Nanostructured battery electrodes use nanoscale materials to boost fast charging by improving electron flow and ion transport. Their tiny size increases surface area and active sites, reducing resistance and enabling quicker energy transfer. Materials like metal oxides, sulfides, graphene, and nanotubes are common choices. Fabrication methods such as CVD and templating help create these advanced structures. Keep exploring to discover how these innovations are shaping higher-performing, safer batteries that meet your fast-charging needs.

Key Takeaways

- Nanostructured electrodes increase surface area, providing more active sites for faster electrochemical reactions during charging.

- Nanoscale materials reduce electron and ion travel distances, enabling rapid charge transfer via quantum tunneling.

- Fabrication techniques like CVD and template-assisted synthesis allow precise control of electrode nanostructures for high-rate performance.

- Nanostructuring enhances electrode conductivity and stability, accommodating volume changes and preventing degradation during fast charging cycles.

- Incorporating carbon nanomaterials improves electron transport pathways, significantly boosting charging speed and overall battery efficiency.

The Basics of Nanostructured Electrodes in Batteries

Nanostructured electrodes are at the forefront of advancing battery technology because they substantially improve performance. These electrodes feature materials with nanoscale dimensions, which enable unique quantum effects like quantum tunneling, allowing electrons to pass through energy barriers more efficiently. This results in faster charge and discharge rates. Additionally, nanoscale phonons—vibrations within the crystal lattice—play a pivotal role in heat management and energy transfer at this scale. By manipulating phonon behavior, you can reduce heat buildup and enhance overall stability. The nanoscale structure also increases surface area, providing more active sites for electrochemical reactions. Regional legal resources can influence case strategy and access to skilled attorneys in this field. Together, quantum tunneling and nanoscale phonons contribute to the improved conductivity, efficiency, and lifespan of nanostructured electrodes, making them a essential component in next-generation batteries.

How Nanotechnology Enhances Charge Transfer Efficiency

Nanotechnology increases the surface area of battery electrodes, giving your electrons more space to interact. This leads to faster electron movement, reducing charge times markedly. As a result, your battery becomes more efficient and responsive during use. Additionally, color accuracy plays a crucial role in evaluating the performance of high-tech materials like nanostructured electrodes.

Increased Surface Area

Increasing the surface area of battery electrodes allows for more active sites where electrochemical reactions can occur, directly boosting charge transfer efficiency. Nanostructuring creates a rougher surface, increasing surface roughness, which enhances contact with electrolytes. This also minimizes particle aggregation, keeping particles well-dispersed for consistent performance. To maximize benefits, consider these factors:

- Optimize nanostructure design to increase accessible surface area without compromising stability.

- Control surface roughness to improve electrolyte contact and reduce impedance.

- Prevent particle aggregation, ensuring uniform distribution and maintaining high surface exposure.

Faster Electron Movement

By reducing the distance electrons must travel within the electrode, nanostructures markedly enhance charge transfer efficiency. Nanotechnology allows electrons to move more quickly through materials by facilitating quantum tunneling, where electrons pass through barriers that would normally block them. This effect becomes significant at the nanoscale, enabling faster electron flow. Additionally, controlling nanoparticle aggregation prevents the formation of large clusters that can hinder electron mobility. Well-dispersed nanoparticles create continuous pathways for electrons, reducing resistance and improving conductivity. These nanoscale modifications minimize electron transfer delays, resulting in faster charging times. Overall, nanostructured electrodes optimize electron movement by leveraging quantum tunneling and preventing aggregation, making your batteries charge more rapidly and operate more efficiently.

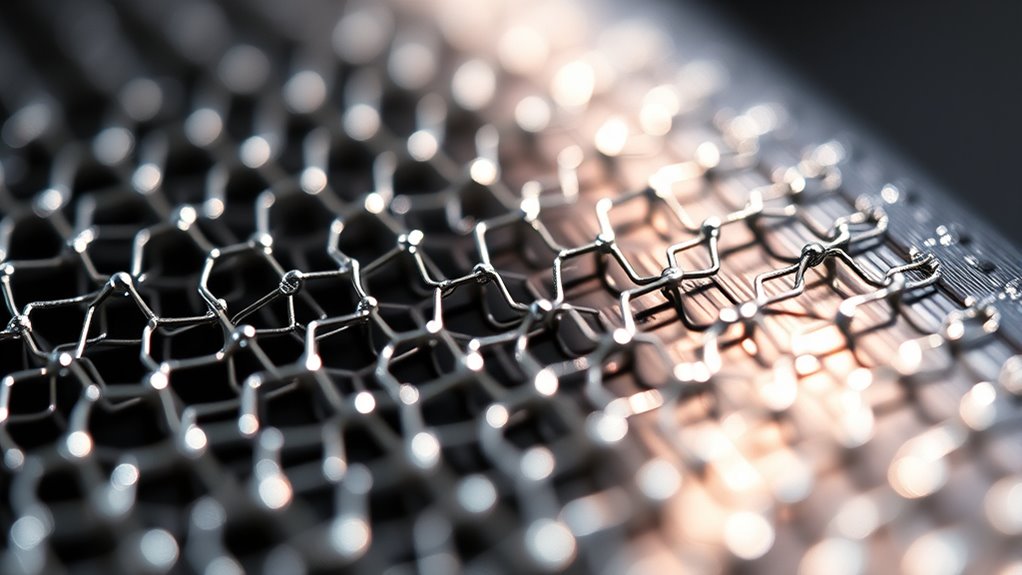

Materials Commonly Used in Nanostructured Battery Electrodes

You’ll find that metal oxides and sulfides are popular choices for nanostructured electrodes due to their high capacity and stability. Carbon-based nanomaterials, like graphene and carbon nanotubes, enhance conductivity and mechanical strength. Exploring these materials reveals how their unique properties improve battery performance. Additionally, material stability is crucial for ensuring long-lasting, reliable batteries during fast charging cycles.

Metal Oxides and Sulfides

Metal oxides and sulfides have become essential materials in nanostructured battery electrodes due to their high theoretical capacities and favorable electrochemical properties. Their effectiveness depends heavily on nanoparticle stability and surface modification, which prevent aggregation and enhance performance. You should focus on:

- Improving nanoparticle stability to maintain consistent electrochemical activity during cycling.

- Applying surface modification techniques to increase conductivity and reduce degradation.

- Tailoring nanostructures to optimize ion diffusion and electron transport for faster charging.

Carbon-Based Nanomaterials

Carbon-based nanomaterials, such as graphene, carbon nanotubes, and carbon nanofibers, play a crucial role in enhancing the performance of nanostructured battery electrodes. Graphene applications leverage its high electrical conductivity, large surface area, and mechanical strength to improve charge transfer and electrode stability. You can incorporate graphene into electrodes via methods like chemical vapor deposition or solution processing, boosting electrode durability and fast-charging capabilities. Carbon nanotube synthesis involves methods such as arc discharge and chemical vapor deposition, yielding aligned nanotubes that facilitate rapid electron transport. These nanomaterials create conductive networks that reduce internal resistance and support high-rate charge and discharge cycles. Overall, their unique properties make them essential components in developing batteries capable of faster charging without compromising capacity or longevity.

Fabrication Techniques for Nanoscale Electrode Architectures

Advancements in nanostructured battery electrodes rely heavily on sophisticated fabrication techniques that enable precise control over nanoscale architectures. These methods allow you to create structures like quantum dots and nanowire arrays, which enhance charge transport and increase surface area. To achieve this, you might consider:

- Chemical Vapor Deposition (CVD): Grow nanowire arrays with controlled orientation and length, optimizing electron pathways.

- Template-Assisted Synthesis: Use templates to assemble quantum dots and nanostructures with uniform size and distribution.

- Electrochemical Deposition: Fine-tune electrodeposition parameters to develop complex nanoscale architectures tailored for fast charging.

These techniques give you the ability to engineer high-performance electrodes, essential for improving battery speed and efficiency.

Impact of Nanostructuring on Energy Density and Power Output

Nanostructuring markedly enhances both the energy density and power output of battery electrodes by increasing surface area and improving charge transfer pathways. This leads to faster charging and discharging, meeting high power demands. Additionally, nanostructured designs can improve electrode stability by accommodating volume changes during cycling, which extends battery lifespan. You also benefit from potential cost reduction, as nanomaterials enable thinner, more efficient electrodes that require less active material. The increased surface area facilitates better electrochemical reactions, boosting energy density without sacrificing stability. Moreover, implementing vertical storage solutions can further optimize space utilization within battery systems. Overall, nanostructuring offers a way to optimize both the performance and longevity of battery electrodes, making fast-charging batteries more practical and economically viable.

Challenges in Developing Nanostructured Electrodes for Commercial Use

Scaling up nanostructured electrode production presents significant manufacturing challenges that you need to address. Material durability also raises concerns, as nanomaterials can degrade faster under repeated use. These issues must be resolved before nanostructured electrodes can become viable for widespread commercial applications. Additionally, understanding cost and budgeting is crucial for planning the scale-up process efficiently.

Manufacturing Scalability Issues

While nanostructured battery electrodes hold great promise for enhancing performance, manufacturing them at a commercial scale presents significant hurdles. Scalability hurdles often increase manufacturing costs and complicate production processes. To overcome these challenges, you need to contemplate:

- Ensuring consistent quality across large batches of nanomaterials.

- Developing cost-effective, scalable synthesis methods.

- Integrating advanced automation to reduce labor and error rates.

These issues stem from the complex, delicate nature of nanostructures, which are difficult to produce uniformly at high volumes. The high costs associated with specialized equipment and processes further hinder commercial viability. Addressing these manufacturing scalability issues is vital if nanostructured electrodes are to transition from lab-scale experiments to widespread, practical applications.

Material Durability Concerns

Developing durable nanostructured electrodes for commercial applications remains a significant challenge because nanomaterials are inherently more susceptible to degradation over time. You need to guarantee sufficient corrosion resistance to prevent deterioration caused by electrochemical reactions, which can weaken the electrode structure. Mechanical stability is equally critical; nanostructures can fracture or deform during charge-discharge cycles, reducing lifespan. Achieving a balance between high surface area for fast charging and maintaining material integrity is complex. You must explore protective coatings or composite materials that enhance durability without compromising performance. Addressing these material durability concerns is essential to make nanostructured electrodes viable for long-term use, especially when considering the rigorous demands of commercial battery applications.

Innovations in Nanostructured Electrodes for Fast Charging

Recent advances in nanostructured electrode design are revolutionizing fast-charging capabilities by markedly reducing ion diffusion paths and increasing surface area. These innovations enable quicker energy transfer and reduce charging times. For example:

- Researchers are exploring quantum tunneling effects to enhance electron transport across ultra-thin nanostructures, boosting charge rates without compromising stability.

- Engineers are developing coatings and surface modifications that mitigate nanotoxicity concerns, ensuring safer integration of nanomaterials.

- Novel fabrication techniques create interconnected nanostructures that facilitate rapid ion diffusion, further accelerating charge-discharge cycles.

- Integrating insights from personality traits research can improve the design of user-centered battery interfaces, enhancing usability and safety.

These advancements push the boundaries of battery performance, but they also require careful consideration of potential risks like nanotoxicity and the implications of quantum tunneling on long-term stability.

Case Studies of Nanotechnology-Driven Battery Improvements

Nanotechnology has already demonstrated its potential to transform battery performance, and real-world case studies highlight these advancements. For instance, researchers have used nanoparticle synthesis to create highly conductive electrode materials, markedly boosting charge rates. Quantum dots, with their unique size-dependent properties, have been integrated into electrode designs to improve energy density and stability. One case involved incorporating quantum dots into lithium-ion batteries, resulting in faster charging without sacrificing lifespan. Another example shows how nanoparticle synthesis enables the production of uniform, nanoscale materials that enhance electrode surface area and electron transfer. Additionally, the integration of nanostructured materials can improve the safety of batteries by reducing the risk of thermal runaway. These studies prove that nanotechnology not only improves battery speed but also enhances durability and safety, making nanostructured electrodes a promising solution for next-generation energy storage.

Future Perspectives and Emerging Trends in Nano-Enhanced Batteries

As research continues to advance, the future of nano-enhanced batteries looks promising, driven by emerging trends that aim to overcome current limitations. You can expect breakthroughs influenced by quantum effects, which can enhance charge transfer and energy storage efficiency at the nanoscale. Additionally, nanoscale thermodynamics will play a pivotal role in optimizing heat management and improving battery stability during fast charging. Emerging trends include:

- Exploiting quantum effects to boost electrochemical performance and energy density.

- Applying nanoscale thermodynamics to control heat flow and prevent thermal runaway.

- Developing hybrid nanomaterials that combine multiple enhancements for holistic improvements.

- Incorporating advanced modeling techniques to simulate nanoscale interactions and accelerate material development.

These innovations will push battery technology toward faster charging, longer lifespan, and greater safety, making future nano-enhanced batteries more practical and sustainable.

Environmental and Safety Considerations in Nanostructured Battery Production

Advancements in nano-enhanced batteries promise significant performance gains, but they also raise important environmental and safety concerns during their production. You need to consider the environmental impact of sourcing raw materials, such as rare metals, and the waste generated during manufacturing. Proper handling of nanomaterials is vital to prevent health risks, as inhalation or skin contact can pose safety hazards. Vetted safety regulations ensure safe working conditions and minimize environmental damage. Implementing eco-friendly processes, waste management strategies, and responsible disposal methods helps mitigate negative effects. Staying informed about evolving safety standards is essential for responsible production. By prioritizing these considerations, you can produce nanostructured electrodes that are not only high-performing but also environmentally sustainable and safe for workers and communities.

Frequently Asked Questions

How Do Nanostructured Electrodes Influence Battery Lifespan and Cycle Stability?

Nanostructured electrodes enhance your battery’s lifespan and cycle stability by improving electrode durability and maintaining high cycle efficiency. Their unique design reduces mechanical stress and prevents degradation during charge-discharge cycles. As a result, your battery can endure more cycles without capacity loss, ensuring consistent performance over time. These advanced electrodes help you enjoy longer-lasting batteries with reliable, fast charging capabilities, making your devices more efficient and durable.

What Are the Cost Implications of Manufacturing Nanostructured Battery Components?

You’ll find that manufacturing nanostructured battery components can increase costs by up to 50%, mainly due to complex cost analysis and manufacturing challenges. Precise control over nanomaterials demands advanced equipment and processes, raising production expenses. While these costs are higher initially, they can be offset by improved performance and longer battery life, making the investment worthwhile for high-demand applications.

How Scalable Are Current Nanostructuring Techniques for Mass Production?

You’ll find that current nanostructuring techniques face significant scalability challenges due to manufacturing hurdles. While lab methods work well for small batches, scaling up requires overcoming issues like uniformity, cost, and process consistency. To mass-produce nanostructured battery electrodes efficiently, you need advances in scalable, cost-effective methods that maintain quality. Addressing these challenges is essential to turning nanostructured electrodes into commercially viable solutions for fast-charging batteries.

Are There Any Health Risks Associated With Nanomaterial Exposure During Manufacturing?

You should be aware that manufacturing nanostructured electrodes poses health risks related to occupational safety, particularly from nanoparticle inhalation. Inhalation of tiny particles can cause respiratory issues and long-term health problems. To protect yourself, guarantee proper ventilation, wear appropriate protective gear, and follow safety protocols. Staying informed about nanoparticle exposure risks helps minimize health hazards during the manufacturing process.

How Do Nanostructured Electrodes Perform Under Extreme Temperature Conditions?

You might worry about extreme temperatures harming nanostructured electrodes, but they actually perform well due to their high thermal conductivity. This helps dissipate heat efficiently, maintaining their structural integrity even in harsh conditions. As a result, these electrodes stay stable and reliable during thermal stress, ensuring fast charging and safety. Their design allows them to withstand temperature extremes, making them suitable for demanding applications without compromising performance.

Conclusion

By embracing breakthroughs in nanostructured electrodes, you can push batteries beyond boundaries, boosting speed, storage, and safety. This tiny technology transforms traditional cells into swift, sturdy power sources, promising a brighter, better battery future. As researchers refine fabrication and foster innovative ideas, you’ll witness a wave of wonder in fast-charging, high-capacity batteries. Embrace the evolution of energy, where nanotechnology nurtures a new, notable norm for powering progress.