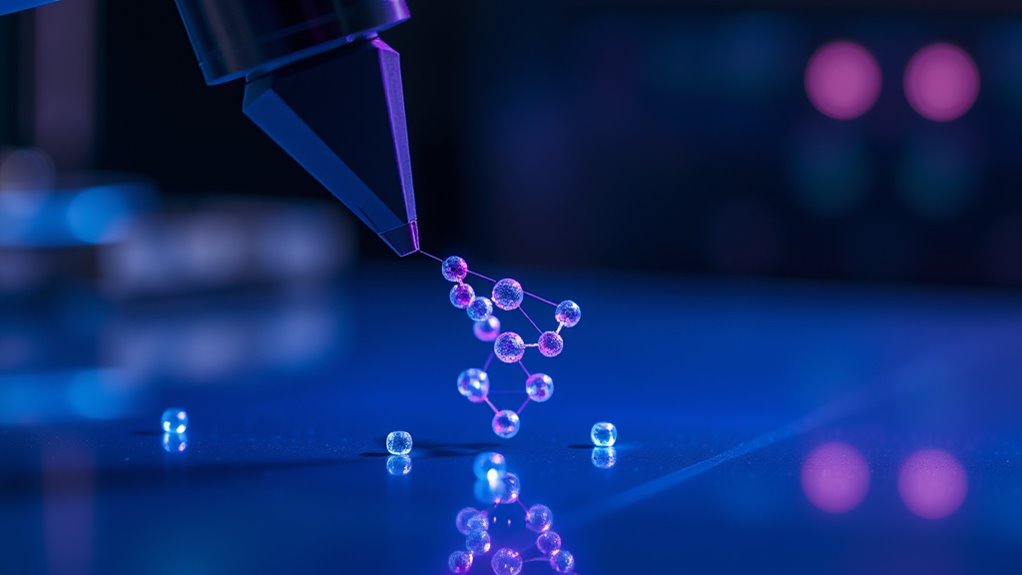

Building nanostructures atom by atom involves using highly precise techniques like atomic layer deposition and molecular beam epitaxy to position individual atoms intentionally. This process relies on advanced fabrication methods to control size, shape, and surface chemistry, enabling you to harness quantum confinement effects for tailored properties. By mastering atomic-level assembly and surface functionalization, you can create innovative materials with unique electronic and optical behaviors—keep exploring to discover how these techniques open new technological possibilities.

Key Takeaways

- Atomic-level assembly techniques precisely position individual atoms to construct nanostructures with desired configurations.

- Surface functionalization during assembly stabilizes structures and introduces tailored chemical or physical properties.

- High-resolution fabrication methods like molecular beam epitaxy enable layer-by-layer atomic control.

- Quantum confinement effects are exploited by controlling nanostructure size and shape at the atomic scale.

- Precise atomic construction facilitates the development of advanced materials for electronics, photonics, and biomedical applications.

Building nanostructures involves designing and assembling materials at the atomic and molecular levels to create precise, functional architectures. When you manipulate matter at such a small scale, quantum effects become significant, especially quantum confinement. This phenomenon occurs when electrons are restricted within tiny structures, altering their energy levels and optical properties. As you engineer nanostructures, quantum confinement allows you to tune their electronic and optical behaviors, making them ideal for applications like quantum dots, solar cells, and LEDs. By controlling the size and shape of these structures, you can harness quantum confinement to achieve desired functionalities, such as specific color emissions or enhanced charge transfer capabilities. Additionally, high-resolution fabrication techniques enable you to assemble nanostructures with atomic precision, further optimizing their properties for targeted applications.

Manipulating matter at the nanoscale enables quantum confinement, tuning electronic and optical properties for advanced functional applications.

Surface functionalization plays an indispensable role in building effective nanostructures. It involves attaching specific molecules or chemical groups to the surface of nanomaterials, which not only stabilizes the structures but also imparts new properties. For you, surface functionalization means customizing the surface chemistry to improve compatibility with other materials, enhance reactivity, or target specific biological processes. This process is essential when you’re working on biomedical devices, sensors, or catalysts, where surface interactions dictate performance. By carefully selecting functional groups, you can influence how nanostructures interact with their environment, ensuring they perform optimally in real-world conditions.

When constructing nanostructures atom by atom, you need to pay close attention to how these atoms are arranged and bonded. Techniques like atomic layer deposition, molecular beam epitaxy, or chemical vapor deposition allow you to precisely control material growth at an atomic level. Through these methods, you can build structures with exact dimensions, ensuring quantum confinement effects are maximized or minimized as needed. Additionally, surface functionalization can be integrated during or after synthesis, giving you the flexibility to modify the surface properties without compromising the core structure.

As you assemble nanostructures, you’re essentially guiding atoms and molecules into specific configurations to achieve the desired architecture and functionality. This precise control opens up possibilities for creating materials with unprecedented properties, such as increased strength, enhanced electrical conductivity, or tailored optical responses. Whether you’re designing quantum dots for display technology or functionalized nanowires for sensing, understanding and leveraging quantum confinement and surface functionalization are key to transforming atomic-scale precision into practical, innovative solutions. Building nanostructures atom by atom isn’t just about miniaturization; it’s about harnessing quantum phenomena and chemical versatility to develop the next generation of advanced materials.

Frequently Asked Questions

What Are the Potential Environmental Impacts of Nanostructure Fabrication?

You should be aware that nanostructure fabrication can pose environmental risks, including environmental toxicity and ecological disruption. As you develop nanomaterials, they might release particles or chemicals that harm ecosystems or contaminate water and soil. These impacts could affect wildlife and human health. Consequently, it is crucial to carefully assess and manage the environmental safety of nanostructure production processes to minimize potential ecological disruption and toxicity.

How Long Does It Typically Take to Build a Nanostructure?

Building a nanostructure is like orchestrating a delicate dance—fabrication duration varies from minutes to hours, depending on process complexity. You might spend a quick burst of time on simple structures or invest days perfecting intricate designs. The speed depends on the tools used and the precision required. So, it’s a balance of patience and mastery, with each step unfolding in its own time to achieve perfection at the nanoscale.

Can Nanostructures Be Repaired or Recycled After Damage?

Yes, nanostructures can be repaired and recycled. Nanostructure repair involves precise techniques like atomic force microscopy to fix damaged areas at the atomic level, restoring functionality. For nanostructure recycling, experts often break down the damaged structures and repurpose the materials for new constructions. These processes help extend the lifespan of nanomaterials, reduce waste, and promote sustainable nanotechnology development.

What Are the Safety Precautions During Atomic-Scale Manipulation?

You might worry about safety risks, but you can stay protected during atomic-scale manipulation. Always wear appropriate ultraviolet safety gear to prevent harmful exposure, and follow contamination prevention protocols to keep your workspace clean. Handle equipment carefully, use shielded environments, and maintain proper training to avoid accidents. Your vigilance guarantees both your safety and the integrity of the delicate nanostructures you’re building, making the process safe and successful.

How Cost-Effective Is Nanostructure Manufacturing at Scale?

Scaling manufacturing of nanostructures can be costly initially, but it becomes more cost-effective over time through automation and process optimization. You’ll see significant cost reductions as you increase production volume, making large-scale nanostructure manufacturing more feasible. While early investments are high, ongoing improvements in techniques and equipment help lower costs, enabling you to produce nanostructures efficiently and affordably at an industrial scale.

Conclusion

By now, you see how precise control at the atomic level can revolutionize technology. Building nanostructures atom by atom isn’t just science fiction; it’s a powerful reality shaping our future. With every atom positioned perfectly, you wonder—what new possibilities will emerge from this microscopic craftsmanship? As you continue exploring, remember that mastering these tiny building blocks could unleash innovations beyond your wildest dreams. Isn’t it exciting to think about what’s possible when you work at the smallest scale?