polymer Materials

Polymer materials form the backbone of nanofiber synthesis, offering the necessary flexibility, strength, and processability required for producing high-quality nanofibers. Common polymers include polyvinyl alcohol (PVA), polyacrylonitrile (PAN), polyvinylidene fluoride (PVDF), and poly(lactic acid) (PLA). PVA is water-soluble and easy to process, making it ideal for biomedical applications. PAN is widely used for carbon nanofibers due to its excellent stability and mechanical properties. PVDF offers chemical resistance and piezoelectric properties, suitable for sensors and filtration. PLA, a biodegradable polymer, appeals to eco-friendly applications. These polymers are chosen based on their solubility, melting points, and mechanical traits, which influence fiber morphology and functionality. Selecting the right polymer guarantees the nanofiber’s performance aligns with specific application needs. Additionally, understanding the material properties of each polymer helps optimize the synthesis process and tailor nanofiber characteristics for targeted uses.

Inorganic Nanofiber Precursors

Inorganic nanofiber precursors serve as the foundational materials for synthesizing nanofibers with unique properties such as high thermal stability, chemical resistance, and electrical conductivity. You’ll find that these precursors include various inorganic compounds tailored for specific applications. For example, they can be classified into:

- Metal oxides like alumina, silica, and titania, known for their durability and high-temperature performance.

- Metal salts such as silver nitrate or zinc chloride, which enable functional antimicrobial or conductive properties.

- Ceramics and glass-based materials that provide excellent chemical stability and thermal resistance.

These inorganic precursors are processed through techniques like electrospinning or sol-gel methods to produce nanofibers suited for filtration, catalysis, and advanced textiles.

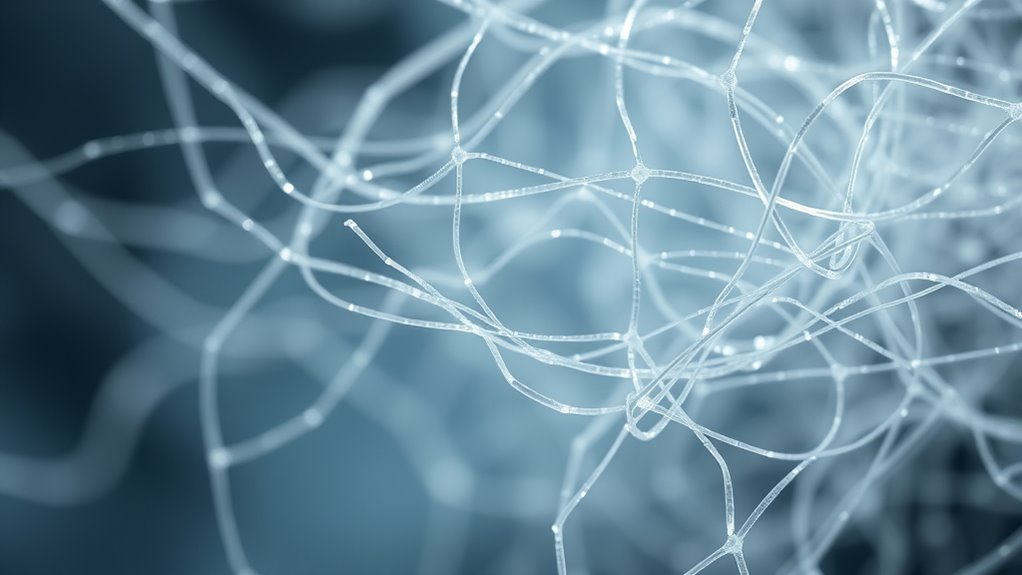

Characterization Techniques for Nanofibers

To understand nanofibers better, you need to explore various characterization techniques. Microscopy methods reveal their morphology, while surface property analysis shows how they interact with environment. Mechanical testing then helps you assess their strength and durability effectively. Additionally, understanding material properties is essential for optimizing nanofiber applications in filtration and textiles.

Microscopy Methods Overview

Microscopy techniques are essential tools for examining nanofibers, providing detailed insights into their morphology, surface features, and internal structures. These methods help you understand fiber diameter, surface roughness, and porosity. Three key microscopy techniques include:

- Scanning Electron Microscopy (SEM): Offers high-resolution images of fiber surface topology and morphology.

- Transmission Electron Microscopy (TEM): Reveals internal structures and nanofiber cross-sections with atomic detail.

- Atomic Force Microscopy (AFM): Measures surface roughness and topography at nanometer scale, providing 3D surface profiles.

Using these techniques, you can thoroughly characterize nanofiber features, guiding synthesis adjustments and application development. Mastering microscopy methods allows you to evaluate nanofiber quality and optimize performance in filtration and textile applications. Additionally, understanding the resolution capabilities of each microscopy method helps determine the most suitable technique for specific nanofiber analyses.

Surface Property Analysis

After examining nanofibers with advanced microscopy techniques, understanding their surface properties becomes the next step in thorough characterization. You’ll want to use techniques like contact angle measurements to assess surface wettability, which influences filtration efficiency and textile performance. X-ray photoelectron spectroscopy (XPS) helps identify surface chemical compositions, revealing functional groups and potential contaminants. Atomic force microscopy (AFM) allows you to analyze surface roughness and topography at the nanoscale, critical for understanding interactions with fluids or particles. Additionally, Fourier-transform infrared spectroscopy (FTIR) provides insights into surface chemical bonds and modifications. These methods give you a detailed view of surface characteristics, enabling optimized nanofiber design for specific filtration or textile applications. Accurate surface analysis ensures better performance, durability, and functionality in your nanofiber-based products.

Mechanical Testing Techniques

Mechanical testing techniques are essential for evaluating the strength, flexibility, and durability of nanofibers. These methods help you understand how nanofibers perform under different stresses and strains. First, tensile testing measures how much force a fiber can withstand before breaking, giving insights into its strength and elongation. Second, nanoindentation assesses hardness and elastic modulus by pressing a small indenter into the fiber surface. Third, dynamic mechanical analysis (DMA) evaluates viscoelastic properties, such as storage and loss moduli, under varying temperatures and frequencies. These techniques enable you to determine the mechanical limits and performance characteristics of nanofibers, ensuring their suitability for filtration, textiles, and other applications. Proper testing guides material optimization and quality control effectively. Understanding AI-powered testing methods can further enhance the precision and efficiency of nanofiber characterization.

Applications in Air and Water Filtration

Have you ever wondered how nanofibers enhance air and water quality? Their tiny diameter creates an enormous surface area, allowing them to trap particles, pollutants, and microbes more effectively than traditional filters. In air filtration, nanofibers form dense mats that capture dust, allergens, and even viruses, improving indoor air quality. For water filtration, they remove contaminants like bacteria, toxins, and heavy metals, ensuring cleaner drinking water. Their high porosity allows for efficient flow rates while maintaining filtration efficiency. Because nanofibers can be tailored with specific surface properties, they also help target particular pollutants. This versatility makes them ideal for air purifiers, HVAC systems, and water treatment plants. Additionally, advancements in lifestyle and workspace setup can influence the effectiveness of filtration systems by reducing indoor pollutants. Overall, nanofibers markedly improve filtration performance, providing cleaner air and water for everyday use.

Enhancing Textile Performance With Nanofibers

Nanofibers revolutionize textile performance by adding strength, durability, and functionality. When integrated into fabrics, they enhance properties such as tensile strength, abrasion resistance, and moisture management. This means your textiles become more long-lasting and capable of withstanding daily wear and tear. Additionally, nanofibers improve breathability and comfort by creating finer, more uniform fibers that allow better air flow. Here are three ways nanofibers boost textile performance:

Nanofibers enhance textiles with increased strength, durability, breathability, and resistance to wear.

- Increasing tensile strength and durability

- Improving moisture wicking and breathability

- Enhancing resistance to abrasion and environmental factors

Functionalization and Surface Modifications

To open the full potential of nanofibers in textiles, surface modifications and functionalization play an essential role. By tailoring surface properties, you can enhance nanofibers’ functionality, such as adding antimicrobial, hydrophobic, or conductive features. These modifications improve durability and performance, opening new application avenues. Techniques include chemical grafting, plasma treatment, and coating, which alter surface chemistry without affecting fiber integrity. Consider the following approaches:

| Technique | Purpose | Benefits |

|---|---|---|

| Chemical Grafting | Attach functional groups | Improves adhesion, functionality |

| Plasma Treatment | Surface activation | Increases hydrophilicity or hydrophobicity |

| Coating | Add protective layers | Enhances durability and specific properties |

Surface modifications and functionalization are crucial for customizing nanofibers to meet specific application requirements, leveraging surface chemistry to optimize their performance in textiles and filtration systems.

Challenges and Future Perspectives

Despite their promising potential, integrating nanofibers into commercial filtration and textile applications faces several challenges. First, manufacturing scalability remains difficult, as producing consistent, high-quality nanofibers in large quantities is complex. Second, cost-effectiveness is a concern; advanced synthesis methods often require expensive equipment and materials. Third, durability issues can limit long-term performance, especially under harsh conditions or repeated use. To overcome these hurdles, you need to focus on developing more efficient production techniques, reducing costs through innovation, and improving the mechanical stability of nanofibers. Additionally, assessing the material durability of nanofibers under various conditions is essential for ensuring their longevity and reliability. These efforts will be essential for widespread adoption. Future advancements should aim at integrating nanofibers seamlessly into existing manufacturing processes while maintaining performance and affordability.

Environmental Impact and Sustainability

Have you ever considered the environmental implications of using nanofibers in filtration and textiles? While nanofibers offer impressive benefits like enhanced filtration efficiency and lightweight properties, their production and disposal can raise environmental concerns. Manufacturing processes may involve hazardous chemicals or high energy consumption, contributing to carbon footprints. Additionally, the small size of nanofibers makes them difficult to recover and recycle, potentially leading to environmental release and microplastic pollution. To promote sustainability, researchers focus on developing eco-friendly synthesis methods and biodegradable nanofibers. Improving nanofiber recyclability is essential to reducing environmental impacts. You can help by choosing products made with sustainable materials and supporting innovations aimed at reducing ecological impacts. Balancing performance with environmental responsibility is *vital* for the future of nanofiber applications in a greener, more sustainable world.

Innovations and Emerging Trends

Innovations in nanofiber technology are rapidly transforming how you approach filtration and textiles. Cutting-edge developments are driving new applications and improving performance. For instance:

- You now see multifunctional nanofibers that combine filtration with antimicrobial, UV protection, or self-cleaning features, expanding their use.

- Researchers are exploring environmentally friendly production methods, like electrospinning with biodegradable polymers, to reduce ecological impact.

- Advanced manufacturing techniques, such as 3D printing, enable precise control over nanofiber architecture, enhancing durability and efficiency.

These innovations make nanofibers more versatile and sustainable, opening doors for smarter, more effective filtration systems and textiles tailored to modern needs. Staying informed helps you leverage these emerging trends for better solutions.

Frequently Asked Questions

What Are the Health Risks Associated With Nanofiber Manufacturing?

You should be aware that manufacturing nanofibers can pose health risks like inhaling tiny particles that may cause respiratory issues or lung inflammation. Prolonged exposure might lead to skin irritation or other health problems if safety protocols aren’t followed. To stay safe, always wear proper protective gear, guarantee proper ventilation, and follow industry safety guidelines to minimize risks associated with handling nanomaterials.

How Do Nanofibers Compare Cost-Wise to Traditional Fibers?

You’ll find that nanofibers tend to be more expensive than traditional fibers due to their complex manufacturing processes and the need for specialized equipment. However, their unique properties, like higher filtration efficiency and strength, can offset costs in certain applications. While initial expenses are higher, their performance benefits often justify the investment, especially in high-demand fields like filtration, healthcare, and advanced textiles.

Can Nanofibers Be Recycled or Reused Effectively?

You can definitely recycle or reuse nanofibers, but it’s not always straightforward. They often require specialized processes, like solvent recovery or thermal treatments, which can be costly. While some nanofibers, especially those made from biodegradable materials, lend themselves well to recycling, others pose challenges due to their small size and composition. It’s a bit of a double-edged sword, but ongoing research aims to make reuse more practical and efficient.

What Are the Most Promising New Applications Beyond Filtration and Textiles?

You should explore nanofibers’ potential in energy storage, such as advanced batteries and supercapacitors, where their high surface area boosts performance. They also show promise in biomedical fields for drug delivery and tissue engineering, thanks to their biocompatibility and nanoscale structure. Additionally, look into their use in sensors and environmental remediation, where their sensitivity and large surface area enable efficient detection and removal of pollutants.

How Do Regulatory Standards Influence Nanofiber Development?

Regulatory standards shape your nanofiber development by setting safety and quality benchmarks, ensuring your products are safe for users and the environment. You must comply with these regulations, which can influence material choices, manufacturing processes, and testing protocols. Staying updated on evolving standards helps you innovate responsibly, avoid legal issues, and gain market acceptance, ultimately guiding your research and development efforts toward compliant, high-quality nanofiber solutions.

Conclusion

Remember, Rome wasn’t built in a day, and the same applies to nanofiber advancements. As you explore their synthesis and applications, stay curious and innovative. Nanofibers hold immense potential for transforming filtration and textiles, but overcoming current challenges is key. By embracing sustainability and continuous research, you’ll contribute to a future where nanotechnology benefits both industry and the environment. Keep pushing boundaries—great things happen when you dare to innovate.