Nanocomposites combine nanoscale fillers like nanoparticles and nanotubes into a matrix, such as polymer or ceramic, to boost properties like strength, durability, and thermal stability. The tiny size fosters strong interactions with the matrix, leading to improved performance in various industries. Manufacturing techniques like ultrasonication and layer-by-layer assembly help guarantee uniform dispersion. If you keep exploring, you’ll discover how these advanced materials are revolutionizing multiple fields and their future potential.

Key Takeaways

- Nanocomposites combine a matrix material with nanoparticles like nanowires or nanotubes to enhance physical, chemical, and electrical properties.

- Uniform dispersion of nanoparticles is critical for achieving improved strength, thermal stability, and barrier properties in nanocomposites.

- In situ polymerization and layer-by-layer assembly techniques enable strong interactions and controlled nanomaterial integration.

- Enhanced properties include increased mechanical strength, thermal resistance, durability, and improved electrical conductivity.

- Applications span aerospace, electronics, healthcare, and environmental sectors, leveraging nanocomposites for stronger, lighter, and smarter materials.

Understanding Nanocomposites and Their Composition

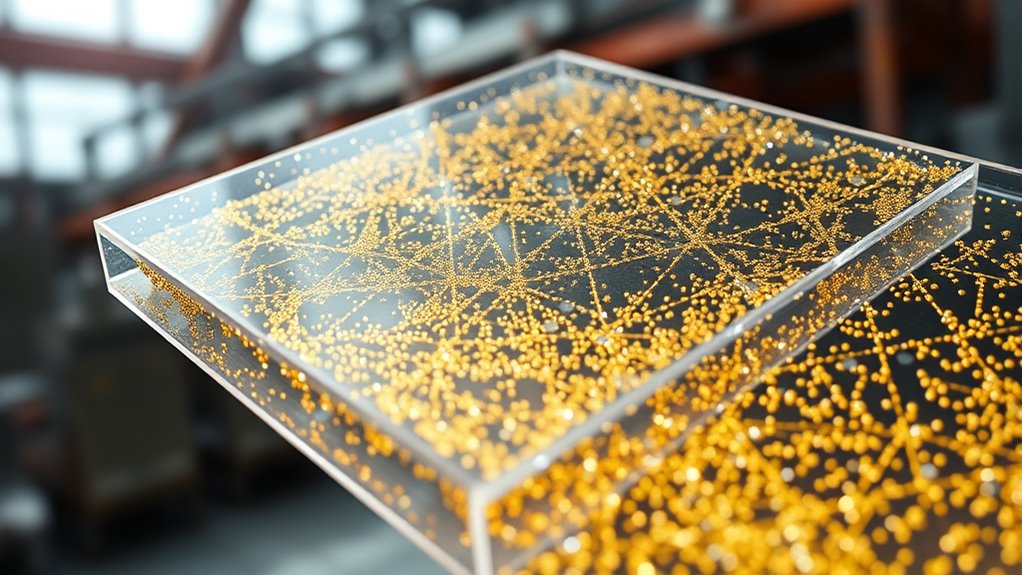

Nanocomposites are materials made by combining a matrix with nanometer-sized fillers to enhance properties like strength, durability, and conductivity. You’ll find that the matrix, often a polymer, metal, or ceramic, provides the bulk and shape of the material. The nanofillers—such as nanoparticles, nanowires, or nanotubes—are dispersed within the matrix at a very small scale, typically less than 100 nanometers. This tiny size allows them to interact uniquely with the matrix, leading to significant improvements in physical, chemical, and electrical properties. The process of creating nanocomposites involves careful mixing and dispersion techniques to make certain uniform distribution of the nanofillers. By understanding their composition, you can better appreciate how these materials outperform conventional alternatives in various applications. Nanoparticle dispersion is a critical factor in achieving optimal properties in nanocomposite materials.

Key Properties and Advantages of Nanoparticle Reinforcement

Nanoparticle reinforcement can considerably boost the mechanical strength of materials, making them more durable under stress. It also enhances thermal stability, allowing the composite to withstand higher temperatures without degrading. These properties give you stronger, more reliable materials for a variety of demanding applications. Additionally, incorporating energy-efficient nanoparticles can contribute to sustainable material development by reducing energy consumption during manufacturing and use.

Enhanced Mechanical Strengths

When reinforced with nanoparticles, materials often exhibit markedly improved mechanical strengths, making them more durable and resistant to failure. These tiny particles improve load transfer within the matrix, increasing tensile and compressive strength. They help prevent crack propagation by acting as barriers, which enhances toughness and impact resistance. The high surface area of nanoparticles promotes strong interfacial bonding, ensuring stresses are efficiently transferred throughout the composite. As a result, nanocomposites can withstand higher stress levels without deforming or breaking. This reinforcement also reduces the material’s ductility, making it stiffer and more rigid. Overall, incorporating nanoparticles considerably elevates the mechanical performance, enabling you to design lighter, stronger, and more reliable materials for diverse applications.

Improved Thermal Stability

Reinforcing materials with nanoparticles not only boosts their strength but also substantially enhances their thermal stability. This means your nanocomposites can withstand higher temperatures without degrading, making them suitable for demanding environments. Nanoparticles create a barrier effect, slowing heat transfer and preventing thermal breakdown. They also improve the material’s resistance to thermal cycling, reducing cracks and deformation over time. To illustrate, consider the following advantages:

| Benefit | Effect |

|---|---|

| Higher Temp Resistance | Withstands extreme heat |

| Reduced Thermal Degradation | Longer lifespan |

| Enhanced Heat Barrier | Protects internal structure |

| Improved Thermal Cycling | Less material fatigue |

Additionally, incorporating specific nanoparticles can further optimize thermal performance for specialized applications. These features make nanocomposites ideal for aerospace, electronics, and automotive applications where thermal stability is critical.

Manufacturing Techniques for Nanocomposite Materials

To create effective nanocomposites, you need to understand the key manufacturing techniques involved. These include mixing and blending methods, in situ polymerization, and layered assembly strategies. Each approach offers different advantages depending on the desired properties and applications. Understanding foraging range can also inform the development of biomimetic nanomaterials that mimic natural resource distribution.

Mixing and Blending Methods

Mixing and blending techniques are crucial for producing uniform nanocomposites with ideal properties. You typically start by dispersing nanoparticles into a base matrix using methods like high-shear mixing, ultrasonication, or ball milling. High-shear mixers apply intense mechanical forces to break up agglomerates and evenly distribute particles. Ultrasonication uses sound waves to create cavitation, helping nanoparticles disperse at a microscopic level. Ball milling involves grinding materials together in a rotating container, promoting uniform blending. You must optimize process parameters, such as mixing time, speed, and temperature, to prevent nanoparticle aggregation and ensure proper distribution. Proper mixing leads to consistent properties, improved strength, and enhanced functionality in the final product. Selecting the right method depends on material type, particle size, and desired nanocomposite characteristics. Additionally, understanding dispersibility is essential for achieving a homogeneous nanocomposite structure.

In Situ Polymerization Techniques

Have you ever considered how nanocomposite materials can be integrated directly during polymer formation? In situ polymerization involves adding nanoparticles to monomers or oligomers before polymerization begins. This process allows nanoparticles to disperse uniformly as the polymer network forms, creating strong interactions at the molecular level. Imagine:

- Nanoparticles acting as anchors within the growing polymer chains

- Enhanced bonding between fillers and the matrix

- Controlled distribution of nanoparticles throughout the material

- Improved mechanical, thermal, and barrier properties due to tight integration

This technique guarantees better compatibility and dispersion compared to mixing after polymerization. By controlling reaction conditions, you can tailor the nanocomposite’s properties at a fundamental level, resulting in high-performance materials suited for advanced applications. Resilience in the manufacturing process is crucial for achieving consistent quality in nanocomposite production.

Layered Assembly Strategies

Layered assembly strategies involve constructing nanocomposite materials by sequentially depositing or stacking different nanomaterials to form well-organized structures. You can use techniques like layer-by-layer (LbL) assembly, where you alternate depositing oppositely charged materials to build up precise multilayers. This method allows you to control thickness, composition, and interface properties at the nanoscale. Alternatively, you might employ physical methods such as spin coating or Langmuir-Blodgett techniques to create uniform, thin films with layered arrangements. These strategies enable you to tailor the mechanical, electrical, or optical properties of the composite by adjusting layer composition and order. Layered assembly is especially useful when you need high precision, improved interfacial bonding, or specific directional properties in your nanocomposite. Incorporating natural materials like wood or stone can also enhance the sustainability and aesthetic qualities of the nanocomposite.

Applications Transforming Industries With Nanocomposites

Nanocomposites are revolutionizing industries by enhancing material performance and enabling innovative applications. You can see their impact in healthcare, where lightweight, stronger materials improve implants and drug delivery systems. In electronics, nanocomposites enable flexible displays, faster circuits, and durable sensors. The transportation sector benefits from lighter, more fuel-efficient vehicles with enhanced safety features. Additionally, in environmental protection, nanocomposites help create efficient filtration systems, pollution sensors, and durable packaging materials. Imagine:

- Ultra-strong, lightweight aerospace components soaring through the sky

- Flexible, conductive wearables wrapping around your wrist

- High-performance filters capturing pollutants at the microscopic level

- Durable, eco-friendly packaging extending product shelf life

These applications are transforming how industries operate, making products smarter, safer, and more sustainable. Materials with improved properties continue to expand the potential of nanocomposites across various fields.

Challenges and Future Directions in Nanocomposite Development

Despite their promising potential, developing nanocomposites faces significant challenges that hinder widespread adoption. Achieving uniform dispersion of nanoparticles remains difficult, often leading to inconsistent properties and compromised performance. Controlling the interface between nanoparticles and the matrix is complex, affecting durability and strength. Manufacturing processes need refinement to scale up production cost-effectively while maintaining quality. Additionally, understanding long-term stability and potential degradation over time is vital but still limited. Future directions involve advancing synthesis techniques, such as greener methods and better surface modifications, to improve compatibility and dispersion. You’ll also need to focus on standardization and establishing industry guidelines to guarantee safety and reliability. Moreover, considering AI Security implications can help develop more secure and reliable manufacturing systems. Overcoming these hurdles will reveal the full potential of nanocomposites across various industries.

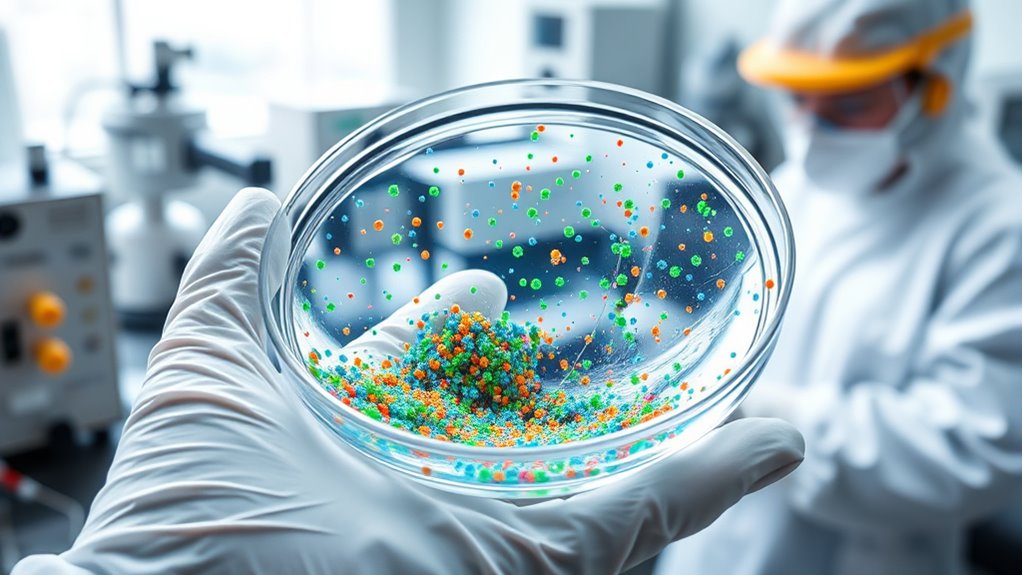

Environmental and Safety Considerations of Nanoparticles

As nanocomposites become more prevalent in various industries, understanding the environmental and safety implications of incorporating nanoparticles becomes increasingly important. You need to contemplate potential risks, such as environmental contamination, worker exposure, and long-term health effects. Nanoparticles can become airborne during manufacturing or disposal, posing inhalation hazards. They may also enter water sources, affecting ecosystems and food chains. To visualize this, think of:

- Tiny particles dispersing into the air, inhaled unknowingly

- Contaminating soil and water during waste disposal

- Accumulating in living organisms, causing unknown health impacts

- Challenging regulations and safety standards to keep pace with innovation

Being aware of these concerns helps you implement proper safety protocols and develop eco-friendly practices, ensuring nanotechnology benefits society without unintended harm. Additionally, integrating AI security measures can assist in monitoring and managing nanoparticle risks more effectively.

Frequently Asked Questions

How Do Different Nanoparticle Combinations Influence Nanocomposite Performance?

Different nanoparticle combinations can considerably boost nanocomposite performance by enhancing strength, durability, and functionality. When you mix nanoparticles like graphene with metal oxides, you improve electrical conductivity and mechanical properties. Adding silica or carbon nanotubes can increase thermal stability and toughness. Your choice of combinations influences dispersion, interfacial bonding, and overall enhancements, allowing you to tailor materials for specific applications like electronics, aerospace, or packaging.

What Are the Cost Implications of Producing Multi-Nanoparticle Nanocomposites?

Imagine a bustling factory where tiny particles dance together, creating stronger, lighter materials. Producing multi-nanoparticle nanocomposites can be costly, as it involves advanced equipment and precise control to guarantee uniform distribution. You might face higher raw material expenses and complex processing steps. However, these investments can pay off through superior performance, durability, and potential savings in the long run, making the initial costs worthwhile.

Can Nanocomposites Be Recycled or Reused Effectively?

Yes, nanocomposites can often be recycled or reused effectively, but it depends on their specific materials and applications. You might find that some nanocomposites retain their properties after recycling, especially if designed with re-processability in mind. However, challenges like nanoparticle agglomeration or degradation can complicate reuse. To maximize recyclability, you should consider developing processes that allow for separation and reprocessing without losing performance.

How Do Nanocomposites Affect the Recyclability of Conventional Materials?

Nanocomposites are like puzzles with tiny, hard-to-remove pieces, making recycling trickier. They can hinder the recyclability of conventional materials because the nanoparticles often alter material properties, complicating separation and processing. You might find that recycling streams get contaminated or require special procedures, increasing costs. So, nanocomposites can pose significant challenges, demanding innovative solutions to guarantee they don’t compromise sustainability efforts or the efficiency of recycling systems.

What Are the Long-Term Stability and Durability Concerns for Nanocomposites?

You should be aware that long-term stability and durability of nanocomposites can be compromised by nanoparticle agglomeration, which weakens the material over time. Environmental factors like humidity, temperature fluctuations, and UV exposure may cause degradation or deterioration of nanoparticle-matrix interfaces. Additionally, mechanical stresses can lead to crack propagation. To guarantee longevity, ongoing research focuses on improving the bonding and protective coatings within nanocomposites, but challenges remain.

Conclusion

Think of nanocomposites as a recipe where tiny ingredients transform the final dish. Just like adding a pinch of spice elevates a meal, nanoparticles enhance material strength and functionality. As you explore this field, remember that overcoming challenges is like perfecting a complex recipe—delicate but rewarding. With ongoing innovation, nanocomposites will continue to reshape industries, proving that even the smallest components can create the most remarkable results.