If you’re searching for the 14 best laboratory robotic arms in 2025, I recommend models that combine high precision, reliability, and versatility. These include AI-powered kits like LeRobot SO-ARM101, advanced control options from HIWONDER, and user-friendly options like the Arduino-based 6DOF arms. Many support programming in Python or ROS, with features like voice and gesture control. Keep exploring, and you’ll find the perfect fit for your lab’s needs.

Key Takeaways

- Advanced robotic arms with high precision (0.1-0.5mm) and reliable repeatability are ideal for laboratory applications in 2025.

- Compatibility with multiple control platforms (Python, ROS, AI frameworks) enhances automation and customization options.

- Models featuring AI integration like vision, voice, and gesture recognition improve efficiency in complex tasks.

- Durable mechanical design using aerospace-grade materials ensures stability and load capacity for demanding laboratory tasks.

- Open-source and modular robotic arms facilitate scalability, user customization, and integration with diverse laboratory environments.

AI Robotic Arm Kit with Servo Motors (LeRobot SO-ARM101)

If you’re an AI robotics enthusiast or developer looking for an affordable, versatile robotic arm kit, the LeRobot SO-ARM101 is an excellent choice. It’s a low-cost, open-source 6-DOF robotic arm compatible with LeRobot, Hugging Face frameworks, and Nvidia Jetson devices like the Jetson Orin NX. Its improved wiring prevents disconnections, and the gear-ratio motors ensure smoother, more durable operation. The kit supports imitation and reinforcement learning, with real-time leader-follower tracking for human interaction. Plus, its open-source software and complete guides make customizing, testing, and deploying AI-driven tasks straightforward, helping you develop precise robotic solutions efficiently.

Best For: AI robotics enthusiasts and developers seeking an affordable, open-source 6-DOF robotic arm compatible with popular AI frameworks and edge devices.

Pros:

- Open-source design allows for extensive customization and experimentation.

- Supports imitation learning and reinforcement learning, ideal for real-world AI applications.

- Real-time leader-follower tracking enables human interaction and hands-on training.

Cons:

- 3D-printed parts are not included, requiring additional resources for assembly.

- Limited range of motion compared to more advanced robotic arms.

- Compatibility may require technical expertise for integration with specific hardware and software platforms.

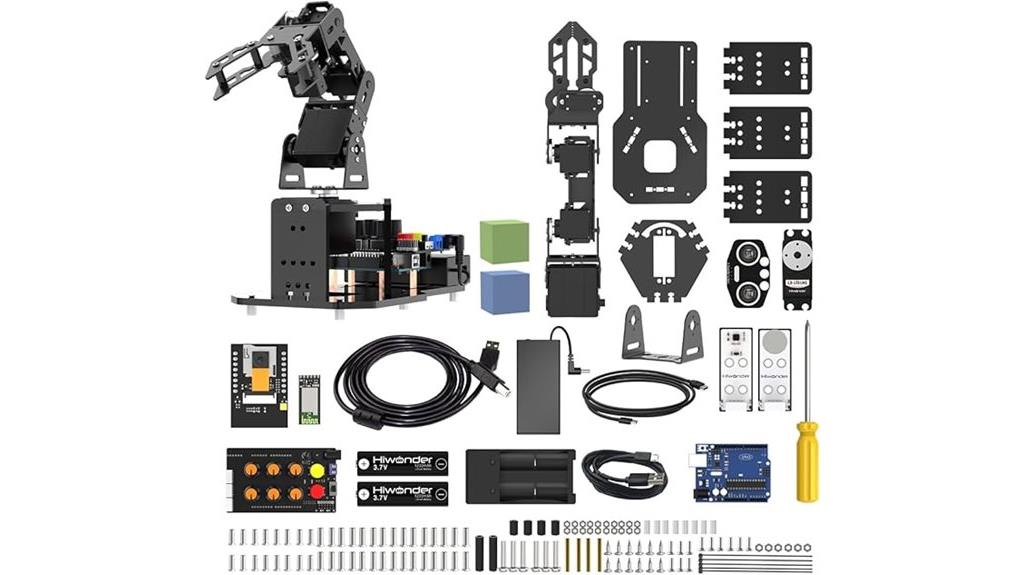

HIWONDER ROS2 ROS1 Robotic Arm Kit with AI and Voice Commands

The HIWONDER ROS2 ROS1 Robotic Arm Kit with AI and Voice Commands stands out as an ideal choice for educators and developers seeking an advanced, versatile platform. Powered by Jetson Nano, Orin Nano, or Orin NX controllers, it supports ROS1 and ROS2, making it highly adaptable. Its six high-torque servos, 3D depth camera, and microphone array enable complex tasks like 3D scene understanding, target tracking, and object sorting. The integration of multimodal AI models and ChatGPT allows for natural voice and human-robot interactions. With all-encompassing tutorials, it’s perfect for mastering AI, vision, and robotics, pushing the boundaries of precision and efficiency.

Best For: educators and developers seeking an advanced, versatile robotic arm platform with integrated AI, vision, and voice interaction capabilities for complex robotics and AI projects.

Pros:

- Supports both ROS1 and ROS2, offering broad compatibility for various development environments

- Equipped with high-torque servos, 3D depth camera, and microphone array for sophisticated scene understanding and interaction

- Provides comprehensive tutorials covering robotics, AI, vision, and simulation to facilitate quick mastery

Cons:

- May require a steep learning curve for beginners new to ROS or AI integration

- Dependence on high-performance controllers like Jetson Nano, Orin Nano, or Orin NX could increase setup complexity and cost

- Advanced features and hardware might be overkill for simple or entry-level robotics projects

Robotic Arm for Arduino Coding Programming (6DOF)

Designed with educational and hobbyist users in mind, the Hiwonder-xArm1S offers precise 6DOF control through Arduino programming, making it an ideal platform for learning robotics and developing custom automation projects. Made from durable aluminum alloy, it features industrial-grade bearings and high-torque serial bus servos that provide real-time feedback on position, voltage, and temperature. Capable of grasping objects up to 500g, it supports remote control, object transportation, and graphical programming via PC, smartphone, or Arduino. With about 0.24-degree servo precision, it enables accurate positioning, but movements can sometimes be jerky, especially at full extension. It’s perfect for hobbyists seeking hands-on experience.

Best For: hobbyists and educational users seeking a versatile, precise, and programmable robotic arm for learning robotics and developing custom automation projects.

Pros:

- High-precision control with approximately 0.24-degree servo accuracy, suitable for accurate positioning.

- Made from durable aluminum alloy with a full metal structure and industrial-grade bearings for stability and longevity.

- Supports multiple control methods including PC software, mobile app, Arduino, and remote controllers, offering versatile operation.

Cons:

- Movement can be jerky, especially at full extension, due to motor weight and stability issues.

- Assembly can be challenging with limited instructions and incomplete documentation, requiring careful effort.

- Lacks advanced motion features like smooth motion and complex axis rotation, limiting high-precision industrial applications.

Yahboom 6DOF Robotic Arm Kit for Mechanical Engineers

Mechanical engineers seeking to deepen their understanding of AI vision and robotic control will find the Yahboom 6DOF Robotic Arm Kit especially valuable. This kit combines advanced hardware, including Jetson Nano, Orin Nano, and Orin NX boards, with a 6DOF metal arm featuring intelligent serial bus servos. Its binocular 3D depth camera enables precise measurement, recognition, and height detection, supporting complex tasks like sorting and grasping. The system offers multiple control options—app, wireless handle, ROS, and keyboard—and supports open-source programming with Python, ROS, and AI vision tools. It’s a versatile platform perfect for exploring cutting-edge AI and robotic applications in a lab setting.

Best For: mechanical engineers and robotics enthusiasts looking to learn and experiment with AI vision, 3D perception, and robotic control in educational or lab environments.

Pros:

- Equipped with powerful hardware like Jetson Nano, Orin Nano, and Orin NX for advanced AI processing.

- Supports multiple control methods including app, wireless handle, ROS, and keyboard, offering versatile operation.

- Features a 6DOF metal robotic arm with intelligent serial bus servos and a binocular 3D depth camera for precise and complex tasks.

Cons:

- The system’s complexity may require prior robotics or programming experience for effective use.

- Relatively large and heavy, which might limit portability or space for some users.

- Price point may be higher compared to simpler robotic kits, impacting accessibility for casual hobbyists.

Thames & Kosmos Bionic Robotic Arm STEM Kit

If you’re looking for an engaging STEM activity that combines hands-on building with real-world engineering concepts, the Thames & Kosmos Bionic Robotic Arm STEM Kit is an excellent choice. It includes nearly 300 pieces and a detailed manual that guides you through constructing a functional robotic arm. The design operates without motors or batteries, controlled by two joysticks that manipulate nylon cables for precise movements. This setup demonstrates biomimicry and mechanical engineering principles while encouraging problem-solving and fine motor skills. Suitable for ages 10 and up, it offers a fun, educational experience that fosters curiosity and understanding of robotics and mechanical systems.

Best For: STEM enthusiasts aged 10 and up who enjoy hands-on building and exploring robotics concepts.

Pros:

- Engages users with nearly 300 pieces for an immersive building experience

- Operates without motors or batteries, demonstrating mechanical principles through manual control

- Includes a detailed, step-by-step manual that enhances learning of biomimicry and engineering

Cons:

- May require adult supervision or assistance for younger children during assembly

- Limited to manual operation, which might not appeal to those seeking motorized robots

- The complexity of the build might be challenging for some users within the younger age range

Robotic Arm for Arduino Coding and Learning (Hiwonder-xArm1S, 6DOF)

The Hiwonder-xArm1S is an excellent choice for educators and hobbyists seeking an accessible yet precise robotic arm for Arduino coding and learning. Made from durable aluminum alloy, it offers six degrees of freedom with a high-precision 0.24-degree servo accuracy. It can grasp objects up to 500g and supports multiple control methods, including PC, smartphone, and Arduino. Its modular design allows for creative programming, object transportation, and custom actions. While assembly can be tricky, its sturdy build and versatile controls make it ideal for hands-on robotics education. The arm excels at repetitive tasks but may produce jerky motions when reaching for distant objects, reflecting its hobbyist focus.

Best For: hobbyists, educators, and beginners interested in learning robotics and programming with a precise, versatile, and durable robotic arm.

Pros:

- High-precision 0.24-degree servo accuracy for accurate repeated positioning

- Multiple control options including PC, smartphone, Arduino, and wireless controllers

- Robust aluminum alloy construction with industrial-grade bearings for durability and stability

Cons:

- Assembly can be challenging due to limited instructions and incomplete parts list

- Movements may be jerky, especially when reaching for distant objects, due to motor weight and stability issues

- Limited smooth motion and advanced axis rotation features for industrial-grade applications

Robotic Arm with Arduino 5DOF/Axis AI Smart Robot Arm Kit

Are you looking for a versatile and user-friendly robotics kit suitable for beginners and educators? The Robotic Arm with Arduino 5DOF/Axis AI Smart Robot Arm Kit fits the bill perfectly. Built on the Atmega328 platform, it’s compatible with Arduino programming and features high-performance digital servos. It offers multiple control options, including app control, real-time knob adjustments, and offline programming. With expandability for sensors like ultrasonic or touch sensors, it encourages creativity and hands-on learning. Ideal for STEM education, this open-source kit helps users explore robotics, coding, and engineering through practical projects, making it an excellent tool for fostering innovation and technical skills.

Best For: educators, students, and hobbyists seeking an easy-to-use, expandable robotics kit for learning and experimenting with programming and engineering concepts.

Pros:

- Compatible with Arduino, allowing for easy customization and programming.

- Multiple control options including app control, knobs, and offline programming enhance versatility.

- Expandable with sensors like ultrasonic and touch sensors to foster creativity and project diversity.

Cons:

- May require prior knowledge of Arduino or programming for full utilization.

- Limited to 5 degrees of freedom, which might restrict complex movements.

- Hardware setup and calibration can be time-consuming for beginners.

Robot Arm for Arduino, Smart Robot Building Kit

Designed for beginners, teens, and adults alike, the Robot Arm for Arduino is an excellent choice for anyone enthusiastic to explore robotics and coding hands-on. This smart building kit includes a versatile 4-axis robot arm capable of grabbing objects in any direction, with a 260° clip opening and 180° rotations at the wrist, elbow, and base. It’s easy to assemble with step-by-step instructions and tutorials, making learning accessible and engaging. You can control it manually via a joystick or program up to 170 actions for automatic repeats. It’s a perfect educational tool to develop skills in electronics, programming, and robotics.

Best For: beginners, teens, and adults interested in learning robotics, electronics, and programming through hands-on building and coding projects.

Pros:

- User-friendly with step-by-step assembly instructions and tutorials.

- Versatile 4-axis design allowing complex object manipulation.

- Capable of manual control via joystick and programming up to 170 actions for automation.

Cons:

- Requires two batteries (not included) for operation.

- Assembly may take some time for complete beginners.

- Limited to Arduino-compatible platforms, which may require additional components for some users.

VANLINNY Robotic Kit for Kids Ages 8-12

If you’re looking for an engaging way to introduce kids aged 8-12 to robotics and programming, the VANLINNY Robotic Kit is an excellent choice. It offers a hands-on STEM experience with a durable robotic arm that moves at multiple angles, picks up objects, and supports simple programming. The kit includes easy-to-follow instructions, building components suitable for beginners, and fun sound effects for an interactive experience. With accessories like a remote control, USB charger, and a track, kids can operate the robot from a distance and explore their creativity. Plus, VANLINNY’s 24-month guarantee guarantees peace of mind as young learners develop their tech skills.

Best For: kids aged 8-12 interested in learning robotics, programming, and engaging hands-on STEM activities.

Pros:

- Durable construction with high-quality ABS and aluminum alloys ensuring safety and longevity

- Supports simple programming, encouraging creativity and technical skills development

- Comes with interactive sound effects and long-distance remote control for an engaging experience

Cons:

- May require adult supervision during assembly for younger children

- Limited to beginner programming, which might not suit advanced young coders

- Batteries and accessories are not included in the initial kit, requiring additional purchases

Robotic Arm Kit for Kids Aged 8

The Robotic Arm Kit by VANLINNY is an excellent choice for kids aged 8 and up who are curious about robotics and engineering. I love how it combines hands-on building with interactive programming, making learning fun and engaging. The kit features a sturdy, high-quality metal design that’s built to last, ensuring safe, reliable use over time. Kids can move the arm at different angles, pick up objects, and even simulate sound effects—all designed to spark creativity and problem-solving skills. With simple programming options and a manageable size, it’s perfect for young beginners enthusiastic to explore STEM concepts.

Best For: kids aged 8 and up interested in exploring robotics, engineering, and STEM concepts through hands-on building and programming activities.

Pros:

- Made from high-quality, durable metal for long-lasting performance

- Supports simple programming to enhance creativity and problem-solving

- Engages children with multiple functions like moving at different angles and sound effects

Cons:

- May require adult supervision for younger children during assembly

- Slightly heavier at 3.96 pounds, which could be cumbersome for small hands

- Limited to basic programming features suitable for beginners rather than advanced robotics

AI Vision & Voice Interaction Robotic Arm Kit for Arduino and STEM Projects

The AI Vision & Voice Interaction Robotic Arm Kit for Arduino and STEM Projects stands out as an ideal choice for students and beginners enthusiastic to explore artificial intelligence and robotics. It combines AI vision and voice modules, enabling features like color recognition, facial tracking, and voice control. Supporting Arduino, Scratch, and Python, it offers flexible programming options for diverse skill levels. The open architecture and multiple ports allow for customization and secondary development. With extensive tutorials, it promotes hands-on learning and creativity. Designed for durability and precision, this kit makes complex AI-powered robotics accessible, inspiring future engineers and programmers in STEM education.

Best For: students, beginners, and educators interested in exploring AI, robotics, and STEM projects through versatile programming options and hands-on learning experiences.

Pros:

- Supports multiple programming platforms including Arduino, Scratch, and Python for flexible development.

- Equipped with advanced AI modules like vision and voice recognition for engaging features.

- Open architecture with multiple ports allows for customization and secondary development.

Cons:

- Designed for users aged 16 and older, which may limit accessibility for younger students.

- Weighs approximately 6.39 pounds, making it somewhat less portable for mobile projects.

- Requires some technical knowledge for setup and programming, potentially challenging beginners.

Waveshare Robotic Arm Kit with ESP32, 4-DOF, Wireless Control

Designed for hobbyists, educators, and researchers, the Waveshare Robotic Arm Kit with ESP32 stands out with its wireless control capabilities and open-source flexibility. Weighing under 850g, it offers a 4-DOF design with a 0.5kg payload at 0.5m, providing a 360° workspace. The onboard ESP32 enables wireless control via Wi-Fi, Bluetooth, or wired connections, supporting multiple protocols and interfaces. It’s pre-assembled, easy to mount, and includes an expansion plate for custom end-effectors like sensors or cameras. Its smooth movement, power, and expandability make it ideal for complex projects, educational purposes, and research, with ample room for secondary development.

Best For: hobbyists, educators, and researchers seeking a versatile, expandable, and wireless-controlled robotic arm platform for complex projects and educational purposes.

Pros:

- Supports wireless control via Wi-Fi, Bluetooth, and wired connections, offering flexible operation options

- Open-source design with expandability for sensors, cameras, and custom end-effectors, ideal for secondary development

- Lightweight yet powerful, capable of precise movements and handling a 0.5kg payload at 0.5m

Cons:

- Limited in-box documentation and some initial hardware setup issues may require troubleshooting

- Power management requires external power sources for servos, as USB is mainly for programming

- Customer support experiences vary, and some users face delays or difficulty in obtaining assistance

6-Axis Metal Robot Arm Kit with Joystick Control for Arduino Programming

If you’re looking for a versatile and durable robotic arm kit suitable for beginners and advanced users alike, the Axis Metal Robot Arm Kit with Joystick Control is an excellent choice. It features a sturdy aluminum alloy frame and high-torque servos, allowing for precise movements and heavier loads. The smooth joystick control makes maneuvering easy, perfect for tasks like pick-and-place or drawing. Compatible with Arduino IDE, it supports custom programming for automation or advanced projects. The all-in-one kit includes wiring guides and sample code, making setup quick and straightforward. Whether you’re learning or creating complex automation, this kit offers durability, flexibility, and educational value.

Best For: hobbyists, students, and educators seeking a durable, versatile robotic arm for learning, DIY projects, and automation development.

Pros:

- Made with a sturdy aluminum alloy frame for durability and heavier load handling

- Smooth joystick control allows for precise and intuitive maneuvering

- Compatible with Arduino IDE, supporting custom programming and automation projects

Cons:

- First available date listed as February 26, 2025, which may be a future release

- Slightly heavier weight (2.5 pounds) may require stable mounting during operation

- Potential restocking fees for returns if items are damaged or misrepresented

diymore Robotic Arm Kit Silver ROT3U 6DOF Aluminum Robot Arm Kit

For hobbyists and students enthusiastic to learn robotics hands-on, the diymore Robotic Arm Kit Silver ROT3U offers a solid foundation. This 6DOF aluminum arm features a mechanical clamp and requires assembly, but instructions are limited and mostly pictorial. You’ll need to source additional components like servos, control boards, and power supplies. Heavy-duty servos such as MG996R are recommended for better load handling. The arm’s performance depends heavily on upgrades and precise assembly. Although some users find the parts insufficient or instructions lacking, it’s a great platform for DIY experimentation and learning about robotic mechanics and control systems.

Best For: hobbyists, students, and DIY robotics enthusiasts eager to learn mechanical design and control systems through hands-on assembly and upgrades.

Pros:

- Provides a solid foundation for learning robotics with customizable components and upgrade options.

- Made from durable aluminum, offering stability and a professional feel.

- Encourages hands-on experimentation with mechanical and electronic integration.

Cons:

- Assembly instructions are limited and mostly pictorial, which can be confusing.

- Requires sourcing additional components like servos, control boards, and power supplies separately.

- Some parts may be missing or insufficient, necessitating additional DIY solutions or replacements.

Factors to Consider When Choosing Laboratory Robotic Arms

When selecting a laboratory robotic arm, I focus on key factors like precision and accuracy to guarantee reliable results. I also consider payload capacity, control interfaces, software compatibility, and the arm’s durability to meet long-term needs. Understanding these points helps me choose the best robotic arm for specific laboratory tasks.

Precision and Accuracy

Choosing the right laboratory robotic arm hinges on its ability to deliver precise and accurate movements. High precision models usually have repeatability within 0.1 mm to 0.5 mm, which is essential for delicate tasks. The accuracy depends heavily on joint resolution; higher-resolution encoders enable finer positional control. Regular calibration is critical to maintain accuracy over time, especially after maintenance or reassembly. Mechanical design also plays a key role—gear ratios and backlash directly influence movement precision. Additionally, sensor feedback, such as optical or magnetic encoders, enhances the arm’s ability to position itself accurately and consistently. Overall, selecting a robotic arm with advanced sensors, high-resolution joints, and reliable calibration protocols ensures maximum precision and accuracy for demanding laboratory applications.

Payload Capacity Needs

How do you guarantee a robotic arm can handle your lab tasks without sacrificing performance? First, determine the maximum weight the arm needs to lift or manipulate. Check the payload specifications at various extensions, since capacity often decreases as the arm extends further. Balance your payload needs with the arm’s precision and speed; higher payloads can compromise accuracy. Make sure the arm’s capacity exceeds your typical loads by a safe margin to account for dynamic forces and safety factors. Consider the size and weight of materials you’ll handle regularly to ensure compatibility. Matching the payload capacity to your specific requirements prevents overloading, maintains performance, and extends the robot’s lifespan, ensuring reliable, efficient operation in your laboratory environment.

Control Interface Options

Selecting the right control interface for your laboratory robotic arm directly affects its responsiveness, accuracy, and ease of integration into your existing workflows. Physical options like joysticks, touchscreen panels, and remote controls offer intuitive, direct operation, ideal for manual tasks. Many robots also support wireless connections via Bluetooth or Wi-Fi, enabling remote control and seamless integration with lab systems. Programmable interfaces such as USB, Ethernet, and serial ports facilitate automation and scripting, essential for complex, repetitive tasks. Additionally, advanced options incorporate AI-driven controls, including voice commands and gesture recognition, providing hands-free operation. When choosing, consider your lab’s automation needs, required precision, and user-friendliness, ensuring the control interface aligns with your operational goals and enhances overall productivity.

Software Compatibility

Ensuring software compatibility is crucial when integrating a laboratory robotic arm into your workflow. You need to confirm that its software works seamlessly with your existing operating system, whether that’s Windows, Linux, or macOS. It’s also important that the control software supports the programming languages you plan to use, such as Python, C++, or ROS, to facilitate customization and automation. Check if the software can integrate with AI frameworks like PyTorch or simulation environments like Gazebo, especially for advanced applications. Additionally, verify that firmware and control interfaces can be updated or tailored to meet your project’s specific needs. Finally, thorough documentation, APIs, and support for third-party tools are essential to ensure smooth operation and future scalability of your robotic system.

Mechanical Durability

Have you considered what makes a laboratory robotic arm truly durable? High-quality materials are essential—look for aerospace-grade aluminum alloys or reinforced steel, which can withstand repetitive tasks and harsh environments. The design should feature robust joints with industrial-grade bearings and high-torque servos to prevent wear and ensure stability over time. Corrosion-resistant coatings or sealed components protect against chemicals and humidity common in labs. The structural framework must handle full payloads without bending or deformation, maintaining precision during extended use. Additionally, a modular design allows for easy replacement of worn parts, considerably extending the arm’s lifespan. Prioritizing these factors will ensure your robotic arm remains reliable and effective throughout its operational life.

Integration Flexibility

When choosing a laboratory robotic arm, it’s crucial to take into account its integration flexibility, which determines how well it can connect with and adapt to your existing systems. A highly flexible arm supports multiple communication protocols like USB, Ethernet, Wi-Fi, and serial interfaces, ensuring broad compatibility. Modular design features, such as interchangeable end-effectors and expansion ports, allow customization for specific tasks. Compatibility with robotics frameworks like ROS simplifies integration into automation workflows and software platforms. Additionally, open APIs and SDKs enable you to tailor the system by integrating third-party sensors, vision systems, or AI modules, expanding its functionality. Prioritizing these integration capabilities ensures your robotic arm can seamlessly fit into your laboratory environment, optimizing efficiency and future scalability.

Safety and Reliability

Choosing a robotic arm isn’t just about how well it integrates with existing systems; safety and reliability are equally crucial. I look for features like emergency stop buttons, protective enclosures, and fail-safe mechanisms that prevent accidents during operation. High-quality components, such as industrial-grade servos and sensors, are essential for consistent performance over time. I also ensure robust calibration and maintenance protocols are in place to minimize errors and keep the arm operating within safe parameters. Redundant safety systems, including sensors that detect human presence or obstacles, help prevent collisions and injuries, especially in collaborative environments. To verify dependability, I consider reliability testing under various load conditions and repeated cycles, ensuring the robotic arm performs safely and reliably over prolonged use.

Frequently Asked Questions

How Do Robotic Arms Ensure Safety in Sensitive Laboratory Environments?

Robotic arms guarantee safety in sensitive labs by incorporating advanced sensors that detect unexpected movements or obstacles, stopping operation instantly. I rely on built-in safety protocols like emergency stop buttons and safety enclosures to prevent accidents. Regular maintenance and calibration also help me identify potential issues early. Additionally, I follow strict protocols and safety standards, ensuring the robotic systems operate reliably without risking contamination or harm to personnel.

Can These Robotic Arms Be Integrated With Existing Lab Automation Systems?

Absolutely, these robotic arms can be integrated with existing lab automation systems. Think of them as puzzle pieces perfectly fitting together, enhancing your workflow seamlessly. I’ve seen labs upgrade smoothly, thanks to versatile interfaces and adaptable software. This integration boosts efficiency and reduces errors, creating a harmonious environment where new technology complements what’s already in place. It’s like adding a powerful new instrument to your laboratory orchestra.

What Are the Maintenance Requirements for High-Precision Laboratory Robotic Arms?

High-precision laboratory robotic arms require regular maintenance to stay ideal. I check and calibrate sensors weekly, lubricate joints monthly, and update software quarterly. It’s essential to inspect for wear and tear, replace worn parts promptly, and keep the system clean to prevent dust buildup. Consistent maintenance ensures accuracy, reduces downtime, and extends the lifespan of the robotic arm. I find that a proactive approach really pays off in lab efficiency.

How Do Robotic Arms Handle Complex or Delicate Sample Manipulations?

Imagine a dancer gliding across the stage with grace—that’s how robotic arms handle delicate samples. They use advanced sensors and fine-tuned algorithms to sense, adapt, and execute gentle movements. I’ve seen them adjust in real-time, delicately balancing precision and care. This mastery allows them to manipulate fragile or complex samples without damage, turning what seems impossible into a seamless, ballet-like performance in the lab.

Are There Specific Certifications or Standards for Laboratory Robotic Arms?

Yes, there are specific certifications and standards for laboratory robotic arms. I look for models that meet ISO 13485 for medical devices or IEC 61010 for safety standards, ensuring reliability and safety. These certifications confirm the robotic arm’s compliance with industry quality and safety requirements. Always check that the equipment has proper documentation and certifications before making a purchase, so I can trust its performance and safety in my lab.

Conclusion

Choosing the right robotic arm is like finding the perfect tool to unlock endless possibilities. Each kit on this list offers unique strengths, but the real key is matching them to your specific needs. Think of these arms as your new partners in innovation—ready to elevate your precision and efficiency. So, why settle for less? Embrace the future of lab automation and let your projects soar to new heights!