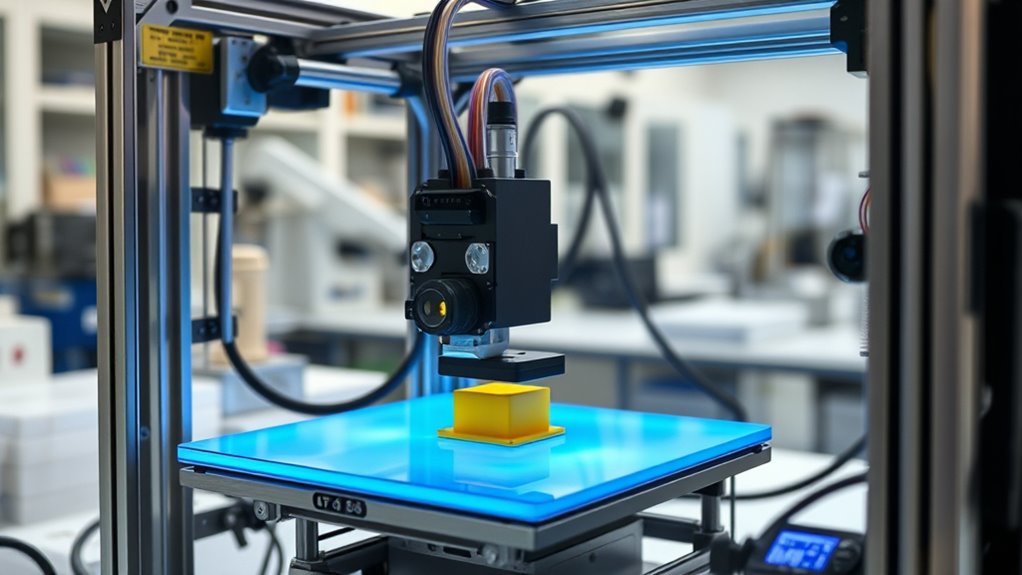

If you’re looking for the best high-temperature 3D printers for PEEK, I recommend models equipped with durable hotends, advanced thermal management, and precise temperature control that can handle at least 450°C. Features like heat-resistant nozzles, efficient insulation, and reliable sensors are essential for quality results. Whether it’s the latest FDM or resin printers, choosing the right components makes a huge difference. Keep going to discover more top picks and what factors to contemplate for success.

Key Takeaways

- High-temperature 3D printers for PEEK need hotends capable of reaching at least 450°C with durable, heat-resistant components.

- Compatibility of nozzles and hotends made from tungsten steel or ceramic ensures wear resistance during demanding high-temp printing.

- Effective thermal management, including insulation and precise temperature sensors, is crucial for consistent PEEK layer adhesion.

- Hotend components like thermistors and thermistor cartridges enable accurate temperature control at elevated temperatures.

- Selecting printers with robust heated chambers and advanced thermal solutions optimizes high-performance PEEK printing.

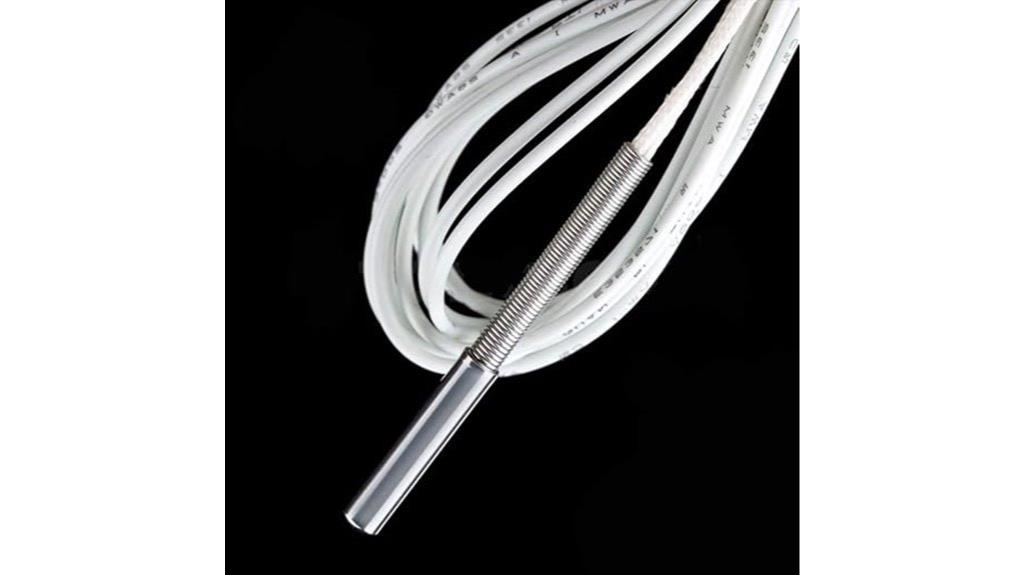

High Temperature Thermistor Cartridge for 3D Printer Hotend

If you’re working with high-temperature materials like PEEK, a reliable hotend temperature sensor is essential, and the High Temperature Thermistor Cartridge is an excellent choice. Designed to handle up to 450°C, it offers precise temperature measurements and quick response times. Compatible with popular hotends like the Volcano V6, it features a 3mm diameter and 15mm length metal cartridge for easy installation. The included high-temperature resistant wiring and resistor upgrades ensure accurate readings and stable operation. This thermistor cartridge is a cost-effective, plug-and-play solution that enhances print quality and reliability, making it ideal for demanding high-temperature 3D printing applications.

Best For: those seeking a high-temperature, accurate, and affordable temperature sensing solution for demanding 3D printing applications involving materials like PEEK.

Pros:

- Supports high temperatures up to 450°C with precise readings and quick response times.

- Compatible with popular hotends like Volcano V6, enabling easy plug-and-play installation.

- Cost-effective alternative to thermocouples, offering improved accuracy and reliability for high-temperature printing.

Cons:

- Requires proper firmware configuration, which may be challenging for some users.

- May need resistor upgrades (from 4.7K to 1K 0.1%) for optimal resolution.

- Limited to applications that can accommodate the 3mm diameter and 15mm length cartridge size.

Creality Thermal Paste for 3D Printer Hotend & Nozzle

Creality Thermal Paste for 3D Printer Hotend & Nozzle stands out as an essential upgrade for users aiming to optimize thermal management in high-temperature 3D printing. This high-performance thermal grease improves heat transfer between the hotend components, ensuring stable temperatures during demanding prints. It’s rated to withstand temperatures up to 250℃, making it perfect for high-temperature materials like PEEK. Non-toxic, non-corrosive, and environmentally compliant, it offers safe, reliable performance. Proper application reduces the need for frequent reapplications, prolongs component lifespan, and helps maintain consistent print quality. It’s an easy, effective way to enhance your printer’s thermal efficiency and overall durability.

Best For: 3D printer users seeking to enhance thermal management, especially those printing with high-temperature materials like PEEK, Ender series, or performing routine maintenance.

Pros:

- Excellent heat transfer and temperature stability up to 250℃

- Safe, non-toxic, and environmentally compliant for eco-friendly use

- Reduces frequency of reapplication, extending component lifespan

Cons:

- May require careful application to ensure optimal performance

- Slightly more expensive than standard thermal compounds

- Not suitable for use with materials or components that cannot tolerate high temperatures

Creality 3D Printer Thermal Grease (2 Pack)

For those seeking reliable thermal management in their 3D printers, Creality’s 3D Printer Thermal Grease (2 Pack) offers an excellent solution. With a thermal conductivity of 12 W/m·K, it ensures rapid heat transfer and stable operation from -50°C to 250°C. Made from non-toxic, non-conductive silicone, it’s safe, eco-friendly, and easy to apply. It fills tiny gaps efficiently, improves heat dissipation, and enhances adhesion on glass beds. Plus, it’s easy to clean with water and doesn’t dry out or solidify over time. This thermal grease is perfect for maintaining high-performance hotends and nozzles, extending component lifespan while simplifying maintenance.

Best For: DIY 3D printing enthusiasts and professionals seeking efficient heat management and reliable bed adhesion for high-quality, long-duration prints.

Pros:

- High thermal conductivity of 12 W/m·K for rapid heat transfer

- Non-toxic, non-conductive silicone formula safe for all printer components

- Easy to apply, clean with water, and maintains effectiveness over time

Cons:

- Reapplication required only after cleaning the print bed

- Slight variability in adhesion performance depending on surface conditions

- May not be suitable for users preferring adhesive substances other than thermal grease

3D Printer Thermistor T-D500 (500℃, M3x15mm, High Temp Sensor)

The D Printer Thermistor T-D500 stands out as an essential component for high-temperature 3D printing, especially when working with advanced materials like PEEK and Carbon Fiber. It’s rated for up to 500℃ and features a compact 3mm x 15mm cylindrical design, compatible with cartridge-style hotends like Volcano V6 and Prusa i3. With a 1-meter cable, it’s easy to install and reliable for extended use. This thermistor provides stable, accurate temperature readings vital for high-performance printing. When paired with the correct firmware adjustments, it guarantees safe, consistent temperature control, making it a top choice for demanding high-temp applications.

Best For: those seeking a high-temperature thermistor for advanced 3D printing applications involving PEEK, Carbon Fiber, and other demanding materials requiring precise and reliable temperature control.

Pros:

- Rated for up to 500℃, suitable for high-performance and high-temperature materials

- Compact cylindrical design (3mm x 15mm) compatible with cartridge-style hotends like Volcano V6 and Prusa i3

- Durable, flexible, and long-lasting with stable temperature readings for extended printing sessions

Cons:

- Requires firmware updates and configuration adjustments for optimal performance

- May need careful installation to ensure proper thermal contact and accuracy

- Limited to use with compatible firmware versions (Marlin v1.1.0 RC7 and later)

Creality Hardened Steel MK8 Nozzles (5 Pack) for 3D Printers

If you’re aiming for reliable, high-precision 3D printing with high-temperature materials, these Hardened Steel MK8 Nozzles are an excellent choice. Made from tungsten steel with over HRC60 hardness, they’re highly resistant to wear, lasting much longer than standard brass nozzles. Capable of handling temperatures up to 450°C, they support materials like PEEK, ABS, and carbon fiber. CNC-machined for perfect concentricity, they ensure smooth filament flow and reduce clogging. Compatible with most FDM printers, including Creality models, they come in a 5-pack with various sizes. This versatility makes them ideal for demanding, high-temperature printing projects.

Best For: hobbyists, professionals, and enthusiasts seeking durable, high-precision nozzles for high-temperature 3D printing with diverse filament options.

Pros:

- Made from high-hardness tungsten steel for exceptional wear resistance and longevity.

- Supports high-temperature printing up to 450°C, compatible with materials like PEEK, ABS, and carbon fiber.

- CNC-machined for perfect concentricity and smooth filament flow, reducing clogging and enhancing print quality.

Cons:

- Slightly more expensive than standard brass nozzles.

- Heavier than brass nozzles, which may impact some printer performance.

- Compatibility may vary with non-FDM or older printer models.

2pcs Ender 3 V3 SE Hardened Steel Nozzles for 3D Printer

These pcs Ender 3 V3 SE Hardened Steel Nozzles are an excellent choice for advanced 3D printers that require high-temperature capabilities, especially when printing engineering plastics like PEEK. Made from durable hardened steel, they resist wear and maintain consistent filament flow, even after extensive use. Designed for high-speed printing at temperatures up to 450°C, they’re compatible with Creality Spider hotend, Ender 7, Ender 5 S1, and Ender 3 V3 SE printers. Easy to install, these nozzles deliver reliable performance and excellent print quality, making them a valuable upgrade for demanding high-temperature applications.

Best For: hobbyists and professionals who need durable, high-temperature nozzles for demanding 3D printing applications with materials like PEEK and high-speed printing.

Pros:

- Made from high-quality hardened steel for exceptional wear resistance and durability

- Capable of withstanding temperatures up to 450°C, suitable for engineering plastics and specialty materials

- Easy plug-and-play installation ensures quick setup and reliable performance

Cons:

- Slightly higher price compared to market alternatives, which may be a consideration for budget-conscious users

- Not compatible with all Ender 3 series models, limiting versatility for some users

- Minor tip wear may occur after prolonged use, especially if heat retention is inconsistent

2 Pack 0.4MM Hotend Kit for Bambu Lab A1 Mini/A1 3D Printer

Designed specifically for Bambu Lab A1 Mini and A1 3D printers, the Pack 0.4MM Hotend Kit offers a quick and reliable way to upgrade your machine’s performance. It includes two high-quality hardened steel hotends—one with a 0.2mm nozzle for fine details and a 0.4mm for general printing—plus wrenches and silicone sock covers. Compatible with various 1.75mm filament types, these nozzles resist wear and high temperatures, ensuring consistent extrusion. The magnetic fixing allows easy, tool-free nozzle swaps, saving time during maintenance. Proper handling and cooling are essential for safety and longevity, making this kit a versatile upgrade for precision and durability.

Best For: DIY enthusiasts and professionals seeking to enhance their Bambu Lab A1 Mini or A1 3D printers with durable, high-precision hotends for versatile filament printing.

Pros:

- High-quality hardened steel construction for wear resistance and high-temperature durability

- Includes both 0.2mm and 0.4mm nozzles for detailed and standard printing needs

- Magnetic fixing allows quick, tool-free nozzle replacement, saving time

Cons:

- Requires proper cooling and handling to ensure safety and nozzle longevity

- Compatibility limited to specific Bambu Lab A1 Mini/A1 models, may not fit other printers

- No mention of additional accessories or replacement parts beyond the kit components

Xtreme Lock 50ml 3D Printer Adhesive for PLA, ABS, PEEK, Nylon, PC, PETG

When working with high-performance materials like PEEK, achieving reliable adhesion is essential for successful 3D printing. That’s where Xtreme Lock 50ml adhesive comes in. It’s a professional-grade, all-in-one solution compatible with a wide range of filaments, including PLA, ABS, PETG, Nylon, PC, and PEEK. Its strong formula reduces warping and lifting, ensuring your prints stay securely in place, even at high temperatures. Easy to apply with the included applicator, it leaves no residue after cooling and detachment. Safe, non-toxic, and versatile, Xtreme Lock is perfect for demanding, high-precision projects.

Best For: hobbyists, professionals, and enthusiasts seeking reliable, high-temperature adhesion for a wide range of 3D printing materials including PEEK, Nylon, and ABS.

Pros:

- Provides strong, durable adhesion suitable for demanding high-performance materials

- Reduces warping and lifting, ensuring print stability and precision

- Easy to apply with included applicator and leaves no residue after detachment

Cons:

- May require careful application to avoid excess use or mess

- Limited information on long-term storage stability

- Specific surface preparation might be necessary for optimal results

Upgrade Bimetal Nozzles for 3D Printer (0.4mm & 0.6mm, Hardened Steel)

Upgrade bimetal nozzles with hardened steel tips are essential for anyone aiming to push their 3D printer’s capabilities, especially when working with high-temperature materials like PEEK, PEI, or carbon fiber. These nozzles, available in 0.4mm and 0.6mm sizes, feature a copper alloy body for superior heat transfer and hardened steel tips for durability against abrasive filaments. The nickel-based plating reduces filament sticking, keeping nozzles clean and improving print quality. Designed for high-temperature use on compatible ELEGOO Neptune 4/4 Pro models, they guarantee consistent performance and longevity, making them a smart upgrade for advanced, high-performance printing.

Best For: users seeking high-temperature, durable nozzles for advanced 3D printing with abrasive or high-performance materials like PEEK, PEI, or carbon fiber on ELEGOO Neptune 4/4 Pro models.

Pros:

- Constructed with a copper alloy body for superior heat transfer and efficient melting.

- Hardened steel tips provide high wear resistance suitable for abrasive filaments.

- Nickel-based plating reduces filament sticking, ensuring cleaner nozzles and better print quality.

Cons:

- Not compatible with Neptune 4 Max or 4 Plus models.

- Proper installation is critical; incorrect assembly may cause filament leakage.

- Slightly more expensive than standard brass nozzles due to advanced materials and design.

ELEGOO Saturn 4 Ultra 3D Resin Printer

The ELEGOO Saturn 4 Ultra 16K Resin 3D Printer stands out for its high-speed printing capabilities and advanced temperature control, making it an excellent choice for users needing detailed, reliable prints in demanding environments. Its large build volume of 211.68×118.37×220mm, combined with intelligent resin tank heating that maintains ideal thermal conditions, guarantees consistent results. The revolutionary tilt-release mechanism speeds up printing by reducing Z-axis movement. AI-powered monitoring detects issues in real time, while Wi-Fi connectivity allows remote operation and file management. Praised for ease of use and stunning detail, it’s ideal for miniatures, scientific, and industrial applications.

Best For: hobbyists, miniature creators, and professionals seeking high-speed, detailed resin 3D printing with reliable thermal management and remote control capabilities.

Pros:

- Large build volume of 211.68×118.37×220mm for versatile printing projects

- Rapid printing speed up to 150mm/h with tilt-release technology for efficiency

- Advanced AI monitoring and Wi-Fi connectivity for real-time issue detection and remote operation

Cons:

- Heavier weight of 41.2 pounds may require sturdy placement and handling

- Higher initial cost compared to basic resin printers

- Complex features might have a learning curve for beginners

Creativity Upgrade Bimetal Nozzles for 3D Printers

Creativity Upgrade Bimetal Nozzles stand out for their high wear resistance and exceptional thermal conductivity, making them ideal for users who need reliable, high-temperature printing with advanced materials like PEEK and Carbon Fiber. These nozzles feature a hardened steel insert tip, increasing durability, and a copper alloy body that offers over three times the thermal conductivity of brass, ensuring efficient heat transfer. The nickel-based plating reduces filament sticking, resulting in smoother prints. Compatible with Neptune 4 and Neptune 4 Pro printers, they enable precise, clean, and consistent high-temperature printing, making them a valuable upgrade for demanding 3D printing applications.

Best For: users seeking durable, high-performance nozzles capable of handling high-temperature printing with advanced materials like PEEK and Carbon Fiber.

Pros:

- High wear resistance due to hardened steel insert tip.

- Excellent thermal conductivity from copper alloy body for efficient heat transfer.

- Reduces filament sticking with nickel-based plating for smoother, cleaner prints.

Cons:

- Slightly more expensive than standard brass nozzles.

- May require adjustments in print settings due to high thermal conductivity.

- Compatibility limited to Neptune 4 and Neptune 4 Pro printers.

FLASHFORGE Adventurer 5M 3D Printer

If you’re searching for a reliable, high-speed 3D printer that’s perfect for rapid prototyping and small-scale projects, the FlashForge Adventurer 5M stands out. It’s an enclosed, all-metal CoreXY design with a 220x220x220mm build volume, offering fast, stable prints. Its direct extruder reaches 280°C, and the high-flow nozzle speeds up production. Features like automatic bed leveling, quick nozzle changes, and vibration compensation make setup and operation straightforward. With a user-friendly touchscreen and wireless connectivity, it’s ideal for beginners and experienced users alike. Overall, the Adventurer 5M combines speed, ease of use, and upgrade options, making it a versatile choice for creative and prototyping needs.

Best For: hobbyists, educators, and small-scale prototyping enthusiasts seeking a reliable, high-speed 3D printer with user-friendly features and upgrade options.

Pros:

- Fast printing speeds with stable, high-quality results

- Easy setup with automatic bed leveling and intuitive touchscreen interface

- Durable all-metal CoreXY design with upgrade potential

Cons:

- Limited build volume for larger projects

- Included slicer software (FlashPrint) may require replacement for advanced control

- Some users report filament feeding and nozzle clog issues

Factors to Consider When Choosing High‑Temperature 3D Printers for PEEK

When selecting a high-temperature 3D printer for PEEK, I focus on its maximum operating temperature and hotend durability to guarantee it can handle the material’s demanding conditions. Precise temperature control and effective thermal management are vital for consistent, high-quality prints. Compatibility with PEEK and robust thermal systems help me find a reliable machine that meets my specific printing needs.

Maximum Operating Temperature

Selecting a high-temperature 3D printer requires careful attention to its maximum operating temperature, especially for materials like PEEK that demand elevated extrusion and bed temperatures. To print effectively, the printer should reach at least 450°C, ensuring proper layer bonding and adhesion. Higher temperature capabilities enable the use of advanced filaments that need intense heat. It’s indispensable that the thermistors or temperature sensors are rated for these high temperatures to provide accurate readings and maintain safety. Additionally, components like the hotend and heated bed must be made from heat-resistant materials such as tungsten steel or ceramic to withstand sustained high heat without degrading. Exceeding the recommended maximum temperature can damage parts, degrade filament quality, and pose safety risks—so choosing a printer with a reliable, high-temperature threshold is essential.

Hotend Material Durability

Choosing the right hotend material is vital for guaranteeing durability and consistent performance during high-temperature 3D printing with PEEK. Hotends made from hardened steel or tungsten alloys are top choices because they resist wear from abrasive filaments like PEEK. These materials can withstand prolonged exposure to temperatures up to 500°C without deforming or losing strength, which is essential for reliability. The thermal expansion coefficient also plays a role; materials with stable expansion help maintain precision over time. Additionally, corrosion resistance ensures the hotend remains unaffected by chemically aggressive filaments, extending its lifespan. Ultimately, selecting a durable hotend material directly impacts the longevity and consistent performance of your printhead, especially in demanding high-temperature applications like PEEK printing.

Precise Temperature Control

Achieving precise temperature control is essential for high-temperature 3D printing with PEEK, as even minor fluctuations can compromise print quality. Stable hotend temperatures, usually within ±1°C, are critical for consistent extrusion and layer adhesion. Accurate regulation minimizes issues like warping and layer separation, which are common with materials requiring temperatures up to 450°C. Advanced heaters and thermistors, such as PT1000 sensors or high-temperature thermistors, provide real-time feedback, enabling fine-tuned adjustments. Proper firmware calibration, including PID tuning, ensures the temperature remains steady during long prints. Reliable temperature control not only improves print quality but also protects components from overheating or underheating, ensuring the longevity of your printer and the integrity of high-performance materials like PEEK.

Thermal Management Systems

A robust thermal management system is essential for high‑temperature 3D printers used with PEEK because maintaining consistent temperatures up to 450°C or higher directly affects print quality. Effective thermal insulation around the hotend and heated chamber minimizes heat loss, improves energy efficiency, and prevents heat creep, which can cause filament jams or poor layer adhesion. Precise temperature sensors, such as PT1000 thermistors, are vital for accurate monitoring and control of both the hotend and build chamber. An integrated cooling system for electronics prevents overheating during prolonged high‑temperature prints, ensuring stability. Additionally, uniform heat distribution across the hotend and heated bed, achieved through optimized heater placement and insulation, reduces warping and layer separation, resulting in better print quality and reliability.

Compatibility With PEEK

When selecting a high-temperature 3D printer for PEEK, verifying that its hotend can reach and sustain at least 430°C is essential, since PEEK typically requires 350°C to 450°C for proper extrusion. Ascertain the temperature sensors and thermistors are compatible with these high temperatures for accurate, stable readings. The hotend components, like nozzles and heat breaks, should be made from hardened steel, bimetal, or tungsten carbide to withstand the abrasive, high-heat environment. Check that the firmware supports high-temperature operation and can be configured for PEEK’s thermal parameters, including safety limits. Additionally, confirm the build chamber can be heated or enclosed to maintain consistent ambient temperatures, reducing warping and promoting proper layer adhesion during printing.

Frequently Asked Questions

What Safety Features Are Essential for High-Temperature 3D Printers?

Safety features are vital when working with high-temperature 3D printers. I always look for automatic shutoff systems that activate if temperatures get too high, preventing fires. Enclosed build chambers protect me from hot surfaces and fumes, while thermal runaway protection ensures safe operation. Additionally, a sturdy, grounded frame and proper ventilation are essential to keep both the user and environment safe during printing.

How Does Bed Temperature Influence PEEK Print Quality?

Bed temperature plays a vital role in PEEK printing quality. When I set it too low, I notice warping and poor layer adhesion, which ruins the print. On the other hand, maintaining an ideal, high bed temperature helps the filament stick better, reduces warping, and guarantees smoother layers. I always keep the bed heated to the recommended temperature to achieve precise, high-quality results with PEEK.

Can Existing FDM Printers Be Upgraded for High-Temperature Printing?

Yes, I can upgrade existing FDM printers for high-temperature printing. I start by replacing the heated bed and extruder with high-temperature components designed for materials like PEEK. Then, I upgrade insulation and consider a sealed chamber to maintain consistent temperatures. These modifications improve print quality and allow my printer to handle high-performance filaments. Just guarantee your printer’s frame can support these upgrades safely and effectively.

What Maintenance Is Required for High-Temperature Hotends?

High-temperature hotends need regular maintenance to stay reliable. I always check the heater block and thermistor for any signs of wear or damage, and I clean the nozzle to prevent clogs. Lubricating the moving parts and inspecting the thermal insulation help maintain consistent temperature. I also replace worn-out components promptly to avoid print failures. Staying on top of these tasks keeps my high-temperature printing smooth and precise.

How Does Print Speed Affect PEEK Layer Adhesion?

Print speed directly impacts PEEK layer adhesion because faster speeds can cause uneven extrusion and insufficient bonding between layers. When I print at high speeds, I notice weaker layer adhesion, leading to potential delamination. To get strong, precise parts, I slow down my print speed, allowing the filament to bond properly. Balancing speed and temperature is key to achieving ideal layer adhesion with PEEK.

Conclusion

As I imagine the perfect high-temperature 3D printer, I see it as a steady forge, capable of shaping PEEK with precision and resilience. With the right components—sturdy thermistors, durable nozzles, and reliable hotends—it becomes a tool of limitless potential. I invite you to choose wisely, so your creations emerge like finely forged metal—strong, detailed, and ready to stand the test of time. Let your imagination heat up and bring your visions to life.