Nanofilms are ultrathin coatings just a few nanometers thick that boost electronic and energy device performance. They provide precise control over optical, electrical, and surface properties, making devices more durable, efficient, and lightweight. These coatings are used in protective barriers, conductive layers, and energy storage enhancements. If you want to discover how nanofilms transform industries and what future innovations they hold, there’s plenty more to explore.

Key Takeaways

- Nanofilms are ultrathin coatings that enhance electronic device performance through improved conductivity, protection, and optical properties.

- Fabrication techniques like ALD and PVD enable precise, uniform nanofilm deposition for electronics and energy applications.

- They improve energy storage devices by increasing active surface area and facilitating efficient ion and electron transport.

- Nanofilms offer protective barriers against environmental damage, extending device lifespan and reliability.

- Their tunable optical and electrical properties support advanced functionalities in flexible displays, solar cells, and sensors.

Understanding the Nature of Nanofilms

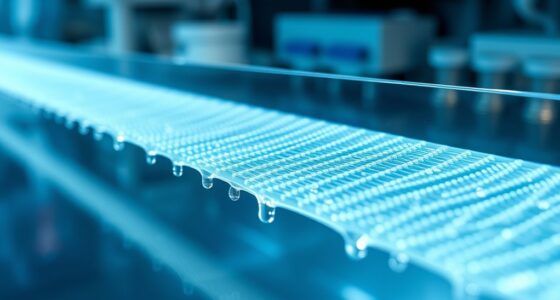

What exactly are nanofilms, and how do they differ from other thin materials? Nanofilms are ultrathin layers of material, typically just a few nanometers thick, that are engineered to have specific properties. Unlike thicker coatings, their nanometer-scale thickness allows them to interact uniquely with light, heat, and electrical signals. This ultra-thin nature makes nanofilms highly flexible and lightweight, yet still functional. They often exhibit properties not found in bulk materials, such as enhanced strength, transparency, or conductivity. Because of their minuscule size, nanofilms are sensitive to surface effects, which means their behavior is dominated by surface interactions rather than bulk properties. This distinct nature enables innovative applications across electronics, energy, and material science. Additionally, their surface interactions significantly influence their performance in various technological applications.

Fabrication Techniques for Ultrathin Coatings

You can choose from various deposition methods to create nanofilms, each offering different advantages for specific applications. Achieving precise control over layer thickness and uniformity is essential in ensuring high-quality ultrathin coatings. Understanding these techniques helps you optimize fabrication processes for better performance and durability.

Deposition Methods Overview

Deposition methods play a crucial role in fabricating nanofilms, as they determine the film’s thickness, uniformity, and properties. Choosing the right technique impacts the performance and durability of your coatings. Common methods include chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), and spin coating. Each offers advantages tailored to specific applications, such as high precision, scalability, or material versatility. For example, ALD provides atomic-level control, while PVD is suitable for depositing metals. Consider these points when selecting a method: material options and environmental conditions, as certain techniques may be more compatible with specific substances and settings.

Precision in Layer Control

Achieving precise control over layer thickness and composition is essential when fabricating ultrathin coatings, as even minor variations can substantially impact their performance. To do this, you rely on advanced techniques like atomic layer deposition (ALD), which allows you to deposit monolayers with atomic precision. You also use molecular beam epitaxy (MBE), which provides excellent control over film composition and thickness at the atomic level. Monitoring tools like quartz crystal microbalances help you measure deposition rates in real-time, guaranteeing accuracy. Consistent calibration of equipment and strict process parameters allow you to minimize errors and achieve uniform coatings. By mastering these techniques, you ensure your nanofilms meet the stringent specifications required for high-performance electronics and energy applications.

Key Properties and Characteristics of Nanofilms

What makes nanofilms unique compared to thicker materials are their remarkable properties at the nanoscale. These ultrathin coatings exhibit exceptional electrical, optical, and mechanical characteristics that differ from bulk materials. Their high surface-to-volume ratio enhances reactivity and interaction with other substances. Nanofilms often display increased flexibility, transparency, and conductivity, making them ideal for advanced applications. Additionally, their properties can be tailored through precise control of thickness and composition. This self-assembly process allows for optimizing performance in various devices. The key properties include:

Nanofilms offer unique nanoscale properties, including enhanced reactivity, flexibility, transparency, and tunable performance for advanced applications.

- Enhanced electrical conductivity or insulation

- Superior optical transparency and interference effects

- Increased mechanical flexibility and strength

- Tunable surface chemistry for specific interactions

Applications in Electronic Devices

Nanofilms play a vital role in advancing electronic devices by making them more durable and reliable. They improve both conductivity and insulation, allowing for better performance and energy efficiency. Additionally, nanofilms enable the miniaturization of components, paving the way for sleeker, more powerful gadgets. As research in AI security continues to evolve, ensuring the safety and robustness of nanofilm applications becomes increasingly important.

Enhancing Device Durability

Because electronic devices are constantly exposed to environmental stressors, incorporating nanofilms can substantially improve their durability. These ultrathin coatings act as protective barriers against moisture, dust, and mechanical wear. By applying nanofilms, you can extend device lifespan and reduce maintenance costs. They also help prevent corrosion and physical damage, ensuring consistent performance over time. Nanofilms can be tailored to resist specific environmental factors, making your devices more resilient. Additionally, nanofilms contribute to homeostasis by maintaining optimal device conditions in varying environments.

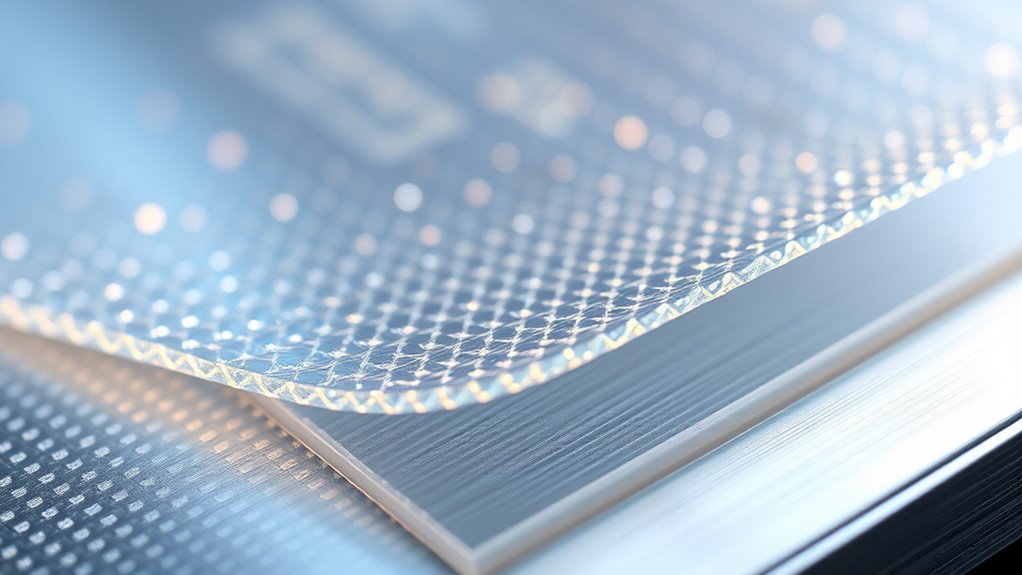

Improving Conductivity & Insulation

Integrating nanofilms into electronic devices not only enhances their durability but also improves their electrical performance by optimizing conductivity and insulation. You can apply conductive nanofilms, such as those made from graphene or metal oxides, to create efficient pathways for electron flow, reducing resistance and boosting device speed. Conversely, insulating nanofilms, like dielectric coatings, serve to prevent unwanted current leakage and protect sensitive components from short circuits. These ultrathin coatings enable precise control over electrical properties without adding bulk. Understanding bank swiftifs codes is essential for secure financial transactions, ensuring your electronic devices and data remain protected during communications. As a result, you benefit from improved device reliability, faster operation, and reduced power consumption. Nanofilms allow you to tailor electrical performance at the microscopic level, essential for next-generation electronics where miniaturization and efficiency are paramount.

Miniaturizing Electronic Components

Miniaturizing electronic components has become essential for advancing modern devices, allowing for smaller, more powerful gadgets that fit seamlessly into everyday life. Nanofilms enable this by reducing component size without sacrificing performance. They help create thinner transistors, sensors, and circuit elements, boosting device efficiency and portability. With nanofilms, you can achieve:

- Enhanced device flexibility

- Reduced power consumption

- Faster signal processing

- Increased device density

These ultrathin coatings support the development of wearables, foldable phones, and compact medical devices. Their ability to maintain functionality at a nanoscale level makes them crucial for next-generation electronics. As nanofilms continue to evolve, they’ll push the boundaries of miniaturization, making electronics smaller, smarter, and more integrated into daily life. Understanding material properties is key to optimizing nanofilm applications for various electronic innovations.

Enhancing Energy Storage and Conversion

Nanofilms play a crucial role in advancing energy storage and conversion technologies by offering unique properties such as high surface area, tunable porosity, and excellent electrical conductivity. These qualities improve electrode performance, boost energy density, and enhance charge/discharge rates. By applying nanofilms to batteries and fuel cells, you can create more efficient, durable systems. They facilitate rapid electron transfer and provide better ion diffusion pathways. Consider the table below to see how nanofilms improve energy devices: Pimple Patch

| Property | Benefit | Application |

|---|---|---|

| High surface area | Increased active sites | Lithium-ion batteries |

| Tunable porosity | Enhanced ion transport | Supercapacitors |

| Electrical conductivity | Faster electron flow | Fuel cells |

Nanofilms in Photonics and Optoelectronics

Nanofilms play a vital role in advancing photonics and optoelectronics by enhancing how light is manipulated within devices. They help improve overall efficiency, making technologies like lasers and sensors more effective. Additionally, nanofilms enable the development of flexible displays, opening new possibilities for portable and adaptable visual interfaces. Their ability to facilitate light manipulation at the nanoscale is crucial for driving innovation in these fields.

Enhancing Light Manipulation

Advances in nanofilm technology have considerably improved your ability to manipulate light at the nanoscale. These ultrathin coatings enable precise control over light propagation, reflection, and transmission, opening new avenues in photonics and optoelectronics. By tailoring nanofilm properties, you can enhance optical resonance, reduce losses, and develop highly selective filters. This control is vital for applications like sensors, lasers, and display technologies. Nanofilms can also be engineered to induce specific phase shifts or manipulate polarization states, markedly improving device performance. Their ability to confine and guide light at subwavelength scales makes them essential in miniaturized optical components. With continued innovation, nanofilms will empower you to design more efficient, compact, and versatile photonic systems. Material versatility allows for customizing nanofilm properties to suit diverse optical applications.

Improving Device Efficiency

By integrating nanofilms into photonic and optoelectronic devices, you can substantially boost their efficiency and performance. These ultrathin coatings improve light management by reducing reflection losses and enhancing light absorption. For example, applying nanofilms as antireflective layers allows more light to enter devices like solar cells and photodetectors, increasing their output. Nanofilms also serve as passivation layers that minimize surface defects, reducing recombination and boosting electronic efficiency. Additionally, their ability to tailor optical properties enables you to design devices with higher sensitivity and faster response times. Overall, nanofilms optimize the interaction of light and electrons, leading to devices that consume less power, deliver more accurate results, and operate more reliably and efficiently across various applications.

Enabling Flexible Displays

Integrating nanofilms into flexible display technologies opens up new possibilities for lightweight, bendable screens that maintain high performance. These ultrathin coatings enhance durability, transparency, and flexibility, making screens more resilient to bending and twisting. Nanofilms enable the development of foldable smartphones, rollable tablets, and wearable devices, revolutionizing user experiences. Their ability to optimize optical properties ensures vivid images and minimal glare even when flexed. Additionally, nanofilms can serve as barrier layers to protect displays from moisture and oxygen, extending device lifespan. With nanofilms, you can achieve seamless integration of electronics into curved surfaces. This flexibility supports innovative designs and new form factors, pushing the boundaries of what’s possible in consumer electronics.

- Improved mechanical flexibility and durability

- Enhanced optical clarity and contrast

- Protection against environmental damage

- Support for innovative, curved device designs

Challenges and Limitations in Nanofilm Technology

Despite the promising potential of nanofilm technology, several significant challenges hinder its widespread adoption. Achieving uniform thickness during production remains difficult, leading to inconsistencies in performance. Scalability is another hurdle; processes that work in labs often fail at industrial levels. Additionally, nanofilms can be fragile, making them prone to damage during handling and application. Compatibility issues also arise, as nanofilms may not integrate well with existing manufacturing methods or materials. Cost factors further limit commercialization, especially for large-scale uses.

| Challenge | Impact |

|---|---|

| Uniformity | Inconsistent device performance |

| Scalability | Limited mass production feasibility |

| Mechanical durability | Increased risk of damage during use |

| Cost | Reduced commercial viability |

Future Directions and Emerging Trends

Advancements in nanofilm technology are paving the way for innovative solutions that overcome current limitations. You can expect emerging trends to focus on enhancing performance, durability, and compatibility across various applications. Researchers are exploring new materials, like 2D nanomaterials, to improve electrical conductivity and mechanical strength. Integration with flexible and wearable devices is also gaining momentum, expanding nanofilm use in consumer electronics. Additionally, precision fabrication techniques will enable more complex, multi-functional coatings. Sustainability will become a priority, driving the development of eco-friendly and recyclable nanofilms. You’ll see progress in scalable manufacturing methods, making advanced nanofilms more accessible. These trends will shape the future of nanofilms, unleashing new opportunities in electronics, energy storage, and beyond.

Nanofilm advancements boost performance, durability, and sustainability for innovative electronic and energy storage applications.

- Development of multifunctional nanofilms

- Adoption of green synthesis methods

- Advances in scalable, cost-effective manufacturing

- Integration into flexible and wearable electronics

Environmental and Sustainability Considerations

How can nanofilm technologies promote environmental sustainability? By enabling more efficient energy use, nanofilms can reduce waste and lower carbon footprints. For example, ultrathin coatings on solar cells improve light absorption and durability, increasing energy generation while extending lifespan. Additionally, nanofilms can enhance electronics’ performance, leading to less frequent replacements and reducing electronic waste. They also enable the development of lightweight, high-performance batteries and energy storage systems that decrease resource consumption. However, sustainability isn’t just about performance; it also involves considering the environmental impact of manufacturing and disposal. To truly promote sustainability, you need to focus on eco-friendly materials, scalable production methods, and recyclability. When these factors align, nanofilm technologies can markedly contribute to a greener, more sustainable future.

Case Studies of Nanofilm Innovations

Nanofilm innovations have already demonstrated significant impacts across multiple industries. You can see this through real-world examples where ultrathin coatings enhance performance and durability. For instance, in electronics, nanofilms improve touchscreen sensitivity and reduce energy consumption. In energy storage, they boost battery efficiency and lifespan. You’ll also find nanofilms used in protective coatings that resist corrosion and wear. These case studies highlight how nanofilms enable advanced functionalities and extend device longevity.

Nanofilm innovations enhance device durability, performance, and longevity across electronics, energy storage, and protective coatings.

- Enhancing solar cell efficiency with anti-reflective coatings

- Improving battery performance with nanostructured electrodes

- Creating flexible, transparent displays

- Developing corrosion-resistant protective layers

Frequently Asked Questions

How Do Nanofilms Impact the Long-Term Durability of Electronic Devices?

Nanofilms considerably enhance your electronic devices’ long-term durability by providing a protective barrier against moisture, corrosion, and physical wear. They effectively prevent damage from environmental factors, reduce electrical failures, and extend device lifespan. With nanofilms, you can enjoy more reliable performance over time, as these ultrathin coatings help maintain your device’s integrity, ensuring it remains functional and less prone to degradation even after prolonged use.

What Are the Main Cost Considerations in Nanofilm Manufacturing?

Cost considerations in nanofilm manufacturing primarily concern materials, equipment, and precision processes. You’ll find that high-quality raw materials and advanced deposition tools drive expenses, while meticulous methods demand more time and expertise. To keep costs controlled, you must balance material quality with process efficiency. Investing in scalable, streamlined techniques minimizes waste and maximizes value. Ultimately, understanding these variables helps you optimize your nanofilm production, ensuring affordability without sacrificing performance or durability.

Can Nanofilms Be Recycled or Repurposed After Use?

Yes, nanofilms can often be recycled or repurposed after use, but it depends on the material and application. You might need specialized processes to recover and reuse the coatings without damaging their properties. Recycling nanofilms can be challenging due to their ultrathin nature, but research is advancing to develop more sustainable methods. By exploring these options, you contribute to reducing waste and promoting environmentally friendly practices in electronics and energy industries.

How Do Nanofilms Influence Device Performance at Extreme Temperatures?

Think of nanofilms as a superhero’s shield, protecting your device at extreme temperatures. They improve performance by enhancing thermal stability, preventing degradation or failure when heat skyrockets or plunges. You’ll notice better reliability, faster response times, and longer device lifespan. Their ultrathin nature ensures minimal interference with device functions, making them essential for high-temperature environments. Fundamentally, nanofilms act like a high-tech armor, keeping your electronics safe under extreme conditions.

Are There Health Risks Associated With Nanofilm Production and Disposal?

Yes, there are health risks associated with nanofilm production and disposal. You might be exposed to nanoparticles that can penetrate your skin, lungs, or eyes, potentially causing respiratory issues or other health problems. Handling nanomaterials requires proper safety measures, like protective gear and ventilation. Disposal can also release particles into the environment, affecting both human health and ecosystems. Staying informed and following safety protocols helps minimize these risks.

Conclusion

Think of nanofilms as the delicate brushstrokes shaping tomorrow’s tech landscape. Their ultrathin layers reveal incredible potential in electronics and energy, like tiny architects building vast, innovative structures. As you explore this field, remember that each breakthrough is a new brushstroke on the canvas of progress. Embrace the challenges and possibilities—they’re the colors that will paint a brighter, more sustainable future. The nanofilm revolution is just beginning, and you’re part of it.