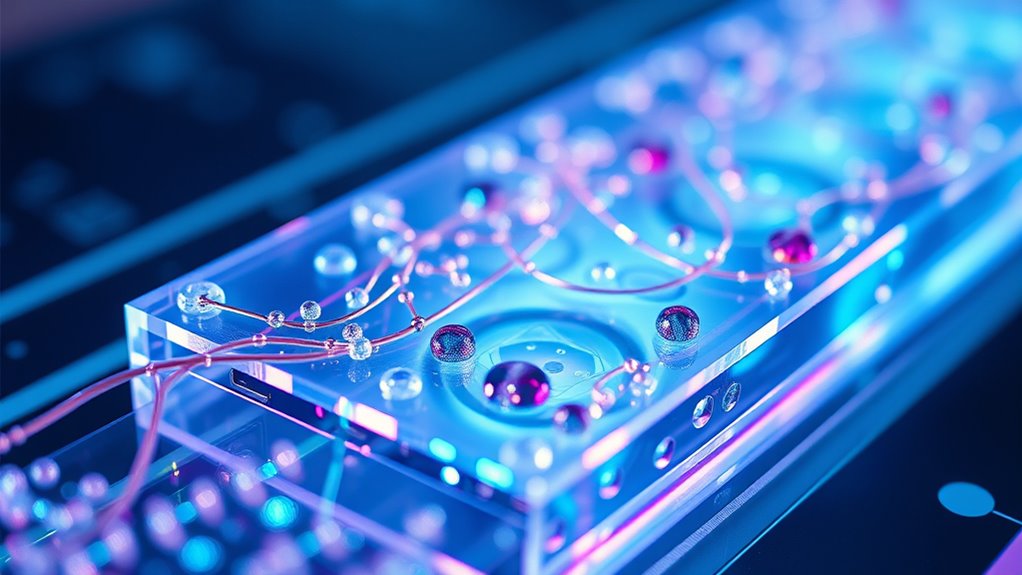

When microfluidics meets nanotech, you open the ability to manipulate fluids and particles at atomic and molecular scales. This fusion enables you to design tiny devices that interact with individual cells or molecules, opening new possibilities in biology, medicine, and chemistry. You can create highly sensitive sensors, targeted drug delivery systems, and advanced diagnostic tools. Keep exploring further, and you’ll discover how this exciting convergence is transforming science and industry.

Key Takeaways

- Microfluidics integrates nanotechnology to manipulate fluids and particles at atomic and molecular scales for advanced applications.

- Nano fabrication enables precise creation of microchannels, sensors, and devices for enhanced control and detection.

- Fluid dynamics at the nanoscale involve unique phenomena like electrokinetics and surface tension, improving system efficiency.

- Combining microfluidics and nanotech allows ultra-sensitive diagnostics, single-molecule analysis, and targeted drug delivery.

- The convergence fosters innovative systems with greater speed, accuracy, and versatility, impacting healthcare, research, and industry.

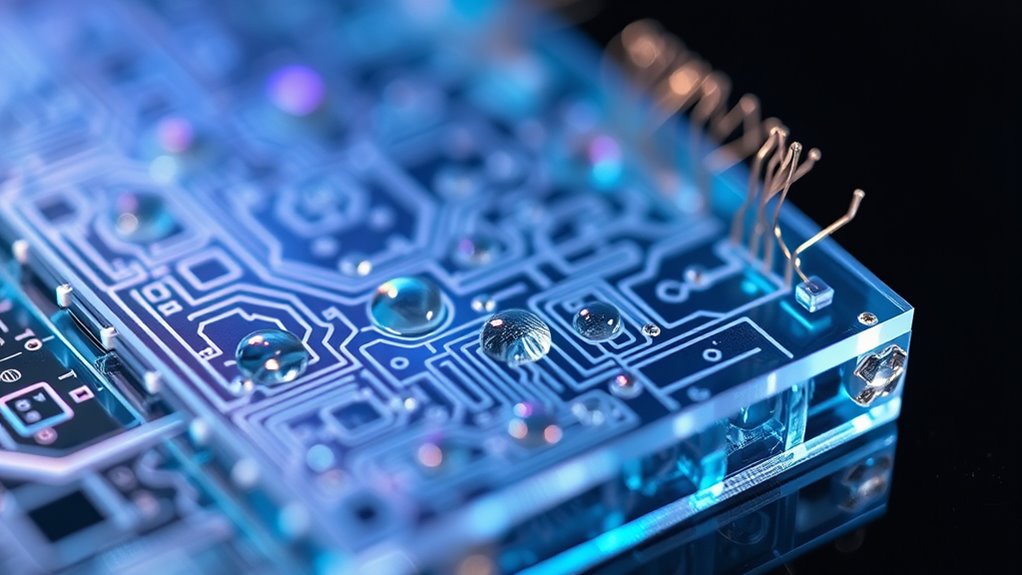

Have you ever wondered how tiny channels and particles can revolutionize science and medicine? It all comes down to the incredible world of microfluidics combined with nanotechnology. When you explore this field, you realize that manipulating fluids at the micro and nano scale opens up possibilities once thought impossible. One of the core aspects is nano scale fabrication, which involves creating structures so small they operate at the atomic or molecular level. This precision allows you to design channels, sensors, and devices that interact directly with individual cells or molecules. These devices can perform complex tasks like sorting, analyzing, or delivering substances with extraordinary accuracy. Nano scale fabrication isn’t just about miniaturization; it’s about harnessing phenomena that only emerge at tiny scales, such as quantum effects or enhanced surface interactions. By mastering this, you can develop tools that are both highly sensitive and incredibly efficient. Proper beneficiary designation is essential to maximizing your investment’s benefits and avoiding costly tax liabilities. Fluid dynamics modeling plays a pivotal role here. When you work with fluids at these tiny dimensions, their behavior diverges markedly from what you observe in the macro world. Traditional fluid mechanics don’t always apply, so you need to use specialized models that account for laminar flow, surface tension, and electrokinetic effects. Fluid dynamics modeling enables you to predict how fluids will behave inside nanofluidic channels, which is essential for designing effective devices. It helps you optimize flow rates, improve mixing, and guarantee precise control over particle transport. Without accurate modeling, you risk designing systems that don’t work reliably or efficiently. When you combine nano scale fabrication with advanced fluid dynamics modeling, you gain the ability to engineer highly sophisticated systems capable of performing tasks like single-molecule detection or targeted drug delivery. This intersection of microfluidics and nanotech transforms how you approach problems in biology, chemistry, and medicine. It’s not just about making things smaller; it’s about creating systems that can manipulate matter at the most fundamental level. As you develop these technologies, you’re pushing the boundaries of what’s possible, enabling breakthroughs like personalized medicine or ultra-sensitive diagnostics. The key lies in understanding how to control fluid flow at the nano scale through precise fabrication and robust modeling. With these tools, you can design devices that are faster, more accurate, and more versatile than ever before. It’s an exciting frontier where engineering and science converge, and your role in mastering nano scale fabrication and fluid dynamics modeling can lead to revolutionary advances that impact lives worldwide.

Frequently Asked Questions

What Are the Main Challenges in Integrating Microfluidics With Nanotechnology?

You face main challenges like scaling issues, where tiny nanostructures are hard to produce consistently at microfluidic levels. Material compatibility also poses problems, as some nanomaterials may react negatively with microfluidic device components, causing clogging or degradation. To overcome these, you need innovative fabrication techniques and carefully chosen materials that can withstand interactions at both scales, ensuring reliable integration of nanotech into microfluidic systems.

How Does Nanotech Improve the Sensitivity of Microfluidic Devices?

Nanotech improves the sensitivity of microfluidic devices by leveraging quantum effects and surface modifications. Quantum effects enhance detection limits, making it easier to identify tiny analyte quantities. Surface modifications increase interaction areas and binding efficiency, boosting signal strength. You benefit from these advancements as they allow for more precise, faster, and reliable measurements, vital for applications like diagnostics and environmental monitoring.

What Specific Applications Benefit Most From This Interdisciplinary Approach?

Like a modern-day Prometheus, you harness nanotech’s power to revolutionize drug delivery and biosensing. These interdisciplinary approaches excel in creating highly targeted therapies and ultra-sensitive detectors, transforming healthcare. You see rapid, precise responses in personalized medicine and early disease diagnosis. By integrating nanotech with microfluidics, you unseal innovations that improve patient outcomes and enable real-time monitoring, making these fields among the most promising beneficiaries of this cutting-edge synergy.

Are There Any Safety Concerns Associated With Nanomaterials in Microfluidics?

You should be aware that nanomaterials in microfluidics pose safety concerns like environmental impact and regulatory issues. These tiny particles might contaminate ecosystems if not properly contained or disposed of. Regulatory concerns stem from limited understanding of long-term effects, making oversight challenging. To guarantee safety, you need strict controls, thorough testing, and adherence to evolving regulations to prevent potential risks associated with nanomaterials.

How Cost-Effective Is the Manufacturing of Hybrid Microfluidic-Nanotech Systems?

You might imagine a sleek device, seamlessly blending tiny channels with nanomaterials. The reality is, hybrid microfluidic-nanotech systems can be quite cost-effective, especially as you optimize the cost analysis and scale up manufacturing. While initial investments can be high, increased manufacturing scalability reduces per-unit costs over time. With strategic planning and technological advances, you’ll find these systems becoming increasingly affordable, revealing new possibilities in diagnostics and research.

Conclusion

As you explore the fusion of microfluidics and nanotech, envision a tiny universe within your grasp—where particles dance like stars in a vast cosmos. This synergy reveal endless possibilities, transforming medicine, electronics, and beyond. Embrace this frontier, where science becomes a brush painting the future’s vivid landscape. Together, you’re not just witnessing innovation—you’re shaping the microscopic worlds that will define tomorrow’s horizons.