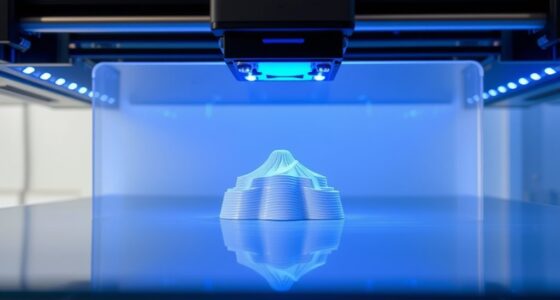

When choosing the top chemical vapor deposition furnaces for precision coating in 2025, I focus on models offering tight temperature control, advanced safety features, and energy efficiency. High uniformity and process stability are essential for consistent results, so I look for furnaces with multiple heating zones and real-time monitoring. Material compatibility and customization options further influence my choice. To discover the best options and guarantee you make an informed decision, keep exploring these key factors.

Key Takeaways

- Advanced temperature control systems with ±1°C accuracy ensure consistent, high-quality coatings.

- Integrated safety features like leak detectors and emergency shut-offs enhance operational security.

- Energy-efficient designs with superior insulation reduce operational costs and environmental impact.

- Customizable process parameters and flexible chamber sizes accommodate diverse substrate and coating needs.

- Real-time monitoring and automation capabilities improve process stability and coating precision.

Mobil Unirex N3, 35 lb Pail

Mobil Unirex N3 in the 35 lb pail is an excellent choice for industries that require reliable lubrication under high-temperature conditions. Its NLGI Grade 3 consistency provides excellent stability, making it ideal for heavy-duty applications like rolling-element bearings and electric motors. The lithium-complex thickener ensures it performs smoothly, even in demanding environments. With a green color, it’s easy to identify and apply precisely where needed. Its high-viscosity base oil (115 cSt) offers superior film strength and protection. If your operations demand dependable, high-temperature lubrication, Mobil Unirex N3 delivers consistent performance, reducing downtime and maintenance costs.

Best For: industries needing reliable high-temperature lubrication for rolling-element bearings and electric motors in demanding operational environments.

Pros:

- Excellent stability and performance at high temperatures due to NLGI Grade 3 consistency

- Superior film strength and protection from high-viscosity base oil (115 cSt)

- Versatile for various industrial applications, including electric-motor lubrication

Cons:

- Heavier consistency may require more effort during application

- Lithium-complex thickener can be more expensive than simpler greases

- May be over-specified for low-temperature or light-duty applications

Master Flame – Fire Retardant – Spray on application – 5 Gallon Pail

Master Flame Fire Retardant in the 5-gallon spray-on pail is an excellent choice for professionals and safety-conscious property owners seeking a versatile, high-performance solution to enhance fire resistance on large surfaces. It’s tested and rated Class A, providing high fire resistance on materials like wood, fabric, and paper. The product is eco-friendly, non-toxic, and free of harmful chemicals, making it safe to use on various surfaces. It can be applied via spraying, dipping, or mixing with paint, offering flexibility for different projects. Although it requires multiple coats and careful handling due to its watery consistency, it markedly improves fire safety and is supported by thorough testing documentation.

Best For: safety professionals, property owners, and contractors seeking an effective, eco-friendly fire retardant solution for large surfaces and various materials.

Pros:

- High fire resistance rated Class A, tested and verified by NFPA and ASTM standards

- Versatile application methods including spraying, dipping, and mixing with paint

- Eco-friendly, non-toxic, free of harmful chemicals like PBDEs

Cons:

- Requires multiple coats for opaque coverage, increasing application time

- Watery consistency causes drips and demands careful masking during application

- Rapid separation from paint necessitates constant stirring, which can be inconvenient

VM&P Naptha – Highly Concentrated by DIYChemicals (1 Gallon (128 fl oz))

VM&P Naphtha by DIYChemicals stands out as an excellent choice for professionals and DIY enthusiasts who need a reliable, high-concentration solvent for cleaning, degreasing, or thinning paints. It’s a clear, colorless petroleum distillate with a flash point above 100°F, ensuring safe handling when proper precautions are taken. Its fast evaporation and clean-burning qualities make it highly effective for removing oil, grease, and residues, as well as preparing surfaces for painting. Packaged securely with clear labels, it emphasizes safety—just remember to wear gloves and eye protection. Overall, its high performance and versatility make it ideal for a variety of applications around the workshop or home.

Best For: DIY enthusiasts and professionals seeking a high-concentration solvent for cleaning, degreasing, thinning paints, and fuel applications.

Pros:

- Highly effective at removing oil, grease, and residues with fast evaporation and minimal residue

- Versatile for multiple applications including painting prep, cleaning, and fueling devices

- Packaged securely with clear labeling, emphasizing safety and ease of use

Cons:

- Permeable plastic bottles may allow evaporation over time, reducing product effectiveness

- Shipping leaks and transit issues can occur if not carefully handled or packed

- Slightly more expensive than hardware store options but justified by performance and quality

190 Proof Ethanol USP 95

Proof Ethanol USP 95 is an ideal choice for industrial and laboratory applications requiring high-purity, anhydrous ethanol. This 190 proof grade, available in various sizes, is a colorless, clear liquid with a boiling point between 78°C and 80°C. It’s primarily used as a botanical solvent for processing medicinal hemp, cannabis, terpenes, and similar extracts. Meeting pharmaceutical standards, it’s suitable for manufacturing pharmaceuticals, cosmetics, and food supplements. However, it’s not intended for beverage production or direct consumption. Its high purity and compliance with federal regulations make it a reliable solvent for precision coating and chemical vapor deposition processes.

Best For: industrial and laboratory professionals needing high-purity ethanol for botanical extraction, pharmaceutical manufacturing, cosmetics, and food supplement processing.

Pros:

- Meets pharmaceutical standards ensuring high purity and quality

- Suitable for a wide range of industrial and laboratory applications

- Comes in various sizes with excise tax included for convenience

Cons:

- Not suitable for beverage production or direct human consumption

- Has a strong, unpleasant taste making it unsuitable for ingestion

- Requires careful handling due to flammability and explosion risk

Factors to Consider When Choosing Chemical Vapor Deposition Furnaces

When selecting a chemical vapor deposition furnace, I focus on key factors like temperature control precision and how evenly it coats materials. Safety features and energy efficiency also matter to guarantee reliable and cost-effective operation. Understanding these points helps me choose the right furnace for my specific needs.

Temperature Control Precision

Achieving precise temperature control is vital when selecting a chemical vapor deposition (CVD) furnace, as even minor fluctuations can compromise film quality and uniformity. Advanced thermocouples and feedback systems are essential to maintain temperature within ±1°C or better. Variations in temperature control can cause defects, uneven coatings, and inconsistent deposition rates. High-precision furnaces often feature programmable controllers with multiple heating zones, allowing for tailored temperature gradients suited to specific materials. Rapid heating and cooling capabilities help control process timing and prevent thermal stress or contamination. Maintaining stable temperatures minimizes issues like cracking or film defects, ensuring consistent, high-quality thin film deposition. Investing in a furnace with excellent temperature control is crucial for achieving optimal CVD process results.

Uniformity of Coating

Ensuring uniform coating in a chemical vapor deposition furnace requires careful consideration of multiple factors. Precise temperature control is essential to guarantee even precursor decomposition across the substrate, preventing uneven layers. Proper airflow and gas flow dynamics within the chamber also play a critical role in maintaining consistent deposition. The design and placement of heating elements influence temperature gradients that can affect coating uniformity, so thoughtful engineering is key. Additionally, stabilizing process parameters like pressure and precursor flow rate helps achieve a consistent film thickness. Regular calibration and monitoring of temperature and gas distribution systems are crucial to minimize variations and maintain high-quality coatings. By focusing on these elements, I can optimize the uniformity of coatings and ensure reliable, precise results.

Material Compatibility

Choosing the right materials for a chemical vapor deposition furnace is essential because incompatible materials can lead to corrosion, contamination, or equipment failure. I focus on selecting furnace components made from high-purity, inert materials like quartz or alumina, capable of withstanding high temperatures and reactive gases. It’s critical to verify that the lining and seals resist corrosive byproducts generated during deposition. I also consider the thermal expansion properties of materials to prevent leaks or damage during temperature cycling. Matching the furnace’s material compatibility with the specific substrates and film materials ensures uniform deposition and process stability. By prioritizing compatibility, I can maintain the integrity of the furnace, improve process reliability, and achieve high-quality, consistent coatings.

Safety Features Included

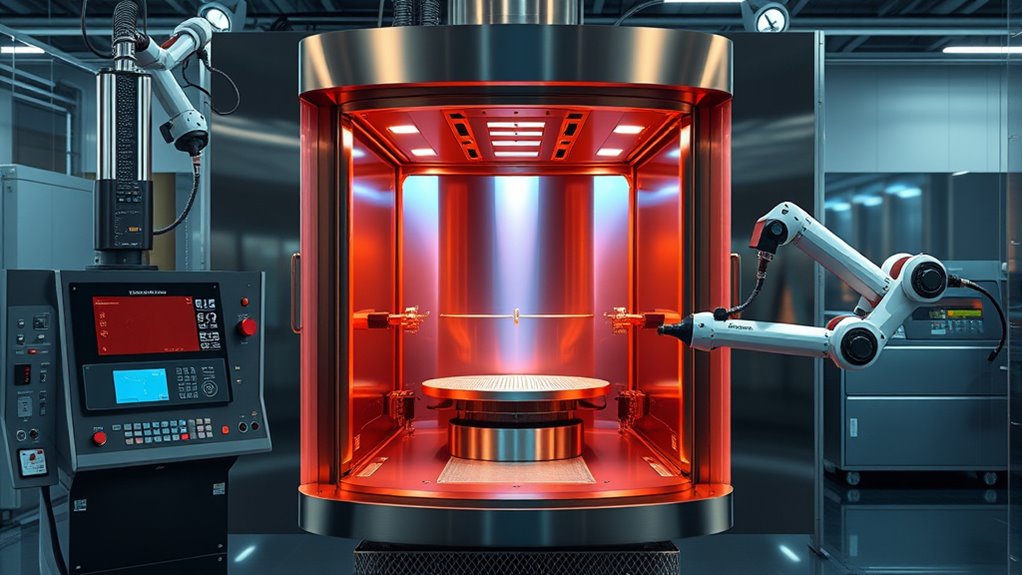

Safety features are a crucial consideration when selecting a chemical vapor deposition furnace because they directly impact operator safety and process reliability. Emergency shut-off systems and automatic gas leak detectors are essential to prevent accidents, quickly halting operations if hazards are detected. Proper ventilation and exhaust controls help remove toxic fumes, reducing inhalation risks. Temperature monitoring and over-temperature protection ensure the furnace stays within safe operating limits, preventing overheating and fires. Fail-safe mechanisms like door interlocks and pressure relief valves protect operators from high temperatures and reactive gases. Clear safety signage, alarms, and user alerts notify operators immediately of malfunctions or unsafe conditions, enabling prompt action. These features collectively create a safer working environment and ensure consistent, reliable coating processes.

Energy Efficiency Level

Energy efficiency in chemical vapor deposition (CVD) furnaces plays a critical role in reducing operational costs and minimizing environmental impact. Advanced insulation materials help cut heat loss, ensuring energy isn’t wasted. Using energy-efficient heating elements like ceramics or quartz can considerably lower power consumption during operation. Programmable temperature controls and rapid thermal processing allow for precise energy use, avoiding unnecessary heating cycles. Proper furnace design, including optimized airflow and chamber shape, enhances thermal uniformity and reduces energy waste. Regular maintenance and calibration are essential to sustain energy efficiency, preventing equipment inefficiencies that lead to unnecessary power consumption. By prioritizing these factors, I can select a CVD furnace that not only saves costs but also aligns with eco-friendly practices, making it a smarter investment for long-term operations.

Maintenance Requirements

Maintaining chemical vapor deposition furnaces requires careful attention to several key factors to guarantee consistent performance and film quality. Regularly inspecting and replacing heating elements ensures uniform temperature distribution, critical for quality coatings. Periodic calibration of temperature controllers and sensors maintains precise process conditions, preventing deviations. Cleaning reactor chambers and gas flow components regularly removes contaminants that could affect film integrity. Lubricating and inspecting moving parts, like door mechanisms and conveyor systems, helps reduce mechanical failures and downtime. Scheduled checks of vacuum seals and gas lines are essential to prevent leaks and maintain the proper process atmosphere. These maintenance routines are essential for reliable operation, consistent results, and prolonging equipment lifespan, making them a vital consideration when selecting a furnace.

Cost and Budget

Choosing the right chemical vapor deposition (CVD) furnace involves more than just evaluating its performance; financial considerations play a crucial role. The initial cost can range from tens of thousands to hundreds of thousands of dollars, depending on size and features. Operational expenses, including electricity, maintenance, and replacement parts, substantially impact long-term budgets. High-end models with advanced controls and automation cost more upfront but may reduce labor and maintenance costs over time. Budget constraints might limit options to smaller or less sophisticated furnaces, potentially affecting process quality and throughput. It’s vital to consider the total cost of ownership—installation, training, ongoing expenses—when making your decision. Balancing performance with affordability ensures sustainable, cost-effective coating processes.

Frequently Asked Questions

What Safety Features Are Essential in CVD Furnaces?

Safety features are essential in CVD furnaces to protect users and guarantee reliable operation. I always look for emergency shut-offs, proper ventilation systems, and temperature controls that prevent overheating. Additionally, safety interlocks and gas leak detectors are necessary to prevent accidents. Regular maintenance and clear safety protocols are also critical. These features help me work confidently, knowing hazards are minimized and safety is prioritized during high-temperature processes.

How Energy-Efficient Are the Latest CVD Furnace Models?

Think of the latest CVD furnace models as high-performance engines in a sports car—they’re incredibly energy-efficient. I’ve found that modern designs incorporate advanced insulation and optimized heating elements, reducing energy consumption profoundly. These furnaces use smart controls that adapt to process needs, cutting down waste. Overall, they’re about precision and power, delivering excellent results while keeping energy use low, which feels like getting more speed with less fuel.

Can CVD Furnaces Be Customized for Specific Coating Types?

Yes, CVD furnaces can definitely be customized for specific coating types. I’ve seen manufacturers tailor parameters like temperature profiles, gas flow rates, and chamber configurations to suit particular materials and application needs. This flexibility allows for precise control over coating quality and characteristics. If you’re considering a CVD system, I recommend discussing your specific requirements with suppliers to guarantee the furnace is optimized for your unique coating processes.

What Is the Typical Maintenance Schedule for High-End CVD Systems?

High-end CVD systems usually require a monthly maintenance schedule. I recommend inspecting the chamber, replacing filters, and checking for any signs of wear or contamination. Every three to six months, I perform a thorough calibration and replace consumables like gases and seals. Regular cleaning and preventive checks guarantee peak performance, minimize downtime, and extend the lifespan of the equipment. Staying consistent with maintenance is key to reliable, high-quality coatings.

How Do Automation and Control Systems Impact Furnace Performance?

Automation and control systems transform furnace performance into something truly extraordinary. They allow me to achieve perfect consistency, lightning-fast adjustments, and maximum efficiency with minimal effort. With advanced controls, I can monitor every parameter in real-time, detect issues instantly, and optimize the process on the fly. This means my coating quality skyrockets, downtime drops dramatically, and I stay ahead of the competition—making my furnace smarter, faster, and more reliable than ever.

Conclusion

So, there you have it—your quick guide to the top CVD furnaces of 2025. Whether you’re after precision, power, or just the best way to coat everything in sight, these options have you covered. Just remember, choosing the right furnace isn’t rocket science… oh wait, with all the chemicals involved, maybe it is! Either way, happy coating—may your layers be flawless and your fumes forever manageable.