Nanomaterials play a essential role in thermal management by boosting heat dissipation and insulation. They have a high surface area, which improves heat transfer and prevents overheating in electronics and energy systems. You’ll find nanostructures like aerogels, nanoparticles, and layered materials that create barriers or scattering mechanisms to reduce heat flow. If you want to discover how innovative designs and hybrid materials can optimize thermal performance, keep exploring these cutting-edge solutions.

Key Takeaways

- Nanomaterials’ high surface area enhances heat transfer efficiency and prevents overheating in electronic and energy systems.

- Engineered nanostructures like aerogels and nanoporous materials provide superior thermal insulation by scattering heat-carrying molecules.

- Phonon scattering at interfaces, defects, and boundaries in nanomaterials reduces thermal conductivity, improving insulation performance.

- Hybrid nanomaterials combine properties like high thermal conductivity and flexibility, optimizing heat dissipation and insulation.

- Advanced manufacturing techniques enable scalable production of nanomaterials tailored for efficient thermal management applications.

The Role of Nanomaterials in Enhancing Heat Dissipation

Nanomaterials play a crucial role in enhancing heat dissipation because of their exceptional thermal properties. Their high surface area-to-volume ratio improves heat transfer efficiency, allowing heat to spread quickly and evenly. When incorporated into electronic devices, nanomaterials help prevent overheating by rapidly conducting heat away from critical components. This rapid heat transfer reduces thermal resistance, enabling devices to operate at ideal temperatures and extend their lifespan. Additionally, nanomaterials can be engineered to have tailored thermal conductivities, making them versatile for various applications. Their unique structures also facilitate better contact with surrounding materials, further boosting heat dissipation. Furthermore, the integration of nanomaterials into thermal management systems enhances overall efficiency, leading to more effective cooling solutions. Overall, nanomaterials markedly improve thermal management systems, ensuring devices stay cooler, more reliable, and operate more efficiently.

Types of Nanomaterials Used in Thermal Insulation

Building on the advancements in heat dissipation, nanomaterials also play an essential role in thermal insulation by reducing heat transfer. You’ll find that nanomaterials like aerogels, silica nanoparticles, and nanostructured polymers are highly effective insulators. Aerogels, with their porous structure, trap air and minimize heat flow, making them excellent for insulation in buildings and clothing. Silica nanoparticles are incorporated into coatings and foams to enhance thermal resistance without adding bulk. Nanostructured polymers modify conventional materials to improve their insulating properties. These nanomaterials work by scattering heat-carrying molecules or creating barriers that slow heat transfer. Their small size and high surface area allow for improved insulation performance, enabling you to develop lighter, more efficient thermal barriers across various applications.

Engineering Nanostructures for Optimal Thermal Conductivity

You can optimize thermal conductivity by carefully designing nanostructure geometry, which influences how heat flows through the material. Enhancing phonon scattering is key to controlling heat transfer, and it can be achieved by introducing specific structural features. By tailoring these aspects, you guarantee the nanomaterial performs efficiently in thermal management applications. Additionally, understanding celebrity transformations can provide innovative insights into adapting designs for improved material performance.

Tailoring Nanostructure Geometry

Optimizing thermal conductivity in nanostructures requires precise control over their geometrical features, as the shape and size directly influence phonon transport. By tailoring nanostructure geometry, you can enhance or suppress heat flow to meet specific needs. Adjusting parameters like aspect ratio, surface curvature, and boundary interfaces helps control phonon scattering and pathways. For example:

- Modifying nanowire diameters to tune thermal conductivity

- Designing layered or core-shell structures for directional heat flow

- Creating patterned surfaces to influence phonon scattering

- Controlling phonon transport through geometrical modifications allows for targeted thermal management strategies.

These strategies allow you to customize thermal properties effectively. Fine-tuning nanostructure geometry provides a powerful tool for optimizing heat dissipation or insulation in advanced nanomaterials.

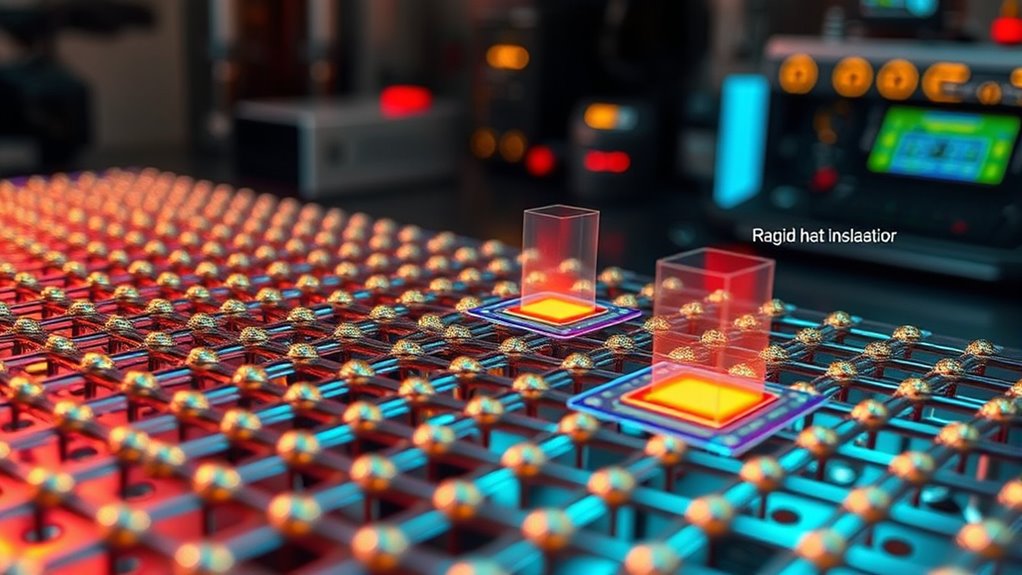

Enhancing Phonon Scattering

By engineering nanostructures to enhance phonon scattering, you can effectively reduce thermal conductivity and improve heat management. Introducing interfaces, defects, or grain boundaries disrupts phonon pathways, increasing scattering events. Nanostructures like superlattices, nanowires, and nanoporous materials create multiple interfaces that impede phonon flow. Embedding nanoparticles within a matrix also enhances boundary scattering. Controlling size, shape, and distribution of these features allows you to fine-tune phonon interactions, balancing scattering and heat transfer. This approach is particularly effective for thermal insulation, where limiting heat flow is essential. By intentionally designing nanostructures to maximize phonon scattering, you optimize thermal properties, enabling better thermal regulation in various applications, from electronic devices to energy-efficient building materials. Understanding phonon interactions helps in precisely tailoring nanostructures for optimal thermal performance.

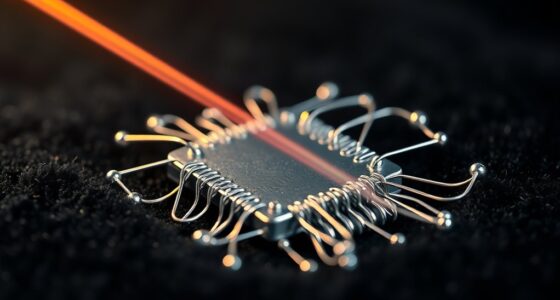

Applications of Nanomaterials in Electronics and Aerospace

Nanomaterials have revolutionized thermal management in electronics and aerospace by enabling more efficient heat dissipation and temperature regulation. Their high surface area and unique properties improve thermal conductivity and reduce overheating risks. In electronics, nanomaterials help design compact, high-performance devices that operate reliably under intense loads. In aerospace, they protect components from extreme temperatures and improve overall system efficiency. You can see these benefits in several ways:

- Enhanced heat sinks and spreaders for faster heat removal

- Lightweight nanocomposite materials for insulation and shielding

- Improved thermal interface materials that ensure better contact and heat transfer

- The diverse applications include diverse genres like action, romance, and fantasy, highlighting the versatility of nanomaterials in various fields.

These applications lead to more durable, efficient, and reliable electronic and aerospace systems, pushing the boundaries of what’s possible in both fields.

Challenges and Future Directions in Nanothermal Management

Despite the promising advances in nanothermal management, several challenges hinder widespread adoption and further development. You face issues with large-scale manufacturing, as producing consistent, high-quality nanomaterials remains difficult and costly. Stability over time is another concern; nanomaterials can degrade or lose effectiveness under operational conditions. Integrating these materials into existing systems also poses hurdles, including compatibility and potential interference with other components. Additionally, understanding long-term environmental impacts and health risks is essential but still incomplete. Future directions should focus on developing scalable synthesis methods, improving material stability, and establishing clear safety protocols. Ensuring cybersecurity in the manufacturing and deployment processes is also critical to protect sensitive data and intellectual property involved in nanomaterials development. Overcoming these barriers will be essential for translating nanomaterials from lab research to real-world applications, enabling more efficient heat management solutions across industries.

Innovations and Emerging Trends in Nanomaterial Technologies

Emerging innovations in nanomaterial technologies focus on advanced nanostructure designs that optimize thermal performance. Hybrid material synergies combine different nanomaterials to enhance functionality and stability. Addressing scalability and manufacturing challenges guarantees these breakthroughs are practical for widespread application. Additionally, integrating breakthrough technologies such as quantum computing and AI-driven manufacturing processes can accelerate the development and deployment of nanomaterials in thermal management applications.

Advanced Nanostructure Designs

How are researchers pushing the boundaries of nanostructure design to enhance thermal management? They’re developing innovative architectures that optimize heat transfer and insulation. By manipulating nanoscale features, they create materials with tailored thermal properties, such as high conductivity or low thermal conductivity, depending on the application. Techniques like layered structures, porosity control, and hierarchical patterns enable precise control over heat flow. Researchers also explore 3D nanoarchitectures to improve surface area and phonon transport. These advanced designs lead to more efficient heat dissipation in electronics and better insulation in energy systems. The focus is on maximizing performance while maintaining material stability and scalability. Nanostructure engineering allows for highly customizable thermal properties, opening new avenues for application-specific solutions.

Hybrid Material Synergies

Hybrid material synergies are transforming nanomaterial technologies by combining diverse nanoscale components to achieve superior thermal properties. By integrating materials like graphene with metal oxides or carbon nanotubes with polymers, you can tailor thermal conductivity and insulation to specific needs. These synergies allow you to leverage complementary properties, such as high thermal conductivity alongside flexibility or lightweight characteristics. Innovations in hybrid nanomaterials enable enhanced heat dissipation in electronics and improved insulation in energy systems. You benefit from customized solutions that outperform single-component materials, leading to more efficient thermal management strategies. As research progresses, these hybrid approaches open new avenues for designing multifunctional nanomaterials that meet the demanding requirements of modern applications, pushing forward the capabilities of nanotechnology in thermal regulation. Advanced material design

Scalability and Manufacturing

Advancements in nanomaterial hybridization are paving the way for more scalable and efficient manufacturing processes. These innovations allow you to produce nanomaterials on a larger scale without sacrificing quality or performance. Emerging techniques such as roll-to-roll processing, spray coating, and automated synthesis streamline production, reducing costs and time. You can now integrate nanomaterials into existing manufacturing lines more easily, which accelerates commercialization. Additionally, new methods focus on environmentally friendly processes, minimizing waste and energy consumption. This progress enables widespread adoption of nanomaterials for thermal management in various industries. To visualize, consider these trends:

- Large-scale synthesis methods like continuous flow reactors

- Additive manufacturing techniques for precise control

- Eco-friendly production processes reducing environmental impact

- Support hours for manufacturing facilities help ensure smooth operations and timely production.

Frequently Asked Questions

How Do Nanomaterials Affect the Longevity of Thermal Insulation Systems?

Nanomaterials can considerably extend the longevity of thermal insulation systems by enhancing durability and resistance to environmental factors. You benefit from their unique properties, such as improved stability, reduced degradation, and better resistance to moisture and temperature fluctuations. These qualities help maintain insulation performance over time, preventing breakdowns and reducing the need for frequent replacements. Overall, incorporating nanomaterials can make your thermal systems more reliable and long-lasting.

Can Nanomaterials Be Recycled or Reused After Thermal Application?

Yes, nanomaterials can often be recycled or reused after thermal application. While their tiny size offers remarkable thermal properties, it also means they can sometimes be separated and recovered through specialized processes. However, the ease of recycling depends on the nanomaterial type and the application. You should consider the environmental impact and cost-effectiveness, as advancements are making reuse increasingly viable, reducing waste and promoting sustainability.

What Are the Environmental Impacts of Nanomaterial Production for Thermal Management?

You should know that producing nanomaterials for thermal management can have significant environmental impacts. It often involves energy-intensive processes, generating greenhouse gases and waste. Additionally, the use of hazardous chemicals poses risks to ecosystems and human health if not properly managed. Recycling options are limited, so careful consideration of environmental safety, sustainable sourcing, and waste disposal practices is essential to minimize negative effects of nanomaterial production.

How Do Nanomaterials Perform Under Extreme Temperature Fluctuations?

You’ll find that nanomaterials excel under extreme temperature fluctuations because their unique structures enable them to maintain stability and performance. They effectively dissipate heat during high temperatures and insulate when temperatures drop. Their high surface area and tailored properties allow you to adapt quickly to changing conditions, making them ideal for applications like electronics and aerospace where temperature swings are common. They provide reliable thermal management even in harsh environments.

Are There Health Risks Associated With Manufacturing Nanomaterials for Heat Management?

Are there health risks when manufacturing nanomaterials for heat management? Yes, you should be cautious because inhaling or touching nanoparticles can cause respiratory or skin issues. During production, proper safety measures like protective gear and ventilation are essential. Do you want to protect yourself and others? By following strict safety protocols, you minimize risks, ensuring safe handling while benefiting from advanced nanomaterials’ thermal properties.

Conclusion

So, here you are, marveling at nanomaterials that effortlessly manage heat—yet, somehow, we still struggle with overheating gadgets and insulation failures. It’s almost ironic that tiny particles promise big solutions, but the journey isn’t over. As you dive deeper into nanotechnology’s potential, remember: groundbreaking innovation often comes wrapped in tiny packages, reminding us that sometimes, the smallest solutions have the largest impact—and the biggest challenges.