Nanoparticles in lubricants help reduce friction and wear by forming protective films, smoothing surface irregularities, and distributing under load to lower shear forces. Common types like metal oxides and carbon nanomaterials enhance durability and thermal stability, extending equipment life and improving efficiency. They create a barrier that prevents direct metal contact, protecting surfaces from damage. If you keep exploring, you’ll discover how these tiny particles revolutionize lubrication across various industries.

Key Takeaways

- Nanoparticles form protective films on surfaces, reducing direct contact and minimizing friction and wear.

- They fill microscopic surface irregularities, creating smoother contact and decreasing material abrasion.

- Metal oxide nanoparticles enhance surface protection, while carbon nanomaterials improve thermal stability and durability.

- Nanoparticles distribute under load, absorbing impacts and lowering shear forces between contact surfaces.

- Proper dispersion and surface modification of nanoparticles are essential for maximizing their friction and wear reduction benefits.

How Nanoparticles Enhance Lubricant Performance

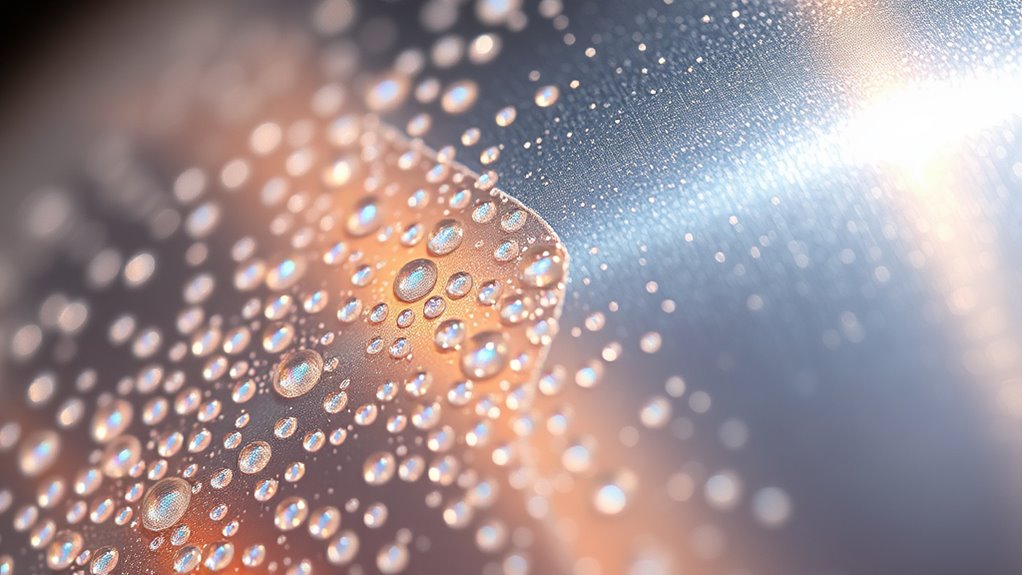

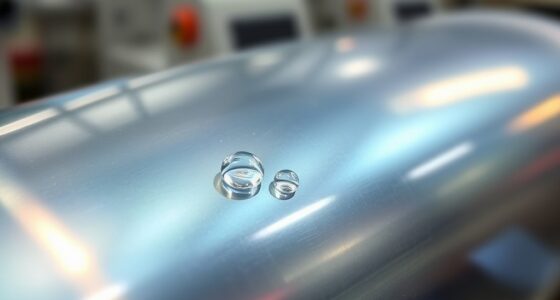

Nanoparticles improve lubricant performance by actively reducing friction and wear between moving surfaces. When well-dispersed, nanoparticles create a uniform suspension known as nanoparticle dispersion, which enhances the lubricant’s ability to coat surfaces evenly. This dispersion helps maintain consistent lubricant viscosity, preventing it from thinning under heat or pressure. As a result, the lubricant forms a more effective protective film, reducing direct contact between metal parts. The small size of nanoparticles allows them to fill microscopic surface irregularities, further decreasing friction and wear. Additionally, stable nanoparticle dispersion guarantees long-lasting performance, preventing clumping or settling that could negatively affect viscosity. A well-maintained lubricant film ensures optimal protection and efficiency. Overall, these factors work together to boost lubrication efficiency, extend equipment life, and improve operational reliability.

Types of Nanoparticles Used in Lubricants

You’ll find that metal oxide nanoparticles like zinc oxide and titanium dioxide are common in lubricants, helping to reduce friction and wear. Carbon-based materials such as graphene and carbon nanotubes also play a significant role by enhancing durability and thermal stability. Understanding these types helps you choose the right nanoparticles for specific lubrication needs.

Metal Oxide Nanoparticles

Metal oxide nanoparticles are among the most commonly employed types of nanomaterials in lubricants due to their excellent wear protection and thermal stability. Their effectiveness depends heavily on proper nanoparticle dispersion, which prevents agglomeration and ensures uniform coverage. Surface modification plays a key role here, improving compatibility with base oils and enhancing stability. These modifications help maintain consistent performance, especially under high temperatures. Metal oxides like TiO₂, Fe₃O₄, and Al₂O₃ are popular choices because they form a protective film on contact surfaces, reducing friction and wear. Here’s a quick overview:

| Nanoparticle | Surface Modification | Benefits |

|---|---|---|

| TiO₂ | Silane treatment | High thermal stability |

| Fe₃O₄ | Organic ligands | Magnetic properties |

| Al₂O₃ | Coating with polymers | Improved dispersion |

Carbon-Based Nanomaterials

Building on the advantages of metal oxide nanoparticles, carbon-based nanomaterials have gained attention for their exceptional lubricating properties. Graphene reinforcement enhances the formation of a protective, low-friction film on contact surfaces, reducing wear effectively. Its high strength and flexibility help distribute load pressures, minimizing surface damage. Carbon nanotubes, with their remarkable tensile strength and aspect ratio, improve the durability of lubricants by bridging asperities and reducing friction at contact points. These nanomaterials also improve heat dissipation, preventing overheating and degradation of lubricants. Incorporating graphene and carbon nanotubes into lubricants can notably enhance their performance, decrease energy consumption, and extend machinery lifespan. Their unique properties make them promising additives for advanced lubrication applications, especially in high-stress environments.

Mechanisms Behind Friction Reduction

Nanoparticles reduce friction in lubricants primarily through their ability to form protective films on contact surfaces. These films act as a barrier, minimizing direct metal-to-metal contact and reducing shear forces. Tribological modeling helps explain how nanoparticles distribute and interact under load, revealing their role in lowering friction coefficients. Efficient nanoparticle synthesis ensures particles are uniform and well-dispersed, which is critical for consistent film formation. When properly synthesized, nanoparticles can fill microscopic surface asperities, smoothing out roughness and preventing adhesion. Their small size allows them to penetrate tight contact zones, reducing friction through mechanisms like rolling or sliding. Additionally, surface interactions between nanoparticles and contact surfaces play a crucial role in adhesion prevention and film stability. Overall, understanding these processes enables the design of more effective nanoparticle additives that optimize friction reduction in lubricated systems.

Impact on Wear and Surface Protection

Nanoparticles in lubricants can considerably reduce surface abrasion, helping your equipment last longer. They also boost lubricant durability, meaning less frequent replacements and maintenance. Understanding these effects can help you optimize your machinery’s protection and performance. Additionally, incorporating nanoparticles can improve anti-wear properties, providing an extra layer of protection against mechanical stresses.

Reduced Surface Abrasion

Because they can fill microscopic surface imperfections, nanoparticles substantially reduce surface abrasion and help prevent wear. By smoothing out surface roughness, these tiny particles create a more uniform contact surface, which lowers the chances of material removal during operation. This improved smoothness enhances abrasion resistance, making surfaces less vulnerable to scratching and erosion. As a result, components experience less material loss over time, extending their lifespan. Nanoparticles also act as a protective barrier, absorbing impacts that would otherwise cause surface damage. Their ability to fill in tiny cracks and gaps minimizes the initiation of wear particles, further reducing surface abrasion. Overall, integrating nanoparticles into lubricants offers a significant boost in protecting surfaces and maintaining ideal performance.

Enhanced Lubricant Durability

Integrating nanoparticles into lubricants considerably enhances their durability by strengthening surface protection and reducing wear over time. Proper nanoparticle dispersion ensures uniform distribution, which is essential for effective reinforcement. This improves the lubricant formulation, making it more resistant to breakdown and degradation during operation. The benefits include:

- Increased resistance to corrosion and oxidation

- Enhanced load-carrying capacity

- Reduced metal-to-metal contact

- Extended service intervals

Advantages for Different Industries

The use of nanoparticles in lubricants offers significant advantages across various industries by enhancing performance and efficiency. In industrial applications, these nanoparticles reduce friction and wear, leading to smoother operations and longer equipment life. This improvement translates into lowered maintenance costs and increased productivity. For manufacturing and automotive industries, nanoparticle-infused lubricants help machines operate more reliably under heavy loads, boosting overall output. Additionally, these advanced lubricants provide economic benefits by decreasing energy consumption and extending lubricant lifespans. As a result, industries can cut operational costs while maintaining high standards of performance. Moreover, ongoing research into nanoparticle dispersion techniques continues to optimize the effectiveness of these lubricants. The adoption of nanoparticle technology in lubricants becomes a strategic move for sectors aiming to optimize efficiency, reduce downtime, and achieve sustainable growth.

Challenges and Considerations in Implementation

Implementing nanoparticles in lubricants presents several challenges that industries must carefully consider. Cost implications can be significant, as high-quality nanoparticles and specialized manufacturing processes increase expenses. Regulatory challenges also pose hurdles, as nanoparticle use may face strict safety and environmental standards that vary by region. You’re also likely to encounter compatibility issues with existing lubricant formulations, which can affect performance and stability. Additionally, safety concerns related to nanoparticle handling and potential health risks must be addressed to guarantee compliance. Skincare Patches can serve as a useful analogy, emphasizing the importance of addressing each challenge systematically before widespread adoption.

Environmental and Sustainability Aspects

As nanoparticles become more common in lubricants, their environmental impact demands careful consideration. Biodegradability concerns arise because some nanoparticles may persist in ecosystems, potentially harming wildlife and water quality. You need to contemplate whether these particles break down safely or accumulate over time. Recyclability issues also pose challenges, as nanoparticle-infused lubricants can complicate disposal and recycling processes. If not properly managed, they may contaminate waste streams or hinder standard recycling methods. It’s essential to evaluate the life cycle of nanolubricants, ensuring they don’t just improve performance but also minimize environmental risks. Developing eco-friendly, biodegradable nanoparticles and establishing proper disposal protocols will help balance technological benefits with sustainability goals. Addressing these concerns now supports responsible innovation in lubrication technology. Additionally, understanding the environmental impact of nanoparticles is crucial for developing sustainable nanolubricants that align with ecological standards.

Future Trends in Nanolubricant Technologies

Advancements in nanolubricant technologies are poised to revolutionize machinery performance and energy efficiency in the coming years. You’ll see progress driven by improved nanoparticle synthesis methods, enabling more uniform and functional particles. Innovations will focus on tailoring nanoparticles for specific applications, enhancing their lubricating properties. Additionally, regulatory standards will evolve to guarantee safety and environmental compliance, guiding responsible development. Future trends include developing eco-friendly synthesis techniques, integrating smart sensors for real-time monitoring, and establishing global standards for nanoparticle use. These advancements will help optimize friction reduction, extend equipment lifespan, and promote sustainable practices. Staying ahead means embracing these trends, understanding regulatory landscapes, and supporting innovations that make nanolubricants safer, more effective, and environmentally responsible. Moreover, incorporating emotional support strategies can assist industry professionals in managing the challenges associated with adopting new technologies and standards.

Frequently Asked Questions

How Do Nanoparticles Affect Lubricant Viscosity and Flow Properties?

Nanoparticles influence lubricant viscosity by enabling viscosity modification, which can either increase or decrease flow resistance depending on their concentration and type. They improve flow behavior by enhancing stability and reducing shear thinning or thickening under stress. As you add nanoparticles, you may notice better lubrication performance, but it’s essential to balance their amount to avoid excessive viscosity, ensuring smooth flow and ideal lubrication efficiency.

Are There Health Risks Associated With Nanoparticle Use in Lubricants?

You should be aware that there are health concerns and toxicity risks associated with nanoparticle use in lubricants. When handling these substances, you might be exposed through inhalation, skin contact, or accidental ingestion, potentially leading to respiratory issues or other health problems. It is crucial to use proper safety measures, like gloves and masks, and work in well-ventilated areas to minimize your exposure and protect your health.

What Are the Long-Term Stability Concerns of Nanolubricants?

You should be aware that long-term stability of nanolubricants can be affected by nanoparticle aggregation, which may cause uneven lubrication or clogging. Over time, particles might settle or cluster, reducing effectiveness and potentially damaging equipment. To guarantee consistent performance, regular monitoring and formulation adjustments are necessary. Addressing nanoparticle aggregation early helps maintain the long-term stability of nanolubricants, prolonging their usefulness and protecting your machinery.

Can Nanoparticle-Enhanced Lubricants Be Recycled or Reused Effectively?

You can recycle and reuse nanoparticle-enhanced lubricants, but recycling challenges exist due to nanoparticle separation and contamination. To effectively reuse them, employing advanced filtration and separation methods, like centrifugation or membrane filtration, is essential. These techniques help recover nanoparticles and clean the base oil, enabling multiple cycles. While feasible, optimizing reuse methods minimizes environmental impact and maintains lubricant performance over time.

How Cost-Effective Are Nanoparticle Additives Compared to Traditional Lubricants?

You’ll find that nanoparticle additives can be more cost-effective over time due to significant cost savings from reduced wear and maintenance. Although production costs for nanoparticle-enhanced lubricants are initially higher, their superior performance extends equipment lifespan and improves efficiency. These benefits often outweigh the upfront expenses, making them a smart investment. Ultimately, the long-term savings and minimized downtime make nanoparticle additives competitive with, or even cheaper than, traditional lubricants.

Conclusion

By adding nanoparticles to lubricants, you reduce friction and wear, protecting surfaces and boosting efficiency. While these tiny particles promise breakthroughs, they also pose challenges like compatibility and environmental impact. Embrace the innovation, but stay mindful of the hurdles ahead. As you explore nanolubricants, remember: small particles can make a big difference, yet balancing performance with sustainability remains essential. The future lies in harnessing this technology responsibly for lasting industrial benefits.