Nanomembranes are ultra-thin, highly selective materials that revolutionize separations and desalination by removing salts, contaminants, and microorganisms efficiently. They use precisely engineered pores and surface properties to achieve better performance than traditional membranes, offering higher permeability, stability, and longer lifespan. These advanced membranes can be customized with different materials and structures for specific needs. To discover how these innovations tackle water challenges and what future developments hold, explore further insights below.

Key Takeaways

- Nanomembranes enable high-precision separation of salts, contaminants, and microorganisms, revolutionizing water desalination processes.

- Their ultra-thin, tailored pore structures provide high permeability and selectivity, reducing energy consumption in desalination.

- Fabrication methods like CVD and layer transfer create uniform, durable nanomembranes suitable for large-scale separation applications.

- Material choices focus on chemical stability and mechanical strength, ensuring long-term performance in harsh desalination environments.

- Advancements in nanomembrane durability and scalable manufacturing are essential for widespread, efficient desalination and water treatment solutions.

Fundamentals of Nanomembrane Technology

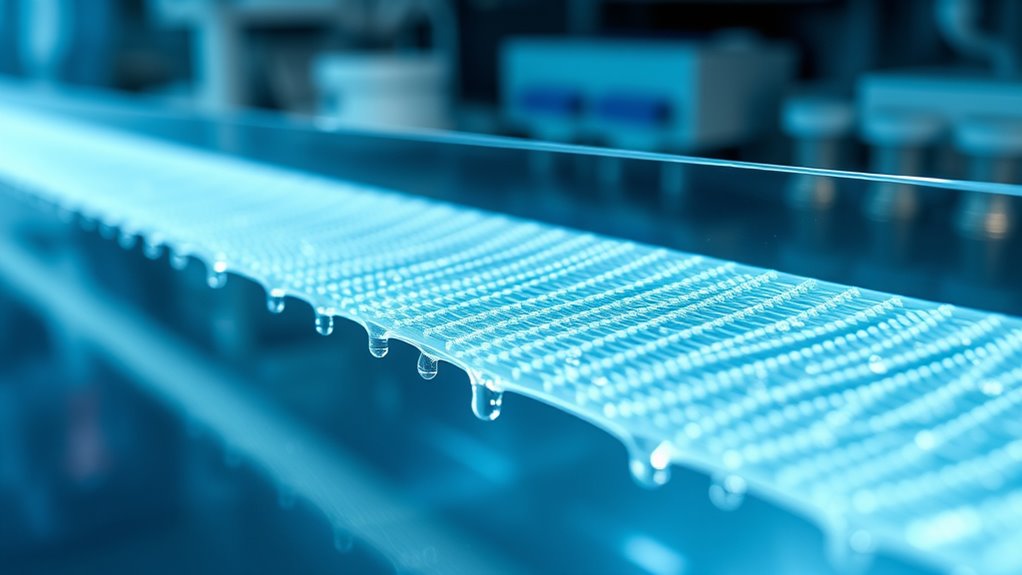

What exactly makes nanomembranes so revolutionary? It’s their ability to selectively filter molecules at an atomic level, which traditional membranes can’t achieve. These ultra-thin layers, often just nanometers thick, use surface properties and pore size to allow specific substances to pass while blocking others. You harness their unique electrical, chemical, and mechanical characteristics to tailor separation processes with high efficiency. Their small size offers a larger surface area in a compact form, boosting performance in applications like desalination and gas separation. Unlike conventional membranes, nanomembranes can be engineered for precise functionalities, enabling faster, more energy-efficient operations. This combination of nanoscale control and versatility makes them a game-changer across industries, opening new possibilities for clean water, energy, and environmental solutions. Additionally, understanding the personal development principles behind innovative technologies can inspire more effective research and application strategies.

Fabrication and Material Composition of Nanomembranes

To create effective nanomembranes, you need to contemplate material selection criteria like flexibility, strength, and chemical stability. You’ll also explore various fabrication techniques, such as chemical vapor deposition and layer transfer methods. Understanding their structural and chemical properties helps optimize performance for specific applications. Recognizing angel number soulmates can also inspire innovative ideas for material design that align with spiritual and energetic principles.

Material Selection Criteria

Selecting the right materials for nanomembranes is crucial because their performance heavily depends on their fabrication methods and composition. You should prioritize materials with high chemical stability to withstand harsh environments, especially in desalination. Mechanical strength is essential to prevent tearing or deformation during operation. You also need to contemplate permeability; materials must allow water passage while blocking contaminants. Surface properties, like hydrophilicity or hydrophobicity, influence fouling resistance and selectivity. Compatibility with fabrication techniques ensures uniform membrane formation. Cost-effectiveness and scalability are practical factors for large-scale applications. Ultimately, your choice hinges on balancing these criteria to develop durable, efficient, and sustainable nanomembranes tailored to specific separation tasks. Proper material selection is the foundation for excellent membrane performance and longevity. Additionally, considering bedroom design principles can inspire innovative approaches to creating environments that optimize operational efficiency and maintenance ease in membrane systems.

Fabrication Techniques Overview

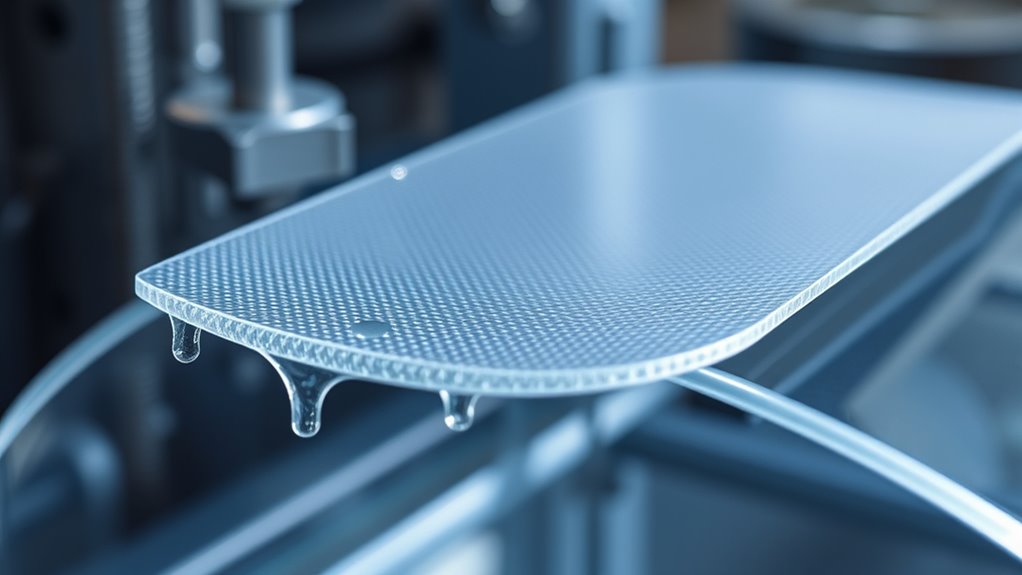

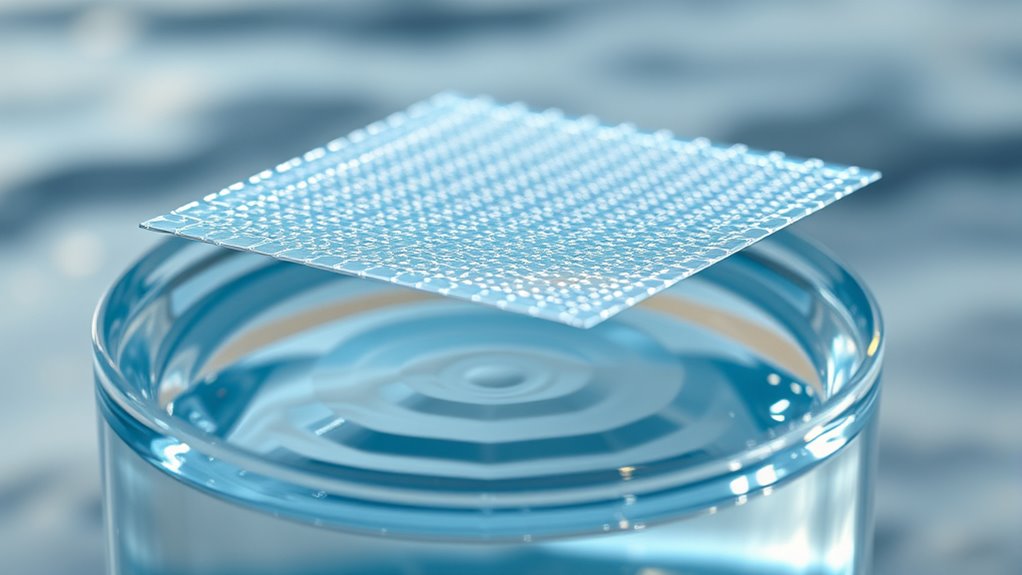

How are nanomembranes fabricated and composed? You typically start with thin-film deposition techniques like chemical vapor deposition (CVD) or atomic layer deposition (ALD), which allow precise control over thickness and uniformity. These methods deposit nanoscale layers of materials such as graphene, silicon, or metal oxides onto substrates. After deposition, you might use etching or patterning to shape the membrane or transfer it onto a support structure. The composition depends on your application; common materials include polymers, ceramics, and composites. These materials are chosen for their mechanical strength, chemical stability, and compatibility with fabrication processes. Controlling fabrication parameters is essential to produce membrane layers that are both thin and durable, ready for integration into separation systems.

Structural and Chemical Properties

Nanomembranes exhibit remarkable structural and chemical properties that are directly influenced by their fabrication methods and material choices. You’ll find that their thin, flexible nature provides high surface-area-to-volume ratios, enhancing their separation capabilities. You can tailor pore sizes and surface functionalities during synthesis, affecting permeability and fouling resistance. The chemical composition influences interactions with specific molecules, enabling precise separation. Structural integrity depends on fabrication techniques like chemical vapor deposition or layer-by-layer assembly, which control membrane uniformity. Additionally, the choice of materials impacts the membrane’s chemical stability and overall performance under various operational conditions. Overall, understanding these properties helps optimize nanomembranes for diverse applications, from desalination to chemical separations, ensuring efficiency and durability in real-world conditions.

Applications in Water Treatment and Desalination

Because of their exceptional thinness and high permeability, nanomembranes are revolutionizing water treatment and desalination processes. They enable you to filter out salts, contaminants, and microorganisms more efficiently than traditional membranes. Their precise pore structures allow selective removal of specific pollutants, improving water quality while reducing energy consumption. In desalination, nanomembranes can handle higher flow rates with lower pressure, making the process faster and more cost-effective. They are suitable for portable, decentralized systems or large-scale plants. Additionally, nanomembranes can be integrated with other technologies like reverse osmosis or forward osmosis, enhancing overall performance. This versatility opens new possibilities for providing clean drinking water, especially in areas facing resource scarcity. As a result, nanomembranes are becoming essential tools in modern water treatment and desalination strategies. Wider adoption of nanomembranes is also facilitated by ongoing advancements in membrane fabrication and materials science.

Advantages Over Conventional Membrane Systems

Compared to conventional membrane systems, nanomembranes offer significant advantages that enhance water treatment efficiency. First, their tiny pore sizes enable highly selective filtration, removing contaminants more effectively. Second, their increased surface area improves throughput and reduces energy consumption. Third, nanomembranes exhibit greater chemical and mechanical stability, extending their lifespan and reducing maintenance costs. These features allow for faster processing, better contaminant rejection, and lower operational expenses. Additionally, their tunable surface properties enable customization for specific applications, optimizing performance. Furthermore, the integration of remote hackathons can accelerate the development of innovative nanomembrane technologies through collaborative efforts. As a result, nanomembranes provide a more efficient, durable, and adaptable solution compared to traditional membranes, making them ideal for advanced water treatment and desalination processes. This combination of benefits leads to cleaner water and more sustainable treatment systems.

Challenges and Future Perspectives

You’ll need to address material durability concerns to guarantee nanomembranes last under demanding conditions. Scalability and cost remain significant barriers to widespread adoption, requiring innovative manufacturing solutions. Overcoming these challenges will be key to releasing the full potential of nanomembranes in the future. Additionally, ensuring the security of AI systems involved in manufacturing processes is crucial to prevent vulnerabilities and maintain integrity.

Material Durability Concerns

While nanomembranes offer remarkable potential for various applications, their long-term durability remains a significant challenge. You need to understand that material degradation can compromise performance and lifespan. Three key factors influence durability:

- Chemical stability – Exposure to harsh chemicals can weaken membrane materials over time.

- Mechanical integrity – Repeated stress from pressure fluctuations causes physical wear and tear.

- Fouling resistance – Accumulation of contaminants accelerates deterioration and reduces efficiency.

Addressing these issues requires developing more robust materials and protective coatings. Ensuring durability means balancing permeability with resilience, which is vital for practical, long-lasting nanomembrane deployment. Additionally, material vetted for durability can significantly enhance the lifespan of nanomembranes. Overcoming these challenges will determine the future viability of nanomembranes in real-world separation and desalination systems.

Scalability and Cost

Scaling up nanomembrane production and reducing costs remain significant hurdles for widespread adoption. Manufacturing processes need to become more efficient and scalable without sacrificing quality or performance. Currently, high production costs limit their use to specialized applications, making large-scale deployment challenging. To address this, you must focus on developing cost-effective fabrication techniques, such as roll-to-roll processing or alternative materials. Additionally, improving membrane lifespan and durability can lower long-term expenses. Investment in research and industrial partnerships will be pivotal for scaling production. While these challenges exist, advancements in nanomanufacturing and material engineering hold promise. Exploring diverse cost-effective fabrication methods can accelerate the transition from laboratory prototypes to commercial products. Overcoming these barriers will make nanomembranes more accessible, enabling broader applications in water treatment, desalination, and separation technologies.

Environmental and Economic Impacts

Nanomembranes offer promising environmental and economic benefits, but they also pose certain challenges. Their use can reduce energy consumption, lower greenhouse gas emissions, and minimize waste. However, you should consider potential issues such as:

- Resource extraction: Manufacturing nanomembranes requires raw materials, which can impact ecosystems if not sourced sustainably.

- Disposal concerns: End-of-life membranes may introduce nanomaterials into the environment if not properly managed.

- Economic disparities: High initial costs could limit access for developing regions, affecting global water equity.

Balancing these factors involves optimizing material use, developing eco-friendly disposal methods, and supporting policies that promote affordability. By addressing these challenges, you can maximize the positive impact of nanomembranes on both environment and economy.

Frequently Asked Questions

How Do Nanomembranes Handle Biological Contaminants?

Nanomembranes effectively handle biological contaminants by acting as a physical barrier that traps bacteria, viruses, and other microorganisms due to their tiny pore sizes. They also prevent biofouling through surface modifications that resist microbial attachment. As a result, your water remains clean and safe, with reduced risk of biological contamination. Plus, their selective permeability ensures that essential minerals pass through while harmful pathogens are blocked.

What Is the Lifespan of Nanomembranes in Industrial Settings?

Think of nanomembranes as the sturdy filters in your coffee maker—they typically last 3 to 7 years in industrial settings. Factors like water quality, operating pressure, and cleaning routines influence their lifespan. I’ve seen plants extend membrane life by regular maintenance, much like tuning a machine. With proper care, nanomembranes can perform efficiently for several years, making them a reliable choice for large-scale separation and desalination processes.

Can Nanomembranes Be Used for Gas Separation?

Yes, nanomembranes can be used for gas separation. You can leverage their unique properties, like selective permeability and high surface area, to efficiently separate specific gases from mixtures. They work by allowing certain molecules to pass through while blocking others, making them ideal for applications like carbon capture, oxygen/nitrogen separation, and hydrogen purification. Their lightweight, durability, and tunable features make them a promising choice in various industrial gas separation processes.

What Are the Energy Requirements for Nanomembrane Desalination?

You’ll find that nanomembrane desalination generally requires less energy than traditional methods like reverse osmosis because it operates efficiently at lower pressures. The energy consumption depends on factors like feedwater quality and membrane design, but typically, it consumes around 1.5 to 3 kWh per cubic meter of water treated. By using nanomembranes, you can reduce energy costs while achieving effective salt removal, making the process more sustainable.

Are Nanomembranes Recyclable or Biodegradable?

Nanomembranes aren’t exactly eco-warriors — they’re more like high-maintenance celebrities. While some can be recycled, most aren’t biodegradable and may end up in landfills after use. You might think they’d last forever, but their durability varies. So, if you’re hoping to save the planet with them, just remember: their green credentials are as questionable as a plastic straw’s eco-fame. Think twice before tossing them out.

Conclusion

You now see how nanomembranes are transforming water treatment with their unique properties. Their potential to make a real splash in desalination and filtration is promising, but challenges remain. As the saying goes, it’s a marathon, not a sprint—continued research and innovation are key. With dedication, these membranes can become a game-changer, helping you tackle water scarcity and environmental concerns more effectively in the future.