Nanomaterials like nanoparticles, carbon nanotubes, and ceramic particles are widely used in thermal barrier coatings (TBCs) to boost insulation, strength, and high-temperature resistance. These materials create denser, more uniform coatings that reduce heat transfer and improve durability against thermal cycling. Advanced fabrication methods such as sol-gel synthesis and electrospinning enable precise control over coating properties. If you explore further, you’ll discover how these innovations are shaping the future of high-performance TBCs.

Key Takeaways

- Nanomaterials like nanoparticles and carbon nanotubes enhance thermal insulation, mechanical strength, and high-temperature resistance in TBCs.

- Fabrication techniques such as sol-gel synthesis and electrospinning enable precise control of nanostructure and coating properties.

- Incorporating nanomaterials results in denser, more durable coatings with reduced thermal conductivity and improved microstructure.

- Benefits include increased resistance to thermal cycling, corrosion, and micro-cracks, extending TBC lifespan.

- Challenges involve scalability, environmental impacts, and integration complexities, prompting ongoing research for eco-friendly, large-scale solutions.

Types of Nanomaterials Used in TBCs

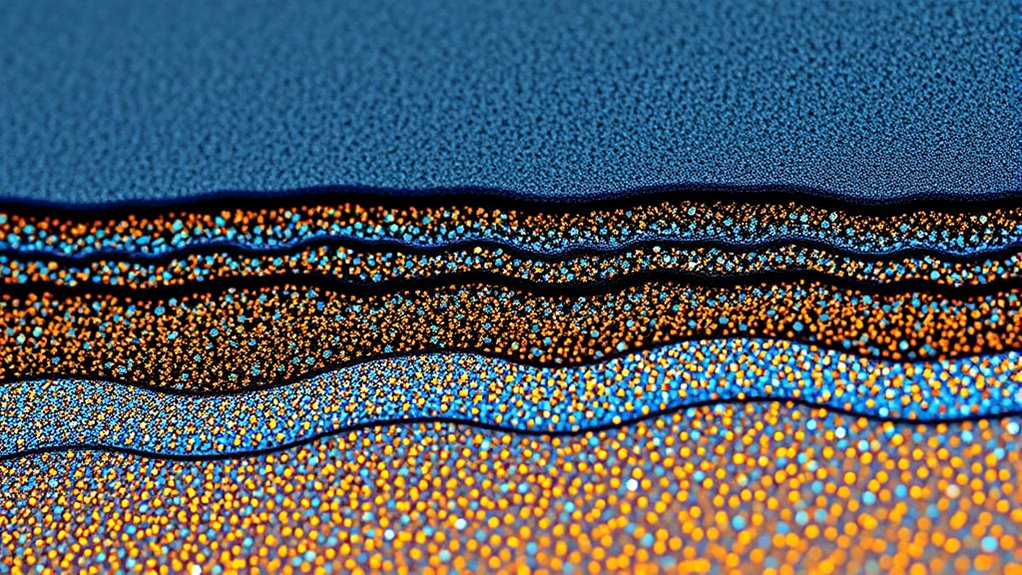

Nanomaterials have revolutionized thermal barrier coatings (TBCs) by offering enhanced thermal resistance and durability. One common type is nanoparticles, which improve the coating’s insulation properties due to their small size and high surface area. You’ll also find carbon nanotubes widely used; these nano-sized tubes provide exceptional strength and thermal stability. Incorporating nanoparticles into TBCs enhances their ability to withstand high temperatures without degrading. Carbon nanotubes, in particular, boost mechanical properties and conductivity, making coatings more resilient under extreme conditions. Other nanomaterials include ceramic nanoparticles, which improve oxidation resistance. By integrating these nanomaterials, you can develop coatings that are more efficient, longer-lasting, and better suited for demanding environments, marking a significant advancement in thermal barrier technology. Understanding risk mitigation in nanomaterial development ensures the longevity and safety of advanced coatings.

Advantages of Incorporating Nanomaterials

Incorporating nanomaterials into thermal barrier coatings substantially enhances their performance by improving thermal insulation, mechanical strength, and durability. You benefit from improved corrosion resistance, which extends coating lifespan, and enhanced mechanical strength, making coatings more resistant to cracks and wear. Nanomaterials create a denser, more uniform coating structure, reducing thermal conductivity and increasing thermal barrier efficiency. They also help in minimizing micro-cracks, ensuring better long-term stability. Additionally, sound healing science suggests that the vibrations and frequencies involved in nanomaterial interactions may further contribute to the coatings’ stability and longevity. Here’s a quick overview:

| Advantage | Impact |

|---|---|

| Improved corrosion resistance | Protects underlying materials from environmental damage |

| Enhanced mechanical strength | Increases resistance to mechanical stresses |

| Better thermal insulation | Reduces heat transfer, improving energy efficiency |

| Increased durability | Longer-lasting coatings with fewer repairs |

| Microstructure refinement | Promotes uniform coating and prevents failure |

Fabrication Techniques for Nanostructured Coatings

Fabrication techniques for nanostructured coatings play a essential role in achieving the desired properties and performance of thermal barrier coatings. You can utilize sol gel synthesis to produce uniform, nanometer-thick films with controlled composition and porosity, enhancing thermal insulation. This method involves hydrolyzing precursors to form a gel, which then transforms into a dense or porous ceramic coating after heat treatment. Electrospinning processes offer another versatile approach, enabling you to create nanofiber mats with high surface area and interconnected porosity. By applying a high-voltage electric field, you can produce fine fibers from polymer or ceramic solutions, which, after calcination, form nanostructured coatings. Both techniques allow precise control over microstructure, ultimately improving the coating’s thermal resistance and durability. Additionally, understanding the material properties of the nanostructures enables optimization for specific high-temperature applications.

Performance Enhancements Achieved With Nanomaterials

The advanced microstructures created through various fabrication techniques markedly improve the performance of thermal barrier coatings. By integrating nanomaterials, you enhance nanomaterial durability, ensuring the coatings withstand high temperatures and harsh environments over time. These nanostructures also enable precise thermal conductivity control, reducing heat transfer and increasing insulation efficiency. As a result, your coatings become more effective at protecting substrates from extreme heat while maintaining structural integrity. The increased surface area and unique properties of nanomaterials contribute to improved resistance against thermal cycling and mechanical stresses. Additionally, monitoring credit card statements regularly can help detect fraudulent activity early, safeguarding your financial assets. Ultimately, these performance enhancements lead to longer-lasting, more reliable thermal barrier coatings that meet demanding industrial requirements. This progress paves the way for advanced applications in aerospace, power generation, and other high-temperature industries.

Challenges and Future Prospects in Nanomaterial-Enhanced TBCs

Despite the promising advantages of nanomaterials in enhancing thermal barrier coatings (TBCs), several challenges hinder their widespread adoption. Scalability issues pose significant barriers, as producing nanomaterials consistently and cost-effectively at large scales remains difficult. You also need to consider the environmental impact, since some nanomaterials may pose health risks during manufacturing or disposal. Additionally, integrating nanomaterials into existing coating processes can be complex, affecting durability and performance. Future prospects hinge on developing eco-friendly synthesis methods and scalable production techniques. You should also focus on understanding long-term stability and environmental safety to guarantee nanomaterial-enhanced TBCs are viable. Moreover, advancements in equipment and techniques can facilitate the precise application and integration of nanomaterials. Overcoming these hurdles will be vital for realizing their full potential in high-temperature applications.

Frequently Asked Questions

How Do Nanomaterials Affect the Environmental Impact of TBC Production?

Nanomaterials can reduce the environmental footprint of TBC production by enhancing resource efficiency, requiring less raw material for the same performance. They often enable lower energy consumption during manufacturing, decreasing emissions. Additionally, nanomaterials may extend coating lifespan, reducing waste and replacement needs. By improving these aspects, you contribute to a more sustainable process, minimizing environmental impacts and promoting eco-friendly practices in the development of thermal barrier coatings.

Are There Health Risks Associated With Nanomaterial Use in Coatings?

You might wonder if health concerns or toxicity risks come with nanomaterials in coatings. While nanomaterials offer impressive benefits, they can pose subtle health risks if inhaled or ingested during manufacturing or disposal. Although advanced safety measures greatly reduce exposure, it is crucial to stay aware of potential toxicity risks. Proper handling, protective gear, and regulation help ensure your safety while harnessing these innovative materials.

What Is the Cost Comparison Between Traditional and Nanomaterial-Based TBCS?

You’ll find that nanomaterial-based TBCs tend to be more expensive upfront due to higher material costs and manufacturing complexity. However, they offer better cost efficiency over time because of their enhanced durability and thermal performance, reducing maintenance and replacement needs. While traditional coatings are cheaper initially, the long-term savings and improved performance of nanomaterials can make them more economical in the long run.

How Do Nanomaterials Influence the Long-Term Durability of TBCS?

Nanomaterials enhance the long-term durability of TBs by improving microstructure stability and crack resistance. You’ll find that their small size helps create a more uniform, dense coating, reducing the likelihood of crack formation over time. This increased resilience means your thermal barrier coating maintains its protective properties longer, even under extreme conditions. As a result, nanomaterials extend the service life of your coatings, offering better performance and cost savings.

Can Nanomaterials Be Recycled or Reused in TBC Applications?

You might think nanomaterials in TBCs are hard to recycle, but with proper reuse strategies, they can be. Recycling challenges exist due to their tiny size and complex integration, yet innovative methods like chemical recovery and thermal reprocessing are developing. These strategies enable you to reuse nanomaterials effectively, reducing waste and environmental impact, and making the durability and sustainability of your thermal barrier coatings more achievable.

Conclusion

Think of nanomaterials in TBCs as tiny architects building a fortress against heat. They improve durability, reduce thermal conductivity, and extend coating life. While challenges exist, ongoing innovations are like revealing new blueprints for stronger defenses. Embracing these advancements means you’ll craft coatings that stand resilient against extreme conditions, much like a fortress standing firm amidst a storm. The future of nanomaterial-enhanced TBCs is bright, promising a new era of thermal protection.