Nanostructured coatings use nanoscale textures and innovative materials like metals and polymers to prevent biofouling and ice buildup on surfaces. By mimicking nature—such as lotus leaves or shark skin—they create water-repellent and anti-adhesion barriers that keep surfaces cleaner and ice-free. These coatings can be applied with scalable methods like spray or sol-gel processes, but challenges like durability and consistency remain. Exploring these solutions can reveal how they’re transforming industries and what future developments are ahead.

Key Takeaways

- Nanostructured coatings mimic natural textures, creating physical barriers that prevent microorganism settlement and ice adhesion.

- Surface topography and high water repellency enhance anti-fouling and anti-icing performance by promoting droplet runoff.

- Fabrication techniques like atomic layer deposition and sol-gel processes enable scalable, uniform nanocoating applications.

- Nanomaterials such as metallic, polymer, and quantum dots improve durability, corrosion resistance, and anti-icing properties.

- Biomimetic design strategies optimize surface textures to delay ice formation and reduce biofouling in harsh environments.

Understanding Fouling and Icing Challenges in Industry

Fouling and icing pose vital challenges across various industries by reducing equipment efficiency and increasing maintenance costs. These issues occur when unwanted materials or ice accumulate on surfaces, impairing performance. To combat this, nanostructure fabrication plays an essential role in developing advanced coatings that resist fouling and icing. Achieving strong coating adhesion is fundamental for durability and long-term effectiveness. Nanostructured surfaces create physical and chemical barriers that prevent particles and ice from adhering, minimizing buildup. By tailoring surface features at the nanoscale, you can notably reduce cleaning needs and downtime. Understanding how nanostructure fabrication influences coating adhesion helps optimize these protective layers, ensuring they stay intact under harsh conditions. Additionally, selecting appropriate high-performance projectors can enhance operational visibility and monitoring in industrial settings. This approach ultimately enhances operational reliability and reduces costs in industries like energy, transportation, and manufacturing.

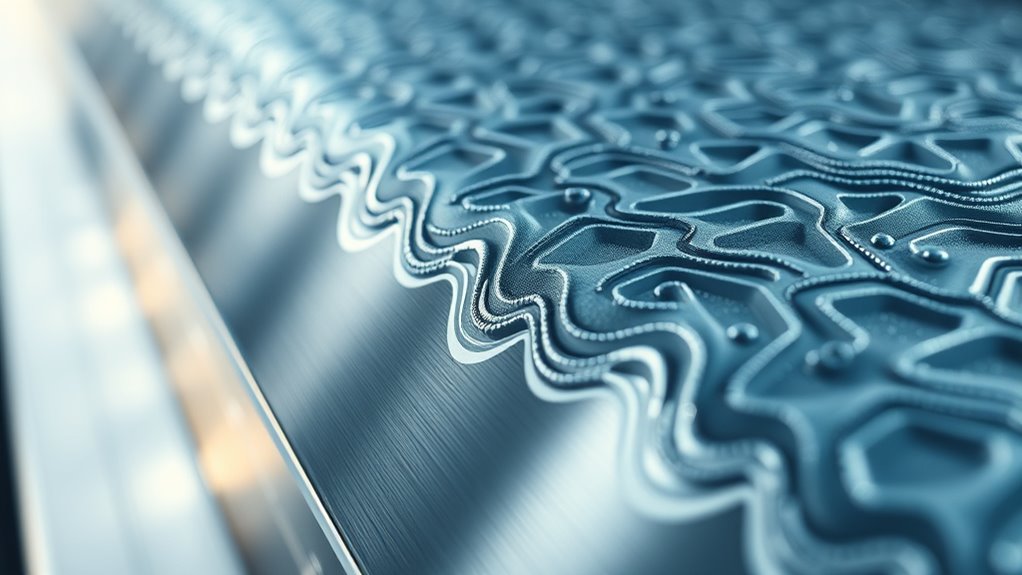

Principles Behind Nanostructured Surface Design

Designing nanostructured surfaces relies on understanding how nanoscale features influence interactions with contaminants and ice. You use biomimetic approaches to replicate natural structures that resist fouling and icing, such as lotus leaves or insect wings. These designs manipulate surface energy, making surfaces either highly water-repellent or slippery, preventing adhesion. By controlling the size, shape, and arrangement of nanostructures, you can minimize contact points where contaminants or ice might stick. Surface energy plays a critical role, as low-energy surfaces discourage wetting and adhesion, while specific topographies trap air pockets that reduce effective contact. Additionally, controlling the topography of nanostructures allows for the creation of surfaces that maintain their anti-fouling and anti-icing properties under various environmental conditions. Surface energy and topographical features work synergistically to guide you in creating nanostructured coatings that effectively deter fouling and icing without relying solely on chemical treatments.

Materials Used in Nanostructured Coatings

You’ll find that nanomaterials form the core of many coatings, offering enhanced properties through their small size. Common metal components like titanium and silver are often incorporated for durability and antimicrobial effects. Additionally, organic and hybrid polymers are used to provide flexibility and specialized functionalities in nanostructured coatings. Exploring advanced materials reveals how their unique properties contribute to improved coating performance and longevity.

Nanomaterials in Coatings

Nanomaterials form the core of nanostructured coatings, offering unique properties that traditional materials cannot match. Quantum dots are a prime example, providing tunable optical properties and high surface area, which enhance anti-fouling and anti-icing capabilities. These nanoscale particles can be embedded into coatings to improve their responsiveness and durability. Additionally, some nanomaterials harness photothermal effects, converting light into heat to prevent ice formation or biofouling. By integrating quantum dots and other nanostructures, you can create coatings that respond dynamically to environmental stimuli, increasing efficiency and lifespan. These advanced nanomaterials open new possibilities for designing coatings that are both functional and resilient, ensuring better protection against fouling and icing in demanding conditions.

Common Metal Components

Metal components are fundamental to many nanostructured coatings because they provide enhanced mechanical strength, corrosion resistance, and electrical conductivity. You’ll often find metals like copper, aluminum, and stainless steel used for their durability and ability to prevent corrosion in harsh environments. These metals help improve wear resistance, making coatings longer-lasting and more reliable under mechanical stress. Their nanostructured forms increase surface area, boosting corrosion prevention and creating protective barriers. Using metal components also enables better electrical conductivity, which can be essential for specific anti-icing applications. Selecting the right metal ensures your coating resists environmental degradation while maintaining its structural integrity. Incorporating these metal components allows you to develop coatings that are both robust and effective in preventing fouling and icing.

Organic and Hybrid Polymers

Organic and hybrid polymers play a pivotal role in nanostructured coatings by offering versatile, lightweight, and adaptable materials that enhance surface properties. You can tailor these polymers through polymer blending, combining different molecular structures to achieve desired anti-fouling or anti-icing functionalities. Organic synthesis allows you to modify polymer chains with specific functional groups, improving durability and surface interactions. Hybrid polymers, integrating organic components with inorganic elements, provide additional strength and stability. These materials enable the creation of nanostructured surfaces with controlled wettability, reduced adhesion, and enhanced resistance to environmental factors. By leveraging organic and hybrid polymers, you can design coatings that are both effective and customizable, addressing the specific challenges associated with fouling and icing in various applications.

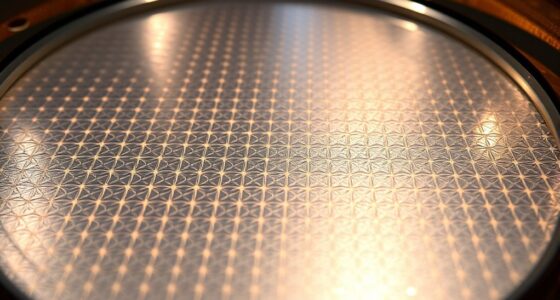

Fabrication Techniques for Nanoscale Coatings

Fabrication techniques for nanoscale coatings encompass a range of methods designed to produce uniform, functional layers at the nanometer scale. You can control surface roughness to influence how the coating interacts with water or biological contaminants, which is critical for anti-fouling and anti-icing properties. Techniques like atomic layer deposition (ALD) provide precise control over coating thickness, allowing you to achieve very thin, conformal layers that enhance durability without adding bulk. Sol-gel processes create dense, uniform coatings by depositing precursor solutions that gel and cure at nanoscale thicknesses. Similarly, spray coating and spin-coating enable rapid, scalable application of nanostructured layers. These methods guarantee consistent surface roughness and coating thickness, which are essential for optimizing the coatings’ functional performance. Ulta Beauty Store Hours

Mechanisms of Anti‑Fouling Action

You can influence fouling resistance through surface topography, which minimizes contact points and prevents organism attachment. Hydrophobic and repellent properties help droplets and contaminants easily roll off, reducing buildup. Self-cleaning capabilities enhance these effects by actively removing fouling agents, keeping surfaces cleaner longer. Additionally, inspirational quotes about fatherhood underscore the importance of guidance and support in fostering resilience and perseverance.

Surface Topography Effects

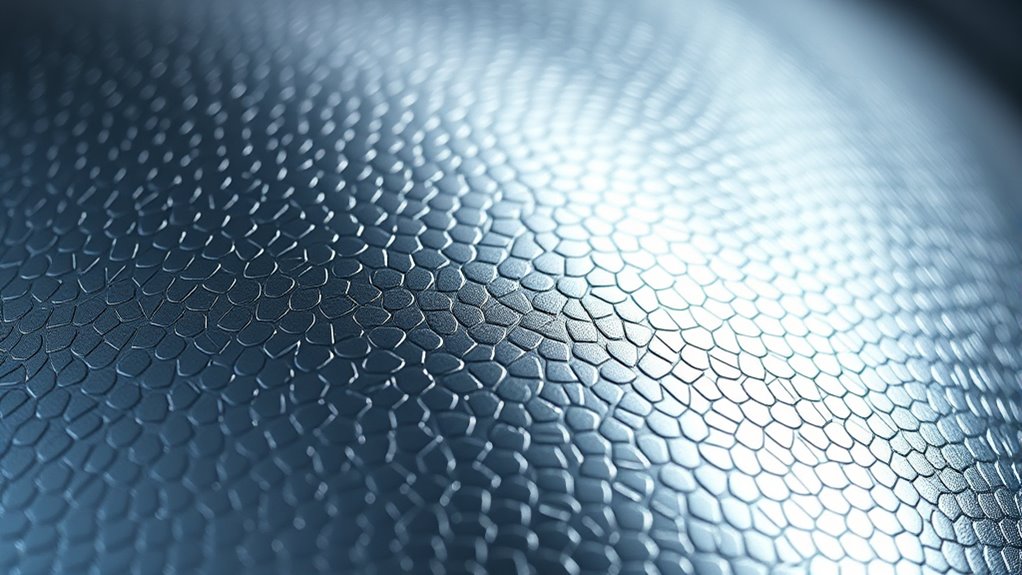

Surface topography plays a crucial role in determining a coating’s ability to resist fouling by disrupting the attachment of unwanted organisms. Biomimetic textures inspired by nature, such as shark skin or lotus leaves, showcase how specific surface features can prevent adhesion. Surface roughness influences how microorganisms settle; smoother surfaces often reduce attachment points, making fouling less likely. Conversely, certain engineered textures create physical barriers or minimize contact area, deterring organisms from anchoring. By mimicking natural topographies, you can design coatings that actively discourage biofilm formation. The combination of biomimetic textures and optimized surface roughness helps maintain a clean surface, reducing the need for chemical agents. This approach enhances the longevity and effectiveness of anti-fouling coatings without relying solely on chemical or hydrophobic strategies.

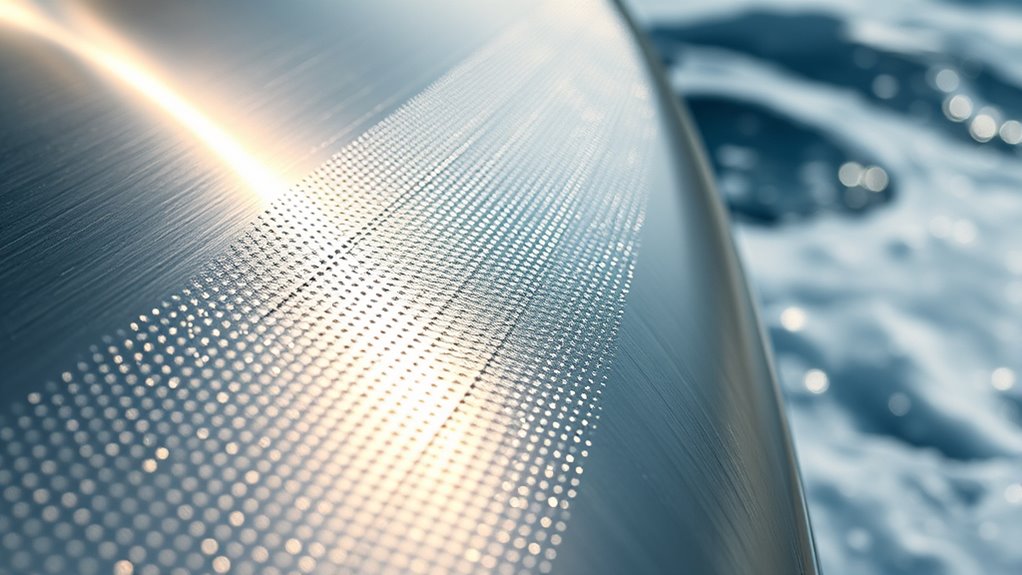

Hydrophobicity and Repellency

Hydrophobicity and repellency are key mechanisms that enable nanostructured coatings to prevent fouling effectively. By enhancing surface wettability, these coatings create a water-repelling barrier that minimizes the attachment of contaminants, biological organisms, and other fouling agents. When a surface is highly hydrophobic, water beads up and rolls off easily, taking dirt and microbes with it. This reduces fouling and makes cleaning easier. Additionally, these coatings often improve coating adhesion by forming a stable, low-energy surface that resists the formation of strong bonds with foulants. The combination of surface wettability and durable adhesion ensures that the coating maintains its anti-fouling properties over time, providing a reliable defense against fouling mechanisms without compromising the coating’s integrity.

Self-Cleaning Capabilities

Self-cleaning capabilities enable nanostructured coatings to actively remove contaminants and prevent buildup without manual intervention. This is achieved through optimized surface roughness that minimizes adhesion of dirt and biological agents. High surface roughness creates micro- and nanoscale features that reduce coating adhesion, making particles easier to detach. When water contacts these surfaces, it forms droplets that roll off, carrying dirt away—this is the basis of the self-cleaning mechanism. Maintaining the right balance of surface roughness ensures durability without compromising coating adhesion. The table below summarizes key factors influencing self-cleaning performance:

| Surface Roughness | Coating Adhesion | Cleaning Efficiency |

|---|---|---|

| Enhances dirt removal | Maintains durability | Improves removal of contaminants |

| Prevents buildup | Supports long-term use | Reduces manual cleaning needs |

| Optimized for self-cleaning | Ensures coating integrity | Maximizes anti-fouling effect |

Strategies for Anti‑Icing Performance

To effectively prevent ice buildup on nanostructured coatings, researchers focus on designing surfaces that either repel water or reduce ice adhesion. Biomimetic approaches draw inspiration from nature, mimicking structures like insect wings or plant surfaces that naturally resist ice formation. Nanoscale patterning plays a pivotal role by creating textured surfaces that minimize contact points, making it harder for ice to adhere strongly. These patterns can trap air or alter surface energy, promoting water runoff or delaying freezing. Combining biomimetic designs with nanoscale patterning enhances anti-icing performance, enabling coatings to stay clear and functional in cold environments. By tailoring surface architecture at the nanoscale, you can develop coatings that effectively combat ice buildup without relying solely on chemical additives. Additionally, research into superhydrophobic surfaces indicates that achieving extremely high water repellency is crucial for optimal anti-icing effects.

Environmental Benefits of Nanostructured Coatings

Nanostructured coatings can markedly reduce chemical usage, cutting down the need for harsh cleaning agents and environmental pollutants. Their enhanced durability means you’ll replace or repair surfaces less often, saving resources and minimizing waste. By choosing these advanced coatings, you contribute to a healthier environment while enjoying longer-lasting protection. Additionally, their ability to promote dental health through natural chewing can extend the lifespan of surfaces that benefit from mechanical cleaning.

Reduced Chemical Usage

Because nanostructured coatings enhance surface properties, they often require fewer chemical cleaners and treatments. Their biomimetic approaches and advanced nanostructure fabrication reduce the need for harsh chemicals, making maintenance more eco-friendly. This means less chemical runoff and lower environmental impact. By mimicking natural surfaces, these coatings resist fouling and ice buildup inherently, decreasing chemical reliance. You’ll see benefits such as:

- Reduced use of biocides and antifouling agents

- Less frequent cleaning cycles

- Decreased chemical waste production

- Lower energy consumption for cleaning

- Enhanced eco-sustainability of applications

This shift not only benefits the environment but also cuts costs over time. As you adopt nanostructured coatings, you support a cleaner, greener approach that leverages nature-inspired design and innovative nanostructure fabrication to minimize chemical dependence.

Enhanced Durability and Longevity

Enhanced durability and longevity in nanostructured coatings markedly reduce the frequency of repairs and replacements, leading to less waste and resource consumption. This sustainability benefit minimizes environmental impact by decreasing material waste and energy use over time. However, you should consider biocompatibility concerns, especially if coatings are used in biomedical or environmentally sensitive areas, as nanomaterials may pose health risks. Additionally, regulatory challenges can slow adoption; agencies often require extensive testing to ensure safety and environmental compatibility. These hurdles can extend development timelines and increase costs. Despite these challenges, the extended lifespan of nanostructured coatings reduces overall environmental footprint, making them a more sustainable choice. Ultimately, their durability supports long-term environmental benefits by conserving resources and decreasing waste generation.

Applications in Maritime, Aerospace, and Energy Sectors

Have you ever wondered how advanced coatings improve the performance and durability of equipment in challenging environments? Nanostructured coatings are transforming sectors like maritime, aerospace, and energy by reducing biological interactions and enhancing coating adhesion. These coatings prevent biofouling on ships, ensuring cleaner hulls and improved fuel efficiency. In aerospace, they protect aircraft surfaces from ice formation and biological buildup, maintaining safety. In energy, especially in wind turbines and underwater structures, they minimize corrosion and fouling, extending operational life. Consider these applications:

- Reducing biological interactions on submerged surfaces

- Improving coating adhesion under harsh conditions

- Preventing ice accumulation on aircraft and turbines

- Protecting against corrosion in marine environments

- Enhancing equipment lifespan and operational efficiency

- Incorporating Honda Tuning techniques can inspire innovative approaches to coating performance and maintenance strategies, leveraging insights from high-performance vehicle modifications to optimize durability and function.

This versatility makes nanostructured coatings essential for high-performance, durable systems in demanding sectors.

Current Limitations and Future Developments

While nanostructured coatings offer significant advantages in maritime, aerospace, and energy applications, they also face notable limitations that hinder widespread adoption. One major challenge is optimizing nanostructure fabrication processes to achieve consistent, scalable results. Variability in fabrication can lead to uneven coating properties, reducing effectiveness. Additionally, coating durability remains a concern; nanostructured surfaces can be prone to wear, erosion, or degradation over time, especially in harsh environments. Improving the longevity of these coatings requires advancements in materials and application techniques. Future developments should focus on refining fabrication methods that guarantee uniformity and durability, making nanostructured coatings more reliable and commercially viable for real-world use. Addressing these limitations is essential to reveal their full potential. For instance, enhancing coating durability through novel material innovations will be critical for long-term applications.

Case Studies Showcasing Effectiveness

Numerous case studies demonstrate the remarkable effectiveness of nanostructured coatings across various industries. For example, applying quantum dots enhances anti-fouling properties, preventing biofilm buildup on marine surfaces. In biomedical settings, nanocoatings with high biocompatibility support implant longevity while reducing immune responses. In aerospace, nanostructured coatings improve ice resistance on aircraft wings, ensuring safety and efficiency. Additionally, some studies highlight how these coatings extend the lifespan of industrial equipment by resisting corrosion and fouling. Finally, innovative applications show that combining quantum dots with other nanomaterials creates multifunctional surfaces that are both anti-icing and environmentally friendly. These cases illustrate how nanostructured coatings deliver tangible benefits, making them a promising solution across sectors. Holistic approaches to health and wellness

Frequently Asked Questions

How Long Do Nanostructured Coatings Typically Maintain Their Anti-Fouling Properties?

Nanostructured coatings typically maintain their anti-fouling properties for several months to a few years, depending on factors like environmental conditions and wear. To extend their durability lifespan, you should consider renewal strategies such as reapplication or surface treatments. Regular inspections help identify when the coating’s effectiveness diminishes, allowing timely renewal. Proper maintenance guarantees you optimize the coating’s performance and prolong its anti-fouling capabilities.

Are Nanostructured Coatings Safe for Marine and Environmental Ecosystems?

Are nanostructured coatings truly safe for marine ecosystems? You might wonder if their environmental impact is well comprehended. While many coatings are designed to meet regulatory compliance, some nanomaterials could pose risks to aquatic life. You should stay informed about ongoing research and choose eco-friendly options. Prioritizing safety ensures you protect marine environments, safeguarding biodiversity and maintaining sustainable practices for future generations.

Can Existing Structures Be Retrofitted With Nanostructured Anti-Icing Coatings?

Yes, you can retrofit existing structures with nanostructured anti-icing coatings. Focus on ensuring surface durability and proper coating adhesion, as these are key for long-lasting performance. Prepare the surface thoroughly, possibly by cleaning or roughening it, to improve adhesion. Applying the coating carefully and following manufacturer guidelines helps maximize effectiveness. This retrofit can markedly reduce ice formation, extending the lifespan of your infrastructure and improving safety.

What Are the Cost Implications of Implementing Nanostructured Coatings at Scale?

Implementing nanostructured coatings at scale can be costly, with a recent cost analysis showing expenses up to 30% higher than traditional coatings. You’ll face manufacturing challenges like maintaining uniform nanostructures and ensuring durability, which can drive up costs. However, these coatings’ long-term benefits, such as reduced maintenance and energy savings, may offset initial investments. Careful planning and innovation can make large-scale deployment more financially feasible for you.

How Do Nanostructured Coatings Perform Under Extreme Temperature and Pressure Conditions?

You’ll find that nanostructured coatings generally offer excellent thermal stability, allowing them to withstand extreme temperature fluctuations without degrading. They also provide notable pressure resilience, maintaining their integrity under high-pressure conditions. However, performance can vary based on specific formulations and application methods. It’s essential to take into account the coating’s design and testing data to guarantee it meets your device or environment’s demanding thermal and pressure requirements.

Conclusion

You now hold the key to turning harsh, sticky foes into distant memories. These nanostructured coatings act like invisible shields, shimmering with promise beneath the surface. As you embrace these innovations, imagine a world where ships glide smoothly through treacherous waters, and turbines spin unburdened by ice. With every breakthrough, you’re crafting a future where fouling and icing are mere shadows, fading away like morning mist under the bright sun of progress.