Nanotubes boost composite materials by markedly enhancing their mechanical strength, flexibility, and durability. Their properties depend on how well they are dispersed and aligned within the matrix, which affects load transfer and overall performance. Techniques like functionalization and alignment improve their reinforcement effects. However, challenges such as agglomeration and uniform dispersion remain. If you explore further, you’ll discover ways to optimize nanotube integration for even better composite strength and potential applications.

Key Takeaways

- Nanotubes enhance composite tensile strength and flexibility through effective load transfer when properly dispersed and aligned.

- Surface functionalization improves nanotube-matrix bonding, boosting mechanical reinforcement in composites.

- Achieving uniform nanotube dispersion reduces agglomeration, optimizing the composite’s overall mechanical properties.

- Aligned nanotubes along the load direction significantly increase stiffness and strength of the composite material.

- Advanced fabrication techniques, such as shear flow and magnetic alignment, facilitate nanotube orientation for superior reinforcement.

Properties and Structure of Nanotubes

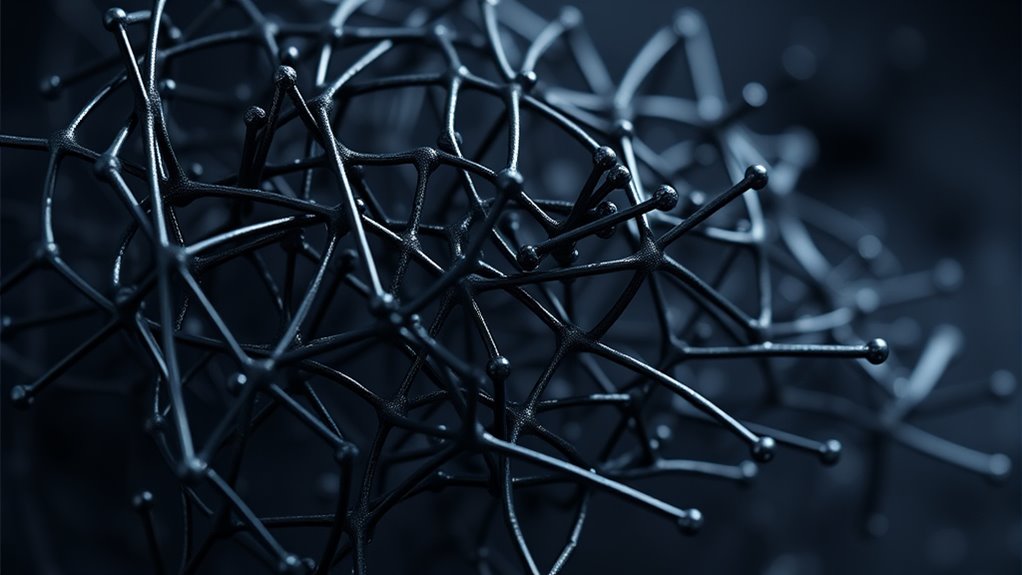

Nanotubes are cylindrical nanostructures composed primarily of carbon atoms arranged in a hexagonal lattice. Their properties depend heavily on nanotube chirality, which determines whether they are metallic or semiconducting. This chirality influences their electrical and mechanical behaviors, making them highly versatile. Additionally, quantum effects become significant at this scale, affecting electron transport and mechanical strength. These quantum phenomena can lead to unique electrical conductivity and enhanced strength, especially when defect-free. The structure’s stability and exceptional tensile strength stem from strong sp2 carbon bonds, allowing nanotubes to withstand high stress. Their remarkable properties arise from this precise atomic arrangement and the interplay of chirality and quantum effects, making them ideal for reinforcing composite materials in advanced applications. quantum effects play a crucial role in defining the electrical and mechanical properties at the nanoscale, further enhancing their utility in composite reinforcement.

Methods of Incorporating Nanotubes Into Composites

To effectively enhance composite materials with nanotubes, selecting appropriate incorporation methods is essential. One common approach involves chemical functionalization, where you modify nanotube surfaces to improve compatibility with the matrix material. This process often uses chemical treatments to attach functional groups, enhancing dispersion and bonding strength. Thermal treatment is another effective method, involving heating nanotubes to alter their surface properties or remove impurities, which can improve their integration into the matrix. These techniques help prevent agglomeration and promote uniform distribution throughout the composite. Combining chemical functionalization with thermal treatment optimizes nanotube-matrix interactions, ensuring better load transfer and overall reinforcement. Additionally, understanding the mechanical properties of nanotubes is crucial for tailoring the reinforcement process to specific application requirements. Choosing the right method depends on your specific material system and desired composite properties.

Mechanical Enhancement Achieved With Nanotube Reinforcement

When you add nanotubes to composites, you can markedly boost their tensile strength and flexibility. This reinforcement helps materials withstand greater forces and last longer under stress. Let’s explore how nanotubes improve durability and overall performance in these advanced materials. Incorporating advanced composite materials with nanotubes can further optimize mechanical properties, making them ideal for high-performance applications.

Increased Tensile Strength

The integration of nanotubes into composite materials markedly boosts their tensile strength, making them more resistant to stretching and breaking under stress. This enhancement allows you to develop stronger, more durable products for various applications. However, it’s essential to consider nanotube toxicity, which raises concerns about health and environmental safety. Ensuring your composites meet regulatory standards is critical to safely leveraging nanotube benefits. Proper dispersion and surface functionalization help maximize strength gains, but overlooking safety measures can lead to regulatory challenges. As you work with nanotube-reinforced composites, prioritize compliance and thorough testing to balance mechanical performance with safety considerations. This approach ensures that increased tensile strength translates into reliable, safe materials suitable for demanding environments.

Improved Flexural Durability

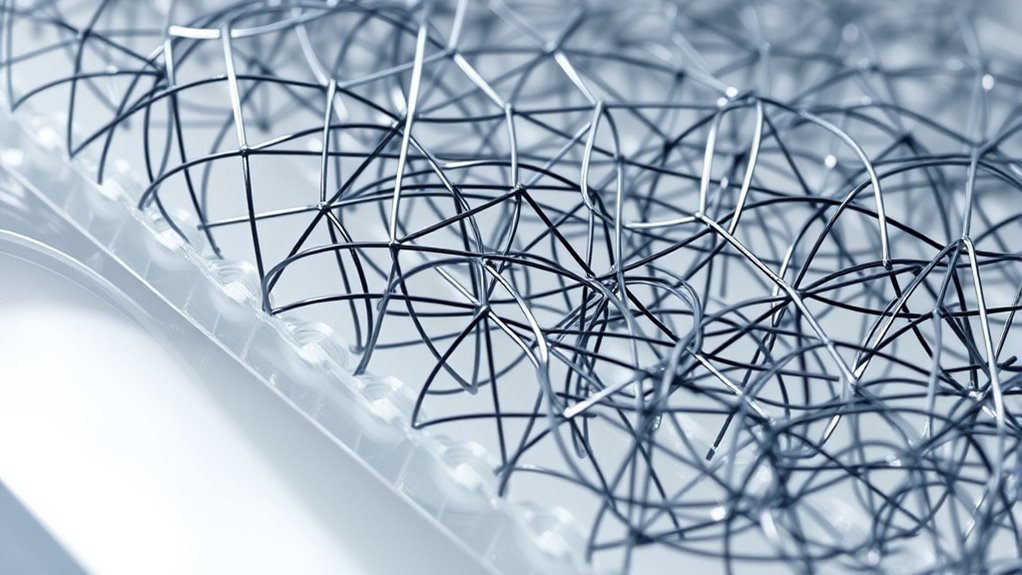

Integrating nanotubes into composites not only enhances tensile strength but also markedly improves their flexural durability. This reinforcement helps the material resist bending forces and reduces the likelihood of crack propagation under flexural stress. Nanotube corrosion is a concern, but surface treatments and composite formulations can minimize degradation, ensuring long-term performance. Additionally, nanotube biocompatibility plays a role in biomedical applications, where durable, flexible materials are vital. Their ability to withstand repeated bending without failure makes composites more reliable in structural and implant contexts. Overall, nanotube reinforcement provides a significant boost to flexural durability, extending the lifespan of composites used in demanding environments while maintaining safety and functional integrity.

Challenges in Dispersing Nanotubes Uniformly

Dispersing nanotubes uniformly within composite matrices remains a significant challenge because their tendency to agglomerate due to strong van der Waals forces makes it difficult to achieve consistent distribution. To improve dispersion stability, surface functionalization is often used to modify nanotube surfaces, reducing agglomeration. However, maintaining uniform dispersion remains tricky, especially at higher loadings. Achieving stable, well-dispersed nanotubes requires balancing surface chemistry and processing methods. Below is a table highlighting key factors:

| Factor | Impact |

|---|---|

| Surface functionalization | Enhances dispersion stability |

| Shear mixing | Breaks up agglomerates |

| Ultrasonication | Disperses nanotubes evenly |

| Solvent choice | Affects nanotube compatibility |

| Processing conditions | Influence uniformity of distribution |

Additionally, selecting appropriate dispersing agents can significantly improve the uniformity of nanotube distribution in the matrix.

Effects of Nanotube Alignment on Composite Performance

When nanotubes are aligned within a composite, you can substantially boost its tensile strength. This alignment also introduces anisotropic properties, meaning the material’s characteristics vary with direction. To achieve ideal performance, you should consider effective alignment techniques that control nanotube orientation during fabrication. Incorporating precise sound design techniques can help optimize the manufacturing process for better nanotube alignment and composite performance.

Enhanced Tensile Strength

The alignment of nanotubes within a composite matrix plays a essential role in determining its tensile strength. When nanotubes are properly aligned, they effectively transfer stress, markedly boosting the composite’s strength. This alignment ensures load is distributed evenly, preventing localized failures. However, you must consider biocompatibility concerns if you’re designing for biomedical applications, as misaligned or poorly integrated nanotubes could cause adverse effects. Additionally, aligned nanotubes enhance thermal conductivity, which can improve heat dissipation under stress, indirectly reinforcing the material’s durability. Proper alignment not only maximizes tensile strength but also optimizes other properties, making your composite more resilient. Achieving consistent nanotube orientation is fundamental for harnessing these benefits and advancing composite performance in demanding environments.

Anisotropic Mechanical Properties

Aligned nanotubes create directional variations in the mechanical behavior of composite materials, leading to anisotropic properties. When nanotubes are oriented along a specific fiber direction, you’ll notice increased strength and stiffness in that axis, while other directions may experience less reinforcement. This fiber orientation affects not only mechanical performance but also thermal conductivity, as aligned nanotubes facilitate heat transfer along their length. Such anisotropic behavior allows you to tailor composites for specific load-bearing applications by controlling nanotube alignment. However, this directional dependency means properties can vary markedly depending on the stress or heat flow direction. Understanding these effects helps you optimize composite design for desired anisotropic mechanical and thermal performance, ensuring efficient reinforcement where it’s most needed.

Optimal Alignment Techniques

Achieving essential nanotube alignment is critical for maximizing composite performance, as the way you orient nanotubes directly influences their reinforcing effectiveness. Proper alignment enhances electrical conductivity by creating continuous pathways that facilitate electron flow, which is indispensable for electronic applications. It also improves thermal management, allowing heat to transfer efficiently through the composite. Techniques like mechanical stretching, magnetic field alignment, and shear flow are effective in controlling nanotube orientation. When nanotubes are aligned parallel to the load direction, you boost both mechanical strength and functional properties. Conversely, misaligned nanotubes can diminish these benefits, leading to suboptimal performance. By carefully selecting and applying alignment techniques, you optimize the composite’s versatility, ensuring superior electrical and thermal properties alongside enhanced mechanical reinforcement.

Characterization Techniques for Nanotube-Enhanced Composites

To understand the effectiveness of nanotube reinforcement in composites, you need to carefully analyze their structural and interfacial properties. Techniques like electron microscopy, Raman spectroscopy, and atomic force microscopy help you assess nanotube dispersion, alignment, and bonding. These methods reveal insights into nanotube toxicity risks and how well the composite is integrated, influencing market adoption. Proper characterization guarantees safe, reliable materials and enhances performance. Here’s a quick overview:

| Technique | Purpose | Key Insight |

|---|---|---|

| Electron Microscopy | Visualize nanotube dispersion | Distribution and interface issues |

| Raman Spectroscopy | Determine nanotube integrity | Defects and functionalization |

| Atomic Force Microscopy | Measure surface topography | Interfacial bonding quality |

| Thermogravimetric Analysis | Assess thermal stability | Nanotube loading and stability |

| X-ray Diffraction | Analyze crystalline structure | Alignment and crystallinity |

Additionally, these characterization techniques are essential for understanding nanotube toxicity risks and ensuring compliance with safety standards.

Applications of Nanotube-Reinforced Materials

Nanotube-reinforced materials have found a wide range of practical applications across industries due to their exceptional strength, conductivity, and lightweight nature. You’ll see them in aerospace, sports equipment, electronics, and biomedical devices, where improved durability and performance are critical. However, biodegradability concerns pose challenges for environmental sustainability, especially in medical implants and packaging. Regulatory hurdles also slow down commercialization, as safety assessments and standards lag behind technological advances. Additionally, ongoing research into biodegradability and environmental impact aims to address these sustainability challenges and improve the eco-friendliness of nanotube composites.

Future Directions in Nanotube Reinforcement Research

As research advances, future directions in nanotube reinforcement focus on overcoming current limitations and revealing new applications. You’ll likely see efforts to improve nanotube biocompatibility, enabling safer integration into biomedical devices and implants. Enhancing biocompatibility will open doors for innovative medical applications while addressing safety concerns. Simultaneously, researchers will explore minimizing nanotube environmental impact by developing eco-friendly production methods and recycling strategies. These efforts aim to reduce potential ecological risks associated with nanotube manufacturing and disposal. Additionally, understanding how nanotubes interact with biological systems and ecosystems will guide responsible development. By addressing biocompatibility and environmental impact, future research can safely unlock the full potential of nanotube-reinforced composites across diverse fields, ensuring they’re both effective and sustainable.

Environmental and Economic Considerations

Advancing nanotube reinforcement techniques requires careful consideration of their environmental and economic impacts. You need to evaluate sustainable sourcing methods to minimize ecological harm and guarantee responsible use of resources. Additionally, appraising economic feasibility is vital for large-scale adoption, balancing production costs with benefits. You should also consider the potential environmental footprint of nanotube manufacturing processes, aiming for greener alternatives. Finally, understanding market dynamics helps determine whether the benefits outweigh costs, ensuring that these advanced materials remain viable and sustainable. Incorporating cost-effective manufacturing strategies can further support scalable implementation.

Frequently Asked Questions

How Do Nanotube Length and Diameter Affect Reinforcement Efficiency?

You’ll find that longer nanotubes and smaller diameters enhance reinforcement efficiency by improving nanotube alignment and stress transfer within the composite. Smaller diameters increase surface area, boosting surface functionalization, which improves bonding. Longer nanotubes provide better load transfer along their length, but if they’re too long, they may entangle, reducing efficiency. Optimizing length and diameter, along with surface functionalization, guarantees stronger, more effective reinforcement in your composite material.

What Are the Long-Term Durability Concerns for Nanotube-Reinforced Composites?

You should know that around 60% of nanotube-reinforced composites face durability issues over time. Environmental impact is a concern, as nanotubes can be released during degradation, potentially harming ecosystems. Recycling challenges also arise; these composites are difficult to break down, making waste management tough. To guarantee long-term durability, you need to take into account proper disposal methods and develop eco-friendly recycling techniques.

How Does Temperature Influence Nanotube Dispersion and Composite Properties?

You find that temperature substantially impacts nanotube dispersion and composite properties. Higher temperatures can enhance thermal stability during processing, improving dispersion if controlled properly. However, excessive heat may cause nanotube agglomeration or degradation, weakening the composite. Using appropriate processing techniques, like sonication or functionalization, helps maintain good dispersion and ideal properties across temperature ranges, ensuring the composite’s durability and performance over time.

Can Natural or Biodegradable Polymers Benefit From Nanotube Reinforcement?

Yes, natural or biodegradable polymers can benefit from nanotube reinforcement. Incorporating nanotubes into biodegradable composites enhances their mechanical strength, durability, and thermal stability, making them more suitable for various applications. When you reinforce natural polymers with nanotubes, you improve their performance while maintaining eco-friendly properties. This approach supports sustainable development by creating biodegradable composites that meet modern material demands without compromising environmental benefits.

What Are the Safety Risks Associated With Manufacturing Nanotube Composites?

A stitch in time saves nine, so you should know that manufacturing nanotube composites poses safety risks like occupational exposure to airborne nanoparticles, which can cause respiratory issues. You also need to contemplate the environmental impact if nanotubes are released into ecosystems. To protect yourself and the environment, always use proper protective gear, work in well-ventilated areas, and follow strict safety protocols during production.

Conclusion

As you explore nanotube reinforcement in composites, you’ll uncover remarkable improvements and persistent challenges. Will future innovations overcome dispersion and alignment hurdles? The potential for groundbreaking applications beckons, but uncertainties remain. Stay tuned, as ongoing research promises to unleash even greater performance and sustainability — yet, the path ahead is filled with intriguing questions. The next chapter in nanotechnology’s story is just waiting to be written, and you’re right at its edge.