Nanotech recycling can considerably reduce e-waste by providing precise, eco-friendly methods to recover precious metals and dismantle complex devices. Using nanostructured filters and targeted reactions, it improves metal recovery rates while minimizing energy use and environmental impact. This approach helps keep pace with the growing volume and complexity of discarded electronics. If you want to discover how nanotech can transform e-waste management, keep exploring these innovative solutions.

Key Takeaways

- Nanotech enables precise extraction of valuable metals from complex, miniaturized electronic components, minimizing waste.

- Targeted nanomaterials and nanostructured filters improve recovery efficiency and reduce resource loss.

- Nanotech-based processes are cleaner and more environmentally friendly, lowering energy use and pollution in recycling.

- Advanced nanomaterials facilitate gentle, selective disassembly of electronics, preventing damage and maximizing material recovery.

- Implementing nanotech solutions supports sustainable e-waste management, reducing environmental impact and promoting circular resource use.

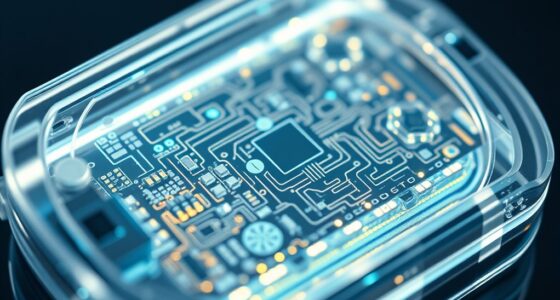

As electronic waste continues to grow at an alarming rate, traditional recycling methods struggle to keep up with the increasing volume and complexity of discarded devices. You might think that simply shredding and melting down old gadgets is enough, but the tiny, intricate components inside modern electronics pose a significant challenge. That’s where nanotech recycling steps in, offering innovative solutions for nanomaterial recovery and circuit miniaturization. These advancements enable you to extract valuable materials from e-waste more efficiently and with less environmental impact.

Nanotech recycling enhances e-waste recovery and minimizes environmental impact through innovative, precise nanomaterial extraction and circuit miniaturization.

Nanomaterial recovery is a game-changer because it allows you to isolate and reclaim metals like gold, silver, copper, and rare earth elements at a nano-scale. Instead of disposing of e-waste or using energy-intensive smelting processes, nanotech techniques use targeted chemical reactions or nanostructured filters to separate these materials precisely. This process not only improves recovery rates but also reduces the loss of precious resources. You can recycle critical components from increasingly miniaturized circuits, where traditional methods often miss small but valuable traces of metals embedded within complex substrates.

Circuit miniaturization is driving the evolution of electronics, making devices smaller, faster, and more powerful. However, this creates a dilemma for recyclers like you. The tiny, densely packed components become harder to disassemble and separate using conventional techniques. Nanotech approaches address this by employing nanomaterials and nanostructured processes that can gently break down circuit layers or selectively dissolve specific materials. This precision minimizes damage to the recovered metals and allows you to reclaim more value from each device. For instance, nanostructured acids or catalysts can target specific metals without degrading the surrounding plastics or silicon, making the recycling process cleaner and more sustainable.

Additionally, nanotechnology can help optimize the recycling process by reducing energy consumption and waste generation, making it a more sustainable option overall. In your efforts to reduce e-waste, embracing nanotech solutions means you can process discarded electronics faster and more thoroughly. These methods can adapt to the increasing complexity of modern devices, ensuring you don’t leave valuable materials behind. By implementing nanomaterials for recovery and leveraging nanotechnology for circuit dismantling, you make recycling more efficient, environmentally friendly, and economically viable. Ultimately, nanotech recycling helps close the loop in electronic manufacturing, making it possible for you to recover maximum value while minimizing waste and pollution. As technology advances, staying at the forefront with nanotech solutions will be key to tackling the e-waste crisis effectively.

Frequently Asked Questions

How Cost-Effective Is Nanotech Recycling Compared to Traditional Methods?

Nanotech recycling is generally more cost-effective than traditional methods, primarily due to its superior efficiency and precision. You’ll find that the cost comparison favors nanotech, especially in long-term applications, because it reduces material waste and energy consumption. While the initial investment might be higher, the economic feasibility improves over time as nanotech processes become more scalable and affordable, making it a smart choice for sustainable e-waste management.

What Are the Environmental Risks of Nanomaterials in Recycling Processes?

The environmental risks of nanomaterials in recycling are profound, potentially more dangerous than a thousand storms. You must consider environmental toxicity, as nanomaterials can harm ecosystems if released. Additionally, nanomaterial accumulation poses long-term threats, contaminating soil and water. While nanotech offers innovative solutions, unchecked release could lead to irreversible damage, making it vital to manage their use carefully and implement strict safety protocols.

Can Nanotech Recycling Be Applied to All Types of Electronic Waste?

Nanotech recycling can’t be applied universally to all electronic waste because of material limitations. Some components, like certain plastics or complex circuits, aren’t easily processed with current nanotech methods. You’ll find that while nanotech offers promising solutions for metals and specific materials, its universal applicability is limited by these material constraints. To maximize efficiency, you’ll need to combine nanotech with other recycling techniques tailored to different types of e-waste.

What Is the Timeline for Widespread Adoption of Nanotech Recycling?

Imagine waiting for a garden to bloom—you’re enthusiastic, but it takes time. Widespread nanotech recycling adoption hinges on market readiness and overcoming regulatory challenges. Currently, it’s like a seedling just breaking ground; full bloom might take 10-20 years. As research advances and policies evolve, expect gradual growth. You’ll see more adoption once technology proves reliable and regulations catch up, turning the landscape into a thriving eco-forest.

How Does Nanotech Recycling Impact the Lifespan of Electronic Devices?

Nanotech recycling can substantially extend your device’s lifespan by improving battery longevity and component durability. As nanotech enhances material strength and reduces wear, your electronics last longer and perform better over time. This means fewer replacements and less e-waste. You’ll notice your devices stay functional and efficient longer, saving you money and helping the environment. Embracing nanotech recycling benefits both your gadgets and the planet by promoting sustainable use.

Conclusion

By embracing nanotech recycling, you can help cut down the staggering 53.6 million tons of e-waste generated annually worldwide. Imagine turning tiny nanomaterials into powerful tools that recover precious metals efficiently, reducing environmental harm. Every electronic device you recycle with nanotech saves resources and energy, making a real difference. So, next time you discard an old gadget, remember that advanced nanotech could transform waste into valuable resources, helping create a more sustainable future for everyone.