Green catalysis through nanoparticles uses eco-friendly catalysts that make chemical reactions more efficient and sustainable. These tiny particles, under 100 nanometers, provide more active sites, allowing reactions at lower temperatures and producing less waste. They are durable, reusable, and can be made from abundant, less toxic materials. This approach reduces energy use and environmental impact while improving control over reactions. Keep exploring to discover how innovations in nanocatalysts are transforming sustainable chemistry.

Key Takeaways

- Nanoparticles serve as eco-friendly catalysts, promoting sustainable chemical reactions with minimal waste and energy consumption.

- Their high surface area enhances reaction efficiency and selectivity, reducing byproducts and purification needs.

- Nanocatalysts are durable, reusable, and can be made from abundant, less toxic materials, supporting material sustainability.

- They enable better reaction control, lower operational temperatures, and decreased solvent use, aligning with green chemistry principles.

- Advances in synthesis and surface modification foster innovative, eco-friendly processes that maintain productivity while minimizing environmental impact.

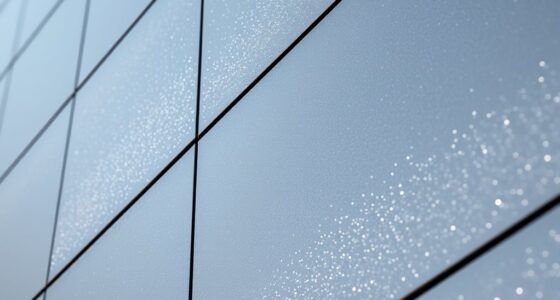

Green catalysis refers to the use of environmentally friendly catalysts that promote chemical reactions with minimal waste and energy consumption. When you explore this field, you’ll discover how nanoparticles are transforming traditional catalytic processes into sustainable methods that align with eco friendly processes. These tiny particles, often measuring less than 100 nanometers, have unique properties that make them highly effective catalysts, reducing the need for heavy metals or hazardous chemicals commonly used in conventional methods.

By utilizing nanoparticle-based catalysts, you can markedly cut down on waste production and energy use. Their high surface area-to-volume ratio means they offer more active sites for reactions, which accelerates processes and lowers energy demands. This efficiency not only speeds up manufacturing but also minimizes the environmental footprint. For example, in industrial syntheses, nanoparticle catalysts can often operate at lower temperatures and pressures, further conserving energy and reducing emissions. This aligns perfectly with sustainable methods aimed at achieving maximum productivity with minimal environmental impact.

Nanoparticle catalysts reduce waste and energy use by operating efficiently at lower temperatures and pressures.

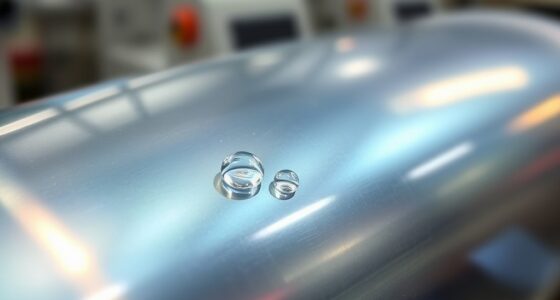

You’ll also benefit from the durability and reusability of nanoparticles, which contribute to eco friendly processes. Unlike traditional catalysts that often degrade quickly and require frequent replacement, many nanoparticles maintain their activity over multiple cycles. This longevity means less waste and fewer resources spent on catalyst production. Additionally, nanoparticles can be engineered from abundant and less toxic materials, making their production more sustainable. For instance, using nanoparticles made from bio-based or earth-abundant elements helps reduce reliance on scarce or harmful substances, aligning with the principles of green chemistry.

Moreover, nanoparticle catalysts open doors to innovative green processes that weren’t feasible before. Their small size allows for better control over reaction pathways, leading to higher selectivity and fewer byproducts. This precision reduces the need for extensive purification steps, cutting down on solvent use and waste. As a result, you can develop cleaner, more efficient processes that adhere to environmental standards without sacrificing productivity or quality.

In addition, advancements in nanoparticle synthesis techniques enhance catalyst quality and surface modifications further improve their performance and sustainability. In essence, exploring green catalysis through nanoparticles puts you at the forefront of sustainable chemistry. You’re adopting techniques that prioritize eco friendly processes while maintaining high efficiency. This approach not only benefits the environment but also enhances economic viability by lowering costs and waste. As you continue to innovate, you’ll find that nanoparticle catalysts are a key tool in creating more sustainable, responsible chemical industries that respect our planet’s resources.

Frequently Asked Questions

How Do Nanoparticles Improve Catalyst Recyclability?

Nanoparticles improve catalyst recyclability by enhancing surface modification and stability. When you optimize surface properties, the nanoparticles resist aggregation and degradation during reactions. This stability allows you to reuse catalysts multiple times without losing efficiency. By carefully controlling surface modifications, you guarantee that nanoparticles maintain their active sites, making the catalyst more durable and environmentally friendly. This ultimately reduces waste and improves overall process sustainability.

What Are the Environmental Impacts of Nanoparticle Synthesis?

You might think nanoparticle synthesis is eco-friendly, but it often has a significant environmental footprint. The process can involve toxic chemicals and energy-intensive methods, increasing pollution. Raw material sourcing also impacts ecosystems, especially when rare metals are mined. These factors raise concerns about sustainability. To reduce environmental impacts, adopting greener synthesis techniques and sourcing materials responsibly become essential for minimizing ecological harm.

Can Green Catalysis Be Scaled for Industrial Use?

You can scale green catalysis for industrial use, but scalability challenges like maintaining efficiency and consistency across large batches must be addressed. To guarantee economic feasibility, you’ll need to optimize synthesis methods that reduce costs and energy consumption. While there are hurdles, ongoing advancements in nanoparticle design and process engineering make it increasingly feasible for industry adoption, paving the way for more sustainable and environmentally friendly catalytic processes.

How Do Nanoparticle Size and Shape Influence Catalytic Activity?

Ever wonder how nanoparticle morphology affects catalytic activity? Smaller nanoparticles offer a larger surface area, boosting size-dependent activity, while their shape determines active site exposure. Spherical particles may provide uniform activity, whereas rod-shaped ones expose different facets. By tuning size and shape, you optimize catalytic performance, making processes more efficient and sustainable. So, controlling nanoparticle size and shape directly influences how effectively they catalyze reactions.

Are There Safety Concerns With Nanoparticle-Based Catalysts?

You should be aware that nanoparticle-based catalysts pose safety concerns due to potential nanoparticle toxicity and environmental nanoparticle release. These tiny particles can be harmful if inhaled or ingested, and their release into the environment might cause ecological damage. To mitigate risks, use proper handling procedures, containment, and disposal methods. Always stay informed about safety guidelines and research developments to protect yourself and the environment.

Conclusion

By embracing green catalysis through nanoparticles, you help reduce harmful chemical waste and promote sustainable practices. Did you know that nanoparticle catalysts can cut energy consumption in reactions by up to 50%? This significant efficiency not only saves resources but also protects our environment. So, as you support these innovative solutions, remember you’re making a real difference—helping create a cleaner, greener future for generations to come.