If you’re looking for the top high-capacity rotary evaporators, I recommend considering models like the 5L RE-501, the YUEWO 2L RE2000E, and the 110V 5L units, which offer efficient solvent recovery and precise control for demanding lab work. Factors like capacity, material durability, vacuum and temperature control, and ease of use are key. Keep exploring to find out which options best fit your lab’s needs and how to choose the right one.

Key Takeaways

- High-capacity models like 5L and above are ideal for large-scale solvent recovery and industrial laboratory applications.

- Durable construction with stainless steel, high borosilicate glass, and corrosion-resistant seals ensures long-term reliable operation.

- Advanced control features such as digital temperature, speed regulation, and tilt adjustments enhance efficiency and precision.

- Larger evaporators incorporate double-layer condensers and adjustable components for versatile, high-volume processing.

- Suitable for demanding research, pharmaceutical, chemical, and biopharmaceutical labs requiring high throughput and safety.

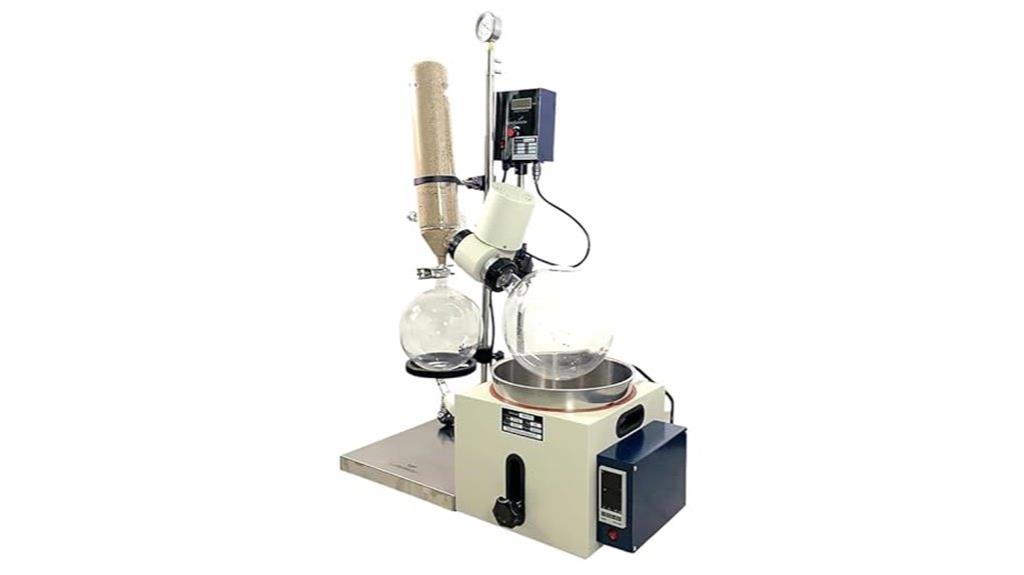

5L Rotary Evaporator RE-501

If you’re looking for a reliable and efficient high-capacity rotary evaporator, the L Rotary Evaporator RE-501 is an excellent choice for laboratories and industries that need to process larger volumes. It features a 5L boiling flask and a 3L receiving flask, making solvent recovery and separation highly effective. Built with durable stainless steel, aluminum alloy, and high borosilicate glass, it resists high temperatures and corrosion. The device offers stepless speed control from 0-90rpm via a digital interface, along with a vacuum gauge for better distillation. Its robust mechanical design guarantees stability, making it ideal for pharmaceutical, chemical, and biopharmaceutical applications.

Best For: laboratories and industries requiring high-capacity solvent recovery and separation, such as pharmaceutical, chemical, and biopharmaceutical sectors.

Pros:

- Durable construction with stainless steel, aluminum alloy, and high borosilicate glass for safety and longevity

- Stepless speed control from 0-90rpm for precise operation

- Effective large-area serpentine condenser for high distillation efficiency

Cons:

- Potential for damaged vacuum gauge upon arrival, affecting performance

- Loose screws may cause gear grease leaks and mechanical issues

- Assembly instructions could be clearer, with some users experiencing difficulty during setup

YUEWO 2L Rotary Evaporator (RE2000E)

The YUEWO 2L Rotary Evaporator (RE2000E) stands out as an ideal choice for researchers and professionals who need reliable, high-performance equipment for vacuum evaporation and solvent recovery. Its Teflon compound heating trough and fully enclosed heater ensure efficient operation, while the rotary mechanism allows consistent rotation under controlled pressure, forming a film for effective distillation. With a digital display, precise control of temperature and speed is simple. Made from rust-proof aluminum alloy and engineering plastics, it’s durable and compact. Perfect for heat-sensitive materials, this evaporator supports scientific research, pilot testing, and production in various industries, all backed by a one-year warranty.

Best For: researchers, chemical engineers, and food industry professionals seeking reliable, efficient vacuum evaporation and solvent recovery equipment for heat-sensitive materials.

Pros:

- Efficient Teflon compound heating trough and fully enclosed heater for optimal heat transfer

- Precise digital control of temperature and rotation speed for accurate operation

- Durable construction with rust-proof aluminum alloy and engineering plastics ensuring long-term use

Cons:

- Limited to a 2L capacity, which may not suit large-scale industrial applications

- Power consumption of 1000W might be high for some laboratory setups

- Requires familiarity with vacuum distillation procedures for safe and effective operation

Rotovap 110V Rotary Evaporator RE-201 Rotavap Warranty lab

For laboratories seeking reliable and efficient solvent recovery, the Rotovap 110V Rotary Evaporator RE-201 stands out thanks to its durable construction and precise control features. It uses PTFE and fluorine rubber composite seals to maintain high vacuum levels, while all glass parts are made from high boron glass for durability and chemical resistance. The high-efficiency condenser maximizes solvent recovery, and the digital thermostatic control ensures accurate temperature regulation. Its sturdy stainless steel and aluminum components, along with imported electrical parts, guarantee longevity. With a thorough warranty, the RE-201 provides a dependable solution for continuous, high-performance evaporation tasks.

Best For: researchers and laboratory professionals seeking a reliable, efficient, and durable rotary evaporator for solvent recovery and evaporation tasks.

Pros:

- Durable construction with high boron glass and stainless steel components for longevity and chemical resistance.

- Precise digital thermostatic control for accurate temperature regulation during evaporation.

- High-efficiency condenser enhances solvent recovery rates, improving process efficiency.

Cons:

- Requires 110V power supply, which may limit use in regions with different electrical standards.

- Manual lifting of the water bath may require additional effort during operation.

- Imported electrical components could lead to higher repair or replacement costs if issues arise.

110V 2L Rotary Evaporator Lab Equipment

A 110V 2L Rotary Evaporator Lab Equipment stands out as an ideal choice for laboratories that require efficient solvent evaporation and high recovery rates. Its stainless steel and high borosilicate glass construction ensure durability and resistance to high temperatures and corrosion. The manual lifting mechanism allows precise control, while the vacuum system achieves up to -0.098 MPa for superior evaporation. With adjustable rotation speeds up to 120 rpm and a temperature range up to 99°C, it’s versatile for various applications like concentration and distillation. Its well-sealed design guarantees high efficiency, making it a reliable tool for pharmaceutical, chemical, and biopharmaceutical labs.

Best For: researchers and technicians in pharmaceutical, chemical, and biopharmaceutical laboratories seeking efficient solvent evaporation and high recovery capabilities.

Pros:

- Durable stainless steel and borosilicate glass construction resist high temperatures and corrosion.

- Precise manual lifting and adjustable rotation speeds provide versatile operation.

- High vacuum capability up to -0.098 MPa ensures efficient solvent recovery and evaporation.

Cons:

- Manual lifting may require more effort and attention during operation.

- Limited to 110V power supply, restricting use in regions with different voltage standards.

- The 2L capacity may not suit large-scale industrial applications.

110V 5L Rotary Evaporator Lab Equipment

Designed for demanding laboratory applications, the 5L rotary evaporator stands out with its robust construction and high sealing efficiency. Made from stainless steel, aluminum alloy, fluororubber, and high borosilicate glass, it offers excellent resistance to high temperatures and corrosion, ensuring long-lasting performance. Its high borosilicate glass rotating shaft and fluororubber skeleton oil seal deliver a vacuum degree up to -0.098 MPa, providing reliable sealing. Equipped with two condenser options—double-line convection for inorganic solvents and single-line for organic solvents—it supports diverse processes like concentration, distillation, and solvent recovery, making it ideal for pharmaceutical, chemistry, and biopharmaceutical labs.

Best For: researchers and laboratories in pharmaceuticals, chemistry, and biopharmaceuticals seeking reliable, high-capacity solvent evaporation and recovery equipment.

Pros:

- Made of durable, corrosion-resistant materials ensuring long-term use

- High sealing efficiency with vacuum performance up to -0.098 MPa

- Versatile condenser options suitable for various solvent types and laboratory processes

Cons:

- Manual lifting of the heating bath may require additional effort during operation

- Requires a 110V power supply, limiting use in regions with different voltage standards

- Larger capacity may take up significant bench space in smaller laboratories

5L Rotary Evaporator for Lab Chemistry, Purification & Extraction

The 5L L Rotary Evaporator stands out as an ideal choice for laboratory professionals seeking reliable and efficient purification or extraction solutions. Its high-quality stainless steel and aluminum alloy construction ensure durability, while all high-temperature resistant boron glass parts guarantee safety during intense operations. The innovative composite seal made from polytetrafluoroethylene and fluorine glue provides a secure vacuum seal, easy replacement, and maintenance. An efficient condenser maximizes recovery rates, and the digital water bath control with a handwheel allows precise temperature adjustments. Overall, its thoughtful design simplifies operation and maintenance, making it perfect for demanding lab chemistry applications like purification and extraction.

Best For: laboratory professionals seeking a durable, efficient rotary evaporator for purification and extraction tasks in chemistry labs.

Pros:

- Constructed with high-quality stainless steel and aluminum alloys for enhanced durability.

- High-temperature resistant boron glass parts ensure safety during intense operations.

- Digital temperature control and efficient condenser maximize recovery and ease of use.

Cons:

- May be expensive compared to smaller or less advanced models.

- Requires proper training to operate complex features safely.

- Large capacity (5L) might be unnecessary for very small-scale laboratory tasks.

4Es USA Rotary Evaporator (1000mL, Adjustable Height, Double-Layer Vertical Condenser, 1300W Heating)

Looking for a reliable rotary evaporator that offers precise control and efficient cooling? The Es USA Rotary Evaporator features a 1000mL capacity with adjustable height and a double-layer vertical condenser, ensuring peak cooling efficiency. Its 1300W heating element provides quick, consistent heat, while the 20-320 RPM rotation speed and 0-360° tilt give you flexibility for various applications. The large LED display and intuitive touch controls simplify operation, and safety is prioritized with built-in overload protection. Built durable and well-packaged, this evaporator is ideal for labs needing high-capacity, precise, and safe evaporation processes.

Best For: researchers and laboratory professionals seeking a reliable, high-capacity rotary evaporator with precise control and efficient cooling for sensitive extractions and evaporation tasks.

Pros:

- Adjustable height and 0-360° tilt for versatile operation and customized workflow

- Double-layer vertical condenser with 1500cm² cooling surface for optimal cooling efficiency

- Intuitive LED display and touch controls for easy, precise operation

Cons:

- Not equipped with a 5L flask, limiting maximum volume capacity for some applications

- Requires a 1300W power supply, which may need specific electrical setup in some labs

- Heavier and potentially less portable due to durable build and larger components

Labrotary Mini Rotary Evaporator 5L

If you’re in need of a reliable and efficient rotary evaporator for small-scale laboratory work, the Labrotary Mini Rotary Evaporator 5L stands out as an excellent choice. Its construction combines stainless steel and aluminum alloy, ensuring durability, while high boron glass components resist high temperatures. The sealing uses PTFE and fluorine rubber for ideal vacuum performance. The high-efficiency condenser guarantees excellent solvent recovery, and the digital water bath provides precise temperature control. Equipped with imported electrical modules and available in B and E types, the latter with an LCD screen and speed indicators, it’s user-friendly and designed for easy maintenance and upgrades.

Best For: researchers and small-scale laboratories seeking a durable, efficient rotary evaporator for solvent recovery and sample concentration.

Pros:

- Constructed with high-quality stainless steel, aluminum alloy, and high boron glass for enhanced durability and temperature resistance.

- Equipped with digital temperature control and LCD screens in E type models for precise operation.

- High-efficiency condenser and continuous feeding capability improve solvent recovery rates and operational efficiency.

Cons:

- The 5L capacity may be insufficient for large-scale laboratory applications.

- The cost of imported electrical modules and specialized materials could be higher than local alternatives.

- Maintenance and replacement parts for high-end components like PTFE seals and LCD modules may require specialized knowledge.

EAST Multi-Function Rotary Evaporator 2L System

For laboratories seeking a versatile and reliable rotary evaporator, the EAST Multi-Function Rotary Evaporator 2L System stands out thanks to its electronic stepless speed regulation and digital display. I appreciate its intelligent temperature control and sturdy construction, featuring GG-17 glass and stainless steel components. The system offers a 2L capacity, with adjustable rotary speed up to 120rpm and precise bath temperature control from 0-400℃. Its compact size, vacuum capability up to 0.098 Mpa, and easy bath lifting make it highly convenient. Whether for small-scale lab work or complex separations, this evaporator delivers efficiency, precision, and durability.

Best For: laboratories requiring a versatile, precise, and durable rotary evaporator for small-scale separations and research applications.

Pros:

- Electronic stepless speed regulation and digital display for accurate control

- Intelligent temperature regulation with a wide range (0-400℃) for versatile use

- Sturdy construction with GG-17 glass and stainless steel components ensuring durability

Cons:

- Limited maximum vacuum of 0.098 Mpa may restrict some high-vacuum applications

- Size and weight (21kg) could be less portable for mobile lab setups

- Power options limited to 110V/60Hz or 220V/50Hz, requiring compatibility checks for different regions

Rotary Evaporator 2000mL with Adjustable Height

The Rotary Evaporator 2000mL with Adjustable Height stands out as an excellent choice for laboratories that require precise control and flexibility in large-scale solvent evaporation. Its robust design features a double-layer vertical condenser and a durable, corrosion-resistant construction, ensuring stability and long-term reliability. The manual lifting mechanism allows quick, accurate height adjustments, optimizing the evaporation process. With rotation speeds from 10 to 120 RPM, it enhances efficiency and speeds up sample processing. The high-precision temperature control maintains stable conditions, and compatibility with vacuum systems supports low-temperature evaporation, making it ideal for complex, large-volume applications.

Best For: laboratories requiring efficient, large-scale solvent evaporation with precise temperature and height control for complex sample processing.

Pros:

- Durable construction with corrosion-resistant materials ensures long-term reliability.

- Adjustable height and variable rotation speeds optimize evaporation efficiency and operational flexibility.

- High-precision temperature control and vacuum compatibility support sensitive and environmentally friendly applications.

Cons:

- Manual lifting mechanism may require extra effort for frequent height adjustments.

- Larger capacity and advanced features could increase cost compared to smaller or simpler models.

- Requires proper training to fully utilize all adjustable and control features effectively.

5L Rotary Evaporator with Digital Controller

A 5L rotary evaporator with a digital controller stands out as an ideal choice for laboratories seeking precise and efficient solvent recovery. It features a 5L evaporating flask and a 3L collecting flask, with a rotation speed adjustable up to 120rpm. The electronic control guarantees stable operation from 0-90rpm, while the vacuum capability reaches -0.098Mpa for effective evaporation. Built with stainless steel and aluminum alloy, it includes a double-layer serpentine condenser for rapid condensation. Manual lifting with a 120mm travel and high corrosion-resistant fluoro rubber sealing make handling straightforward, making it perfect for chemical, biological, and industrial applications.

Best For: laboratories and industrial facilities requiring efficient, precise solvent evaporation and recovery in chemical, biological, or molecular cooking applications.

Pros:

- Precise electronic speed regulation ensures stable rotation from 0-90rpm for consistent results.

- High corrosion resistance with fluoro rubber sealing and durable stainless steel construction.

- Rapid condensation achieved through double-layer serpentine coil condenser enhances evaporation efficiency.

Cons:

- Manual lifting mechanism may require effort during frequent height adjustments.

- Power consumption for water bath (1.5KW) may be high for extended use.

- Limited to 5L capacity, which may not suit very large-scale operations.

Factors to Consider When Choosing High‑Capacity Rotary Evaporators

When selecting a high-capacity rotary evaporator, I consider factors like capacity and size to match my needs, along with temperature and vacuum controls for efficiency. I also look at material durability and ease of operation to guarantee longevity and user-friendliness, while safety features like sealing are essential for secure use. These points help me choose equipment that is reliable, safe, and suited to my specific application.

Capacity and Size

Choosing the right capacity for a high-capacity rotary evaporator depends on your sample volume and future needs. These units typically feature evaporation flasks ranging from 2L to 10L or more, designed for larger sample batches. Size matters because it affects your lab’s footprint, requiring sufficient space for safe operation and maintenance. Larger models often include bigger condensers and collection flasks to improve solvent recovery during extended runs. Keep in mind that physical dimensions and weight can be substantial, sometimes needing reinforced support structures and specialized handling equipment. When selecting capacity, consider your current workload and potential growth. This ensures the evaporator can handle your present tasks while accommodating future scaling, making it a worthwhile investment for efficient, uninterrupted laboratory work.

Temperature and Vacuum

Maintaining precise vacuum levels and temperature control is vital for maximizing the efficiency of high-capacity rotary evaporators. Keeping the vacuum at around -0.098 MPa helps control boiling points, allowing solvents to evaporate at lower temperatures, which is especially important for heat-sensitive materials. Temperature ranges typically from room temperature up to 180°C give flexibility for different solvents and applications. Consistent vacuum and heat settings ensure reproducible results and prevent fluctuations that could affect the quality of evaporation. Proper calibration and monitoring of vacuum gauges and digital temperature controls are essential; they help achieve ideal conditions, maximize solvent recovery, and reduce thermal degradation. In short, precise control over vacuum and temperature directly impacts efficiency, safety, and the integrity of your final product.

Material Durability

Selecting a high-capacity rotary evaporator requires careful attention to material durability to guarantee reliable, long-term performance. I look for units built with robust materials like stainless steel, aluminum alloys, and high borosilicate glass, which can withstand high temperatures and corrosive chemicals. The sealing components, often made from PTFE, fluororubber, or fluorine glue, must sustain high vacuum levels without degrading over time. The condenser and mechanical parts need to be corrosion-resistant and capable of enduring continuous operation without fatigue or failure. I also ensure the glassware is made of high borosilicate glass to resist thermal shock and chemical corrosion. Ultimately, the overall mechanical structure should be sturdy, with high-quality seals and joints to prevent leaks and promote long-term stability.

Ease of Operation

Ease of operation is crucial when working with high-capacity rotary evaporators, as it directly impacts efficiency and safety. I look for units with intuitive controls, like digital displays and stepless speed regulation, which allow me to make quick adjustments effortlessly. Clear assembly instructions and visual guides help me set up swiftly and reduce errors during operation. Smooth hand wheels and manual lifting mechanisms are essential for precise height adjustments without requiring much effort. Automated features like digital temperature control and programmable rotation speeds simplify long or repetitive tasks, saving time and reducing user fatigue. Ergonomic components, such as accessible control panels and easy-to-handle glassware, enhance comfort and operational flow. Overall, ease of operation ensures a smoother, safer lab experience and more consistent results.

Sealing and Safety

When working with high-capacity rotary evaporators, ensuring proper sealing is essential for maintaining a safe and efficient vacuum environment. High-quality seals made of PTFE, fluorine rubber, or high borosilicate glass provide airtight conditions and prevent leaks during operation. Proper sealing is critical to sustain the desired vacuum level, which can reach up to -0.098 MPa in large systems. These seals must resist high temperatures and corrosive chemicals to remain durable and safe over time. Regular inspection and timely replacement of seals are crucial to preserve ideal vacuum performance and avoid system failure. A reliable sealing design minimizes the risk of vacuum loss, leaks, and hazards linked to high-pressure or vacuum conditions, ensuring safe and consistent operation.

Price and Warranty

Choosing the right high-capacity rotary evaporator involves balancing cost and warranty to guarantee long-term value. These units typically range from mid to high hundreds of dollars, depending on features and materials. While cheaper models may seem attractive initially, they often come with limited or no warranty, increasing potential maintenance costs over time. On the other hand, premium models with extended warranties offer better peace of mind, covering defects, support, and replacement parts, sometimes with on-site service. Investing in a unit with a solid warranty helps protect your long-term investment and reduces unexpected expenses. Striking a balance between price and warranty coverage ensures you get reliable performance without overspending, making your lab work more efficient and cost-effective in the long run.

Frequently Asked Questions

What Are the Maintenance Requirements for High-Capacity Rotary Evaporators?

Maintaining high-capacity rotary evaporators is straightforward. I regularly inspect seals and gaskets for wear, ensuring there are no leaks. I clean glassware after each use to prevent residue buildup, and I check the vacuum pump oil level monthly, replacing it as needed. Additionally, I calibrate temperature controls periodically and keep the entire system free of dust. Consistent maintenance keeps my evaporator running smoothly and extends its lifespan.

How Do I Select the Appropriate Condenser Type for Large-Scale Evaporation?

Choosing the right condenser type is essential for large-scale evaporation. I consider whether I need a glass condenser for easy observation or a coil condenser for better heat transfer efficiency. Often, I opt for a vertical or diagonal condenser to save space and improve cooling capacity. I also think about the chemical compatibility and solvent types involved. Ultimately, I match the condenser to my volume, solvent, and space constraints for maximum performance.

Are There Safety Features Specific to High-Capacity Models?

Yes, high-capacity rotary evaporators often include safety features like automatic shut-off systems, pressure relief valves, and over-temperature protection. These features help prevent accidents and equipment damage during large-scale evaporation. I always prioritize models with robust safety mechanisms because they guarantee safer operation, especially when handling volatile solvents at high volumes. Investing in these safety features gives me peace of mind and keeps my lab running smoothly.

How Energy-Efficient Are These High-Capacity Rotary Evaporators?

Imagine a machine that saves both energy and time—high-capacity rotary evaporators do just that. They’re quite energy-efficient, thanks to advanced heating and cooling systems that optimize power use during operation. Many models feature intelligent controls that monitor and adjust energy consumption in real-time. So, not only do they boost lab productivity, but they also help reduce your environmental footprint. I find them pretty impressive in balancing power and efficiency.

What Is the Typical Lifespan of Commercial High-Capacity Rotary Evaporators?

The typical lifespan of commercial high-capacity rotary evaporators is around 10 to 15 years, depending on usage and maintenance. I’ve seen well-maintained units last even longer with proper care, like regular inspections and timely repairs. Investing in quality and following the manufacturer’s guidelines can extend their life, ensuring you get the most value. Proper maintenance really makes a difference in longevity and performance.

Conclusion

Choosing the right high-capacity rotary evaporator is like finding the perfect key to unseal your lab’s full potential. With options ranging from 2L to 5L, each model offers unique features to match your needs. Remember, the best choice isn’t just about capacity but also about precision and reliability. So, don’t just settle—select the tool that’ll turn your lab work into a symphony of efficiency and success.