Nanomaterials like graphene, carbon nanotubes, and metallic nanoparticles help create flexible, stretchable wearable electronics by offering high strength, conductivity, and resilience. These materials can bend, stretch, and endure daily movements without losing performance, making devices more durable and comfortable. Advanced fabrication techniques, such as printing and embedding nanomaterials into flexible substrates, enhance their electrical and optical functions. To discover how these innovations improve wearable tech, explore further details ahead.

Key Takeaways

- Nanomaterials like graphene and carbon nanotubes provide high conductivity, flexibility, and resilience essential for stretchable wearable electronics.

- Their mechanical properties enable devices to withstand bending, stretching, and repetitive movements without performance loss.

- Fabrication techniques such as printing, layering, and embedding nanomaterials into flexible substrates enhance device durability and scalability.

- Incorporating nanomaterials improves electrical, optical, and long-term stability, supporting advanced functionalities in wearable systems.

- Innovations like hybrid nanomaterials and self-healing structures advance the development of reliable, flexible, and stretchable wearable devices.

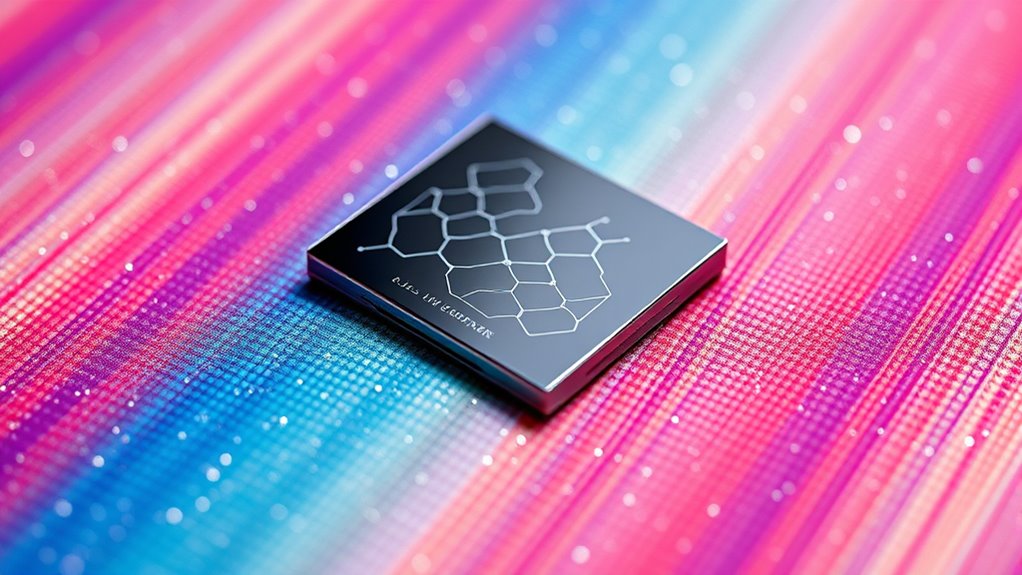

Types of Nanomaterials Used in Wearable Electronics

Nanomaterials play a crucial role in advancing wearable electronics because their unique properties enable flexible, lightweight, and highly conductive devices. You’ll find materials like carbon nanotubes, which offer exceptional strength and electrical conductivity in thin, flexible forms. Graphene is another popular choice, thanks to its incredible conductivity, transparency, and flexibility. Metallic nanoparticles, such as silver and gold, are used for their excellent electrical properties and biocompatibility, making them ideal for sensors and electrodes. Transition metal dichalcogenides, like molybdenum disulfide, provide semiconducting properties suitable for flexible transistors and sensors. Additionally, polymer-based nanomaterials, such as conductive polymers, combine flexibility with conductivity, allowing integration into wearable fabrics and devices. The development of hybrid nanomaterials further enhances device performance by combining multiple properties. These diverse nanomaterials enable the development of versatile and high-performance wearable electronics.

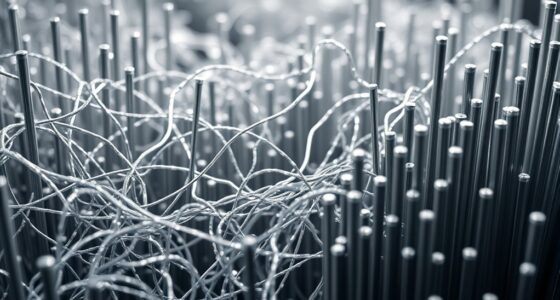

Mechanical Properties and Flexibility of Nanomaterials

You need nanomaterials that can withstand bending and stretching without breaking. Their elasticity and durability determine how well they perform under repeated use. Understanding strain and flex resistance helps you select materials that keep your devices flexible and long-lasting. Additionally, high refresh rates in display components contribute to smoother performance in wearable electronics.

Elasticity and Durability

Because wearable electronics require materials that can withstand frequent movement and bending, the elasticity and durability of nanomaterials are critical factors. You need materials that can stretch, bend, and recover without losing function. High elasticity ensures your device remains comfortable and functional over time. Durability guarantees it withstands daily wear and tear. Nanomaterials like conductive nanowires, graphene, and carbon nanotubes offer excellent stretchability and resilience. They can endure repeated deformation while maintaining electrical properties. Imagine a flexible sensor that stays intact after hundreds of bending cycles. These materials are lightweight yet robust, enabling long-lasting performance. Think of them as the backbone of reliable, flexible devices. With proper design, nanomaterials can balance elasticity and durability, making wearable electronics more comfortable, durable, and effective for everyday use. Additionally, ongoing research aims to enhance AI safety measures to ensure the reliability of these advanced materials in consumer devices.

Strain and Flex Resistance

Strain and flex resistance are vital for guaranteeing nanomaterials can withstand the repetitive movements typical of wearable electronics. When you design flexible devices, you need materials that can stretch, bend, and recover without losing functionality. Nanomaterials like carbon nanotubes and graphene excel here, offering high tensile strength and excellent flexibility. Their ability to endure repeated deformation ensures durability over time. Incorporating these nanomaterials into substrates or composites improves overall strain resistance, preventing cracks or fractures during use. You should also consider how nanostructures distribute stress evenly, reducing localized damage. Achieving high flex resistance means your devices remain dependable even after thousands of bending cycles. This property is fundamental for creating comfortable, long-lasting wearable sensors, displays, and health monitors that can move seamlessly with your body. Additionally, understanding the robust materials used in manufacturing ensures optimal performance and longevity of flexible electronic devices.

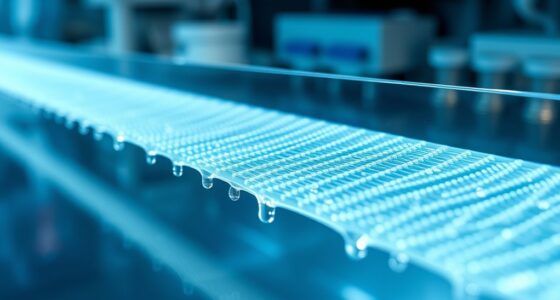

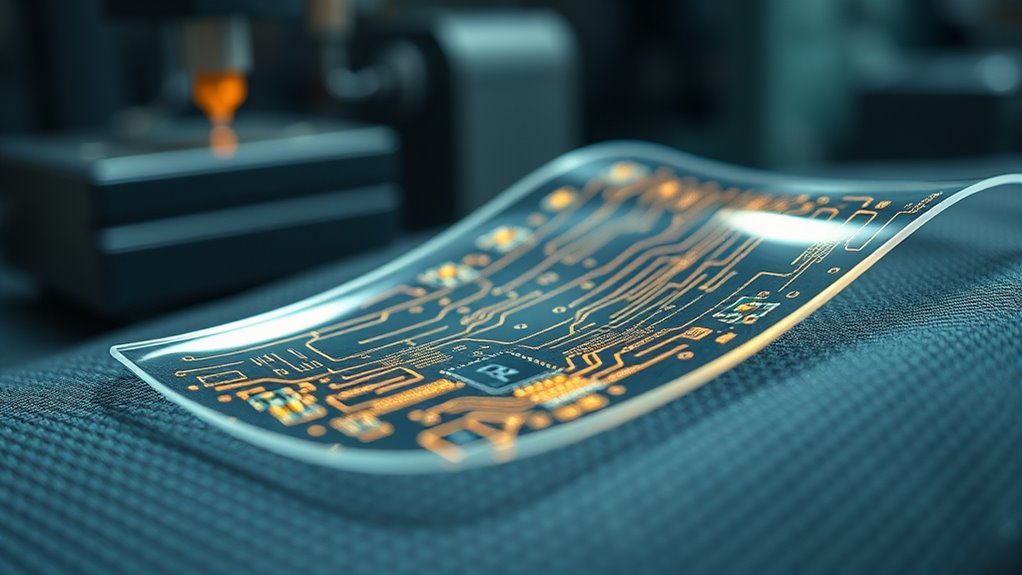

Fabrication Techniques for Flexible and Stretchable Devices

Fabrication techniques for flexible and stretchable devices have rapidly advanced to meet the demands of wearable electronics. You now have options like printing, casting, and layering materials to create adaptable structures. You might use inkjet or screen printing to deposit conductive inks onto flexible substrates, enabling precise patterning. Alternatively, soft lithography allows for detailed mold-based fabrication of microstructures. You can also employ transfer printing to move nanomaterials onto stretchable substrates without damage. Additionally, techniques like laser cutting and embossing help shape and pattern materials for durability and flexibility. These methods allow for scalable manufacturing and customization, ensuring your devices can bend, stretch, and conform comfortably to various surfaces. The choice of technique depends on the device’s complexity, materials, and intended application. Understanding material properties is crucial for selecting appropriate fabrication methods that maintain device performance during deformation.

Enhancing Electrical Conductivity With Nanomaterials

To improve the performance of wearable electronics, you need to understand how different nanomaterial types influence electrical conductivity. You can also enhance flexibility and durability by carefully engineering conductive networks within the device. By optimizing these aspects, you’ll achieve more reliable and efficient wearable systems. Proper maintenance and sanitation are essential to ensure long-term device functionality and safety.

Nanomaterial Types and Conductivity

Nanomaterials have revolutionized wearable electronics by substantially boosting their electrical conductivity. Different types offer unique advantages, allowing you to tailor devices for specific needs. Conductive nanomaterials include:

- Metallic nanoparticles like silver and gold, providing excellent conductivity.

- Carbon-based nanomaterials such as graphene and carbon nanotubes, offering flexibility and high strength.

- Metal nanowires, which form transparent, flexible conductive networks.

- Conductive polymers, combining good conductivity with stretchability.

- Doped nanomaterials, where impurities enhance electrical properties further.

These materials can be integrated into fabrics, films, or composites, enabling your devices to conduct electricity efficiently while maintaining flexibility and lightweight design. Selecting the right nanomaterial depends on your application’s specific performance, durability, and biocompatibility requirements. Understanding conductivity is crucial for optimizing the performance of wearable electronic devices.

Enhancing Flexibility and Durability

Building on the variety of nanomaterials that enhance electrical performance, focusing on flexibility and durability guarantees your wearable devices can withstand daily use without compromising function. Incorporating nanomaterials like carbon nanotubes, graphene, and metallic nanowires strengthens the mechanical resilience of your electronics. These materials can bend, stretch, and endure repeated stress without losing conductivity, ensuring longevity. Embedding nanomaterials into flexible substrates enhances their ability to absorb mechanical deformation, preventing cracks and fractures. Additionally, coating or integrating nanomaterials with elastomers boosts overall durability, making devices more resistant to wear and tear. The choice of dog names can also reflect the personality and style of your device, adding a personalized touch. By optimizing nanomaterial distribution and bonding, you create devices that maintain electrical integrity under physical stress, providing consistent performance in dynamic, real-world environments.

Conductive Network Engineering

Enhancing electrical conductivity in wearable electronics requires carefully engineered conductive networks that facilitate efficient charge transport. You achieve this by integrating nanomaterials like silver nanowires, graphene, carbon nanotubes, or conductive polymers into flexible substrates. These networks form interconnected pathways that reduce resistance and ensure reliable performance under strain. To optimize the network, you focus on:

- Dispersing nanomaterials uniformly to prevent aggregation

- Increasing contact points between conductive elements

- Creating percolation networks for continuous pathways

- Balancing conductivity with flexibility

- Using surface treatments to improve adhesion and contact

- Ensuring stability over time by preventing oxidation and degradation of nanomaterials which can affect electrical performance.

Optical Properties and Their Applications in Wearables

Optical properties of nanomaterials play a crucial role in advancing wearable electronics, offering functionalities that are both innovative and practical. Their ability to absorb, emit, and scatter light enables applications like flexible displays, sensors, and health monitoring systems. For example, nanomaterials such as quantum dots and plasmonic nanoparticles enhance display brightness and color purity while maintaining flexibility. They also enable optical sensing for detecting biological markers, UV exposure, or temperature changes directly on the skin. Their tunable optical responses allow you to develop wearable devices that are not only functional but also aesthetically appealing. Additionally, incorporating diverse designs enhances customization and user experience, making these devices more adaptable to individual preferences. By integrating nanomaterials with unique optical characteristics, you can create lightweight, transparent, and flexible wearables that improve user experience and open new horizons in personal health and environmental monitoring.

Challenges in Integrating Nanomaterials Into Wearable Devices

Integrating nanomaterials into wearable devices presents significant challenges due to their complex interactions with flexible substrates and the demanding environmental conditions these devices face. You must guarantee that nanomaterials adhere properly without compromising flexibility or durability. Environmental factors like moisture, sweat, and temperature fluctuations can degrade performance or cause detachment. Achieving uniform dispersion and consistent electrical properties across large areas is difficult. Mechanical stresses from bending, stretching, or twisting can lead to cracks or delamination. Additionally, scalable manufacturing processes are needed for large-scale production, but they often lack the precision required for nanomaterials.

- Ensuring strong adhesion without sacrificing flexibility

- Maintaining stability under environmental stressors

- Achieving uniform nanomaterial distribution

- Preventing cracks during deformation

- Scaling up production efficiently

Future Trends and Innovations in Nanomaterial-Based Wearables

Emerging trends in nanomaterial-based wearables focus on harnessing advanced fabrication techniques and innovative material designs to overcome current limitations. You’ll see a shift toward scalable, cost-effective manufacturing methods like printing and roll-to-roll processes, enabling mass production of flexible, stretchable devices. Researchers are also exploring hybrid nanomaterials that combine properties such as conductivity, transparency, and biocompatibility, making wearables more functional and comfortable. Incorporating self-healing and self-adapting features will improve device durability and longevity. Additionally, integration with emerging technologies like nanophotonics and quantum dots promises enhanced sensing capabilities and data processing. These innovations aim to create smarter, more reliable wearables that seamlessly blend into daily life, pushing the boundaries of performance and user experience in the wearable electronics landscape.

Real-World Applications and Case Studies

Nanomaterial-based wearables are increasingly making their way into various industries, demonstrating their practical value through real-world applications and case studies. They improve health monitoring, enabling continuous tracking of essential signs like heart rate and hydration levels. In sports, athletes use nanotech-enabled devices for real-time performance analysis. Hospitals deploy flexible sensors for wound healing and patient care, reducing invasive procedures. Consumer electronics benefit from stretchable screens and smart clothing that adapt to movement. Additionally, environmental sensors integrated into clothing detect pollutants and allergens, enhancing safety. These examples showcase how nanomaterials drive innovation, making devices more reliable, comfortable, and versatile for everyday use. Their successful implementations highlight future potential and the expanding role of nanotechnology in wearable technology.

Frequently Asked Questions

How Do Nanomaterials Impact the Long-Term Durability of Wearable Devices?

Nanomaterials greatly boost the long-term durability of your wearable devices by enhancing their mechanical strength, flexibility, and resistance to wear and tear. They create more resilient structures that withstand repeated bending, stretching, and environmental exposure. This means your devices last longer, maintain performance, and are less prone to damage over time. Their unique properties ensure your wearable electronics stay reliable and functional, even with daily use and challenging conditions.

What Are the Environmental Implications of Nanomaterial Disposal in Wearables?

Think of nanomaterials as tiny messengers carrying both promise and peril. When you dispose of wearables with nanomaterials, you risk releasing particles into the environment, potentially harming ecosystems and human health. These particles can accumulate, much like silent invaders, disrupting natural cycles. Responsible disposal and recycling become your shield, ensuring that these technological treasures don’t become environmental burdens, preserving the delicate balance of our planet.

Can Nanomaterials Be Safely Used in Biocompatible Wearable Applications?

Yes, nanomaterials can be safely used in biocompatible wearables when properly engineered. You should guarantee they are non-toxic, stable, and biocompatible through rigorous testing. Using surface modifications and encapsulations can prevent adverse reactions. By choosing appropriate nanomaterials and following safety standards, you can develop wearable devices that are both effective and safe for skin contact and long-term use, minimizing health risks.

How Do Nanomaterials Influence the Energy Consumption of Wearable Electronics?

Nanomaterials reduce energy consumption in wearable electronics by enhancing efficiency and conductivity. They enable components to operate with lower power, thanks to their high surface area and exceptional electrical properties. You’ll notice longer battery life and improved device performance because nanomaterials facilitate faster signal transmission and more efficient energy use. By integrating nanomaterials, you make your wearable devices smarter, more sustainable, and better suited for extended use without draining power quickly.

Are There Regulatory Standards Specifically for Nanomaterials in Wearable Devices?

You might feel overwhelmed by regulatory standards, but yes, there are specific guidelines for nanomaterials in wearable devices. Agencies like the FDA and EPA are developing regulations to guarantee safety and environmental impact. While standards vary globally, they aim to balance innovation with health protections. Staying informed and compliant helps you innovate responsibly, giving users confidence in your wearable tech and safeguarding public trust amid rapid nanomaterial advancements.

Conclusion

Think of nanomaterials as the heartbeat of wearable electronics, pulsing with innovation and promise. Their flexibility and conductivity are the threads weaving a future where devices blend seamlessly into your life. As you embrace this evolving landscape, remember that each nanomaterial is a beacon guiding us toward smarter, more adaptable wearables. Together, they symbolize a bridge—connecting technology with human experience—paving the way for a future where innovation feels as natural as your own heartbeat.