If you’re looking for the 13 best desk CNC milling machines for precision at home in 2025, you’ll find options suited for beginners, hobbyists, and professionals. From compact models like the 3018-PROVer to versatile machines with expandability like the SainSmart 4040 PRO, each offers features for detailed work, material compatibility, and potential upgrades. If you’re curious about which machine fits your needs and budget, keep exploring further—there’s plenty to discover.

Key Takeaways

- High-performance desktop CNC machines like Carvera Air support versatile materials and complex projects with precision and expandable capabilities.

- Beginner-friendly options such as CNC 3018-PRO and CNCTOPBAOS offer easy assembly, software compatibility, and reliable performance for home use.

- Versatile models like SainSmart Genmitsu 4040 PRO and FoxAlien Masuter 3S provide upgrade paths for enhanced accuracy and larger working areas.

- Compact micro mills and accessories, including Proxxon MF 70 and heavy-duty tables, enable precise small-scale milling at home.

- Software compatibility, firmware upgradability, and modular design ensure future-proof precision for hobbyists and small manufacturers.

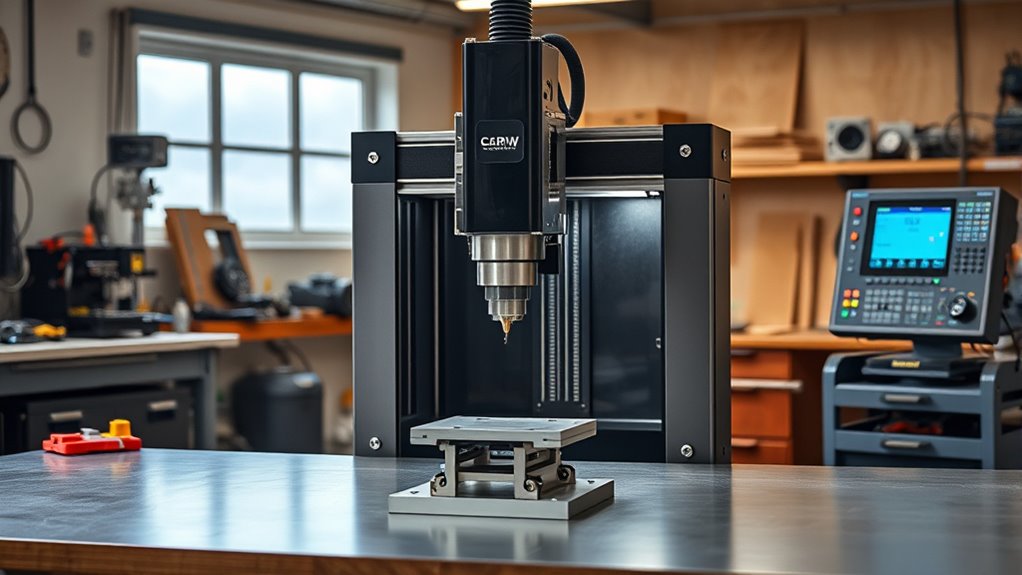

Carvera Air Desktop CNC Machine with 4th Axis and PCB Fabrication Pack

If you’re a hobbyist or DIY enthusiast seeking a compact yet versatile CNC machine, the Carvera Air Desktop CNC Machine with 4th Axis and PCB Fabrication Pack is an excellent choice. It’s a small, enclosed machine that delivers precise milling, engraving, and carving on various materials like wood, plastics, and metals. The quick tool changer and auto-calibration features make setup easy, while the 0–13,000 RPM spindle guarantees high accuracy. The optional 4th axis expands capabilities, allowing for detailed 3D, cylindrical, and multi-sided projects. With user-friendly software and flexible connectivity, it’s perfect for creating intricate designs at home.

Best For: hobbyists and DIY enthusiasts seeking a compact, versatile CNC machine capable of precise milling, engraving, and complex 3D projects with expandability options.

Pros:

- Supports a wide range of materials including wood, plastics, and metals for versatile projects

- Features a quick tool changer and auto-calibration for fast, accurate setup

- Optional 4th axis expands machining capabilities to complex 3D and cylindrical designs

Cons:

- Relatively heavy at nearly 100 pounds, which may require sturdy placement and handling

- Limited active surface area may restrict larger projects

- First availability scheduled for June 5, 2025, which may delay immediate purchase or use

3018-PROVer V2 CNC Milling Machine

The 8-PROVer V2 CNC Milling Machine is an excellent choice for beginners seeking a reliable, easy-to-assemble desktop CNC that delivers precise results. Its compact working area of 284 x 180 x 40mm is perfect for crafting artwork, personalized gifts, and small business projects. Assembly takes about 35 minutes thanks to its semi-preinstalled setup. Upgraded features like quiet Toshiba TB6S109 drivers, a redesigned Z-axis carriage, and a durable aluminum spoilboard improve accuracy and durability. Compatible with popular CAD/CAM software, it’s user-friendly and versatile. Plus, with extensive accessories and strong support from SainSmart, it’s a smart investment for those starting their CNC journey.

Best For: beginners and hobbyists seeking an easy-to-assemble, reliable desktop CNC machine for small projects and personalized crafts.

Pros:

- User-friendly setup with semi-preinstalled components allowing assembly in approximately 35 minutes

- Upgraded hardware features like quiet Toshiba TB6S109 drivers and a redesigned Z-axis carriage for enhanced accuracy and durability

- Compatible with popular CAD/CAM software such as Carveco, Fusion360, and Easel, supporting creative versatility

Cons:

- Limited working area of 284 x 180 x 40mm may restrict larger project sizes

- As an entry-level machine, it may require additional upgrades for advanced or industrial applications

- Assembly and calibration still require some technical skill, which might be challenging for complete beginners

CNC 3018-PRO Router Kit with Offline Controller

Designed for beginners and hobbyists, the CNC 3018-PRO Router Kit with Offline Controller stands out with its user-friendly setup and reliable performance. Its compact design features a 300 x 180 x 45mm working area, suitable for carving plastics, woods, acrylics, and small aluminum parts. With all components pre-assembled and a raised base for stability, setup takes about 45 minutes. The machine uses GRBL software on Arduino for precise control and includes an offline controller, allowing easy operation without a PC. Its durable aluminum frame, safety features, and support for upgrades make it a versatile, accessible choice for small projects and learning CNC basics.

Best For: beginners and hobbyists seeking an affordable, easy-to-assemble CNC machine for small-scale carving, engraving, and prototyping projects.

Pros:

- User-friendly setup with all components pre-assembled, reducing initial complexity

- Compact size with a 300 x 180 x 45mm working area suitable for small projects

- Reliable GRBL control software on Arduino and included offline controller for convenient operation

Cons:

- Limited working area may restrict larger project sizes

- Basic tools and bits included may require additional purchases for more advanced tasks

- Slight learning curve in mastering material-specific settings and software operation

CNCTOPBAOS 1610 PRO CNC Milling Machine with Controller

For hobbyists seeking an affordable, compact CNC milling machine with versatile control options, the CNCTOPBAOS 1610 PRO stands out. It features offline control via SD card, supporting manual axis adjustments, spindle control, and emergency stop. With a working area of 7.08×3.93×1.77 inches, it’s suitable for engraving plastic, wood, acrylic, PCB, and soft metals. Equipped with Nema17 stepper motors and a GRBL1.1f control board, it offers reliable basic operation. While assembly is straightforward, some users face challenges with instructions and software setup. Overall, it’s an excellent entry-level machine for beginners exploring CNC projects at home.

Best For: hobbyists and beginners seeking an affordable, compact CNC milling machine for small-scale engraving and prototyping projects at home.

Pros:

- Easy to assemble with straightforward instructions for beginners

- Supports offline operation via SD card, reducing dependence on a computer

- Compatible with a variety of materials including plastic, wood, acrylic, PCB, and soft metals

Cons:

- Software setup and functionality can be confusing or problematic for some users

- Limited build size and power may not suit larger or more complex projects

- Mechanical issues such as slipping or bearing problems have been reported by some users

SainSmart Genmitsu 4040 PRO CNC Milling Machine

If you’re looking for a CNC milling machine that balances rigid construction with expandability, the SainSmart Genmitsu 4040 PRO stands out as an excellent choice for hobbyists and small businesses alike. Its all-metal frame, including steel linear tubes and dual Y-axis rails, guarantees stability and precision. The 400x400mm workspace can be expanded to 600x600mm with an upgrade kit, and optional rotary modules allow multi-angle and 3D rotary work. Powered by open-source Grbl v1.1 and equipped with quiet drivers, it offers reliable operation. The machine handles wood, acrylic, and light metals well, making it versatile for creative projects and small-scale manufacturing.

Best For: hobbyists and small businesses seeking a versatile, expandable CNC milling machine with solid build quality and the potential for upgrades.

Pros:

- Rigid all-metal frame with steel linear tubes and dual Y-axis rails for stability and precision

- Expandable workspace up to 600x600mm and compatible with rotary modules for multi-angle projects

- Powered by open-source Grbl v1.1 with quiet Toshiba drivers, ensuring reliable and smooth operation

Cons:

- Limited software support and guidance, requiring users to seek online tutorials for advanced use

- Wiring and hardware components like limit switches sometimes require upgrades or modifications for optimal performance

- Initial calibration and assembly can be straightforward, but some users experience challenges with software learning curve

Genmitsu 3018-PROVer V2 CNC Router Machine for Beginners

The Genmitsu 3018-PROVer V2 CNC Router Machine stands out as an excellent choice for beginners entering the world of CNC machining. It offers high value, allowing you to create artwork, gifts, PCB prototypes, and small-scale projects. Capable of engraving wood, plastic, acrylic, PCB, and soft metals like copper and aluminum, it’s versatile enough for hobbyists and startups. The machine’s solid build, easy assembly—taking less than an hour—and support software options like Fusion 360 and Easel make it accessible. With safety features like limit switches and an emergency stop, it’s a reliable, beginner-friendly tool that can grow with your skills and project ambitions.

Best For: beginners and hobbyists seeking an affordable, easy-to-assemble CNC router capable of engraving wood, plastic, acrylic, PCB, and soft metals for small projects and prototypes.

Pros:

- Solid build quality with easy assembly in less than an hour

- Versatile capabilities suitable for engraving a variety of materials

- Support for popular CAD/CAM software like Fusion 360 and Easel

Cons:

- Limited maximum cutting depth and power, especially for metals

- Slight learning curve with G-code commands and software setup

- Occasional need for upgrades such as stronger spindles or dust collection accessories

FoxAlien Masuter Pro 3-Axis CNC Router Machine

The FoxAlien Masuter Pro 3-Axis CNC Router Machine stands out with its all-metal framework, which provides exceptional stability and durability for detailed engraving and cutting. Its robust aluminum structure and linear rail Z-axis support precise work on materials like wood, acrylic, MDF, and nylon. It comes with two spindle clamps compatible with 60W and 300W spindles, plus options for custom upgrades such as a 65mm router or 1.5KW spindle. The user-friendly, dust-proof controller box includes emergency stop and home buttons, making operation safer. Pre-assembled components and a clear manual allow setup in just 10-15 minutes, ideal for hobbyists seeking versatility and reliability.

Best For: hobbyists, DIY enthusiasts, and small workshop users seeking a durable, precise CNC router for detailed engraving and cutting projects.

Pros:

- All-metal framework ensures high stability and durability during operation

- Easy assembly with pre-wired components and detailed manual, setting up in 10-15 minutes

- Supports various spindle options and custom upgrades for versatile project capabilities

Cons:

- Limited work area without the optional Y-axis extension kit

- Requires manual upgrade for larger spindles like 69mm clamp options

- May have a learning curve for beginners unfamiliar with CNC operation

CNC Router Machine 3030-Evo Max with All-Metal XYZ Axes and 800W Router

For those seeking high precision and durability in a compact CNC router, the CNC Router Machine 3030-Evo Max stands out with its all-metal XYZ axes and robust 800W spindle. Its dual steel linear guides guarantee accuracy and stability, even during metal cuts. The upgraded Φ65mm router with six speed settings manages aluminum, copper, stainless steel, and plastics effortlessly. Running on GRBL firmware with wireless control, it offers advanced features like coolant control and future upgrades like a 4th axis. Easy to assemble and compatible with popular software, this machine provides professional-level performance in a compact, user-friendly design.

Best For: hobbyists, small-scale manufacturers, and professionals seeking high-precision metal and material cutting in a compact, user-friendly CNC router.

Pros:

- All-metal XYZ axes with dual steel linear guides ensure high accuracy and stability during operation.

- Upgraded 800W Φ65mm spindle with multiple speed settings capable of cutting metals and plastics efficiently.

- Wireless control via built-in 32-bit MCU and ESP3D Web UI offers convenient operation from PC, smartphone, or tablet.

Cons:

- Limited 4th axis functionality available only as a future upgrade, requiring additional investment.

- Assembly may require technical knowledge despite detailed instructions and pre-assembled components.

- The machine’s size and power may be overkill for very small or purely wood-based projects.

Proxxon MF 70 Micro Mill

If you’re seeking a compact, highly precise mill for hobbyist projects or light prototyping, the Proxxon MF 70 Micro Mill stands out as an excellent choice. Its cast iron base and aluminum components guarantee stability and accuracy, while the play-free axes and adjustable slides improve precision. With a small footprint of about 17 pounds, it’s perfect for detailed work on plastics, aluminum, brass, and Delrin. The machine includes hardened steel collets, a T-slot table, and fine hand wheels for precise positioning. Though limited in height adjustment and prone to minor play, it’s ideal for hobbyists needing a reliable, European-made micro mill.

Best For: hobbyists, model builders, and small-scale prototyping enthusiasts seeking a compact, precise mill for delicate work on plastics and light metals.

Pros:

- High build quality with cast iron base and aluminum components ensuring stability and accuracy

- Play-free axes with adjustable slides for precise workpiece positioning

- Compact size and lightweight design make it suitable for limited workspace and easy handling

Cons:

- Limited height adjustment and table play (~0.010″) can restrict certain projects

- Potential backlash in the Z-axis and slight deflection in the X-axis during operation

- Motor may experience noise, wear, or failure over extended use, requiring maintenance or repairs

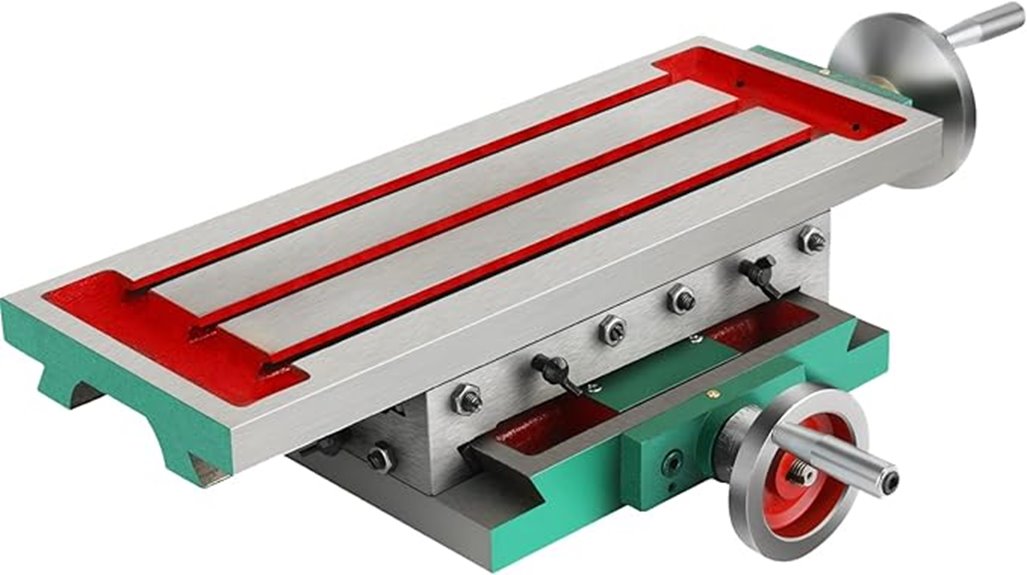

VEVOR Milling Working Table 17.7 x 6.7 Inch

Designed for those seeking reliable precision in their home workshop, the VEVOR Milling Working Table measures 17.7 by 6.7 inches and mounts seamlessly on drilling stands, making it ideal for detailed milling and drilling tasks. Its robust cast iron construction guarantees durability, resistance to rust, and stability during operation. The table’s precise T-slots and trapezoidal thread spindles allow for easy adjustments along the X and Y axes, with travel distances of 8.3 and 4.3 inches. A built-in scale helps achieve accurate positioning, making this versatile accessory perfect for various machining projects in a compact, heavy-duty package.

Best For: DIY enthusiasts and small workshop operators seeking a durable, precise milling table for detailed machining projects at home or in a small professional setting.

Pros:

- Heavy-duty cast iron construction ensures long-lasting durability and stability during use

- Adjustable T-slots and trapezoidal spindles allow for precise positioning and easy adjustments along X and Y axes

- Compact size with a large working surface makes it versatile for various milling and drilling tasks

Cons:

- May be heavy and challenging to reposition without assistance due to its cast iron build

- Limited travel distances (8.3 inches and 4.3 inches) might restrict larger workpieces

- Requires maintenance to prevent rust, despite its anti-corrosion coating

40Pcs CNC Router Bits Set with 1/8 Shank (Mcwdoit)

The Pcs CNC Router Bits Set with 1/8″ shank from Mcwdoit stands out as an excellent choice for hobbyists and small workshop users seeking versatile and reliable tools. This 40-piece set includes flat nose and ball nose end mills, all coated with nano blue and titanium for durability. Made from ultra-fine grain carbide, these bits deliver high hardness and wear resistance, ensuring precise engraving and cutting. With four types of bits, they handle a variety of materials like PCB, plastics, fiber, hardwood, and aluminum. Overall, it’s a extensive, cost-effective solution for those looking to get professional results from their CNC milling projects at home.

Best For: hobbyists and small workshop users seeking versatile, durable CNC router bits for precise engraving and cutting across various materials.

Pros:

- Includes a wide variety of bits (flat nose and ball nose) for different applications

- Coated with nano blue and titanium for enhanced durability and wear resistance

- Crafted from ultra-fine grain carbide for high hardness and clean finishes

Cons:

- Shank size limited to 1/8″, which may not fit all CNC machines

- May be less suitable for heavy-duty industrial use

- The set does not include additional specialized bit types beyond flat and ball nose options

CNC Router Machine 3060-Evo Ultra with Ball Screw & Steel Guides

The CNC Router Machine 3060-Evo Ultra with Ball Screw & Steel Guides stands out as an excellent choice for hobbyists and small-scale professionals who prioritize precision and durability. Its all-metal XYZ axes feature dual steel linear guides and 1204 ball screws, providing high stability and load capacity. Compact yet spacious, it offers a 300*600mm worktable and 287*600*73mm XYZ travel, making it versatile for various projects. Powered by a 300W spindle and upgraded Nema 17 motors, it handles metals, wood, and plastics with ease. With support for multiple operating systems and expansion options like laser modules, this machine combines solid construction with flexible functionality.

Best For: hobbyists and small-scale professionals seeking a high-precision, durable CNC router for metal, wood, and plastic projects with expansion capabilities.

Pros:

- Robust all-metal XYZ axes with dual steel linear guides and 1204 ball screws ensure high stability and load capacity.

- Compact design with a spacious 300*600mm worktable and versatile XYZ travel for various project sizes.

- Supports multiple operating systems and offers expansion options like laser modules for increased functionality.

Cons:

- Limited maximum cut depth of ≤0.2mm per pass at standard settings without upgrade.

- Requires additional investment for upgrades like a 1.5kW spindle for deeper metal cuts.

- Slightly heavier weight (~40 pounds) may require more effort for repositioning or setup.

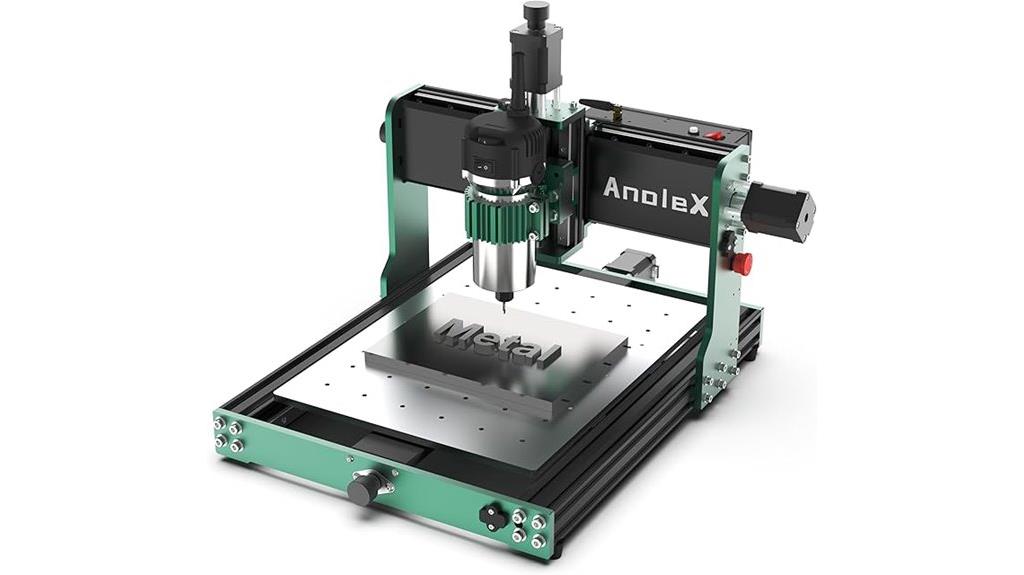

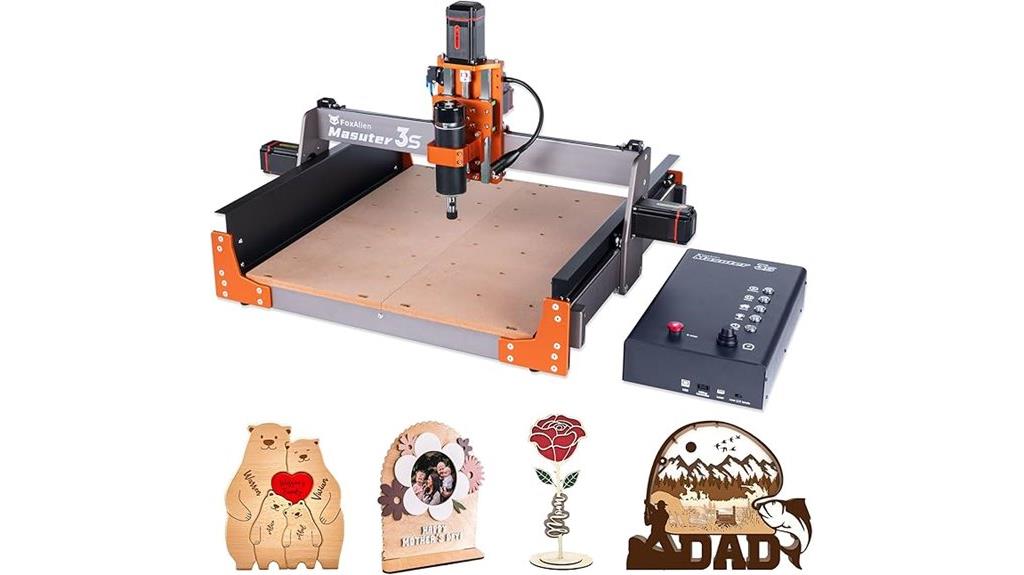

FoxAlien Masuter 3S CNC Router Machine

If you’re looking for a reliable CNC router that combines precision with ease of use, the FoxAlien Masuter 3S stands out as an excellent choice for hobbyists and small-scale professionals alike. Its sturdy build features 2360mm extrusions, dual linear rails on the Z-axis, and a T12 lead screw, ensuring stability and smooth operation. The machine offers a 15.75” x 15.75” x 3.74” work area, with options to expand. Powered by NEMA23 motors and a 400W spindle, it handles engraving and cutting soft metals like aluminum with high accuracy. Easy to assemble and supported by strong community and customer service, it’s a versatile, reliable tool.

Best For: hobbyists and small-scale professionals seeking a reliable, precise, and versatile CNC router for engraving, milling, and light metal work.

Pros:

- Sturdy construction with high-quality materials and smooth operation

- Easy assembly with comprehensive instructions and strong community support

- Capable of high-precision engraving and cutting soft metals like aluminum

Cons:

- Limited work area unless additional extension kits are purchased

- May require electronics modification for advanced or specialized tasks

- Slightly heavier and bulkier compared to smaller hobby CNCs

Factors to Consider When Choosing Deskcnc Milling Machines

When selecting a desk CNC milling machine, I focus on several key factors to guarantee it meets my needs. Things like work area size, material compatibility, and power are essential, but I also consider precision, speed, and software compatibility. These points help me choose a machine that’s reliable and fits my project requirements.

Work Area Size

Choosing the right work area size is essential because it directly impacts the maximum dimensions of the materials you can machine. If you often work on larger projects or multiple pieces at once, a bigger work area provides more flexibility, allowing you to handle complex or multi-piece projects comfortably. However, larger work areas tend to increase the machine’s overall footprint and cost, so balance that with your workspace constraints. If your projects are small and detailed, a compact work area will suffice, saving space and money. Be sure to measure the work surface dimensions carefully to ensure compatibility with your typical materials and project sizes. Considering your usual project scale helps you select a machine that fits both your needs and your workspace.

Material Compatibility

Matching your milling machine to the materials you plan to work with guarantees ideal results. I recommend selecting a machine that supports a broad range of materials like plastics, woods, metals, and PCBs to match your project needs. Check the spindle power and speed—higher wattage and RPM (up to 13,000) are essential for machining harder materials such as aluminum and stainless steel effectively. It’s also important to verify compatibility with different cutting bits and tools designed for specific substrates, ensuring precise, clean cuts. Additionally, consider the machine’s rigidity and stability; a sturdy build reduces vibrations, improving accuracy when working with dense or tough materials. Finally, review the software’s ability to handle material-specific parameters for optimal feed rates, depths, and cutting strategies.

Power and Speed

The power and speed of a desk CNC milling machine are vital factors that directly influence its cutting performance and versatility. A more powerful spindle enables me to cut through tougher materials like metals and dense plastics with ease, expanding my project options. Higher spindle speeds, particularly those exceeding 13,000 RPM, allow for finer detail work and smoother finishes, especially on softer materials like wood and acrylic. The balance between power and speed impacts efficiency, tool longevity, and quality. Supporting higher RPMs means I can use a broader range of bits and achieve better surface finishes. However, I need to be mindful of overheating and tool wear, so selecting a machine that offers the right combination of power and speed is essential for ideal performance across different materials.

Precision and Accuracy

Power and speed are important, but without precision and accuracy, even the most powerful machine can’t produce high-quality results. High precision involves minimal backlash, tight tolerances, and accurate control from stepper or servo motors. The machine’s accuracy largely depends on spindle runout; lower runout (<0.01mm) ensures smoother, more precise cuts. A stable, rigid frame is essential to reduce vibrations and deflections, which can compromise detail and accuracy. Calibration features like auto-probing and leveling help maintain consistent performance across sessions. Additionally, the control system’s resolution—such as step resolution and microstepping—directly impacts the fineness of your finished projects. When choosing a desk CNC milling machine, prioritize these factors to achieve reliable, precise results every time.

Software Compatibility

Choosing a desk CNC milling machine with compatible software is essential for smooth operation and efficient workflow. You want to guarantee the software works seamlessly with your operating system, whether it’s Windows, Mac, or Linux. Compatibility with industry-standard CAD/CAM software like Fusion 360, SolidWorks, or VCarve Pro provides greater flexibility in design and toolpath creation. It’s also important that the control software can import G-code files and features like auto-calibration, auto-probing, and real-time monitoring to streamline your process. Check if the machine offers dedicated software or firmware updates that add functionalities like offline control or wireless operation. Finally, consider the support network, tutorials, and troubleshooting forums available, which can be invaluable when resolving compatibility issues down the line.

Upgradability Options

Upgradability options can substantially extend a desk CNC milling machine’s lifespan and versatility, allowing you to adapt the equipment to evolving project needs. I look for machines with modular designs and compatible accessory ecosystems, which make upgrades easier and more seamless. Supporting hardware modifications like upgraded ball screws, linear guides, or more powerful motors can boost both precision and cutting capacity, pushing the machine’s capabilities further. Software compatibility and firmware flexibility are also essential, as they guarantee new features or control modules can be integrated smoothly. Additionally, considering the availability of upgrade parts and active community support helps protect your investment, offering guidance and resources for future modifications. Overall, a machine with strong upgrade options maximizes your flexibility and extends its usefulness over time.

Budget and Cost

Ever wonder how to get the best value when selecting a desk CNC milling machine? It starts with setting a clear budget to avoid overspending on features you don’t need. Remember, the total cost includes not just the machine but also accessories, replacement parts, and software upgrades. Balance cost with your project needs—buying a more expensive machine isn’t always necessary for hobbyists or beginners. Higher-priced models often offer better precision and durability, but if your projects are simple, a more affordable option may suffice. Also, think about long-term value and upgrade potential to get the most from your investment. This way, you can choose a machine that fits your budget while still meeting your performance expectations.

Frequently Asked Questions

What Safety Features Are Included in Modern Desktop CNC Machines?

Modern desktop CNC machines include several safety features to protect users. I appreciate built-in emergency stop buttons that instantly halt operations if needed. They also have safety shields and covers to prevent contact with moving parts. Additionally, many models come with overload protection and automatic shut-off systems to avoid overheating or mechanical failure. These features give me confidence that I can work safely while achieving precise results at home.

How Noisy Are These CNC Machines During Operation?

Did you know most desktop CNC machines operate at around 60 to 70 decibels? During operation, I find these machines are relatively quiet—comparable to a normal conversation. While they may produce a slight hum or whine, it’s usually manageable, especially in a home setting. I recommend using noise-dampening mats or enclosures if you want to minimize sound further, making your workspace more comfortable.

Can These Machines Be Used for Commercial Manufacturing?

Yes, these machines can be used for small-scale commercial manufacturing, but they’re best suited for prototypes, custom parts, or limited production runs. I’ve found they excel in precision and ease of use, making them ideal for startups or hobbyists shifting to commercial work. Keep in mind, for high-volume manufacturing, larger industrial CNC machines might be more efficient and durable.

What Is the Typical Learning Curve for Beginners?

The learning curve for beginners using desk CNC milling machines can be moderate to steep at first. I found that it takes time to understand software, machine setup, and safety protocols. However, with patience and practice, I quickly gained confidence. Starting with simple projects helps build skills faster. Don’t get discouraged—most users find that consistent use and online tutorials make mastering these machines much easier over time.

Are Replacement Parts Widely Available for These Models?

Absolutely, replacement parts are generally easy to locate for these models, like a trusty map guiding your journey. Most manufacturers maintain good stock and support networks, making repairs straightforward. I’ve found that checking with authorized dealers or online stores ensures I get genuine parts quickly. This availability gives me peace of mind, knowing I can keep my machine running smoothly without long delays or costly custom orders.

Conclusion

So, whether you’re just starting out or looking to upgrade, these desk CNC machines could be just what you need—imagine creating your own precision parts right at home. I’ve found that choosing the right machine often feels like a lucky coincidence, but with this list, you’re already one step closer to turning that chance into reality. Who knows? Your next big project might be waiting just around the corner with the perfect CNC machine.