Graphene is a groundbreaking material that combines incredible strength, excellent electrical and thermal conductivity, and transparency, making it a true wonder. Its unique honeycomb lattice structure provides durability while remaining incredibly lightweight and flexible. This allows it to revolutionize energy storage, electronics, and filtration systems. As you explore further, you’ll discover how its versatile properties are enabling innovations across industries and shaping the future of technology.

Key Takeaways

- Graphene is a single-atom-thick carbon material with exceptional strength, conductivity, and transparency, revolutionizing multiple industries.

- Its unique honeycomb lattice structure provides high electrical and thermal conductivity, enabling faster electronics and improved heat management.

- Graphene’s versatility allows applications in energy storage, flexible electronics, sensors, and advanced filtration systems.

- Its lightweight yet durable properties make it ideal for strengthening composites, coatings, and lightweight structural components.

- Despite manufacturing challenges, ongoing research aims to harness graphene’s full potential for future technological innovations.

What Makes Graphene a Supermaterial

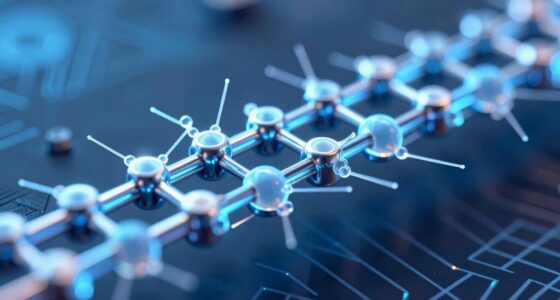

What makes graphene a supermaterial is its unique combination of extraordinary properties. You’re looking at a single-atom-thick sheet of carbon organized in a hexagonal honeycomb pattern, making it incredibly lightweight yet incredibly strong—200 times stronger than steel. Its exceptional electrical conductivity surpasses copper, enabling faster data transfer and energy flow. With the highest thermal conductivity at room temperature, it efficiently dissipates heat, even outperforming diamond. Despite its atomic thinness, it’s transparent, absorbing only 2.3% of white light. These features come together to create a material that’s not only durable and flexible but also highly versatile. Its remarkable strength, conductivity, and transparency make graphene a true supermaterial poised to revolutionize multiple industries. Additionally, free-floating structures are being explored to develop innovative applications in the field of lightweight and flexible materials, leveraging its remarkable strength and conductivity. Furthermore, integrating graphene with eco-friendly fabrics like Suprem can enhance the durability and performance of sustainable textiles, opening new horizons in advanced textile applications. The ongoing research into graphene-based composites continues to unlock new potentials for energy-efficient and sustainable technologies. Moreover, ongoing advancements in manufacturing techniques are making large-scale production of graphene more feasible and cost-effective, accelerating its adoption across various sectors.

The Unique Structure of Graphene

You’ll notice that graphene’s atoms form a hexagonal honeycomb lattice, giving it a perfect two-dimensional structure. Its single-atom thickness makes it incredibly lightweight yet strong enough to support heavy loads. When stacked, these layers create graphite, maintaining the layered, slippery structure that’s key to many of its remarkable properties. Additionally, the layered structure allows for unique electronic behaviors, making it highly versatile for various technological applications. Proper documentation and understanding of tax implications are essential when utilizing graphene in commercial products. The stability of its structure also contributes to its exceptional mechanical strength, making it suitable for use in composite materials and protective coatings. Its eco-friendly potential is further enhanced by its sustainable production methods, which minimize environmental impact while enabling innovative applications. Researchers are continuously exploring new industrial uses to maximize its benefits across different sectors.

Hexagonal Honeycomb Lattice

Have you ever wondered what gives graphene its remarkable strength and electrical properties? It’s the hexagonal honeycomb lattice of carbon atoms that makes this possible. Each carbon atom bonds with three neighbors in an SP2 configuration, forming a perfect chicken-wire pattern. This arrangement creates a two-dimensional structure with extraordinary stability and flexibility. The hexagonal pattern allows electrons to move freely across the surface, resulting in exceptional electrical conductivity. Its uniform, tightly packed structure also contributes to graphene’s strength, making it stronger than steel on a per-weight basis. The lattice’s symmetry and robust covalent bonds give graphene resilience against stress and deformation. Additionally, the layered structure of graphene enables the stacking and integration into various composite materials, enhancing its practical applications. This unique honeycomb architecture is the foundation for its incredible combination of strength, transparency, and conductivity, making it truly a wonder material with limitless potential. Moreover, the conductivity of graphene is so high that it opens up possibilities for revolutionary advancements in electronics and energy storage.

One-Atom Thickness

Graphene’s defining feature is its extraordinary thinness—just a single atom thick. This ultra-thin structure means it’s the thinnest known material, yet incredibly strong and durable. You can think of it as a sheet of carbon atoms arranged in a honeycomb pattern, only one atom thick. Despite its minimal thickness, it’s impermeable to gases like helium, making it an outstanding barrier. Its transparency allows 97.7% of light to pass through, which is remarkable for such a dense material. Its atomic-scale thickness gives it unique electrical and thermal properties, surpassing many traditional materials. This one-atom layer combines strength, flexibility, and conductivity, making it a revolutionary material that’s reshaping industries from electronics to energy storage. Its remarkable properties are partly due to its atomic-scale structure, which influences its behavior at the molecular level. Recognizing patterns in atomic arrangements can further unlock new applications and innovations in various fields. Additionally, understanding material behavior at the nanoscale is crucial for developing advanced technologies based on graphene’s properties. Exploring nanoscale phenomena can lead to even more groundbreaking uses of this extraordinary material.

Layered Graphite Formation

Layered graphite forms when multiple graphene sheets stack through weak van der Waals forces, creating a layered structure with unique properties. This stacking results in graphite’s slippery, lubricating layers that easily slide past each other, giving it its characteristic softness. Each layer consists of a single sheet of carbon atoms arranged in a hexagonal honeycomb lattice. These layers are held together loosely, allowing you to peel off thin sheets of graphene. The weak interlayer forces enable graphite to be used as a lubricant, in pencils, and as a precursor for graphene production. Despite being composed of countless layers, the individual graphene sheets retain their exceptional strength, electrical conductivity, and transparency. This layered structure is fundamental to understanding graphite’s diverse applications and the remarkable properties of graphene. Understanding layered structures is key to advancing nanomaterials and their innovative uses.

Mechanical Marvels of Graphene

Despite its ultra-thin profile, graphene defies expectations by combining exceptional strength and flexibility. It’s the strongest known material, capable of supporting weight equivalent to an average cat despite being just one atom thick. Its high tensile strength allows it to resist immense stress without breaking, making it incredibly durable. At the same time, it’s highly elastic, bending and stretching without damage, thanks to its flexible honeycomb structure. This structure enables the material to sustain mechanical resilience under various forces. Its lightweight nature ensures it adds minimal weight while providing maximum strength. Additionally, graphene’s flexibility allows it to be integrated into wearable technology and other adaptable applications with ease. Its unique combination of properties also makes it ideal for composite materials, which can enhance the performance of various products. Recent studies have shown that graphene can also improve thermal conductivity, opening new avenues for heat management in electronics and industrial applications. Whether used in protective gear, flexible electronics, or composite materials, graphene’s mechanical marvels open up a new world of innovative applications.

Transforming Energy Storage and Generation

Thanks to its remarkable mechanical properties, graphene is revolutionizing energy storage and generation technologies. Its exceptional electrical conductivity enables faster charging and higher capacity in batteries, extending their lifespan. Graphene-enhanced supercapacitors can store and release energy rapidly, making them ideal for quick power bursts. Its transparency and conductivity allow for flexible, lightweight solar panels that outperform traditional materials, boosting renewable energy use. Graphene’s impermeability improves fuel cell efficiency by preventing fuel crossover, while its high thermal conductivity helps dissipate heat, reducing overheating risks. In power transmission, graphene wires offer minimal resistance and heat generation, increasing efficiency over copper. Additionally, material properties such as strength and flexibility make it suitable for innovative energy device designs. These advances collectively lead to more reliable, durable, and efficient energy systems, paving the way for cleaner and smarter energy solutions worldwide. Furthermore, energy storage advancements driven by graphene are enabling the development of more sustainable and resilient energy grids, thanks to its potential for creating high-performance energy components.

Revolutionizing Electronic Devices

Graphene’s unique properties enable the development of ultra-fast transistors that outperform traditional silicon-based ones, making electronic devices more powerful and energy-efficient. Its flexibility allows for innovative display technologies that are both durable and bendable, opening new possibilities for consumer electronics. Additionally, graphene-based sensors offer enhanced sensitivity and rapid response times, transforming how we monitor and interact with our environment.

Ultra-Fast Transistors

Ultra-fast transistors harness graphene’s exceptional electrical properties to markedly boost processing speeds and energy efficiency in electronic devices. Thanks to its high electrical conductivity, graphene allows electrons to move rapidly with minimal resistance, enabling faster switching times. Its atomic thinness reduces device size, making transistors more compact. Additionally, graphene’s high thermal conductivity helps dissipate heat efficiently, preventing overheating during intense operation. This combination of speed and stability opens doors for next-generation processors that outperform silicon-based ones. You can expect smartphones, computers, and other electronics to become faster, more powerful, and energy-efficient. As a result, graphene-based transistors could revolutionize computing, making devices more responsive and extending battery life without sacrificing performance. This leap forward promises a new era of ultra-efficient, high-speed electronics.

Flexible Display Technologies

Flexible display technologies are transforming how you interact with electronic devices by enabling screens that bend, fold, and roll without losing functionality. With graphene’s exceptional strength, transparency, and conductivity, these displays become more durable and lightweight. Here are three ways graphene enhances flexible displays:

- It replaces brittle materials like glass, making screens more resistant to cracking and breaking.

- Its transparency allows for ultra-thin, seamless displays that retain clarity and brightness.

- Its electrical properties enable faster response times and better energy efficiency in flexible screens.

Enhanced Sensor Capabilities

Building on the advances in flexible display technologies, graphene’s exceptional electrical conductivity and atomic thinness are transforming sensor capabilities. You can now develop ultra-sensitive, lightweight sensors that detect even small changes in pressure, temperature, or chemical composition. These sensors are highly flexible, enabling integration into wearable health monitors, smart textiles, or flexible electronics. Graphene’s high surface area enhances detection sensitivity, allowing for rapid, accurate responses. Its impermeability to gases also means sensors can precisely monitor environmental conditions without interference. Additionally, graphene-based bioelectric sensors can detect biomarkers like glucose or DNA with remarkable accuracy, making real-time health monitoring feasible. Overall, graphene’s unique properties are pushing sensor technology into new domains of precision, durability, and versatility, revolutionizing electronic devices across industries.

Innovative Uses in Water and Air Purification

Graphene’s unique structure makes it an ideal material for advancing water and air purification technologies. Its impermeable nature allows it to filter out gases like helium while letting water pass through, enabling ultrafiltration. Its high surface area and conductivity help trap and break down pollutants efficiently. Here are three key innovations:

Graphene’s structure enables advanced filtration and pollutant breakdown in water and air purification systems.

- Desalination membranes: Graphene oxide membranes remove salt from seawater, making freshwater accessible.

- Air filters: Graphene-enhanced filters capture fine particles, volatile organic compounds, and pathogens more effectively.

- Catalytic coatings: Graphene-based materials accelerate chemical reactions that degrade airborne toxins and contaminants.

Enhancing Composites and Coatings

Enhancing composites and coatings with graphene considerably improves their strength, durability, and resistance to environmental damage. When integrated into materials like plastics, metals, or ceramics, graphene boosts tensile strength and elasticity, making products more resilient under stress. Its impermeability helps prevent corrosion and chemical attack, extending the lifespan of coated surfaces. For aerospace and automotive parts, graphene-enhanced composites offer lightweight yet robust alternatives to traditional materials, reducing weight without sacrificing performance. Coatings infused with graphene provide excellent protection against corrosion, UV radiation, and moisture, making them ideal for maritime, infrastructure, and industrial uses. Additionally, the high thermal and electrical conductivity of graphene allows for better heat dissipation and electrical performance, improving the functionality and longevity of various devices and surfaces.

Future Prospects and Challenges

Despite its remarkable properties, realizing graphene’s full potential faces significant hurdles. First, scalable production remains costly and complex, limiting widespread use. Second, integrating graphene into existing manufacturing processes can be challenging due to its delicate nature. Third, ensuring consistent quality and uniformity across large batches is difficult, hindering commercial reliability. These issues slow down adoption in industries like electronics, energy, and healthcare. Additionally, long-term stability and environmental impacts are still under research. Overcoming these challenges requires advances in synthesis techniques, better quality control, and sustainable practices. While graphene’s future is promising, addressing these obstacles is essential to *liberate* its game-changing capabilities across multiple sectors.

Frequently Asked Questions

How Is Graphene Produced at an Industrial Scale?

You produce graphene industrially mainly through chemical vapor deposition (CVD) on metal substrates like copper or nickel. You heat gases containing carbon, such as methane, to high temperatures, causing carbon atoms to settle and form a single-atom-thick layer. Afterward, you transfer this layer onto different materials for various applications. Alternatively, you can use exfoliation techniques, like peeling layers from graphite, for smaller-scale production.

What Are the Environmental Impacts of Graphene Manufacturing?

Imagine harvesting a rare, shimmering gem from a vast, wild forest. The environmental impacts of graphene manufacturing are similar; it involves energy-intensive processes like chemical vapor deposition or exfoliation, which can produce hazardous waste and consume significant resources. You might worry about pollution, water use, and carbon emissions. Careful regulation and greener methods can help, but currently, production’s environmental footprint remains a concern that needs addressing.

Can Graphene Be Safely Used in Biomedical Applications?

Yes, you can safely use graphene in biomedical applications because it’s biocompatible and shows minimal toxicity when properly processed. Its high surface area allows for effective drug delivery and tissue engineering. However, you should guarantee thorough testing and proper handling, as some forms or manufacturing methods might pose risks. When used responsibly, graphene offers promising benefits for medical devices, implants, and regenerative medicine.

How Does Graphene Compare to Other 2D Materials?

You’ll find that graphene surpasses other 2D materials in strength, being 200 times stronger than steel. Its exceptional electrical conductivity outperforms many, often better than copper, while its thermal conductivity exceeds diamond. Unlike many others, graphene is transparent and impermeable to gases. Its unique combination of strength, flexibility, and conductivity makes it more versatile, enabling innovations in electronics, energy, and biomedical fields that other 2D materials can’t match.

What Are the Economic Challenges of Commercializing Graphene Technology?

You face economic challenges when commercializing graphene technology, mainly due to high production costs and scaling issues. You need advanced, cost-efficient methods to produce large quantities without sacrificing quality. Additionally, you must navigate a lack of standardization and regulatory hurdles, which can slow down market adoption. Overcoming these financial and logistical barriers is essential for you to bring graphene-based products to widespread use and realize their full potential.

Conclusion

Just as Icarus soared toward the sun, you hold the power to elevate technology with graphene’s limitless potential. This wonder material, like a modern Prometheus, promises to ignite innovations across energy, electronics, and beyond. Keep dreaming big, because with each breakthrough, you’re shaping a future where this miracle molecule transforms our world—just as legends inspire us to reach for the stars and redefine what’s possible.